7

ABOUT PLUS OZONE OPTION

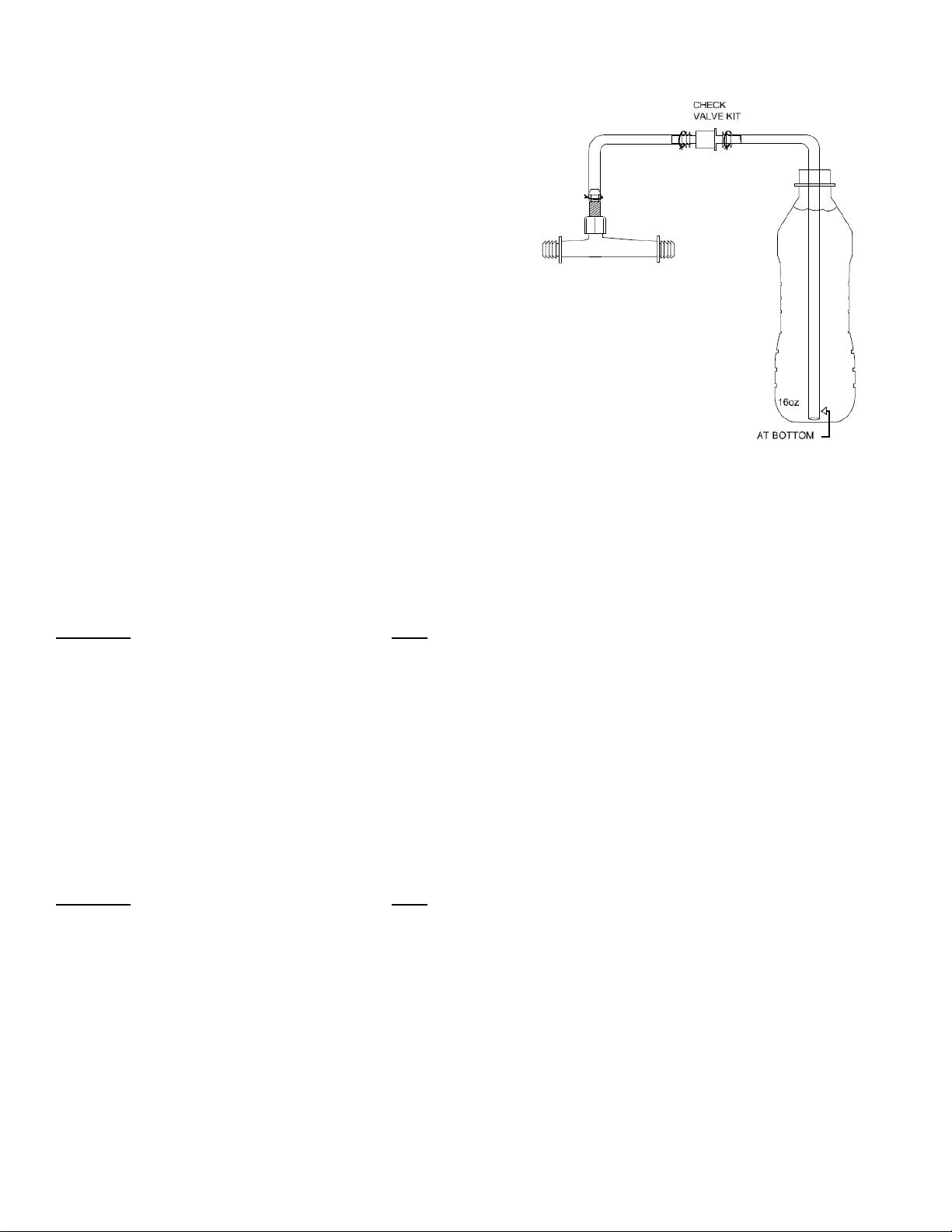

IMPORTANT! Plus Ozone™ generators operate at high voltage and must never come in contact with water at any

time. The ozone tubing kit includes a one-way check valve that must be installed correctly to prevent the backflow of

water into the ozone generator. Failure to install the valve or installing the valve backwards may cause permanent damage

and will void the product warranty.

WARNING! Ozonators exposed to water may cause system electrical problems and potential harm to the

user. DO NOT connect tubing to the ozone generator barb, unless the check valve has been installed correctly

per the instructions

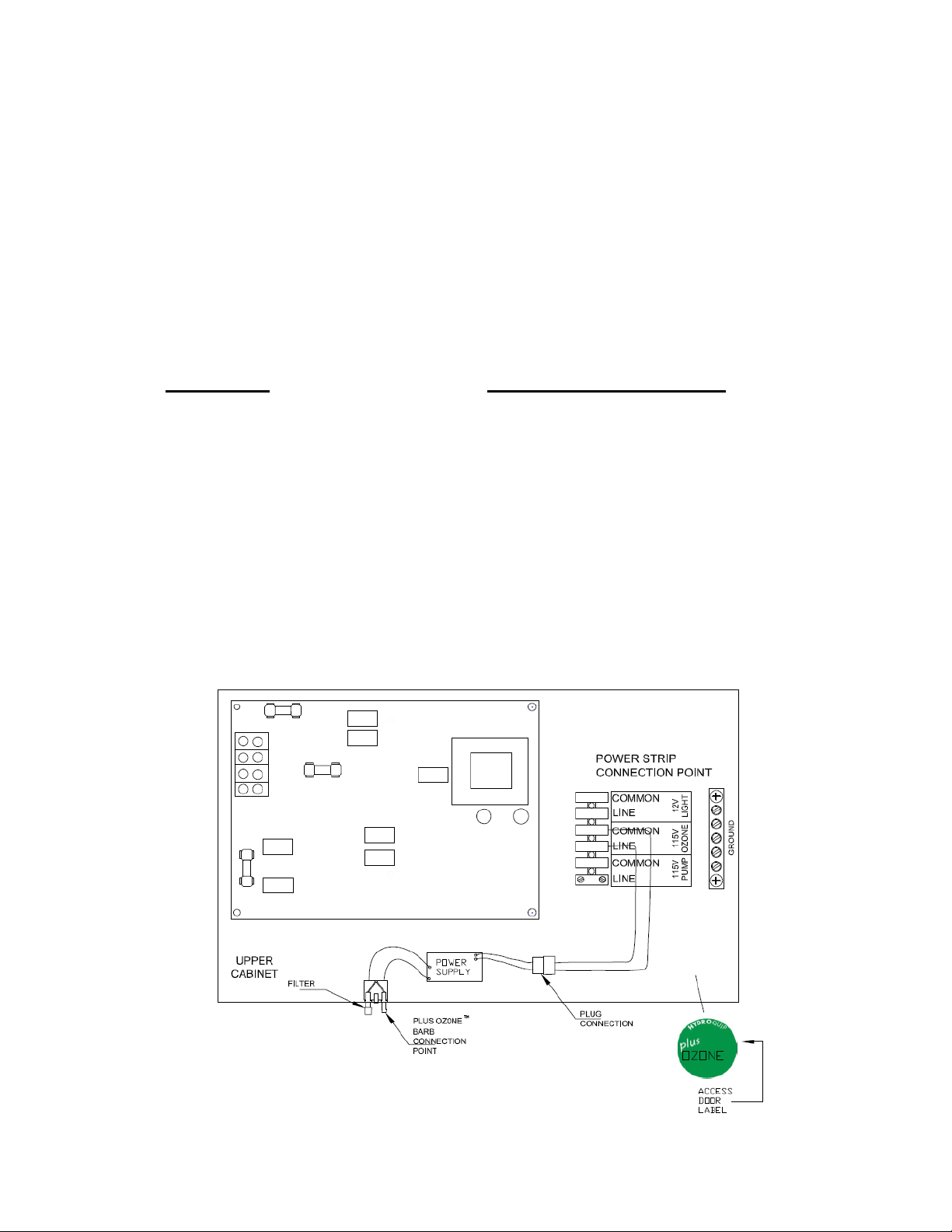

DISABLE PLUS OZONE™ OPTION:

If you are unsure how to connect plumbing, or if you choose not to use the Plus Ozone™ it's important to disconnect the

electrical power. To disconnect power, simply disconnect the male and female plug connection point as shown in Dia #1,

then coil and store plugs out of the way in the cabinet.

OPERATION:

The Plus Ozone™ system is only activated when the main filter pump (pump #1) is operating in a filter cycle. Reference

“Filtration Settings” in your operation manual to adjust filter cycle duration, that will directly affect the length of time the

Plus Ozone™ operates each day.

ABOUT:

Plus Ozone™ is a Corona Discharge (CD) ozone generator that is self- operating, self-regulating and contains no serviceable

parts. DO NOT attempt to alter, adjust or repair this device. The Plus Ozone™ generator is automatically activated by

system programing, to insure it does not operate without the pump.

It is normal to encounter a purification smell at the water surface confirming ozone is being generated and delivered.

Potency has been regulated on this device, and remains non-adjustable for your safety and convenience. Ozone gas applies

an instant sanitation effect to the water, however, is does not build or maintain a lasting residual. Therefore, ozone

becomes ineffective shortly after the generator is turned off.

Ozone generated by this device is solely intended for the sanitation of water and the inner walls of the delivery piping

system by means of direct exposure, the effectiveness and expected benefit is strictly limited to the time during operation.

IMPORTANT! Consult with your tub manufacturer and/or local pool and spa professional to establish an additional

chemical regiment for water care.