PLENTZIA BIDEA, 3 BILLELA AUZOTEGIA

48100 MUNGIA- SPAIN

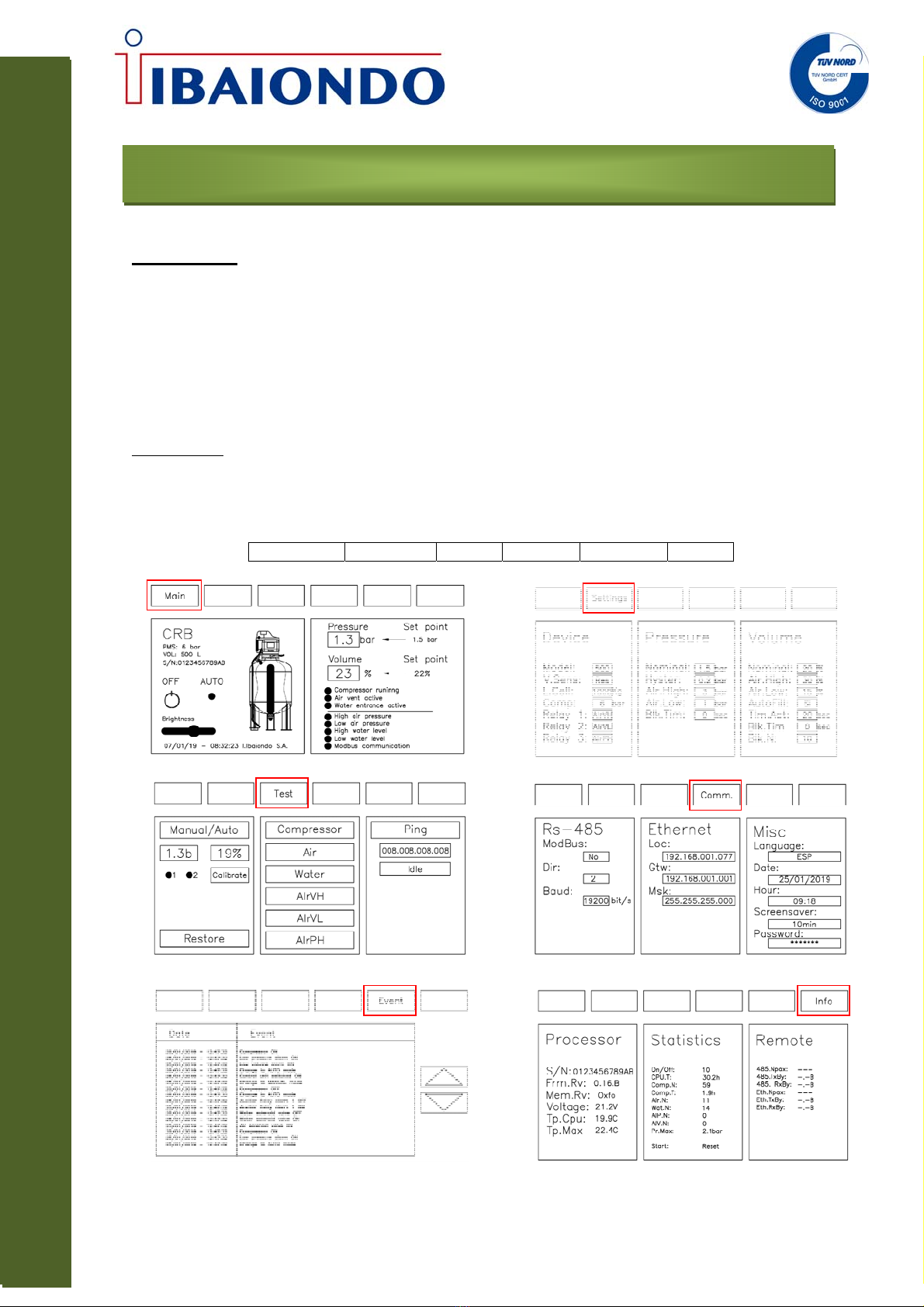

CRB AUTOMAT

Control unit

Electronic board

The electronic board include de following elements:

Terminals for 230Vac power input

Magnetothermic protection 10A serie C

Microcontroller for the management and control of the equipment

Relay for the activation of the 230Vac 10A compressor with function check

Relay for the activation of the air solenoid valve 230Vac 10A with function check

Relay for the activation of the 230Vac 10A automatic filling solenoid valve with function check

Voltage alarm relay of 230Vac 10A potential-free

Pressure alarm relay 230Vac 10A potential-free

Analog input 4 - 20 mA of pressure measurement

Analog input 4 - 20 mV of volume / weight measurement (load cell)

Pressure output 4 - 20 mA mirror of the pressure input

Volume output 4 - 20 mA mirror volume / weight input

Connection with the touch screen

RS485 connection

Ethernet connection

Lithium battery for the maintenance of the hour

Connectors

Connector for the power supply (phase, neutral and ground)

DB9 connector for RS45 communication is connected (A, B, GND)

RJ45 female connector for Ethernet port

Connector of double row of 30 contacts whose connections are:

01: Analogue In Pressure -> +24VDC

02: Analogue In Pressure -> A

03: Analogue In Pressure -> B

04: Analogue In Volume/Weigth ->

+24VDC

05: Analogue In Volume/Weigth -> A

06: Analogue In Volume/Weigth -> B

07: Analogue Out Pressure -> Vref

08: Analogue Out Pressure -> A

09: Analogue Out Pressure -> B

10: Analogue Out Volume/Weight -> Vref

11: Analogue Out Volume/Weight -> A

12: Analogue Out Volume/Weight -> B

13: Digital In Water -> Signal

14: Digital In Water -> Ref (GND)

15: Auxiliar In -> Signal

16: Auxiliar In -> Ref (GND)

17: Pressure alarm Out -> A

18: Pressure alarm Out -> B

19: Volume/Weight alarm Out -> A

20: Volume/Weight alarm Out -> B

21: Alarm Out CPU -> A

22: Alarm Out CPU -> B

23: Auxiliar Out-> A

24: Auxiliar Out-> B

25: Compressor out -> Phase

26: Compressor out -> Zero

27: Solenoid valve air Out -> Phase

28: Solenoid valve air Out -> Zero

29: Solenoid valve autofilling -> Phase

30: Solenoid valve autofilling -> Zero