- 3 -

1. USEOFTHEMANUAL............................................................................pag. 4

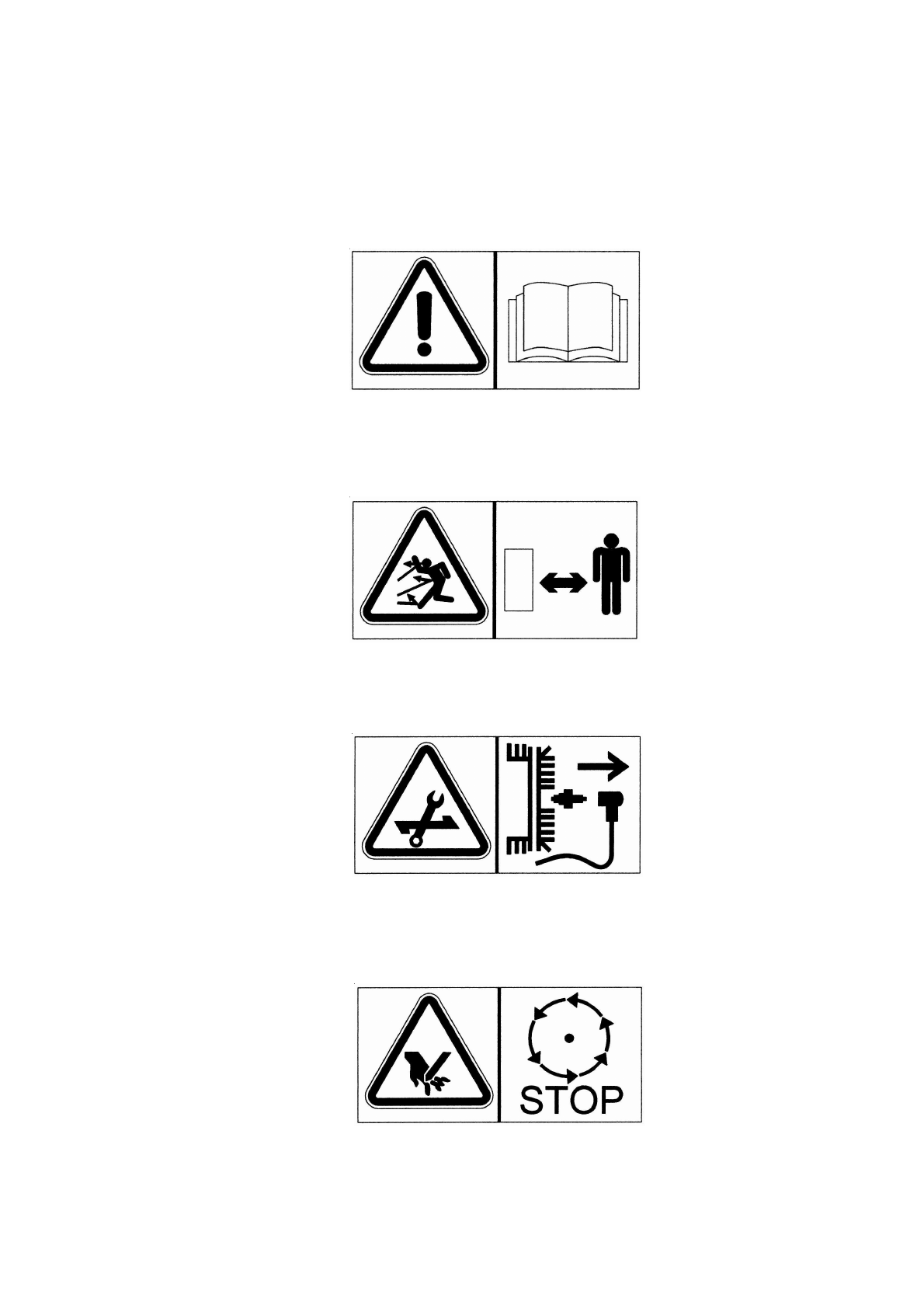

2. NOTICES ONTHE MACHINE..................................................................pag. 5

3. TECHNICALDATA.....................................................................................pag. 8

4. LIFTINGANDTRANSPORTATION...........................................................pag. 9

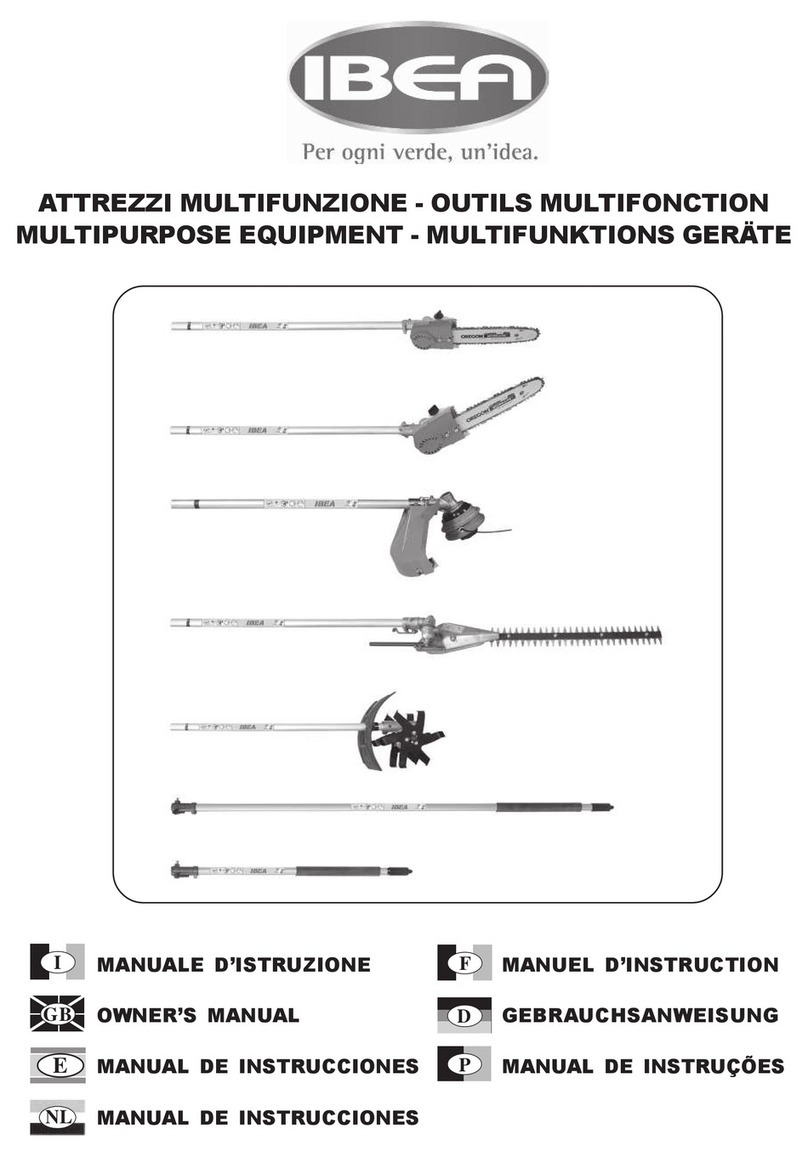

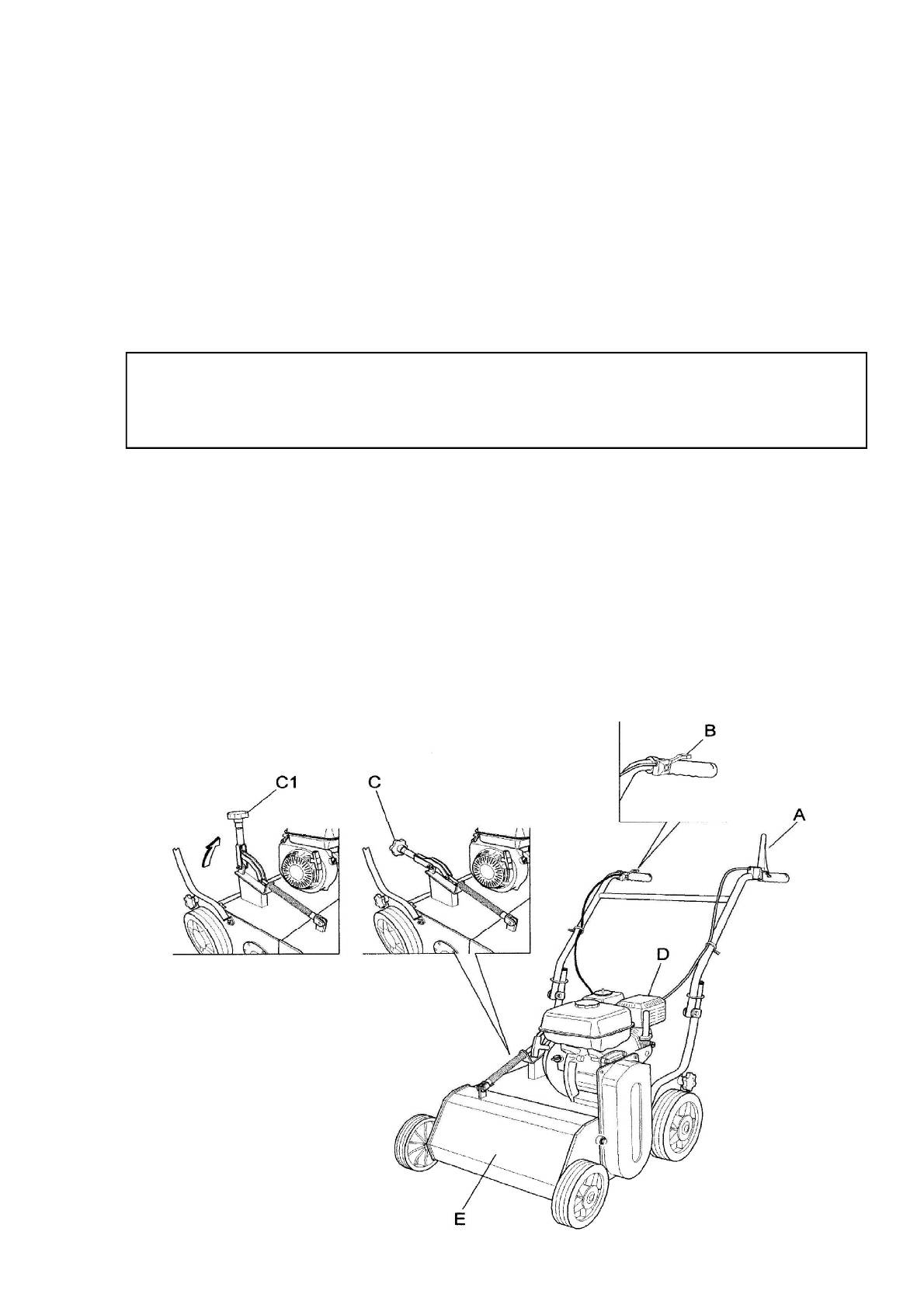

5. MAIN PARTS OF THE MACHINE............................................................pag. 9

6. CONTROLS AND ADJUSTMENTS.......................................................pag. 10

7. ASSEMBLYINSTRUCTIONS FOR THE HANDLEBARS........................pag. 11

8. SAFETY INFORMATION

A) GENERALINSTRUCITONS..............................................................pag.12

B) TRAINING..........................................................................................pag.12

C) PREPARATION.................................................................................pag. 12

D) WORKINGUSE.................................................................................pag.13

E) AFTERWORK...................................................................................pag.14

9. TRANSPORTATIONOFTHEMACHINE.................................................pag.14

10. SAFETYSYSTEMSANDGUARDS.........................................................pag.15

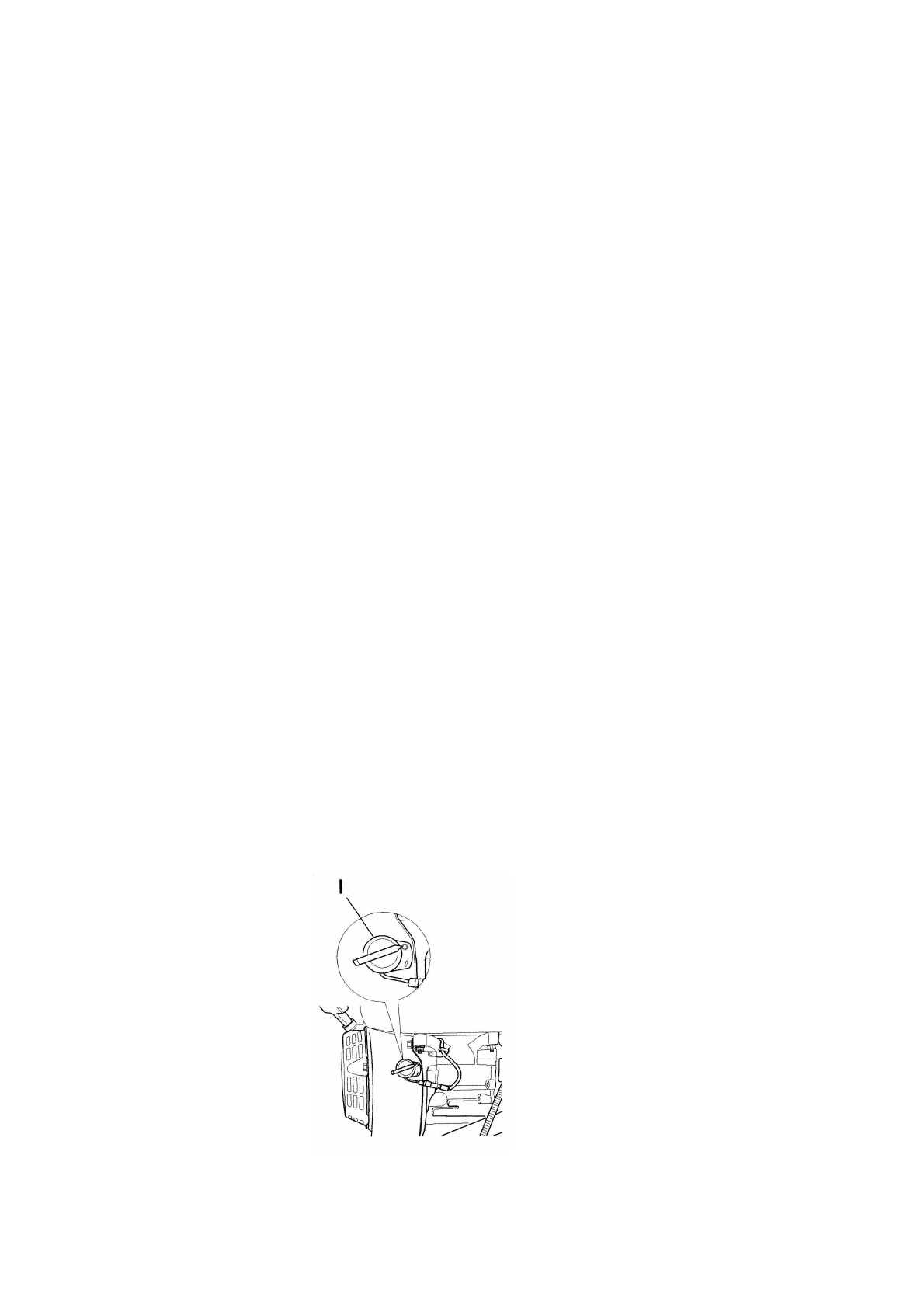

11. OPERATIONSTO BE CARRIEDOUTBEFORE SWITCHINGON........pag.16

12. STARTING AND DRIVING THE SCARIFIER........................................pag. 17

13. CUTTING TIPS......................................................................................pag. 18

14. CHECKS

A) CABLECONTROL ADJUSTMENT....................................................pag.19

B) BLADE ROTOR BELT ADJUSTMENT..............................................pag. 19

C) CHECKINGAND REPLACINGTHE BLADES...................................pag.20

D) ROTOR BRAKE................................................................................pag. 21

15. MAINTENANCEAND STORAGE..........................................................pag. 22

16. CLEANINGTHE MACHINE....................................................................pag.22

17. SEASONALLONG-TERM STORAGE PERIODS..................................pag.23

18. DECOMMISSIONINGANDSCRAPPING................................................pag.23

19. TECHNICAL ASSISTANCE......................................................................pag.23

20. WARRANTY..............................................................................................pag.24

21. CE MARKING........................................................................................pag. 24

Enclosure 1. NOTES

Enclosure 2. Declaration of Conformity

- SCARIFIER MANUAL -

CONTENTS