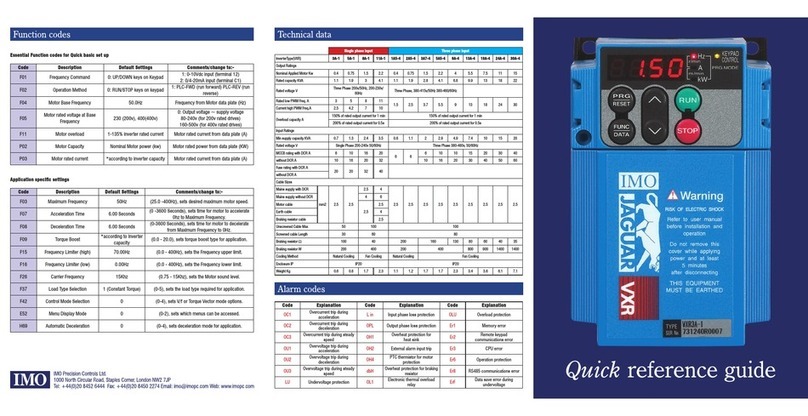

Connections

Menu

Data setting

Data

check

Drive

monitor

I/O check

Maintenance

check

Alarm

information

Data

copy

Displays

1.F##

1.E##

1.C##

1.P##

1.H##

1.J##

1.y##

2.rEP

3.oPE

4.i_0

5.CHE

6.AL

7.CPy

Menu #

#1

#2

#3

#4

#5

#6

#7

F codes

(Fundamental

functions)

E codes

(Extension terminal

functions)

C codes

(Frequency control

functions)

P codes

(Motor parameters)

H codes

(High performance

functions)

J codes

(Application functions)

Y codes

(Application functions)

Main functions

Selecting these codes enables data to

be displayed or changed

Display only those function codes that have been changed from

factory set defaults.

Display Hz, rmp, A, kW, V(O/P), PID values etc.

Display drive control input and output status.

Display maintenance information including accumulated hours

run time.

Display the last four alarm codes and running data at the time of

last trip condition.

Feature for reading, writing and verifying data for transferring to

other drives of same type (remote keypad only).

Programming ModeBasic key operations

7-segment LED display shows In Run mode:

Hertz, Amps, Volts, kW, I/O signal status, run

time, rpm, PID values. In Program mode:

Menus, Function codes and their data. In Alarm mode:

Trip codes and alarm information.

Motor RUN and STOP

keys active only when inverter is operating in

keypad mode.

On-board frequency setting potentiometer.

PRG/RESET key. Use to change operating

modes. In Run mode: press to enter program

mode. In Program mode: press to enter run mode. In

Alarm mode: Resets a trip condition (after fault has

been removed).

FUNC/DATA key. In Run mode: press to change

display from Output frequency _ Motor current

(A)_Power (P) _ Output voltage (V) _ Out. In Program

mode: press to display function code value or to store /

write data to memory. In Alarm mode: Displays

information about alarm state shown on LED panel.

UP/DOWN keys used to scroll through menus

and function codes, also used to increase/

decrease actual set value of function codes

(value must be stored in memory by pressing

FUNC/DATA key). When operating in keypad mode they

are used to increase/decrease motor speed.

Simultaneous Keying In Run mode: STOP + UP

keys together – gives entry to or exit from jogging

operation. In Program mode: STOP + DOWN keys

together – allows changes to special function codes

F00 (Data protection) and H03 (Reset all function codes

to factory set default values). In Alarm mode: STOP +

PRG/RESET keys together – switches to program mode

without resetting trip condition.

Display flashes a frequency value

from on-board pot, say 0.00 (Hz) or

other value.

Press DOWN key until display shows

00.55 (last 5is flashing).

Press FUNC/DATA key until display

shows SAVE (last 5is flashing).

Press PRG/RESET key. Display

shows 1.F__ (1is flashing).

Press FUNC/DATA key. Display

shows 0.75 (5is flashing).

Press UP key three times. Display

shows 1.P__ (1 is flashing).

Press FUNC/DATA key. Display

shows P 02 (2is flashing).

Connect mains, motor and earth

cables as shown in the diagram.

Connect all necessary control

circuits. Check all wiring for

faults / errors. Switch power ON.

If in doubt - consult IMO or CUB instruction manual

Getting started

Example of changing a typical parameter;

Function P02 (motor capacity) from say 0.75kW

to 0.55kW. This would be necessary if a Cub

5A-1 (0.75kW / 230V – 1ph inverter) or Cub

2A5-4 (0.75kW / 415V – 3ph inverter) was to

be used to drive a 0.55kW motor. In this case it

would be necessary to check / change P03

(rated current) and other function codes.

If in doubt - consult IMO or CUB instruction manual

If in doubt - consult IMO or CUB instruction manual

DONE! Display automatically moves to next

function number (P03 in this case)

Press PRG/RESET key to escape.

START

The above data is for basic reference only.

It is strongly recommended to use the correct EMC filter and screened/armoured motor cable (not shown).

WARNING: THIS EQUIPMENT MUST BE EARTHED