SFC 15-99 / SFB 15-99 - Fuel Conversion to Natural Gas - Kit P-805 |5

Note:AllowtheunittooperateatHighFirefor3minutestostabilize.(Theunitoperatesinmanualmodefor10

minutesthenswitchbacktothenormaloperatingmode.Toextendmanualmodeoperation,presstheService

andPlusbuttonstogethertwicewhiletheunitisoperatinginmanualmodetoresetthetimerfor10more

minutes.)Donotmakeadjustmentsiftheservicedisplayshowsan“h”.

5. Clockthegasmeter(seeinstructionsClocking the Meter (for Natural Gas only) on page 6)toconfirmfull

maximumratingplateinput.

a. Withacombustionanalyzerprobeinthefluegastestport,checkthemeasuredresultsagainstTable 1 -

HighFire.

b. Iftheresultsareoutsidethepermittedrange,checktheinletpressure,andconfirmthatthecorrectorificeis

installed.

6. SwitchtheunittolowfirebypressingtheServicebuttonandMinusbuttonatthesametime.Theunitwilldropto

lowfire.“L”willshowintheservicedisplay.

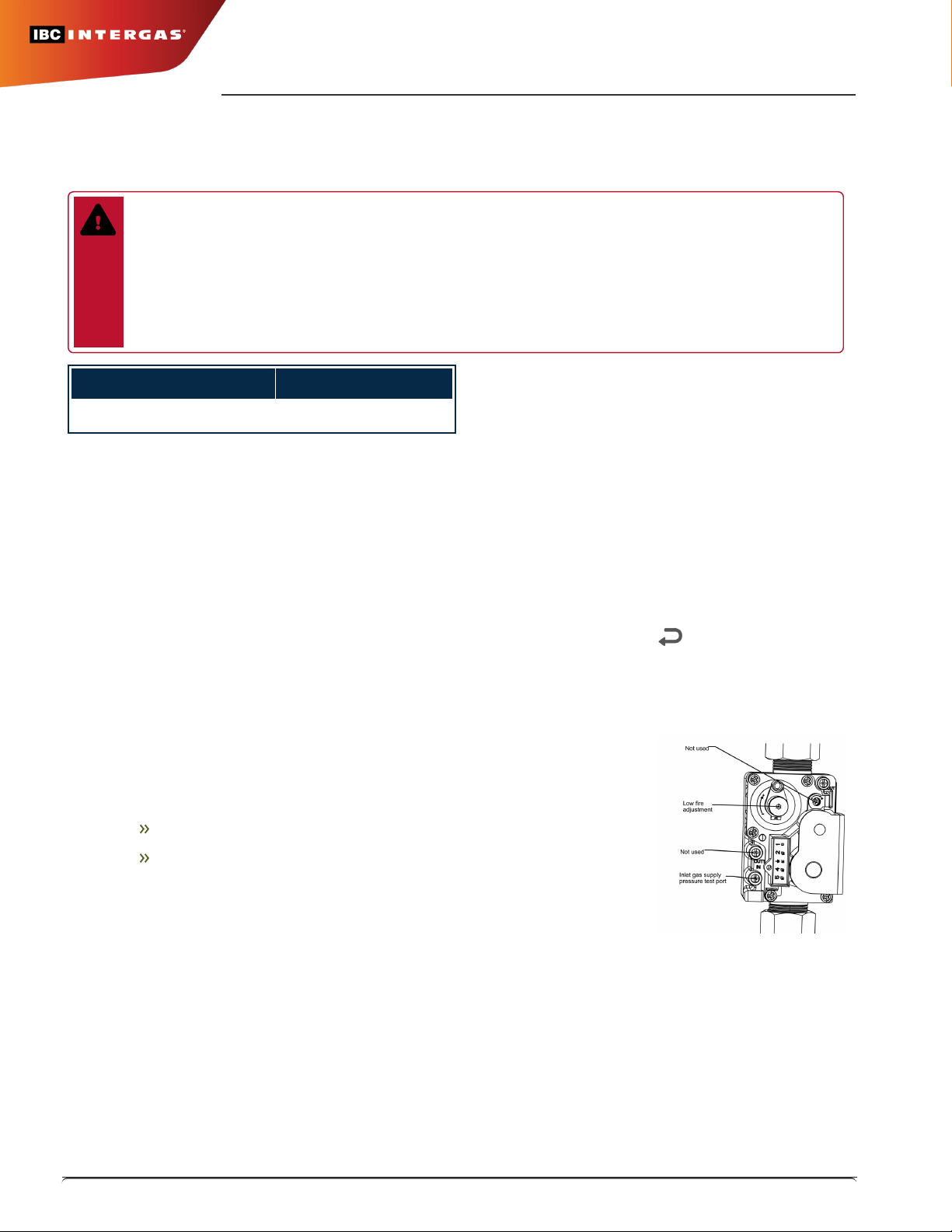

a. ComparethereadingswithTable 1 -LowFire.Ifadjustmentisnecessary,removetheLowFire

AdjustmentcaptorevealaTorxheadscrew.

b. Maketinyadjustments,typicallylessthan1/8thofaturnatatime.Turnthescrewclockwisetoincrease

CO2andcounter-clockwisetoreduceCO2.Ifthetargetcannotbemet,evenafterahalfturn,contactthe

factory.

c. Whenfinished,replacetheLowFirecap,andleavethemanualmodebypressing+AND-

simultaneously.

7. Switchofftheunitbypressingthespaceabovethedot.

8. Turnoffthegasattheunit'smanualgasvalve.

9. Removethefluegasanalyzerfromthetestport,andreinstallthetestportcap.

10. Removethegaspressuremanometerfromthegasvalve,andfullyclosethetestport.

11. Turnonthegasattheunit’smanualgasvalve.

12. Ensuretherearenogasleaksbeforereinstallingthefrontcover.

13. Turnontheunitbypressingthespaceabovethedot.

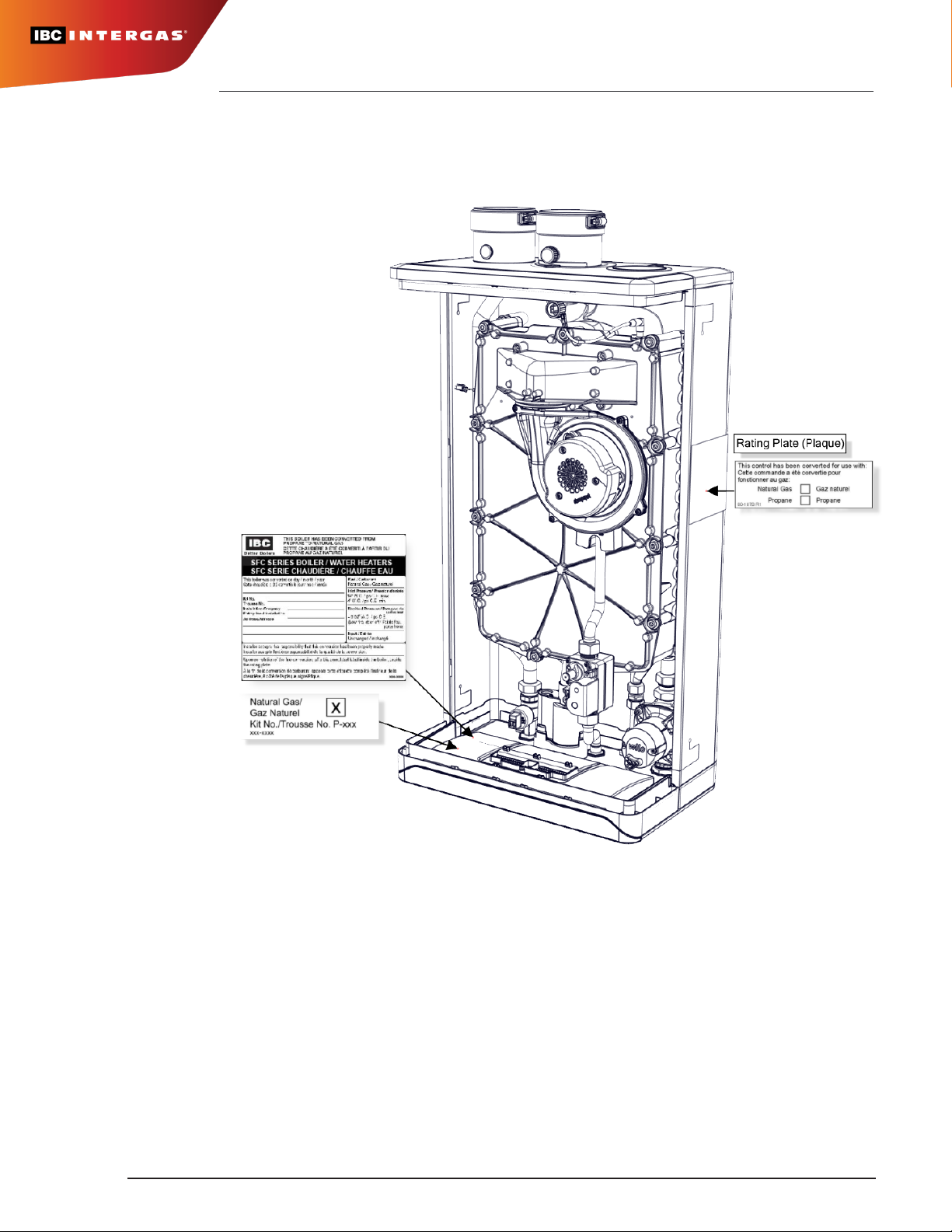

Nextyoumustfillintheinformationandaffixtheincludedfuelconversionlabelstotheunitasindicatedafterthe

conversioniscompleted.

Completing and Affixing the Conversion Labels

1. Fillintheconversionlabels(includedinthekit)associatedwiththenewfueltype.

2. Placetheconversionlabelsontotheboilerasindicatedonthelastpage.