I-Panda 40A Series User manual

MPPT Solar Charge Controller

12V/24V/48V Automatic Recognition

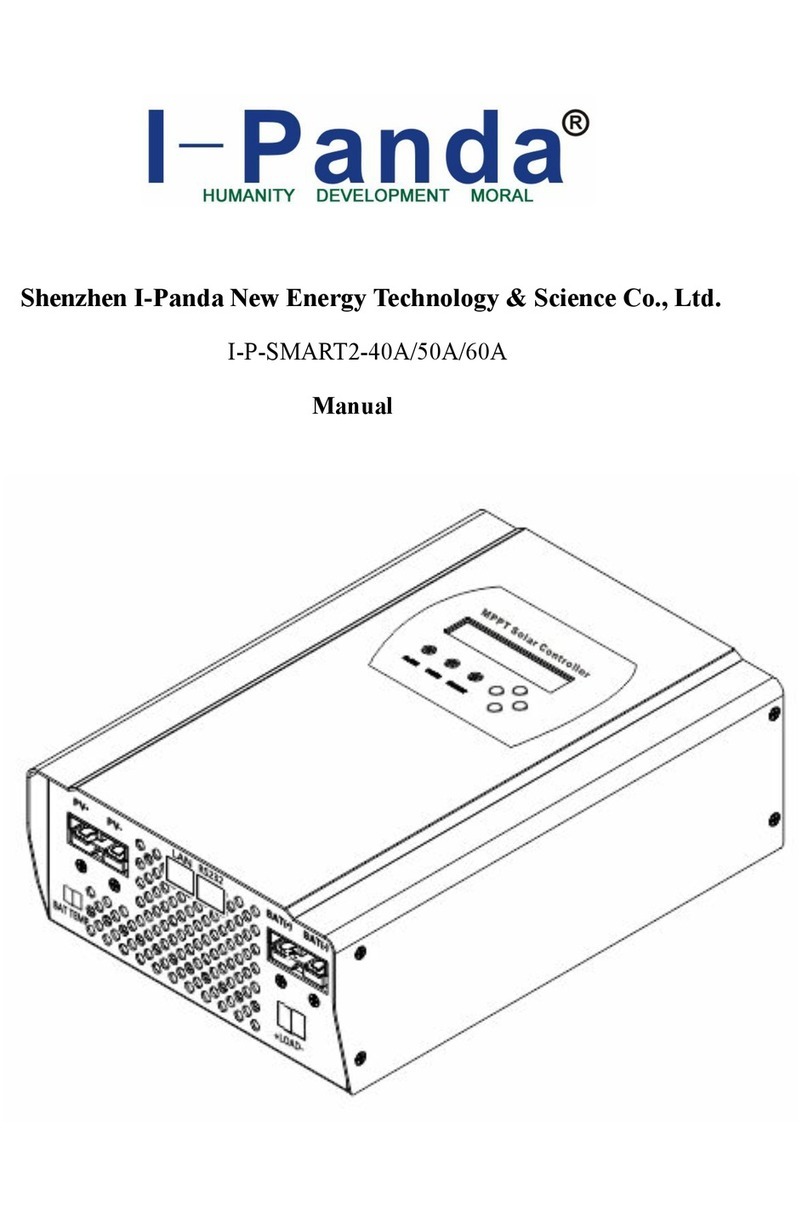

40A 50A 60A Series

Manual

2

Contents

1 Notes on This Manual............................................................................3

2 Safety Instructions................................................................................. 4

3 Unpacking..............................................................................................6

4 Assembly............................................................................................... 7

5 MPPT Controller Connection................................................................8

6 Steps for Commissioning or Shutdown..............................................11

7 LED/LCD and Function Key..............................................................12

8 Technical Parameters..........................................................................17

9 Maintenance and Cleaning.................................................................20

10 Storage and Disposal...........................................................................21

11 Recovery Processing and Warranty.....................................................21

3

1. Notes on This Manual

This manual describes how to install and service your MPPT solar charge controller.

1.1 Validity

This manual applies to MPPT solar charge controller models produced by our

company.

1.2 Target Group

This manual is intended for the installer and the operator.

1.3 All manuals for the device and installed components should be stored in the

immediate vicinity of the charge controller and must be accessible at all times.

1.4 Symbols Used

The following types of safety messages and general information appear in this

document:

Warning!

WARNING indicates a hazardous situation which, if not avoided, could

result in machine stoppage or serious injury.

Warning!

WARNING indicates a hazardous situation which, if not avoided, could

result in machine stoppage or serious injury.

Note!

In order to operate this device well, please read the operation

instructions carefully.

4

2. Safety Instructions

2.1 General Safety Instructions

2.2 Explanation of Symbols

Below is the explanation for all the symbols shown on the device and label.

Symbol

Explanation

Risk of electric shock

Energy stored in capacitors will remain for 5 minutes; don’t touch within this

period after disconnecting

Both input and output lines have power, disconnect both and don’t operate for at

least 5 minutes after disconnection

No self-serviceable parts are inside the enclosure, don’t attempt to remove the

cover.

Only qualified persons are permitted to operate and maintain the equipment.

Only insulated tools are permitted for use to reduce risks of hazard to

individuals.

Beware of hot surface.

The solar charge controller can become hot during operation. Avoid contact

during operation. Never put any goods onto the controller.

Caution!

Unit may emit some radiation which may be harmful.

•Do not stay within 1 foot of controller for any extended period of time.

Warning!

The input voltage of this device may be extremely high and life

threatening.

• All work on the charge controller must only be carried out by an electrically

skilled person.

•The controller is not to be used by children or persons with reduced physical

sensory or mental capabilities, or lack of experience and knowledge, unless

they have been given supervision or instruction.

•Children should be supervised to ensure that they do not play with the

controller.

Caution!

Surface may be extremely hot and may cause burns.

• Do not touch the enclosure of the charge controller during operation.

If possible keep in a cool environment.

5

Symbols Label

Symbol

Explanation

CE FCC CB ROHS mark;

The controller complies with the requirements of the applicable CE FCC CB

ROHS guidelines.

●Important Safety Instructions

When using the product, please do remember the below information to avoid fire,

lightning or other personal injury:

Warning!

Ensure input DC voltage is no more than Max. DC voltage (Voc) .Over voltage

may cause permanent damage to solar charge controller or other losses, which

will not be covered by the warranty! This chapter contains important safety and

operating instructions. Read and keep this operation guide for future reference.

Warning!

Authorized service personnel must disconnect both DC and battery bank power

from the solar charge controller before attempting any maintenance or cleaning

or working on any circuits connected to the solar charge controller.

● Before using the solar charge controller, please read all instructions and cautionary

markings on the solar charge controller, and all corresponding sections of this

guide.

● Contact I-Panda for any questions or concerns about your controller. Trying to

modify or repair it may result in a fire, electric shock, or injury.

● To reduce risk of fire and electric shock, make sure that existing wiring is in good

condition and that all wire is properly sized. Do not operate the solar charge

controller with damaged or substandard wiring.

● Do not disassemble the solar charge controller. It contains no user-serviceable parts.

See Warranty for instructions on obtaining service. Attempting to repair the solar

charge controller by yourself may result in a risk of electric shock or fire and will

void your warranty.

● To reduce the risk of electric shock, authorized service personnel must use

insulating tools when connecting or working on the controller.

● Keep away from flammable, explosive materials to avoid fire.

6

● If at all possible keep away for excessively humidity to avoid corrosion.

● To reduce the chance of short-circuits, authorized service personnel must use

insulated tools when installing or working on this equipment.

3. Unpacking

3.1 Parts List:

Object

Quantity

Description

A

1 unit

Charge controller

B

2 pcs & 4 pcs

Hang bracket & screws

C

1pce

CD

D

2 pcs

PV input (blue), DC output (red)

E

1 pce

RS232 to RJ45 comm cable

F

1 pce

Manual

If there is any parts missing, please contact your dealer.

3.2 Check for Transport Damage

Check the charge controller for visible external damage, such as dents on the

enclosure. Please contact your dealer.

E

F

D

A

C

7

3.3 Identifying the Charge Controller

You can identify the charge controller by the type label. The type label is in the

enclosure.

4. Assembly

4.1 Operator:technical personnel;

4.2 Selecting the Mounting Location

4.2.1 Dimensions

L * W * H:10.63*5.91*3.46 in

270mm*150mm*88mm

4.2.2 Net Weight

Weight:6.6Lbs or 3kg

4.2.3 Ambient Conditions

• The mounting location and method must be suitable for the weight and dimensions.

• Mount on a solid surface.

• The mounting location should be accessible at all times.

• The charge controller should be easy to remove from the mounting location at any

time.

• The ambient temperature should be between -4 and 140F (-20 and 60 °C) to

guarantee optimal operation.

Danger:

Possible fire and explosion hazard

The charge controller enclosure may become hot during operation.

• Do not mount the charge controller on flammable construction material.

• Do not mount the charge controller near highly flammable materials.

• Do not mount the charge controller in potentially explosive areas.

• Do not expose the charge controller to direct sunlight to avoid power

loss due to overheating.

Caution:

Enclosure may become hot to the touch and may cause burns

• Mount the charge controller in such a way that it cannot be touched

inadvertently during operation.

8

• Do not expose the charge controller to direct sunlight to avoid power losses due to

overheating.

4.2.4 Safety Clearance

Observe the following safety clearance to wall, other devices or objects to ensure

sufficient heat dissipation.

Direction

Safety clearance

Sides

8in or 20cm

Top

12in or 30cm

Bottom

8in or 20cm

5. MPPT Controller Connection

5.1 Safety

Danger!

High voltages are present and dangerous

• Disconnect the PV array using a disconnection unit and secure it against

accidental reactivation.

• Disconnect the circuit breaker and ensure that it cannot be reconnected.

• Ensure that no voltage is present in the system.

Warning:

Risk of injury due to electric shock。

If all cables with different voltages are routed in parallel, damaged cable

insulations may lead to a short circuit.

• Route all cables separately if possible.

Warning:

Over voltage can destroy the system.

• Use an external over voltage protector in areas with an increased risk of

lightning.

9

5.2 Connections of the PV power system

5.2.1 PV String

Solar charge controller device can be connected in parallels to charge the same battery

bank. Please select PV modules with excellent function and reliable quality. Solar

panels may be connected in series or in parallel. Open-circuit voltage (Voc) of module

arrays connected in series should be less than Max. DC input Voltage (150V) of the

MPPT solar charge controller; operating voltage (Vmax) should conform to MPPT

voltage range.

Please use PV cable to connect modules to the charge controller. It should be outdoor

uv rated and we recommend 10Awg to prevent excessive losses due to distance. It is

beneficial to increase the dc voltage to optimize performance and decrease

inefficiencies.

5.2.2 Specification for cable and micro-breaker

Model

I-P-MSC 40A

I-P-MSC 50A

I-P-MSC 60A

Cable (Cu)

≥0.16 in or

4mm

≥0.16 in or

4mm

≥0.16 in or

4mm

Micro-Breaker

63 A

63 A

63A

Micro-breaker should be installed between DC input and outputs. Kindly check the

following picture (we do not provide external breakers)

Note:

Do not connect the PV panel positive or negative to ground.

Warning:

PV module voltage may be very high! Electrical shock and

fire may result due to improper connections. Please comply

with electric safety rules when connecting.

10

5.3 Solar charge controller and PC connection

If PC has RS232 connector, check the following picture:

5.3.1 RS232 Communication

RS232 is one standard communication interface. It transmits the data between PC and

one charger controller. One end of the cable is RJ45 connector, the other end is

RS232 male connector.

This manual suits for next models

5

Table of contents

Other I-Panda Controllers manuals

Popular Controllers manuals by other brands

Digiplex

Digiplex DGP-848 Programming guide

YASKAWA

YASKAWA SGM series user manual

Sinope

Sinope Calypso RM3500ZB installation guide

Isimet

Isimet DLA Series Style 2 Installation, Operations, Start-up and Maintenance Instructions

LSIS

LSIS sv-ip5a user manual

Airflow

Airflow Uno hab Installation and operating instructions