i-milk mini User manual

i-milk mini Operating Manual

Please read thoroughly before use

i-milk V1 Operating Manual July 2018

2

i-milk Pty Ltd warrants equipment sold against

defects in parts other than consumables and

workmanship for a period of twelve (12) months

from the date of installation.

The warranty will be void if not installed in

accordance with the directions from I-milk or if not

used in accordance with the operating instructions

in this manual.

i-milk recommend cleaning products which

are proven to clean milk residues which may

accumulate and stop your system operating.

Failure to use a recommended cleaner will void

this warranty.

Consumable Items included in the parts box are not

covered by your warranty.

Your warranty will also be voided if:

1. Milk pumps may be damaged due to running

them dry for extended periods.

2. Freezing the milk lines or even the milk in the

pumps may also cause damage to the pumps

and this will also void the warranty. Ensure your

refrigeration is correctly adjusted to a temperature

between 1 – 5 C.

If a warranty claim is to be made, please contact

your distributor for further information or

i-milk is manufactured in Sydney, Australia by i-milk Pty Ltd.

For all operating and service enquiries please contact your distributor or i-milk.

24 hour hotline number: +61 3 9877 3995

Email: [email protected]

The machine is not for outdoor use.

Warranty

i-milk V1 Operating Manual July 2018 3

Contents Page

Warranty ....................................................................................................................................... 2

1. Familiarisation......................................................................................................................4-5

2. Essential Maintenance.......................................................................................................... 6

3. Loading Milk Bladders........................................................................................................... 7

4. Operating Instructions.......................................................................................................... 8

5. Cleaning Instructions ...................................................................................................... 9-11

6. Trouble Shooting..................................................................................................................12

7. Technical Adjustments..................................................................................................13-14

8. Maintenance Records .........................................................................................................15

i-milk V1 Operating Manual July 2018

4

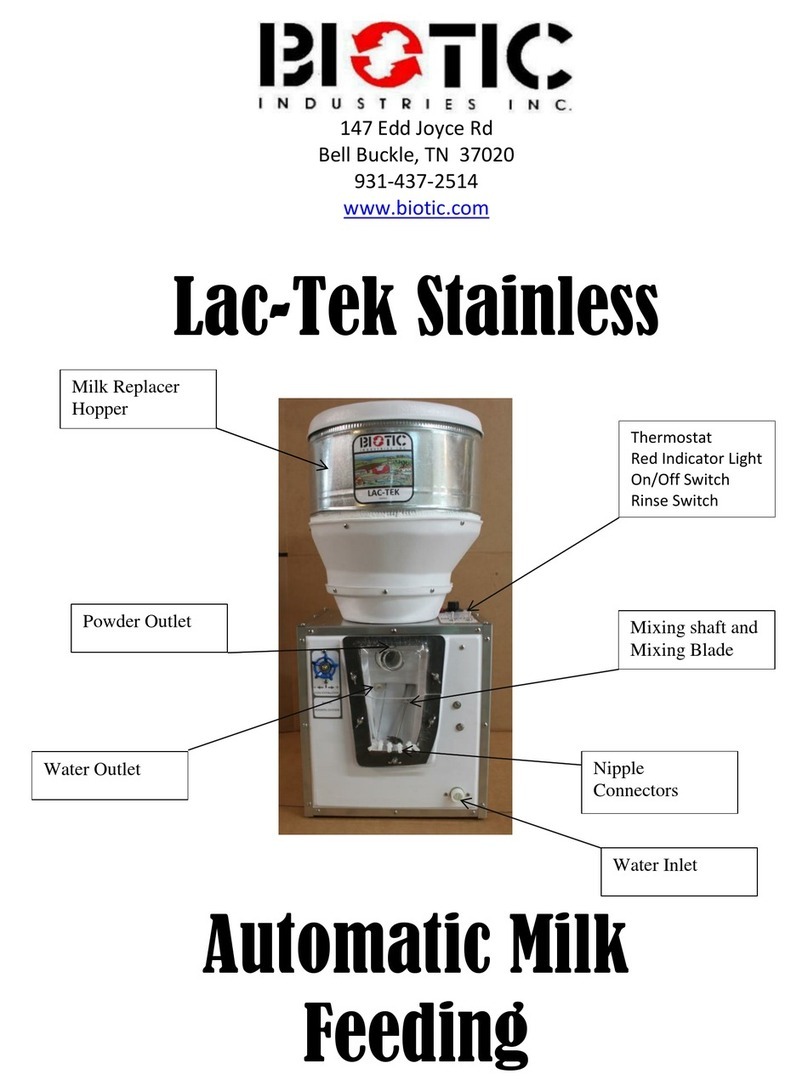

Dispensing Head

Pump Box

Power Supply

This dispenses the milk and should be installed on a at

horizontal surface.

This should be installed in a refrigerated environment,

either oor or wall mounted. Installing in a non-refrigerated

environment will void your warranty.

Each i-milk mini is supplied with a 110/220v converter with a plug

suitable to use in the country of sale. These plugs are earthed

and must not be substituted with non-earthed plugs.

The converter produces 24VDC 5A that operates the i-milk mini.

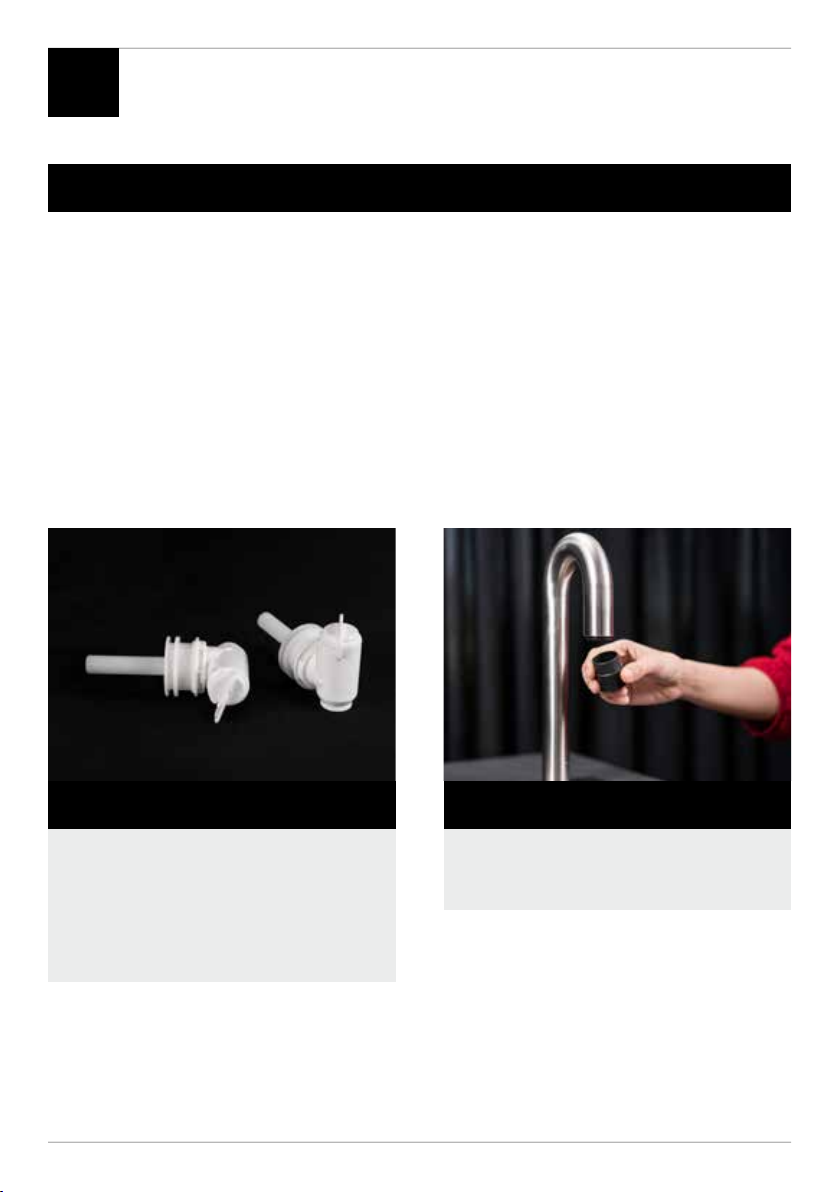

ARemovable Milk Filter

BMilk Font

CVariety A Milk Button

DVariety B Milk Button

EOutlet for milk line and signal cable. Also accessible

on opposite side of dispenser and underneath

ALITE IN

BFULL IN

CLITE OUT

DFULL OUT

EPump Box Input

Familiarisation

1

360

185

50

235

120

A

B

E

D

C

A B

DE

C

i-milk V1 Operating Manual July 2018 5

Milk is supplied for the i-milk system in many

dierent formats. In Australia the most common is

the 10 litre bladder available from milk processing

companies. There are several storage systems

available.

This manual describes the bladder system,

but instructions relevant for using other bulk

systems are available on request from:

The Milkstak system consists of crates that

stack on top of each other and hold the milk

bladders. This system is designed to be installed

into existing refrigeration.

These systems must be installed in a permanently

refrigerated environment that can hold temperatures

between 1c – 5c constantly.

Emergency Taps

Two manual taps are supplied with each

i-milk for emergency use so milk can

be conveniently accessed direct from

the bladders in the event of power or

system failure.

Milk Filter Housing

i-milk is designed to pour a uniform,

steady, non-turbulent stream of milk.

Milk Storage Systems

Familiarisation cont.

1

i-milk V1 Operating Manual July 2018

6

Daily Cleaning

Complete the required daily cleaning. Refer to page 10.

Weekly Maintenance, suggest each Monday

Inspect Milk Font Filter Housing. See page 11

Monthly Maintenance, suggest 1st Monday of each month

Lubricate “o” rings in each cleaning assembly point, located:

• in the tting on each cleaning bucket

• in the pouring font – lter head connection point

• inside each cleaning sock

Use the Inox Food Grade lubricant supplied in a tube with your

i-milk. Lubricate the “o” rings by applying the lubricant to the milk

spigot or stem as you insert it in the tting.

Essential Maintenance

2

i-milk V1 Operating Manual July 2018 7

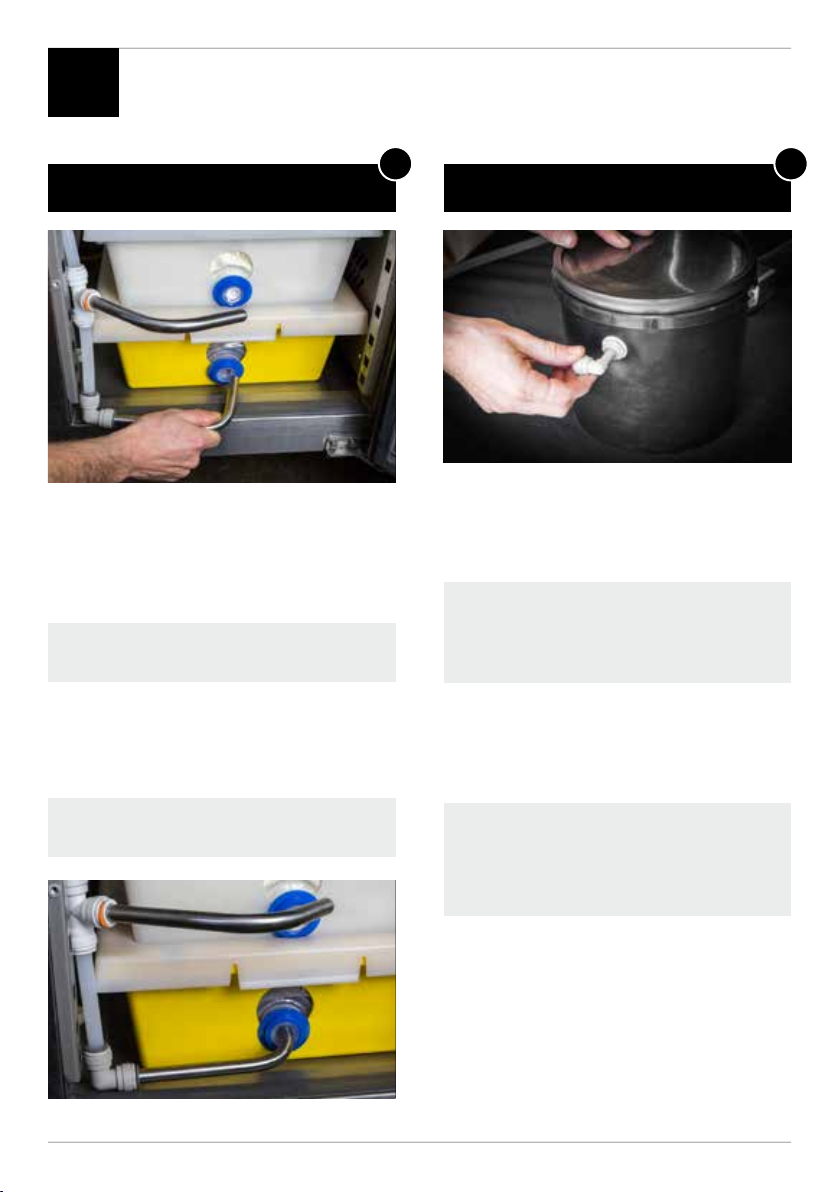

Settle the bladder at on the base of the

container with the connector nearest the

cutout slot, face down. The bladder seal

must be above the connector.

Connect to Milkstak

Stack the tubs adjacent to the daisy chain

of spigots. Nesting tubs should be rm.

Remove (and retain) the black safety cap

from the spigot, remove the travel cap

from the bladder connector and push the

spigot rmly into the connector.

Overlled bags in Milkstak tubs may cause

the stack to become unstable. This will

rectify as milk is removed by the milk pumps.

Take care when sliding bladder connector

into slot. Otherwise the cap may be pulled

o resulting in a loss of milk.

Lift the bladder to position and slide the

bladder connector into the slot pushing it

to the bottom of the slot as shown.

Loading The Milk Bladders

3

DO NOT LOCATE HERE

i-milk V1 Operating Manual July 2018

8

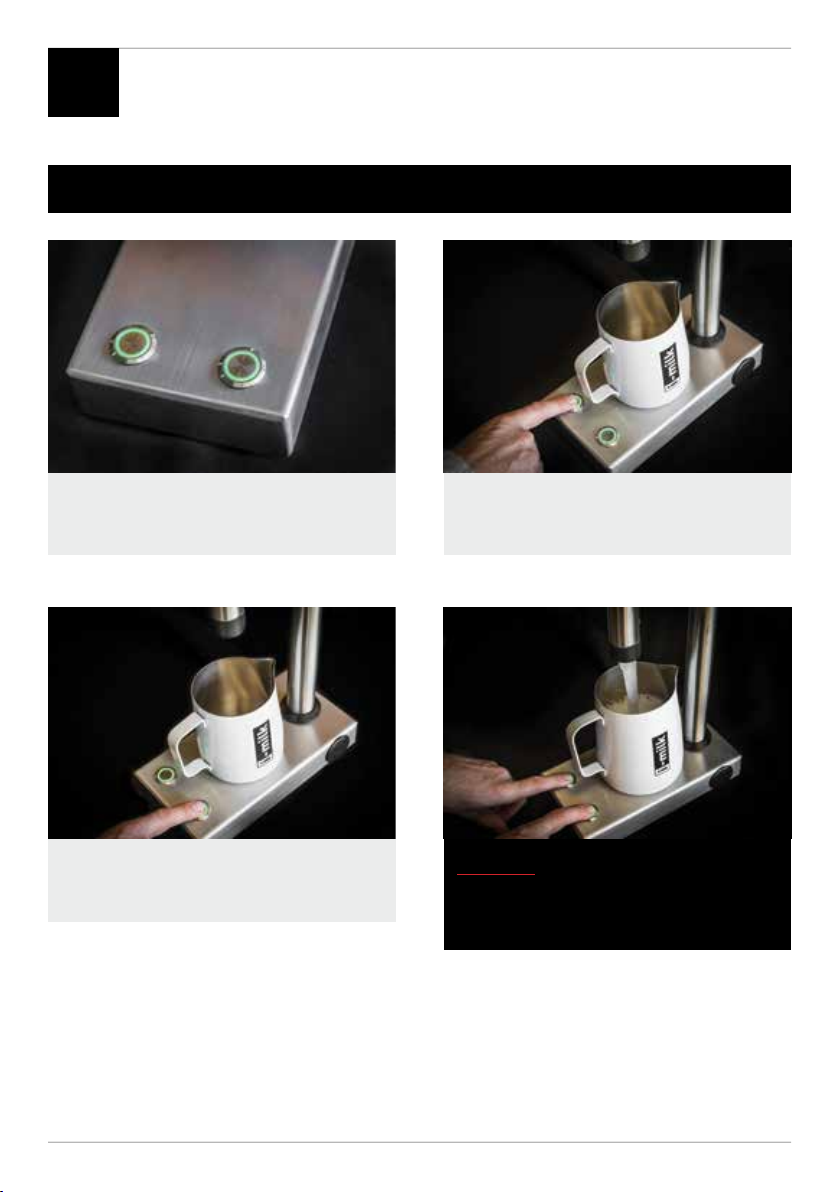

To Pour Milk

When i-milk mini is connected to power the

buttons will illuminate.

To pour milk variety B push the right button

and release to stop the pour.

To pour milk variety A push the left button

and release to stop the pour.

WARNING

Do not push both at the same time. As it

will deliver 2 milk types at the same time.

Operating Instructions

4

i-milk V1 Operating Manual July 2018 9

Cleaning Instructions

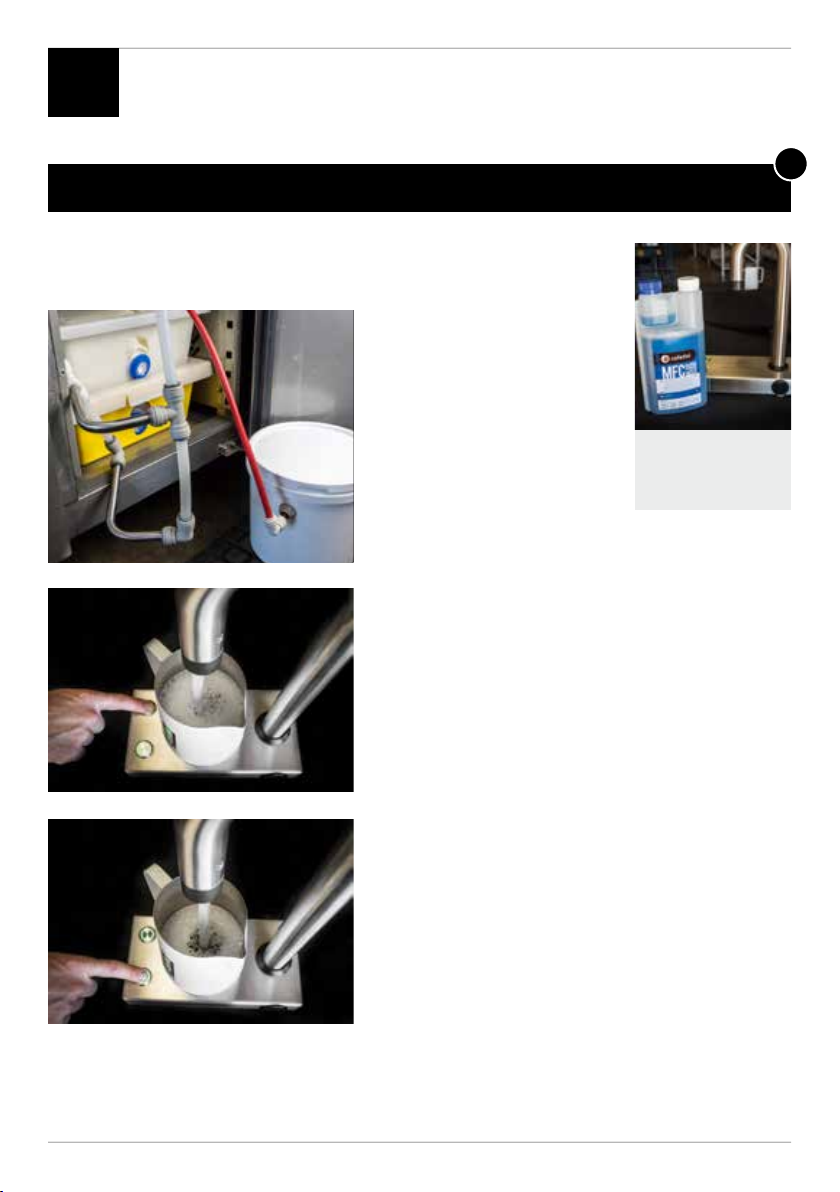

Preparation Flush out milk lines with COLD water

Remove each milk spigot and reseal the

bladder connector using the milk transport

seal. If this still leaks use the ½” bung

supplied in your Parts Kit.

To remove all milk residue from the

plumbing, place a large container under

the font.

Fill BLACK cleaning bucket with COLD

(NOT HOT) water and connect as shown.

Press the left button to pump all milk

from that source. Keep pumping until

water runs clear.

Press the right button to pump all milk

from that source. Keep pumping until

water runs clear.

Disconnect the cleaning bucket and pump

lines until water ow stops.

Clean each spigot thoroughly with food

grade sanitiser spray using a clean single

use paper towel.

Connect each milk spigot into its cleaning sock.

Leave the milk tubs in the fridge

Complete for all spigots.

12

5

i-milk V1 Operating Manual July 2018

10

Cleaning Instructions cont.

HOT Chemical Soak

Make up enough Cafetto Chemical Solution for the daily clean (50ml

chemical for 1L water) with HOT (60C) water in White bucket.

Leave Chemical to

soak for 5 minutes.

Suggest use timer on

phone as a prompt.

3

5

Recommended

chemical to use.

Connect milk lines from

both sources to bucket

of chemical.

Pump the cleaning solution

using the left button until

the chemical starts to pour

into the jug. Push the right

button to pump chemical

into the other milk line.

i-milk V1 Operating Manual July 2018 11

Rinse Out Chemical

Disconnect the White chemical bucket and

replace with Black bucket relled with cold water.

4

Press left button until all chemical is removed and

clear water is being pumped (empty jug)

Place a jug under the font.

Push right button until all chemical is removed

and clear water is being pumped (empty jug)

Wipe the dispenser to complete the daily clean.

Cleaning Instructions cont.

5

i-milk V1 Operating Manual July 2018

12

Issue Comments And Possible Solution

i-milk is pouring frothy milk

i-milk is squirting milk into

the jug

Possibly caused by the system sucking air when the pumps

are active. Check that all quick t plumbing connections are

rm. Sometimes disconnecting and reconnecting is best as

the leak may be hard to detect.

Ensure that there is no hole in the wall of one of the milk

bladders attached to the system.

Possibly caused by something blocking the lter housing on

the end of the pouring font.

Remove the milk lter and clean it by following the

instructions on page 10.

Trouble Shooting

6

i-milk V1 Operating Manual July 2018 13

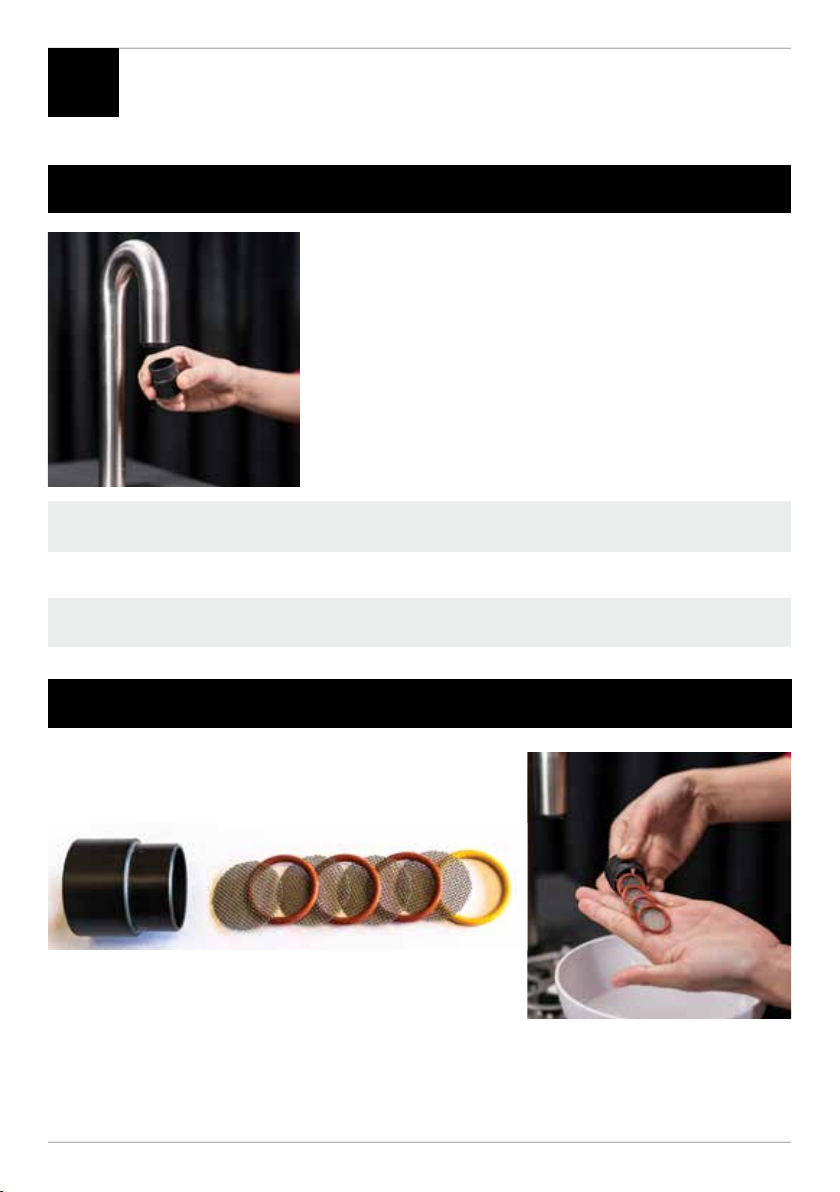

To Clean the Milk Filter Housing

Monthly Milk Filter Cleaning

i-milk has a milk filter located on the font outlet. This black

fitting delivers a uniform, steady, non-turbulent stream of

milk. If the filter mesh becomes blocked it may cause the

milk to squirt or froth.

To remove the milk filter rotate it as you pull it down.

If debris has collected on the visible lter mesh carefully reverse ush it.

Replace the lter into the font rotating it as you push it in place and test the milk ow.

If the milk ow is still not satisfactory carry out the monthly cleaning process outlined below.

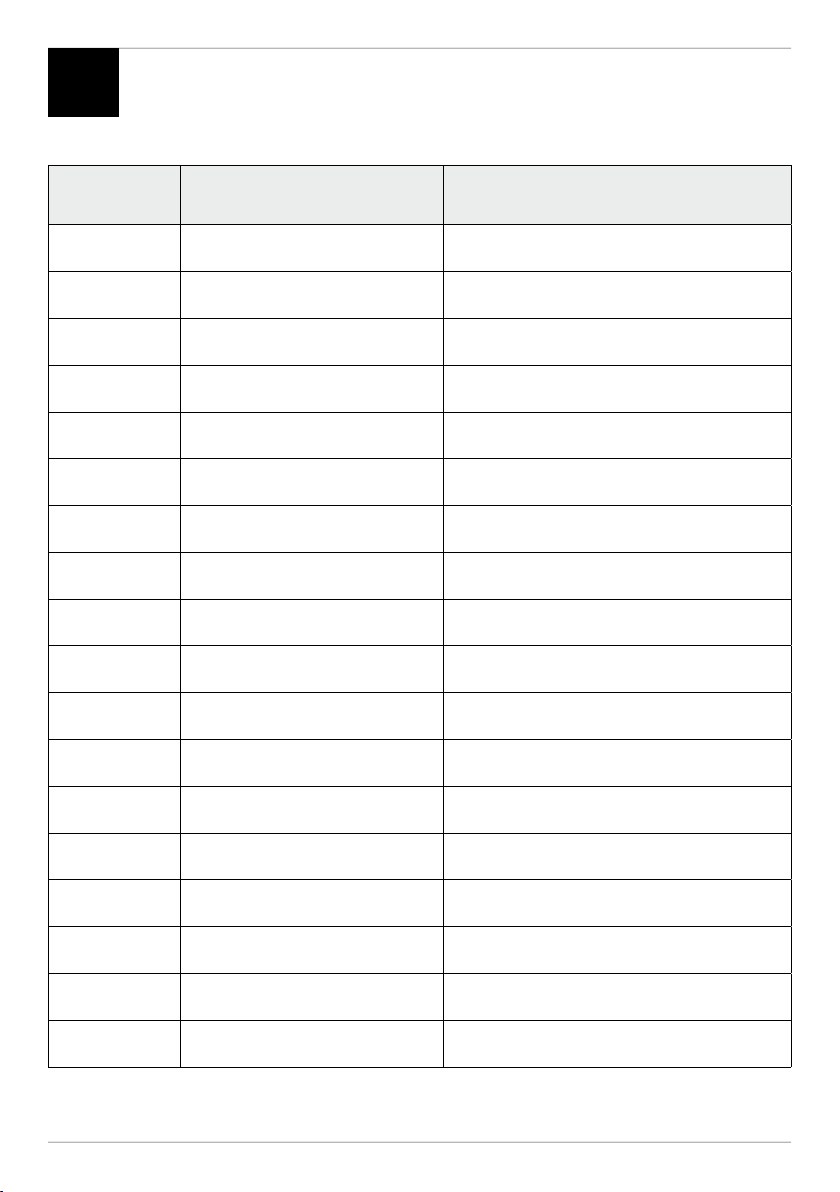

As shown in the picture below, the lter is made up of

4 stainless steel mesh lters each separated by 1 of 3

smaller “O” Rings. The must be in this sequence.

To disassemble gently push the

lters and “O” Rings out of the

lter housing into a large bowl

so as not to lose any parts.

1 black lter housing

4 identical stainless steel mesh lters

3 smaller “O” Rings that separate each mesh lter.

These drop freely into the black lter housing.

1larger “O” ring that is inserted last. It needs to be

pushed in place as it holds the mesh assembly in

the lter housing.

Technical Adjustments

7

i-milk V1 Operating Manual July 2018

14

Cleaning The Mesh Filters

To Use Emergency Taps

Gently clean each mesh lter in warm soapy water and then

re-assemble in the order as shown in the picture, taking care

to insert the large o-ring as the nal piece of the assembly.

Your i-milk has 2 manual

taps located in your Spare

Parts box. These taps allow

you to manually pour milk

from bladders in the event

that your i-milk cannot

dispense milk.

To use, load a bladder in

a drawer or tub as normal

but do not locate the

connector.

Insert the spigot of the

manual tap into the bladder

and secure the manual tap

into the key hole in the tub

or drawer. This secures the

tap and allows for it to be

operated with one hand.

Position the drawer or tub at

the edge of a bench to pour

directly into a jug.

After use ensure the manual

taps are thoroughly cleaned

and stored back in the spare

parts box for any future use.

Technical Adjustments cont.

7

i-milk V1 Operating Manual July 2018 15

Maintenance Records cont.

8

DATE NAME CHECK MILK FILTER

Please duplicate this page to extend your recording.

www.i-milk.com.au

Table of contents

Other i-milk Dispenser manuals

Popular Dispenser manuals by other brands

Nordson

Nordson Asymtek X-1000 Series Training guide

ZURN

ZURN Z6900-SD-WM Installation, operation, maintenance and parts manual

Gardebruk

Gardebruk 102619 instructions

START International

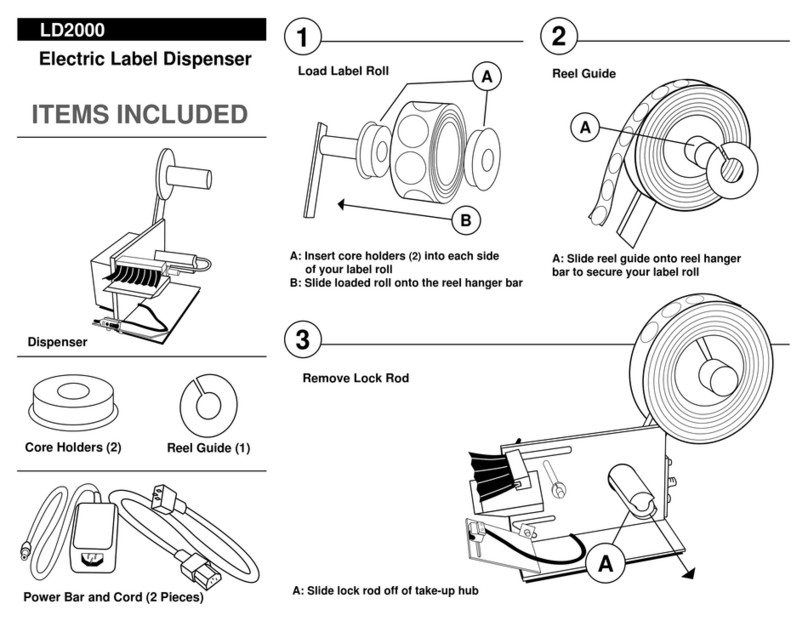

START International LD2000 instructions

Henkel

Henkel Loctite Machine manual

Tork

Tork Performance Maxi W2 Service and parts manual