3

Do not carry a plugged-in tool with a finger on the switch. Ensure switch is in OFF position when

plugging in.

r) Use outdoor extension leads

When tool is used outdoors, use only extension cords intended for outdoor use and therefore marked.

s) Stay alert

Watch what you are doing. Use common sense. Do not operate tool when you are tired.

t) Check damaged parts

Before further use of the tool, a guard or other part that is damaged should be carefully checked to

determine that it will operate properly and perform its intended function.

Check for alignment of moving parts, free running of moving parts, breakage of parts, mounting and any

other conditions that may affect its operation.

A guard or other part that is damaged should be properly repaired or replaced by an authorized service

centre unless otherwise indicated in this instruction manual.

Have defective switches replaced by an authorized service facility.

Do not use the tool if the switch does not turn it on and off.

u) Warning

The use of any accessory or attachment, other than those recommended in this instruction manual or

the catalogue, may present a risk of personal injury.

v) Have your tool repaired by a qualified person

This electric tool is in accordance with the relevant safety requirements. Repairs should only be carried

out by qualified persons using original spare parts, otherwise this may result in considerable danger to

the user.

Additional instructions

- When using the saw, wear personal protective equipment such as safety goggles or a screen,

helmet, dust mask, gloves, non-slip footwear and protective clothing

- Ensure that there is sufficient, generalized or localized lighting.

- Do not use the saw when the protective parts are not in place.

- Do not use the saw to cut metal or masonry parts.

- Do not allow persons under 18 to operate the tool.

- Ensure that users of this tool have received professional training and know how to set and use

this tool.

- Do not use the saw to cut firewood

- Remove all stumbling blocks from the work area.

- Report or record any defects as soon as possible, including the guards and the saw blade.

- Install the saw as much as possible on a work stand. Res Always stay on the side when the

saw is turning.

- Never use a saw blade that is cracked or deformed.

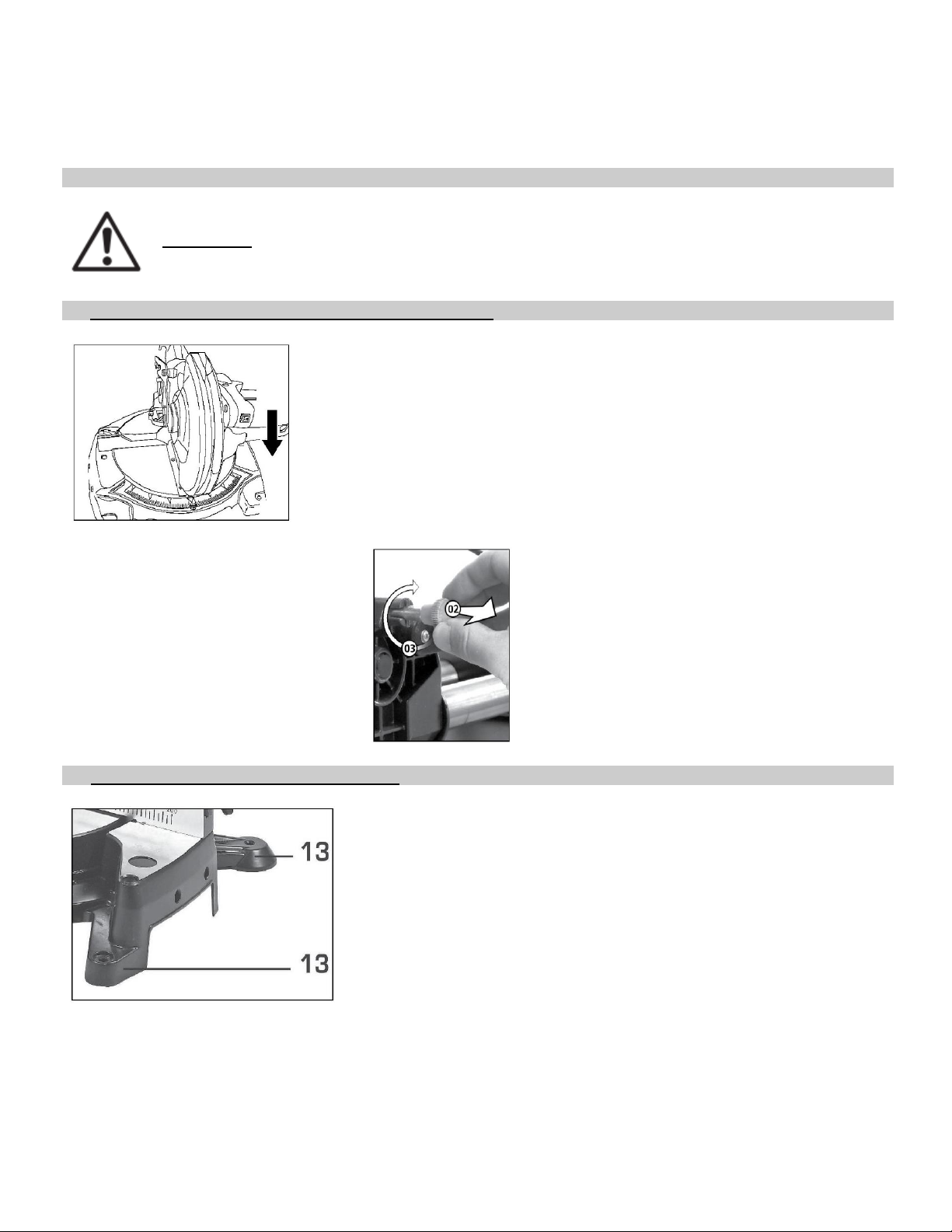

- When cutting round wood, use a clamping assembly to prevent slippage of the workpiece.

- Do not use your hand to remove sawdust, chips or debris near the saw blade.

- Use only blades recommended by the manufacturer that comply with EN847-1.

- Do not use high speed steel blades (HSS blades).

- If the plate inserted on the swivel table is worn or damaged, have it replaced by an authorized

service center

- Objects such as cloth, strings, should never be left in the working wone. Avoid cutting nails.

Check the workpiece and remove all nails and other foreign objects before starting the machine.

- Hold the workpiece firmly.

- Avoid collecting debris or sawdust on the saw before the saw is completely stopped and the

blade guard is in the open position.

- Do not attempt to release a blocked blade before stopping the machine by pressing the switch

- Do not attempt to slow down or stop the blade when it is still in the workpiece.

- Let her stop by herself.