New R-Line Refuse Collection Micro

User Manual RCM10

5

2 Safety Rules

This chapter covers all the safety issues related to

the installation of the RCM10. In order to avoid

personal injury to the operator or (serious) damage

to the materials, please operate strictly following the

rules defined in this chapter.

Please provide this user manual, including all the

safety rules mentioned in it, to all staff involved in

the installation of the RCM10 and require them to

read carefully.

If anything is unclear about the

safety rules, please contact the

equipment manufacturer for proper

explanation.

2.1 Regulations and prohibitions concerning

machine transportation

Goods always travel at the buyer's risk as and from

delivery to the carrier. Transport is always to the

buyer's charge unless otherwise agreed at the time

of drawing up the contract.

The lifting of the machine, excepting via vehicle

lifts, is expressly forbidden without prior

consultation with HYVA.

The machine should always be transported by

driving or using suitable equipment built for

transporting motor-vehicles. The manufacturer

expressly forbids the lifting of the vehicle with

any type of system.

Following transportation, check the machine

has suffered no damage. In the event of

damage, it is forbidden to start up the machine.

Inform the authorised head immediately.

2.2 Preparations for safe transport

Check whether the connection between the

plug and the adapter is disconnected.

Check to ensure the cover plate/door of the

feed inlet is locked.

Check whether all the doors and valves are

locked tightly.

If a foldaway hook is used for your equipment, it

shall also be locked tightly.

Check whether the hook placed on the lifting

support for handling has been removed.

2.3 Control panel

There is an emergency stop button on the

control panel. In case of emergency, press this

button to stop all the moving parts immediately

(only superstructure).

A release button is provided on the master

control panel. In case of emergency, press this

button to retract the garbage compaction

mechanism back to its initial position. When

this button is released, the garbage

compaction mechanism will stop retracting.

Even when the emergency stop button has

been pressed or even when the door is in open

state, this function shall still be able to work

properly.

2.4 Preparations for safe use

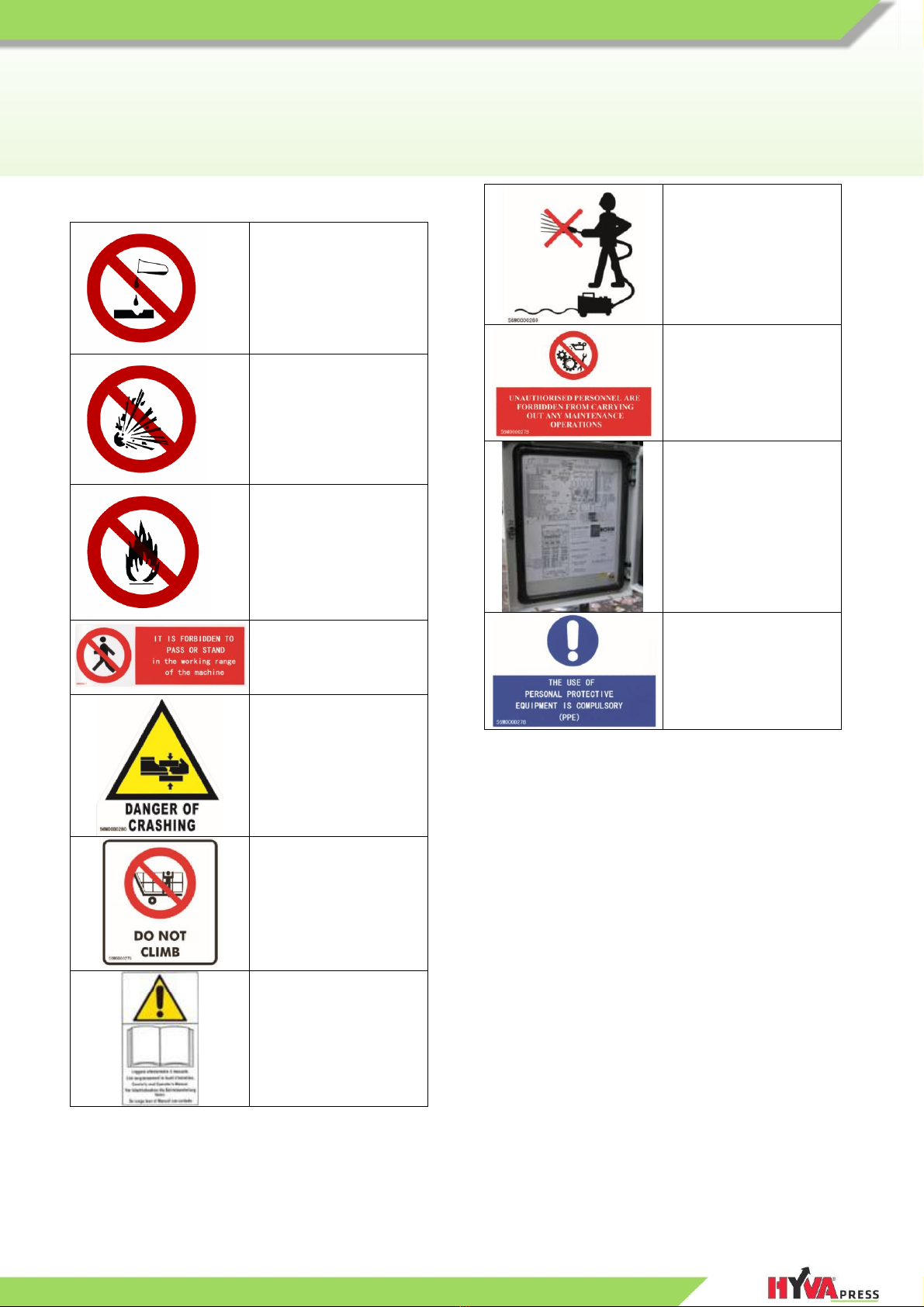

Do not remove any warning mark or plate from

the equipment. If the content on such warning

mark or plate becomes illegible, replace with

the same one immediately.

Make sure that all the staff operating the

equipment or conducting daily maintenance for

the equipment can find this user manual easily

for reference.

Make sure that the RCM10 is operated only by

the staff familiar with the performance of such

equipment. Such staff should know all the

knowledge concerning the equipment and get

familiar with the content of this user manual.

2.5 Safety measures in the course of use

In adverse weather conditions, please do not

use this RCM10.

During the course of operation, it is strictly

prohibited for any person to enter or step onto

the RCM10.

There should be no obstacle, which may affect

the operation or movement of the equipment,

around the RCM10.

Technical malfunctions may be very dangerous.

Therefore, in case of any such malfunctions,

contact the person in charge of installation

supervision immediately. The power supply to

the RCM10 must be cut off until the dangers are

removed,

It is strictly prohibited to put any flammable,

explosive articles or erosive chemicals and

other hazardous materials into the RCM10.

When any solid or fragile garbage (such as

glass or plastic) is processed with the