Heat Exchanger Cleaning

DC / HC Series (all models)

www.ibcboiler.comOctober 29, 2019 Page 2 of 2

INSTRUCTIONAL

NOTE

The heat exchanger has a

small amount of combustion

chamber insulation

(refractory), which contains

ceramic fibers.

When exposed to extremely

high temperatures, the

ceramic fibers, which contain

crystalline silica, can be

converted into cristobalite -

which is classified as a

possible human carcinogen.

Care should be taken to

avoid disturbing or damaging

the refractory. If damage

occurs, contact the factory

for directions.

Avoid breathing and contact

with skin and eyes and follow

these precautions:

1. For conditions of frequent

use or heavy exposure,

respirator protection is

required. Refer to the

“NIOSH Guide to the

Selection and Use of

Particulate Respirators

Certified under 42 CFR 84"

for selection and use of

respirators certified by

NIOSH. For the most current

information, NIOSH can be

contacted at 1-800-356-4676

or on the web at

www.cdc.gov/niosh.

2. Wear long sleeved, loose

fitting clothing, gloves and

eyes protection.

3. Assure adequate

ventilation.

4. Wash with soap and water

after contact.

5. Wash potentially

contaminated clothes

separately from other

laundry and rinse washing

machine thoroughly.

6. Discard used insulation in

an air tight plastic bag.

NIOSH stated first aid:

• Eye contact - Irrigate and

wash immediately.

• Breathing - Provide fresh

air.

CAUTION

Any evidence that the front cover can no longer mate with the heat exchanger walls means that

the either the front cover or the heat exchanger must be replaced.

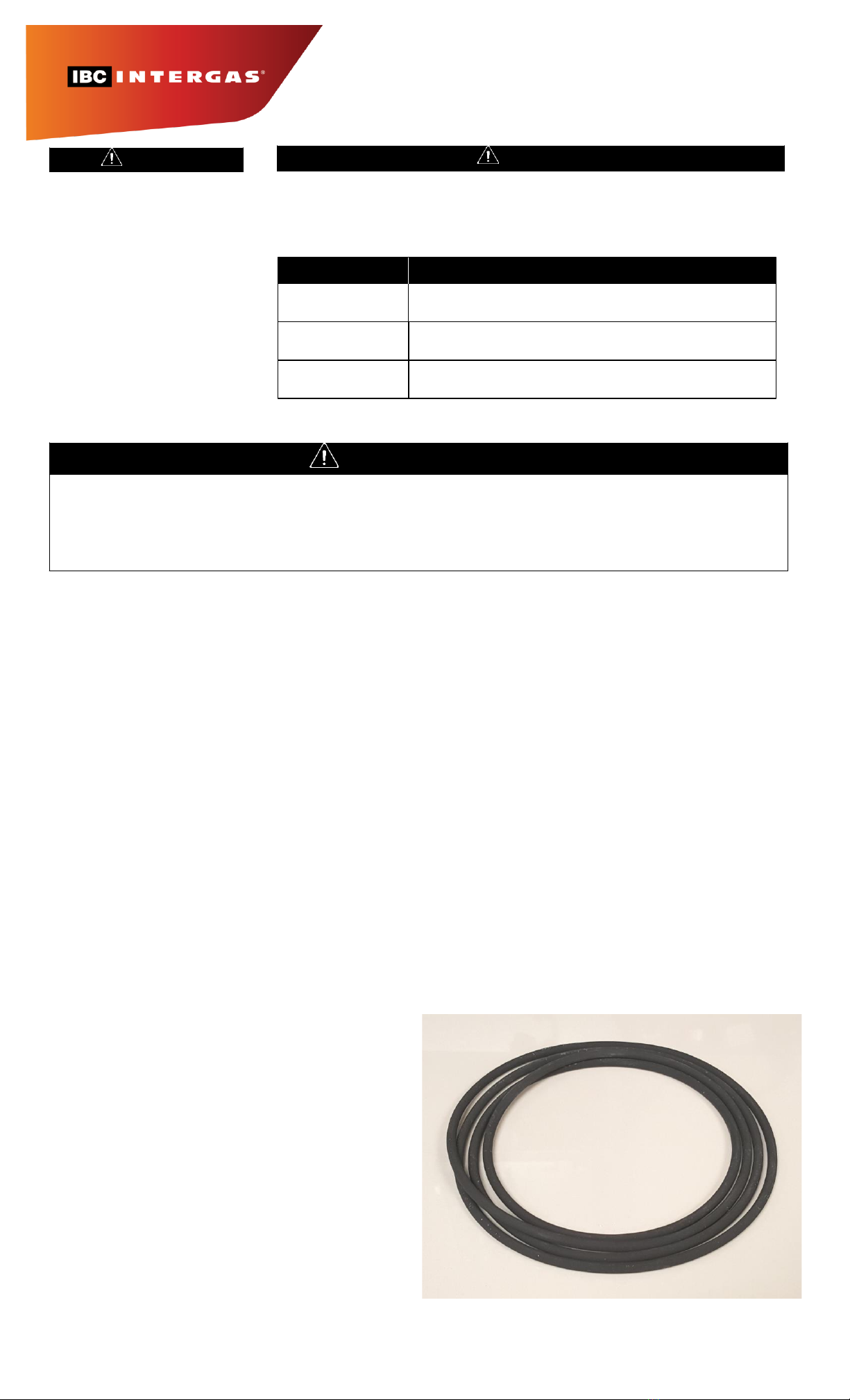

11. Peel heat exchanger gasket from its groove. See Fig. 3. Carefully inspect the gasket sealing

the heat exchanger to the heat exchanger cover for damage, hardness, cracks, and or

discoloration. If damaged in any way the gasket must be replaced.

12. Clean as necessary. IBC recommends cleaning with a stiff plastic brush, such as used for

scrubbing cooking pots. See Fig. 4. Wear protective gear such as eye protectors, gloves and a

particle mask. Care should be taken to protect the bottom of the boiler cabinet: drape a small

plastic sheet to gather debris from the cleaning. It is especially important to protect the lower

gas supply line from being fouled and the controller from getting wet.

When the heat exchanger is heavily fouled (see Fig. 5), a stiffer brush, scraper or implement may

be needed.

13. In some cases chemical intervention is also necessary; for heavily fouled heat exchangers,

contact your heating wholesaler for a cleaning solution approved for use on the gas side of an

aluminum heat exchangers, such as the two-solution process available from Axiom.

14. While the heat exchanger is open, carefully inspect the heat exchanger gasket for any signs of

discolouration, cracking or brittleness. Replace the gasket at the first signs of wear, at least

every two years, and every year in the case of heavy-use units.

Also inspect the burner, burner gasket, and ignitor.

Figure 2: 6mm Hex Bolts

Figure 5: Heavily fouled HX may require stiffer brush or tool.

How to Access the Heat

Exchanger for Cleaning

continued

9. Using a ball-ended 6mm hex key,

remove all bolts from the heat

exchanger front cover and carefully

remove the front cover, complete

with the fan attached.

10. Place the heat exchanger front

cover in a safe location. Inspect its

back surface for warpage,

especially at the top corners.

Figure 3: Removing a HX gasket

15. Reassemble in reverse order, or

see section 3.5.1 for detailed

instructions. Retighten HX bolts in

a cross pattern. Soap test all gas

connections.

Figure 4: Cleaning HX with a plastic brush.