-3-

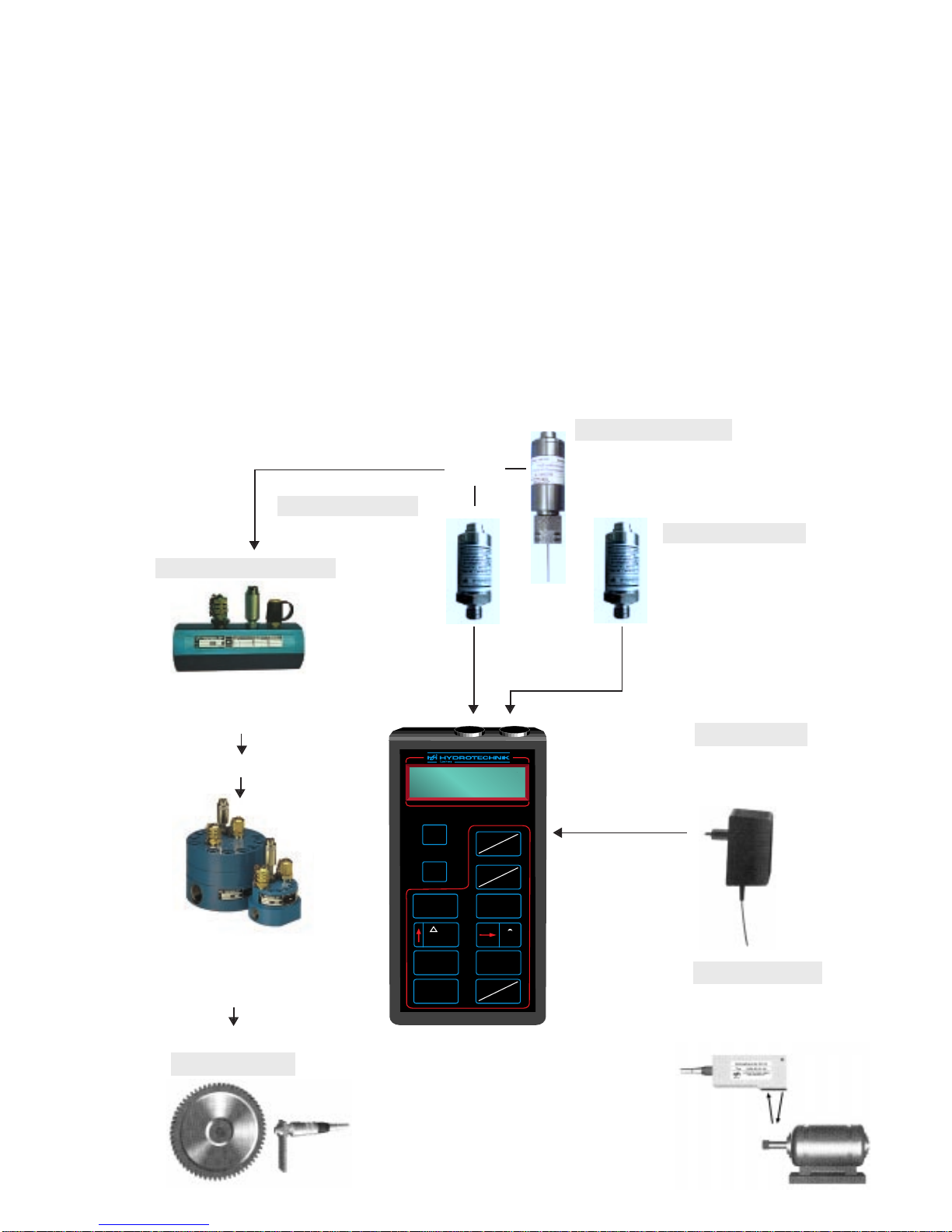

Preface

General ..................................................................................................................................................................

Instruction for the correct charging of the internal instruments batteries ...................................................................

Important comments .................................................................................................................................................

1. Operation Multi-Handy 2040 .............................................................................................................................

1.1 Display examples .....................................................................................................................................................

1.2 Initialisation...............................................................................................................................................................

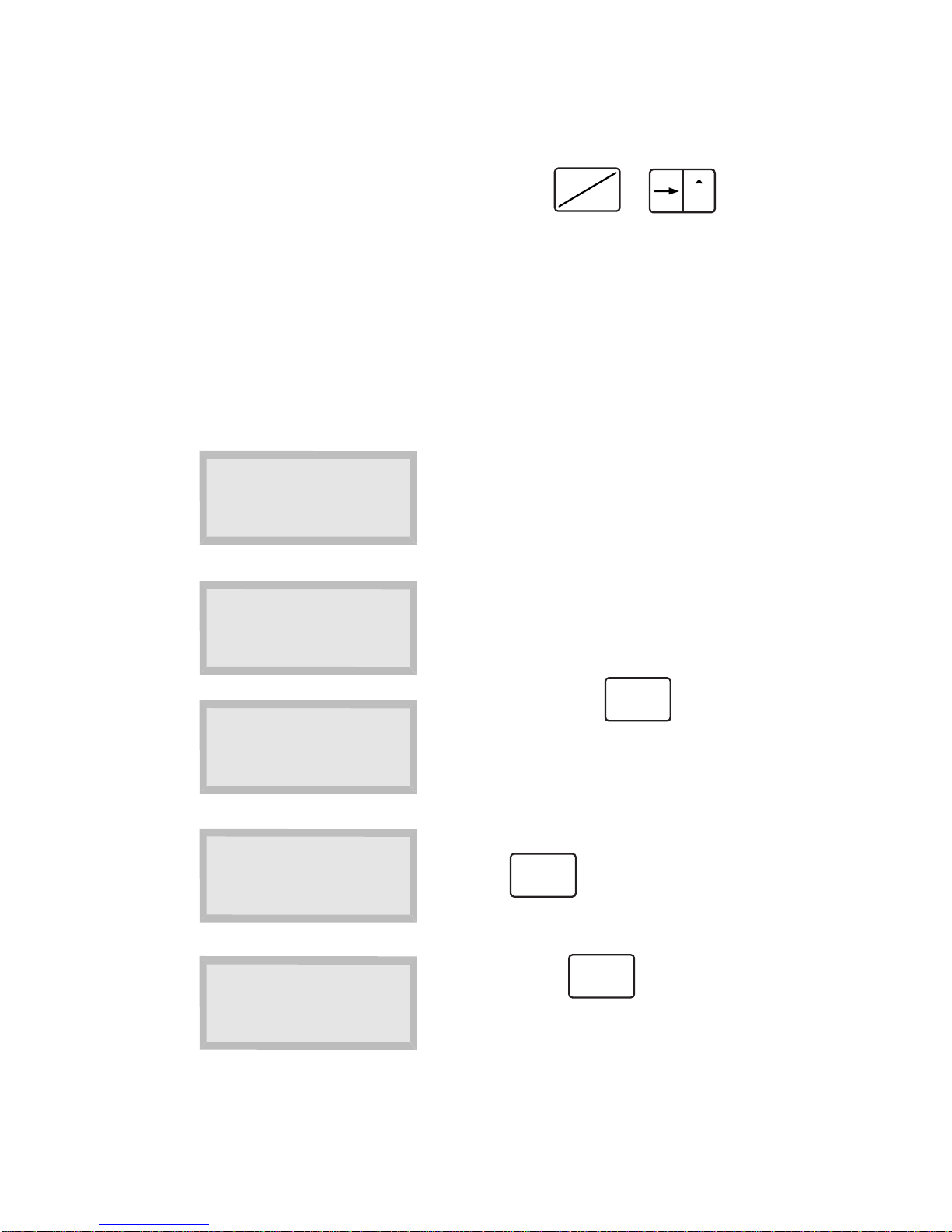

2. Programming.........................................................................................................................................................

2.1 Selection of unit of measurement .............................................................................................................................

2.2 Selection of pressure sensor for signal 0 to 20 mA or 4 to 20 mA ...........................................................................

2.3 Checking of current signal adjustment......................................................................................................................

2.4 Error message at 4 to 20 mA sensors .......................................................................................................................

2.5 Measuring value display at 4 to 20 mA sensors .......................................................................................................

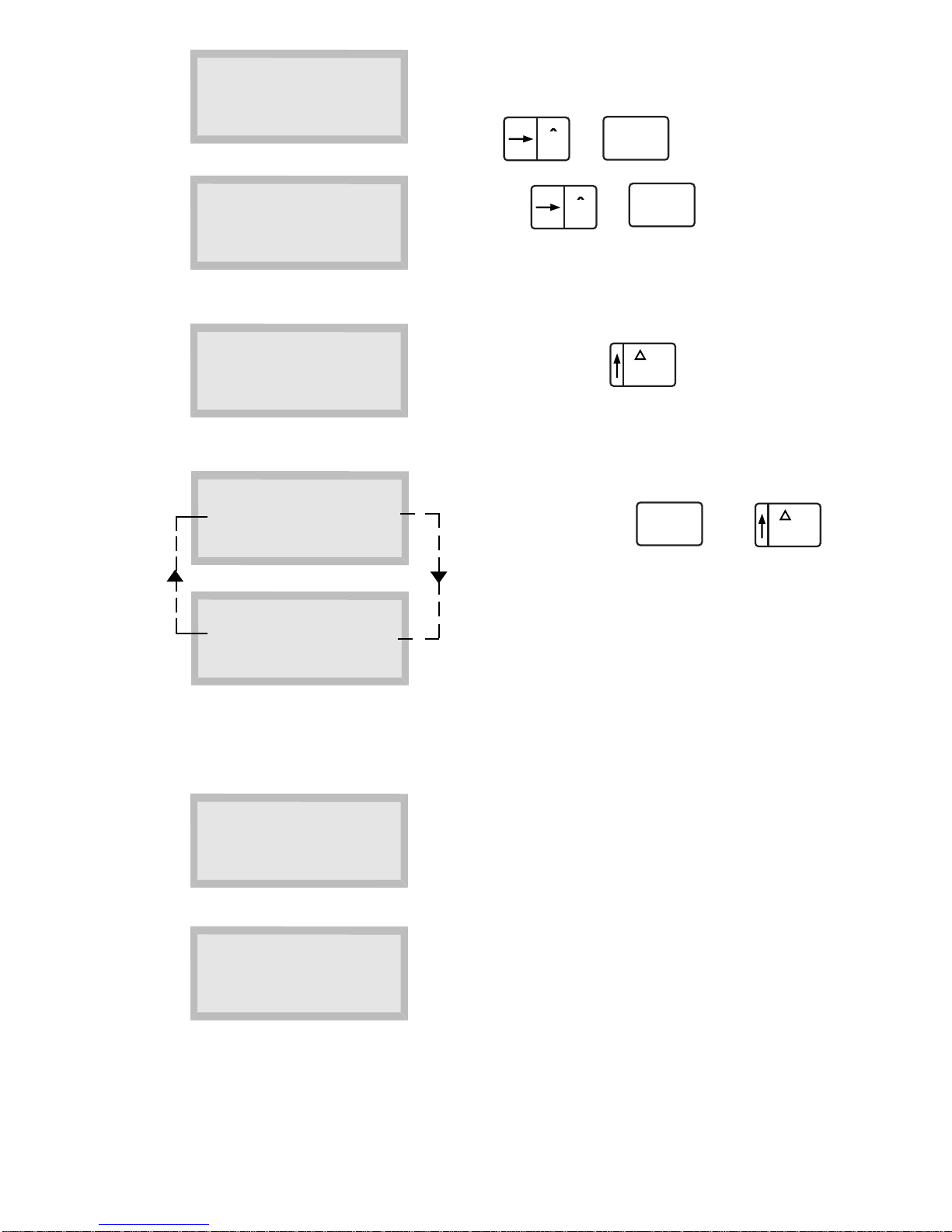

3. Measurement of pressure .................................................................................................................................

3.1 Selection of pressure measuring ranges ...................................................................................................................

3.2 Zero point alignment ................................................................................................................................................

3.3 Measurement of pressure peaks ...............................................................................................................................

3.4 Invocation of min/max. values in the display ............................................................................................................

3.5 Deletion of pressure peak .........................................................................................................................................

3.6 Change-over from measurement of pressure peaks to normal pressure measurement .............................................

3.7 Measurement of pressure differential .......................................................................................................................

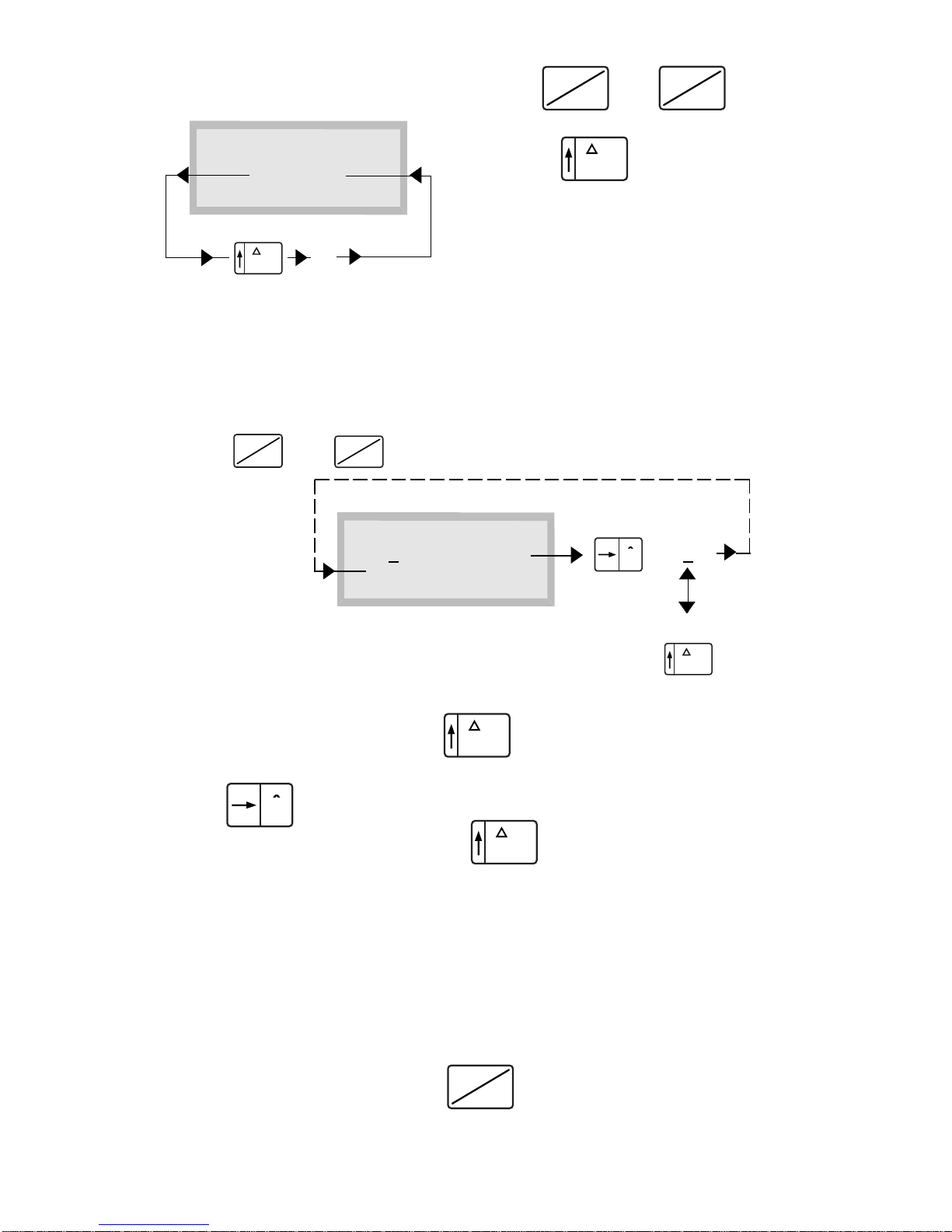

4. Measurement of temperature ..........................................................................................................................

5. Measurement of volume flow rate ..................................................................................................................

5.1 Input of calibration value ..........................................................................................................................................

5.2 Zero point alignment ................................................................................................................................................

6. Measurement of rev. speed...............................................................................................................................

6.1 Input of calibration value ..........................................................................................................................................

6.2 Zero point alignment ................................................................................................................................................

6.3 Further technical advice for the measurement of rev. speed ......................................................................................

7. Technical data of Multi-Handy 2040 ...............................................................................................................

8. Pin connections of Multi-Handy 2040..............................................................................................................

8.1 Technical background information for connection of pressure sensors,

0 to 20 mA- and 4 to 20 mA-type..............................................................................................................................

9. Error detection .....................................................................................................................................................

10. Information on guarantee ..................................................................................................................................

11. Maintenance..........................................................................................................................................................

4

5

6

7

7

9

10

10

10

11

11

11

12

12

13

14

14

14

14

15

16

17

17

17

18

18

18

19

20

21

22

23

24

24

Index