4

Motor:

Each motor is provided with heat

sensor thermostats attached

directly to the motor windings.

The thermostats open if the motor

windings see excessive heat and,

in turn, open the motor contactor

in the control panel, breaking the

power to the pump. When the

motor is stopped due to an

overheat condition, it will not

start until the motor has cooled

and the heat sensor reset button is

manually pushed on the front of

the Hydromatic control panel.

This circuitry is provided in the

Hydromatic control panel

designs.

The SPX50 and SPX50H pumps

are equipped with internal

thermostats. The SPX50 and

SPX50H models are designed to

meet Class B heat rise of

266°F (130°C).

NOTE: Failure to use proper

circuitry and to connect the

motor overheat protection in

the control panel would negate

all warranties and CSA listings.

Motor Seal Failure Warning:

The seal chamber is oil filled and

provided with moisture sensing

probes to detect water leakage

through the lower shaft seal. The

probes can also detect moisture

present in the upper motor

housing.

The presence of water energizes a

red seal leak warning light at the

control panel. This is a warning

light only, and does not stop the

motor. It indicates a leak has

occurred and the pump must be

repaired. Normally, this indicates

the outboard seal has leaked.

Allowing the unit to operate too

long after the warning could

cause upper seal leakage along

with motor failure.

The resistance across the moisture

sensing (seal failure) probes

should be checked after a seal

leak warning light has been

activated. This can be done by

disconnecting the red and orange

control wires from the control

panel and measuring the

resistance with an ohmmeter

between the wires. For an

explosion-proof pump the reading

should be above 30,000 ohms. If

the measured values are below

those indicated above, the pump

may have a lower seal failure and

require service.

On the Hydromatic explosion-

proof control panels the seal leak

test switch tests the seal leak

circuit continuity. When pushed,

the seal leak test bulb should

light. If the test bulb does not

light, it means either the wiring

circuitry to the seal leak probes

has been broken or the bulb has

burned out.

NOTE: Hydromatic built

control panels supply the

correct circuitry for moisture

and heat sensor connections.

Failure to install the correct

circuitry with the proper

connection would negate

warranty and CSA listing.

See page 9.

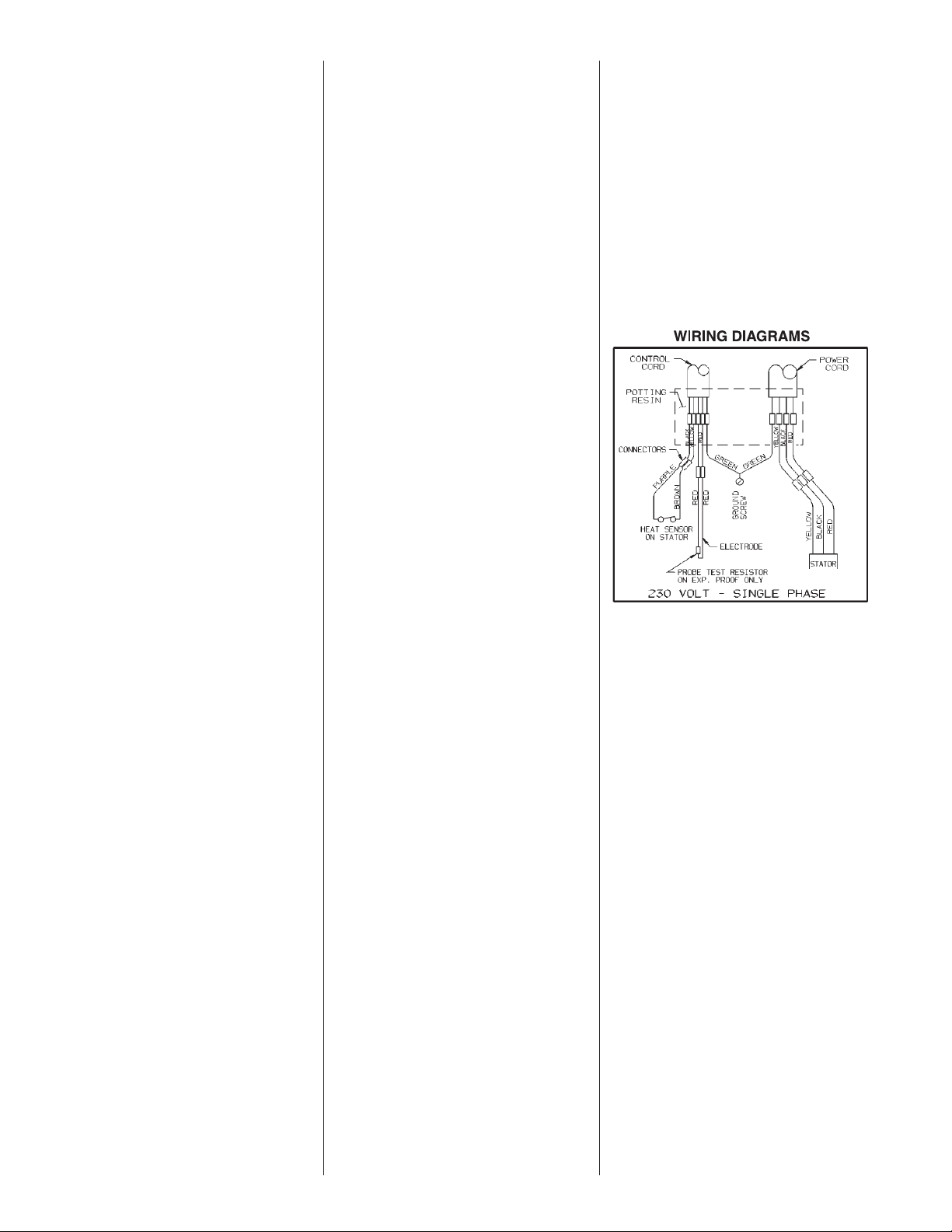

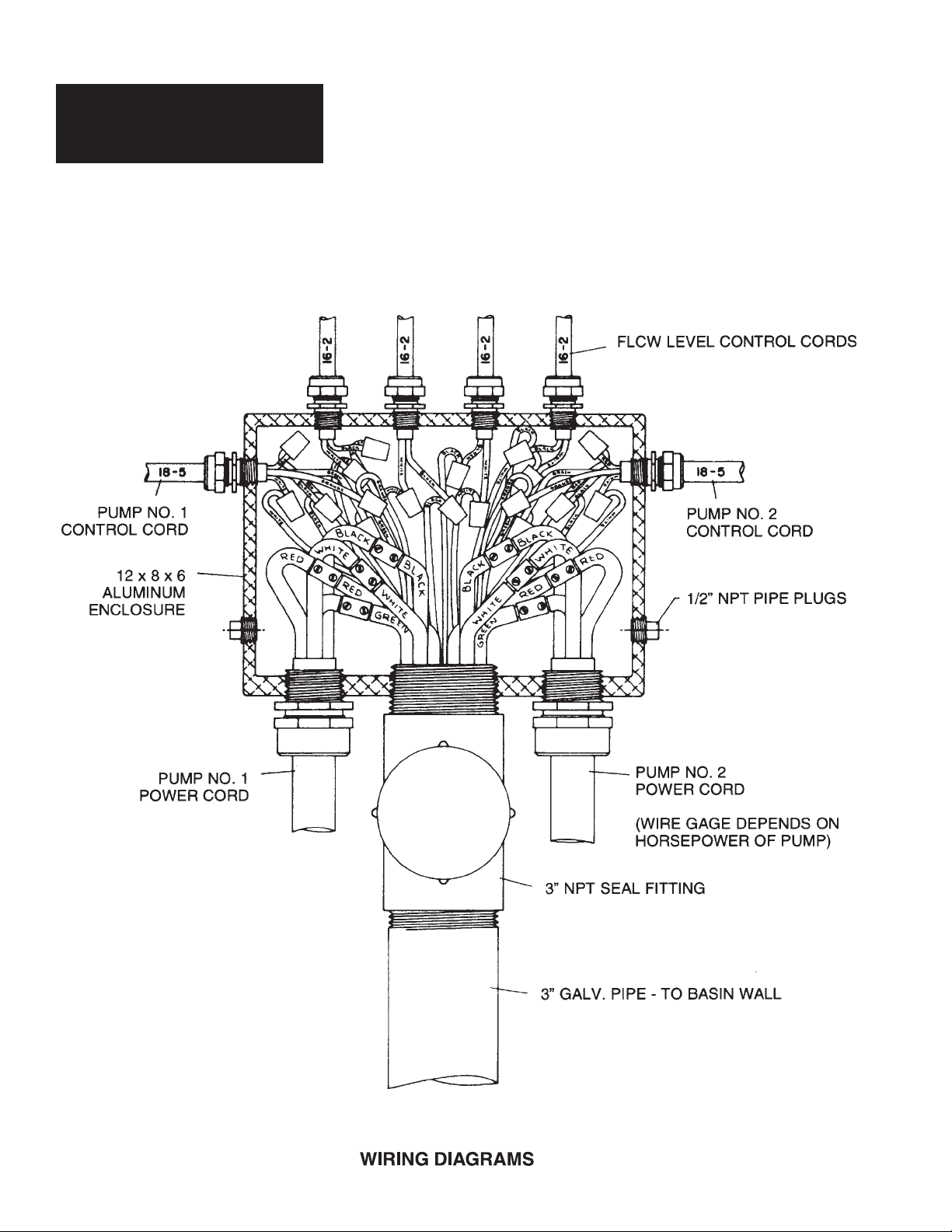

Motor Power Cord, Control

Cord and Cord Cap Assembly:

Each motor power cord has 4

conductors: white, black, red and

green. For a single phase motor

the black is connected to the

common lead, the white is

connected to the main lead, while

the red is connected to the start

circuitry, and the green is

attached to a good ground. The

rotation of a single phase pump is

set properly at the factory.

NOTE: Rotation should be

clockwise when observed from

the top of the pump. This can

be checked by noting which

direction the pump torques

upon initial starting. A properly

rotating pump will torque

counterclockwise upon start.

The control cable has 5

conductors: black, white, red,

orange and green. White and

black connect to the heat

sensor terminals in the control

panels; red and orange

connect to the seal failure

terminals in the control panel;

and the green connects to the

ground in the control panel.

The cord cap is epoxy

potted. This allows the cord cap,

with cords, to be removed from

the motor. With this arrangement,

the cords can be permanently

installed in a sealed fitting in

the sump. This should be

an approved explosion-proof

junction box for hazardous

locations. The control and power

cables cannot be spliced!