Page 3

1. About this documentation ................................................................................................ 5

1.1 Intended use ..................................................................................................................... 5

1.2 Structure ............................................................................................................................ 6

1.3 Depictions .......................................................................................................................... 7

1.3.1 Action steps .................................................................................................................... 7

1.3.2 Safety instructions and information notes ...................................................................... 7

1.4 The documentation is part of the system .......................................................................... 7

1.5 Customer service .............................................................................................................. 8

2. Safety .................................................................................................................................. 9

2.1 Measures for safe operation .............................................................................................. 9

2.2 Personnel .......................................................................................................................... 10

2.3 Personal protective equipment .......................................................................................... 10

2.4 Safety-conscious working .................................................................................................. 11

3. Transport and storage ...................................................................................................... 13

3.1 Transport notes ................................................................................................................. 13

3.2 Scope of supply ................................................................................................................. 13

3.3 Inspecting for correctness and completeness ................................................................... 13

3.4 Storage .............................................................................................................................. 13

3.5 Preservation ...................................................................................................................... 14

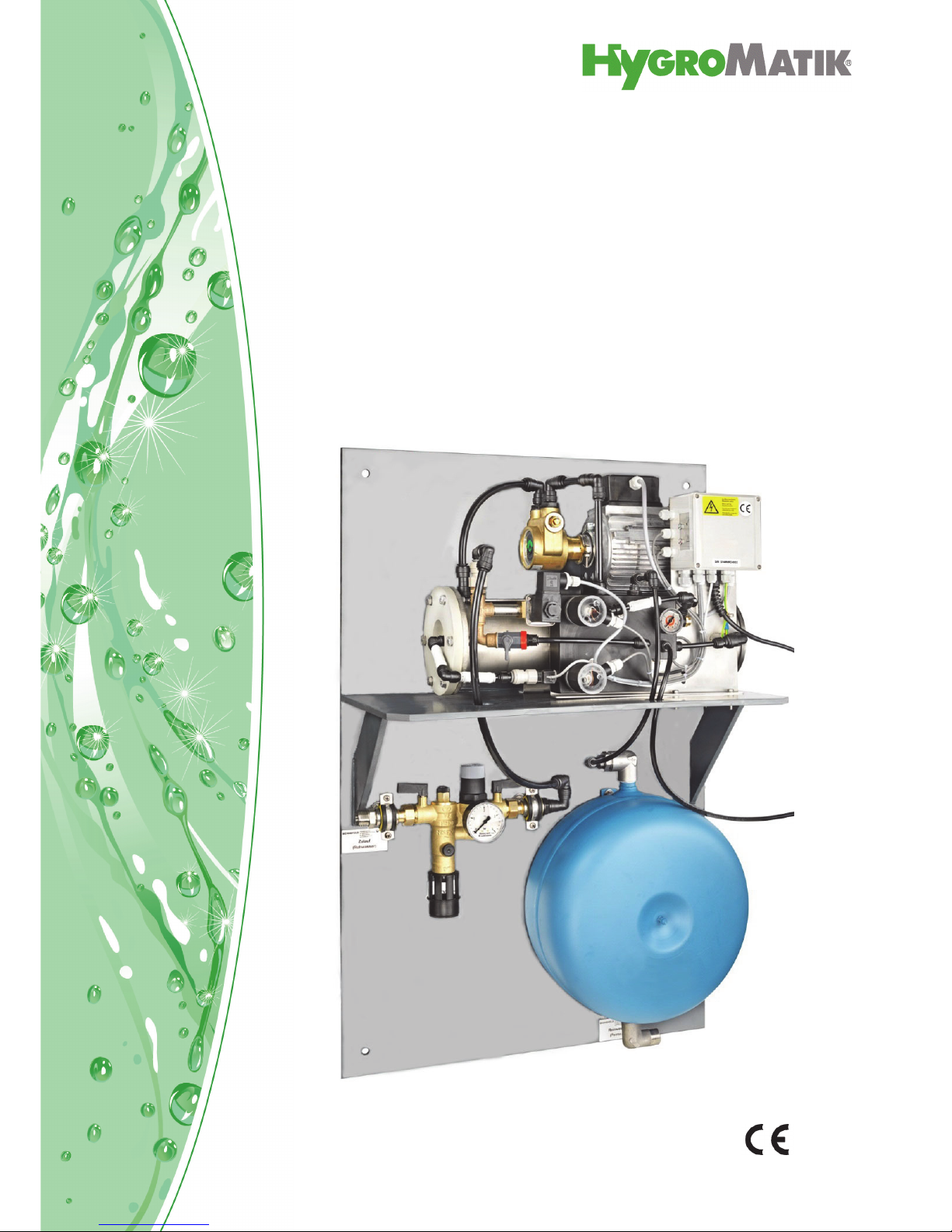

4. System description .......................................................................................................... 15

4.1 Principle of osmosis/reverse osmosis ............................................................................... 15

4.2 Overview of components ................................................................................................... 15

4.3 Functional description ....................................................................................................... 17

5. Technical Data ................................................................................................................... 19

5.1 Raw water requirements regarding water quality .............................................................. 19

5.2 Raw water requirements regarding pressure .................................................................... 19

5.3 Permeate quality ............................................................................................................... 19

5.4 Performance data .............................................................................................................. 20

5.5 Dimension sheet ................................................................................................................ 21

5.6 Emissions .......................................................................................................................... 23

5.6.1 Operating and auxiliary materials ................................................................................... 23

5.6.2 Noise emission from the system .................................................................................... 23

6. Mounting ............................................................................................................................ 24

6.1 Mounting the securing and fixing plate .............................................................................. 24

6.2 Connecting the plant ......................................................................................................... 25

7. Inital start-up (System was preserved by manufacturer) .............................................. 27

8. Settings .............................................................................................................................. 29

8.1 Setting the switch-off pressure .......................................................................................... 29

8.2 Setting raw water inlet pressure on the pressure regulator ............................................... 31

9. Production/Stand-by operation ........................................................................................ 32

9.1 Starting production ............................................................................................................ 32

9.2 Set blending (ROB plant only) ........................................................................................... 33

9.3 Stand-by operation ............................................................................................................ 34