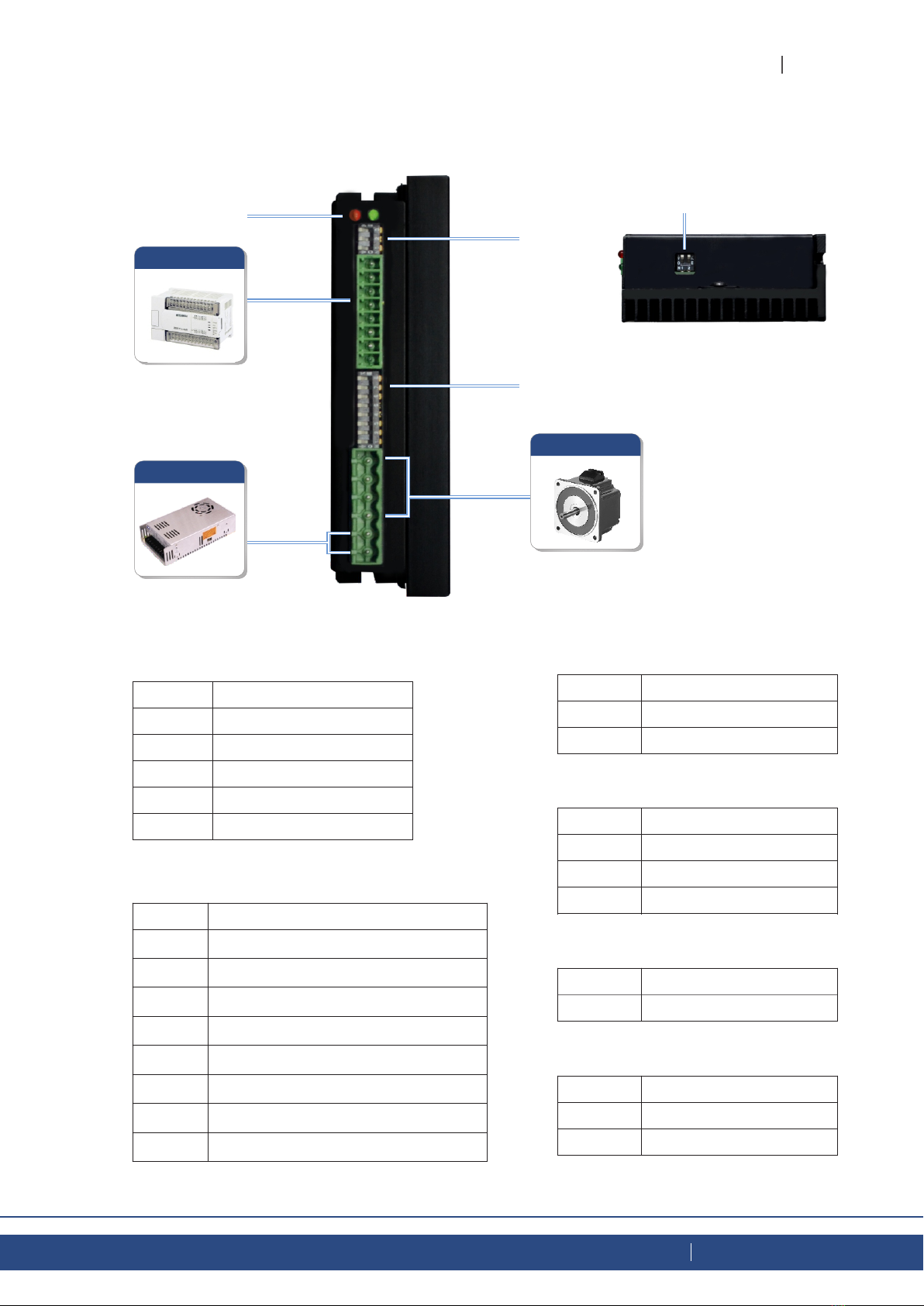

ICAN July 2016 8

S W 1 2

K

E

SW13

K

E

SW4

K

E

3-Phase Stepper Motor Drive 3MR8

■ Function setting

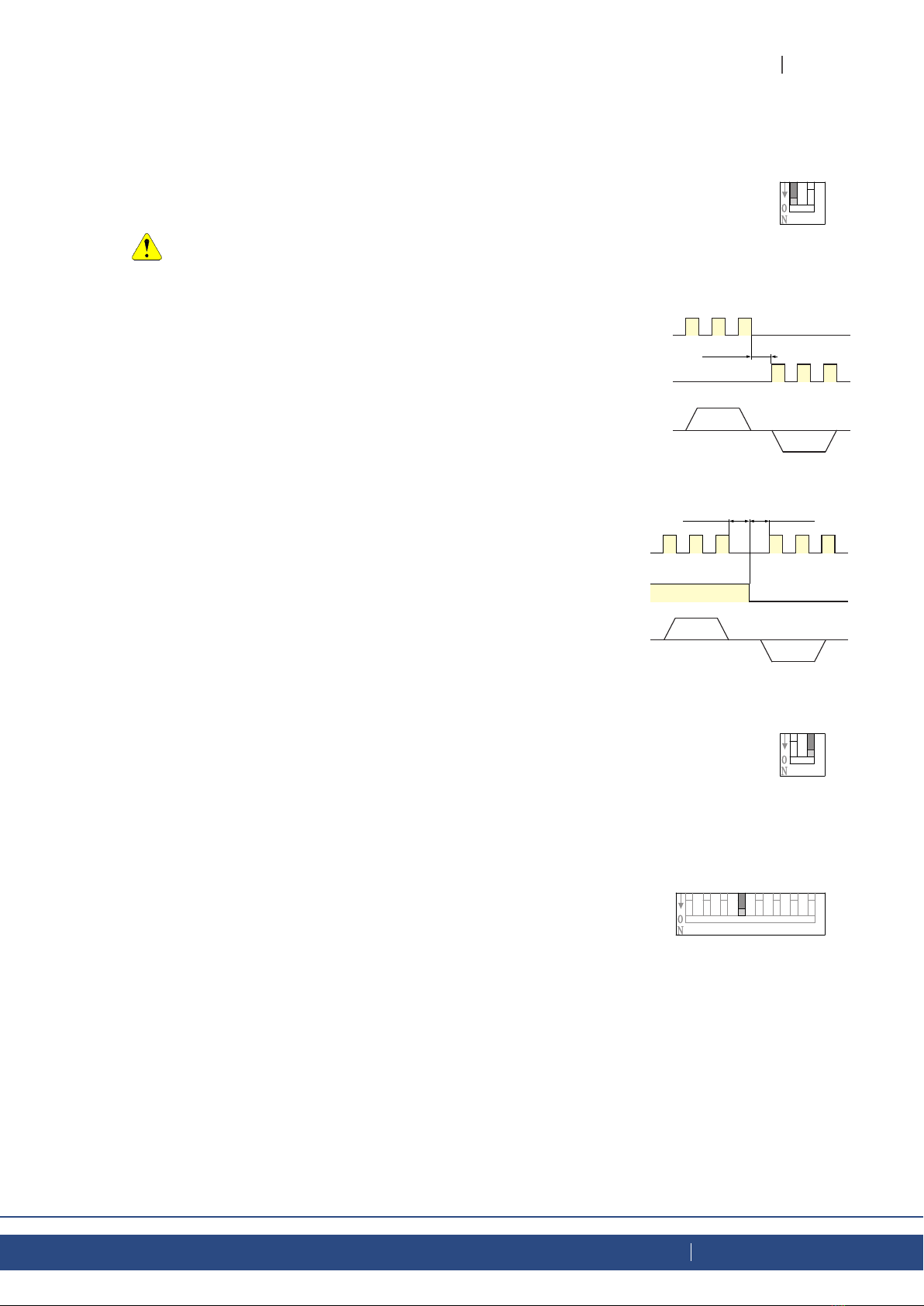

● Pulse Input Mode

CW/CCW mode: SW12=ON

PUL/DIR mode: SW12=OFF (factory setting)

The setting will take effect after recycle the power

CW/CCW Pulse

When pulse is input at PUL/CW terminal,

the motor will rotate by one step in one

direction.

When pulse is input at DIR/CWW terminal,

the motor will rotate by one step in the other

direction.

PUL/CW H

L

H

L

DIR/CWW

CW

CWW

Motor Motion

Above 2μs

Pulse & Direction

When pulse is input at PUL terminal, and DIR

terminal is high voltage, the motor will rotate

by one step in one direction. When pulse is

input at PUL terminal, and DIR terminal is low

voltage, the motor will rotate by one step in the

other direction.

H

L

H

L

CW

CWW

Above 2μsAbove 2μs

PUL input

DIR input

Motor Motion

Setting switch SW13 to ON after the drive is powered up will

cause the drive to perform a self test rotate the motor back and

forth, two turns in each direction, setting switch SW13to OFF

will disable this feature.

●Self Test

●

The running current of the motor driver is automatically reduced

whenever the motor hasn’t moved for 1 second. Setting the SW4

switch to ON reduces the current to 50% of its running value.

Setting this switch to OFF maintains 90% of the running current.

This 90% setting is useful when a high holding torque is required.

To minimize motor and drive heating it is highly recommended that

the idle current reduction feature be set to 50% unless the

application requires the higher setting.

Idle Current