Model Plate (Large)

Refer to “External Dimensions”

for the attached position.

Model Plate (Large)

Refer to “External Dimensions”

for the attached position.

Serial Numbe

-SC, -PS2

200V Power Supply Unit, 200V Driver Unit,

Fan Unit, Terminal Unit for 200V

First Step Guide First Edition

Thank you for purchasing our product.

Make sure to read the Safety Guide and detailed Instruction Manual (DVD) included with the

product in addition to this First Step Guide to ensure correct use.

This Instruction Manual is original.

Using or copying all or part of this Instruction Manual without permission is prohibited.

The company names, names of products and trademarks of each company shown in the sentences

are registered trademarks.

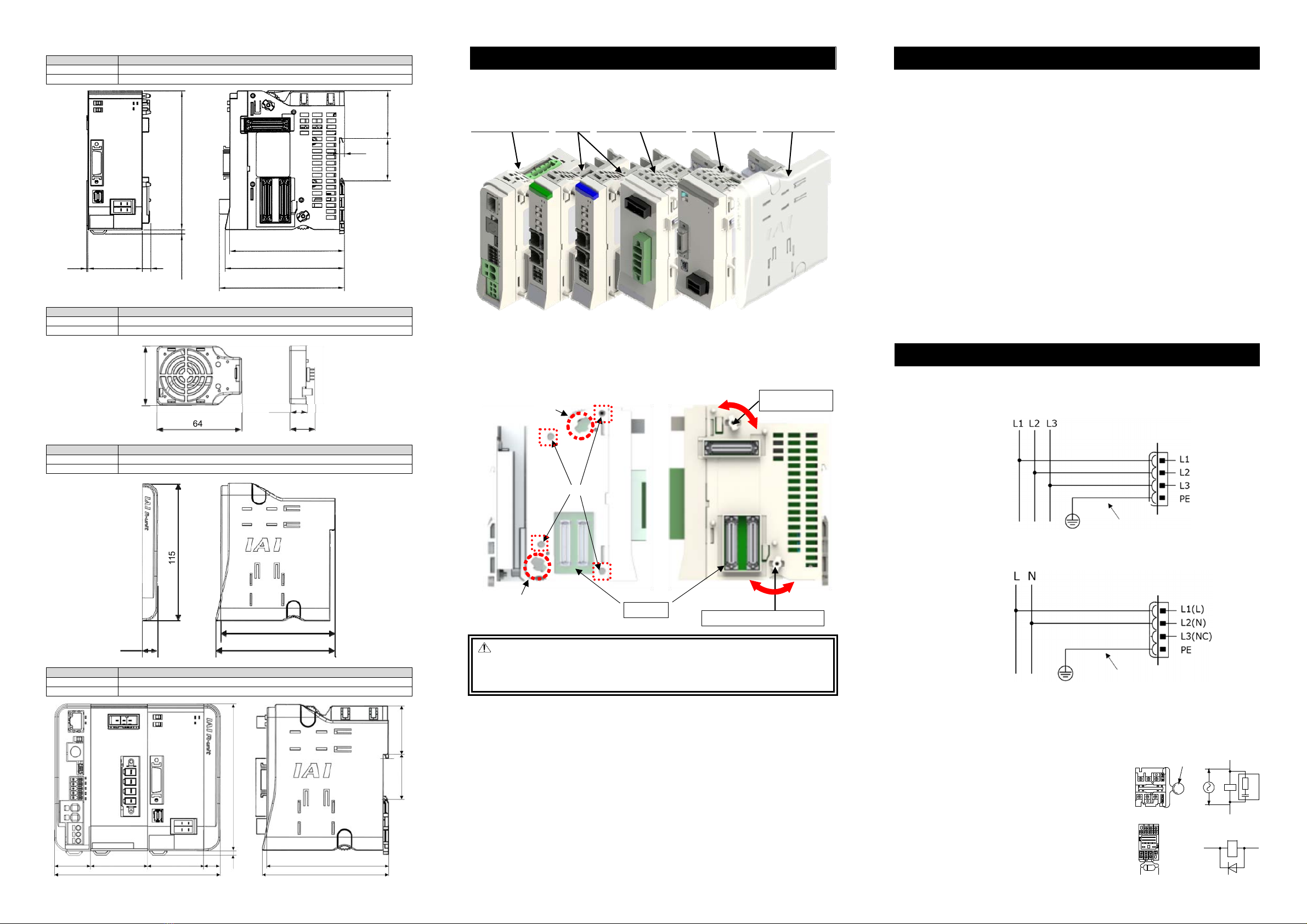

R-unit constructs a systemwide combining the Gateway Unit (RCON/RSEL), 24V and 200V Driver Units,

Extension Unit, Simple Absolute Unit, Fan Unit and Terminal Unit.

In this guide, describes about the 200V Power Supply Unit, 200V Driver Unit, Fan Unit and Terminal Unit for

200V.

For instruction of other units, refer to the first step guide and instruction manual (DVD) of each unit.

This product is comprised of the following parts if it is of standard configuration.

If you find any fault in the contained model or any missing parts, contact us or our distributor.

1. Parts

(1) 200V Power Supply Unit

No. Part Name Model

Numbe

Remarks

1 200V Power Supply

Unit

Refer to “How to read the model

plate”, “How to

ead the model code” 1

Accessories

2 Terminal Unit for 200V RCON-GW-TRS 1 Not enclosed in TRN Type

3 Fan Unit RCON-FU 1

4 Power Connector SPC5/4-STF-7.62

(Manufactured by PHOENIX CONTACT)

1

5 First Step Guide ME0397 1 This Manual

6 Safety Guide M0194 1

(2) 200V Driver Unit

No. Part Name Model

Numbe

Remarks

1 200V Driver Unit Refer to “How to read the model

plate”, “How to read the model code” 1

Accessories

2

Fan Unit for 200V Drive

RCON-FUH 1

3 Dummy Plug DP-6 1

4 First Step Guide ME0397 1 This Manual

5 Safety Guide M0194 1

2. Teaching Tool (Please purchase separately)

A teaching tool such as PC software is necessary when performing the setup for position setting, parameter

setting, etc. that can only be done on the teaching tool. Please prepare either of the following teaching tools.

No. Part Name Model

1 PC Software

SEL Controlle

:I

-101X/N

Position Controller: IA-OS

RCM-101-MW/USB

2

Touch Panel Teaching Pendant TB-02 (Standard

Dead Man’s Switch Mounted)

TB-02/TB-02D

3 Touch Panel Teaching Pendant TB-03 TB-03

3. Instruction manuals related to this product, which are contained in the instruction manual (DVD).

No. Name Manual No.

1 RCON System Instruction Manual ME0384

2 RSEL System Instruction Manual ME0392

3 PC Software RCM-101-MW/RCM-101-USB Instruction Manual ME0155

4 PC Software I

-101-MW/USB Instruction Manual ME0154

5

Touch Panel Teaching Pendant TB-02 Applicable for Position Controller Instruction Manual

ME0355

6

Touch Panel Teaching Pendant TB-02 Applicable for Program Controller Instruction Manual

ME0356

7

Touch Panel Teaching Pendant TB-03 Wired Link Applicable for Position Controlle

Instruction Manual

ME0376

8

Touch Panel Teaching Pendant TB-03 Wired Link Applicable for Program Controlle

Instruction Manual

ME0377

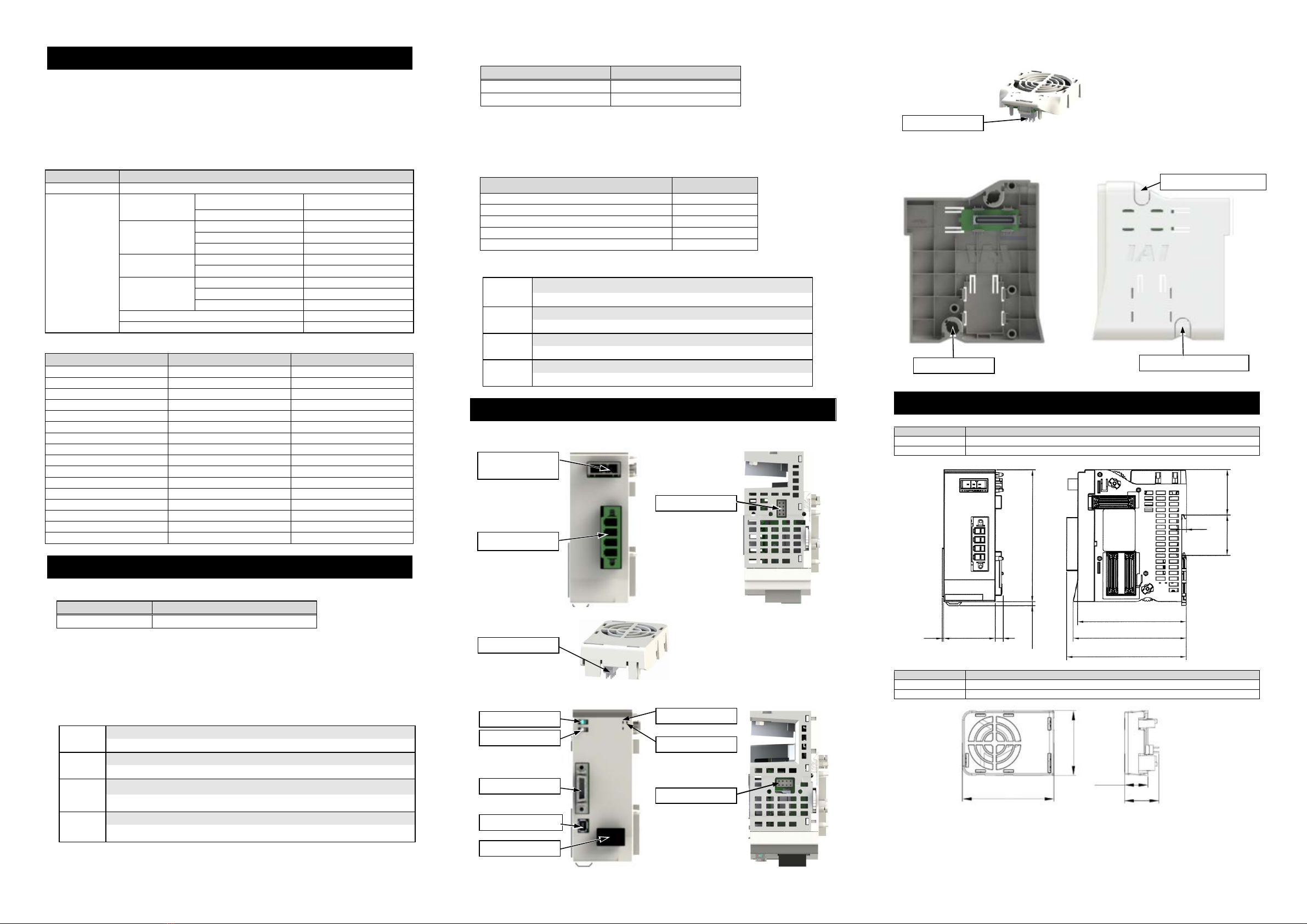

4. How to read the model plate (This design is what is after UL/CE acquired.)

(1) 200V Power Supply Unit

(2) 200V Driver Unit

(3) Fan Unit

Mark Explanation of Mark

Use IAI specified cables only.

Where residual-current-operated protective device (RCD) is used for

protection in case of direct or indirect contact, only RCD of Type B is

allowed on the supply side of this Electrotonic Equipment (EE).

Do not touch terminals within 10 minutes after disconnect the power.

Risk of electric shock.

Do not touch product when power is ON. Risk of burn.

5. How to read the model code

(1) 200V Power Supply Unit

(2) 200V Driver Unit

Type : SC

60-700W Motor

1 axis

60

100

100

150

200

200

300

400

600

750

60W Servo-motor

100W Servo-motor

100W Servo-motor (for LSA)

150W Servo-motor

200W Servo-motor

200W Servo-motor (for LSA, DD)

300W Servo-motor (for LSA)

400W Servo-motor

600W Servo-motor

750W Servo-motor

(3) Fan Unit

1. Specifications of Power Supply

Item Specification

Power Input Voltage Range 200 to 230V AC ±10%

Power Supply Frequency Range 50/60Hz

Cu

ent Amperage Refer to “Current Amperage”

In-Rush Curren

25A/axis (with in-rush current limit circuit)

Instantaneous Power Outage Endurance 20ms (with power supply frequency at 50Hz)

16.3ms

with power suppl

frequenc

a

60Hz

Protection Function a

ainst Electric Shoc

Class Ⅰ

Leak Curren

3.0mA or less

2. Specifications of Control Part

Item Specification

Number of Controlled Axes RCON System 1 to 16 axes, RSEL System 1 to 8 axes

Corresponding Motor Capacity 60W to 750W

Corresponding Encoder Incremental Serial, Battery-less Absolute, ABZ (UVW) Parallel, Spurious Absolute

and Index Absolute

Field Network Interface CC-Link, CC-Link IE Field, DeviceNet, EtherCAT, EtherNet/I

, PROFIBUS-D

,

PROFINET IO

Pulse Train Type Unavailable to Control

Brake Output Voltage 45V DC ±10% (Overexcitation 90V)

Connectable Brake Power Max 7W

Calendar Feature Maintained Duration: Approx. 10 days, Charge Time: Approx. 100 hours

Applied Safety Category B (Safety category applicable type is capable to achieve 4 with external circuit)

Driver Source Cutoff System Drive source cutoff with semiconductor (Power MOSFET)

Stop Input Break Contact Input

Stop Action Turning servo OFF + Drive source cutoff

Enable Input None

T. P. Enable Input Available

Enable Action Turning servo OFF

Protective functions Overcurrent, temperature error, encoder line breakage and overload

Preventive / Predictive Maintenance Feature

Electrolytic capacitor capacity dropdown and Fan revolution dropdown

Driver Unit LED Display Refer to “Troubleshooting (LED Display)”

Brake Compulsory Release Feature Brake release switch equipped on 200V Driver Unit

Jog Jog switch equipped on 200V Driver Unit

Cable Length Motor Cable: 20m or less, Encoder Cable: 20m or less

Oversea Certifications Planned to acquire CE and UL

3. Environmental Specifications

Item Specification

Environment

Environment of Use Pollution Degree 2

Surrounding Air Temperature 0 to 55C

Surrounding Humidity 85% RH or less (non-condensing)

Peripheral Ambience of Use Refer to “Installation Environment”

Surrounding Storage Temperature -20 to 70C

Vibration Durability

Frequency 10 to 57Hz/Swing width: 0.075mm

Frequency 57 to 150Hz/Acceleration: 9.8m/s2

XYZ Each direction Sweep time: 10min. Number of sweep: 10times

Protection Class IP20

Altitude 1000m

Cooling Method Forced air cooling with fan unit

Dielectric Withstanding Voltage 1500V for 1 min between power supply terminal and PE

Overvoltage category Ⅰ

Product Check

Basic Specifications

Warnin

: Operation of this equipment requires detailed installation and operation instructions

which are provided on the DVD Manual included in the box this device was

packaged in. It should be retained with this device at all times.

A copy of the DVD Manual can be requested by contacting your nearest IAI Sales

Office listed at the back cover of the Instruction Manual or on the

irst Step Guide.

1B

Fan Unit

200V Power

Supply Unit

Fan Unit for 200V Drive

200V Driver Unit

Terminal Unit for

200V

Model

Se

ial Numbe

Model

Model Plate (small)

It is attached on the

bottom of the panel

front face.

Model

Serial Numbe

Model Plate (small)

It is attached on the

bottom of the panel

front face.

Serial

Model

(Partially)

Serial Numbe

Model

RCON - SC - 1

<Number of Axes>

1 : 1 axis

< Series >

<Type>

SC : 200V AC Servo-motor

<Type>

FU : Fan Unit

FUH : Fan Unit for 200V

RCON - FUH

< Series >

RCON - PS2 - 3 -TRN

< Series >

<Power-supply Voltage >

3 : Sin

le-phase/Three-phase 200V

<Type>

PS2 : 200V

Power Suppl

Uni

<Option>

TRN : With No Terminal Uni