IBM ELECTRONIC MULTIPLIER User manual

I

BM

ELECTRIC PUNCHED CARD

ACCOUNTING MACHINES

CUSTOMER ENGINEERING MANUAL OF INSTRUCTION

ELECTRONIC MULTIPLIER

TYPE

603

INTERNATIONAL BUSINESS MACHINES CORPORATION

NEW

YORK.

NEW

YORK

Published by

Department of Education

International Business Machines Corporation

Endicott, N. Y.

Copyright

1948

International Business Machines Corporation

590

Madison Avenue, New York

22,

N.

Y.

Printed in

U.

S.

A.

Form 22-3838-0

CONTENTS

INTRODUCTION

OPERATING FEATURES

................................................

Main Line Switch

......................................................

Power Indicating Light (Green)

......................................

Start Key

........................................................................

Stop Key

..........................................................................

Error Indicating Light (Red)

.....................................

................................................

Error Reset Push Button

.................................................

Factor Reversal Switch

Card Hopper

................................................................

Card Stacker

...................................................................

Speed

.............................................................................

............................................................................

Current

..............................................................

Control Panel

FUNCTIONAL PRINCIPLES

Multiplication

.....................................................................

Decimals

..............................................................................

One-Half Correction

...........................................................

Double Punch and Blank Column Detection

................

Multiplication Check

.......................................................

Group Multiplication

..........................................................

Product Overflow

................................................................

Product Summary

...............................................................

Column Splits

......................................................................

Punch Suppression

..............................................................

Class Selectors (Optional)

................................................

Distributor (Optional)

......................................................

Sign Control (Optional)

...............................................

Sign Corltrol Checking

.....................................................

MECHANICAL PRINCIPLES

Location of Parts

........................................................

Drive Mechanism

............................................................

Punch Clutch

..............................................................

Feeding Mechanisms

....................................................

Index and Cycles

...............................................................

Geneva Mechanism

..................................................

Single Revolution Timing Cam

..................................

Principle of Punching

................................................

Magnet Unit

.....................................................................

.........................................................................

Oil Pump

Cam Contacts

....................................................................

ADJUSTMENTS

PUNCH CLUTCH

......................................................................

GENEVA MECHANISM

..........................................................

Single Revolution Timing Cam

..........................................

Single Revolution Timing Cam Bracket

.........................

Geneva Clutch

.................................................................

PUNCH UNIT

.............................................................................

Belt Tension

.......................................................................

Feed Roll Tension

................................................................

..........................................................

Feed Knife Guides

Feed Knife Projection

..................................................

...............................................................

Feed Knife Block

........................................................

Hopper Guide Posts

...........................................................................

Throat

......................................................................................

Die

............................................................

Punch Bail Tongue

Interposer Pawl Lock Bar and Spring Bail

....................

Punch Magnet Armatures

................................................

......................................

Punch Bail Connecting Links

Punch Hopper Side Plates

.............................................

Punch Brush Lateral Alignment

..................................

Anchor Slide Adjustment

..............................................

Brush Timing

................................................................

Vertical Registration

.......................................

.....................................................................

Stacker Plate

..........................................................

Stacker Timing

.....................................................................

CONTACTS

Adjustment of Cam Contacts

........................................

...........

Adiustinent of Card Lever Contacts

ELECTRICAL PRINCIPLES

PUNCH UNIT CIRCUITS

........................................................

............................................................

Time Delay Circuits

........................................

Start Circuit and Bias Interlock

Start Interlock Circuits (Gang Punching Only;

............

Start and Running Circuits (No Cards in Machine)

-~----

Start and Running Circuits (Cards in Machine)

...........

......................................................

Reading Brush Circuits

I,

lectronic Computing Control Circuits

..........................

..............................................................

Punch Suppression

...............................................................

Product Summary

...............................................................

Product Overflow

Factor Reversal and Check Circuits

..................................

..............................................................

Group Multiplying

Column Split,

0

and

X,

Hot

1

.....................................

Sign Control (Optional Feature)

.....................................

Class Selectors (Optional)

.................................................

Distributor (Optional)

.....................................................

POWER SUPPLY CIRCUITS

....................................................

Main Transformer and Selenium Rectifiers

........................

Tube Power Supply Chassis

...........................................

Constant Ratio Voltage Regulator

...................................

Screen Grid Supply

.............................................................

Voltage Adjustments

......................................................

PRINCIPLE OF MULTIPLYING

Computing

Circuits-General

BASIC CIRCUITS

TRIGGER CIRCUIT

.......................................................

77

Theory of Operation

....................................................

77

Coupling of Trigger Circuits

........................................

85

Trigger Circuits Used in Electronic Computing

..

86

Control of Other Tubes by Triggers

................................

89

ELECTRONIC COUNTER

........................................................

91

Indicator Blocks

..................................................................

97

Counter Read-In from Card

...........................................

98

Read-In Pulse Circuit

........................................................

100

Counter Read-In at High Speed

..................................

101

COMPUTING CIRCUITS

....................................................

103

Multivibrator and Clippers

........................................

103

Electronic Timers

...................................................

110

Compute Start Control and Primary Timer

...................

112

Secondary and Tertiary Timers

....................................

113

Multiplier Advancing Pulses

....................................

114

Ten-Pulse Control

................................................

119

Multiplicand Counter Rolling Control

.........................

121

Multiplicand Read-Out

...............................................

124

Column Shift Switches

............................................

127

Tertiary Timer and Colun~nShift Control

.................

131

Carry Control and Carry Circuits

.............................

134

Half-Entry

..............................................

139

Compute Stop

...................................................

140

Read-Out Circuits

.................................................

142

TESTING PROCEDURE AND TROUBLE ANALYSIS

Use of Neon Indicator Bulb. Voltmeter and Oscilloscope

149

PURPOSE OF TUBES IN THE COMPUTING SECTION

Feed Hoppar Start-Stop Keys

\

Joggle Plate

/

/

Read

and

Punch

Unit

Electronic Computing

Unit

ELECTRONIC MULTIPLIER

Type

603

IBM ELECTRONIC MULTIPLIER

TYPE

603

INTRODUCTION

THE

CONVENTIONAL

mulriplying machine using

mechanical counters for the computation of pro-

ducts is considerably limited in its speed of oper-

arion because of the inertia of moving parts. By

the use of electrical computation circuits, calculat-

ing speeds can be increased considerably. The Elec-

tronic Multiplier makes use of recently-developed

electronic circuits which calculations at

extremely high speeds. Thus the burdensome and

usually slow-speed process of computing products

is reduced to an automatic high-speed process in

keeping with the other high-speed functions of the

IBM Accounting Machine Method. Calculations

involving earnings, material costs, discounts, in-

ventories, and many other computations can be

effected automatically to speed up the accounting

routines which normally require much time and

ond, between the reading and punching of each

card.

OPERATING FEATURES

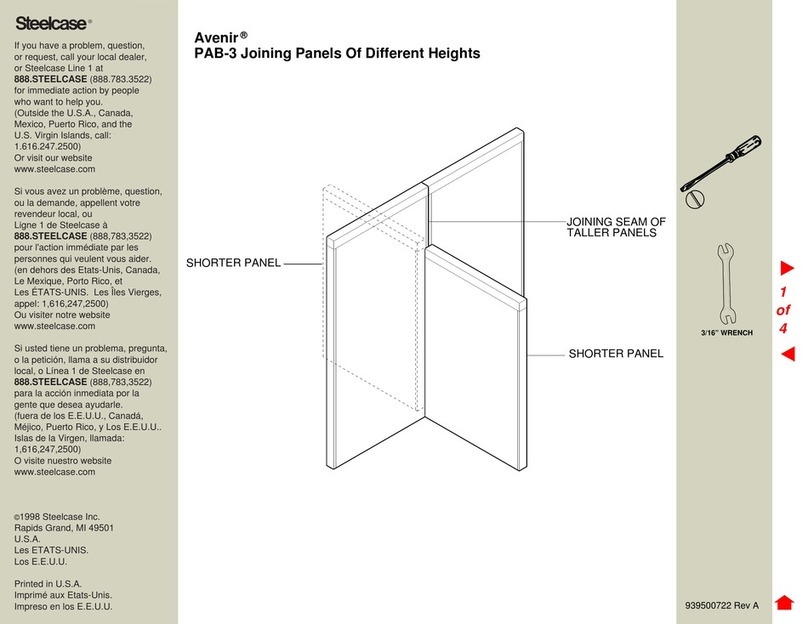

THE

operating controls and features of this ma-

chine, which can be seen in Figure

1,

are all located

on the punch unit.

Main Line Switch

This switch must be

ON

for the machine to be

operative. It must not be turned

OFF

while cards

are feeding through the machine.

Power Indicating Light (Green)

When this light is

ON,

the machine is ready for

operation. It will not turn on until suficient time

has been allowed for the electronic tubes to warm

effort. UP.

The Type 603 Electronic Multiplier consists es-

Start Key

sentially of a unit for reading and punching and

an electronic computing unit connected by a cable This key is depressed to start the feeding of

as shown by the general view of the machine on the cards at the beginning of a run. It must be held

frontispiece. The factors punched in an IBM Card down through three machine cycles, when first

are read by the reading unit, computations are starting, before automaric operation begins.

automatically made by the electronic computing

unit, and +theresult is then punched in the same

card by the punching unit. No time is lost wait-

ing for the completion of the computing oper-

ations; all computations are performed between

the time a card leaves the reading brushes and the

time it reaches the punching position. The mach-

ine is equipped with a control panel which makes

it entirely flexible as to the reading and punching

of information.

The IBM Electronic Multiplier, Type 603, repre-

sents the first commercial use of electronics for

multiplication. The use of electronic circuits for

computing permits operation of this multiplier at

maximusr punching speed of 6000 cards per hour.

The multiplication itself is performed in .027 sec-

Stop Key

This key is depressed for manual control of stop-

ping the feeding of cards while the machine is

through running.

Error Indicating Light (Red)

This light glows when an error is detected by the

Double Punch and Blank Column Detection De-

vice, or when a product exceeds the card field

capacity as indicated by the Product Overflow

feature.

Error Reset Push Button

This button is depressed to extinguish the error

light and restore the machine to normal operation,

after the machine has stopped because of an error.

2

TYPB,

603

'E.LECTR.ON.lt'MULTlPLF,ER

;

Card

Face

Edge

Figure

I.

Operating Features

Indicating

(Red)

#

Factor Reversal Switch Speed

When set

ON,

this switch autamatically reverses The operating speed of rhis machine is

100

cards

the multiplier and multiplicand entry hubs. It is per minute regardless of the number of columns

used in checking operations. punched and the size of the multiplier or multi-

Card Hopper

plicand fields.

Cards are placed in the card hopper face down,

current

9

edge first. The capacity of the hopper is approxi- This machine is supplied to operate only on

11

5

mately

800

cards. volts or

230

volts

A.C.,

SO

or

60

cycle current.

Card Stacker Control Panel

After leaving the last set of brushes, cards enter

the stacker which has a capacity of approximately The automatic control panel provides a means

1000

cards. If the stacker fills

to

capacity, the for flexible setup of rhe machine for all operations.

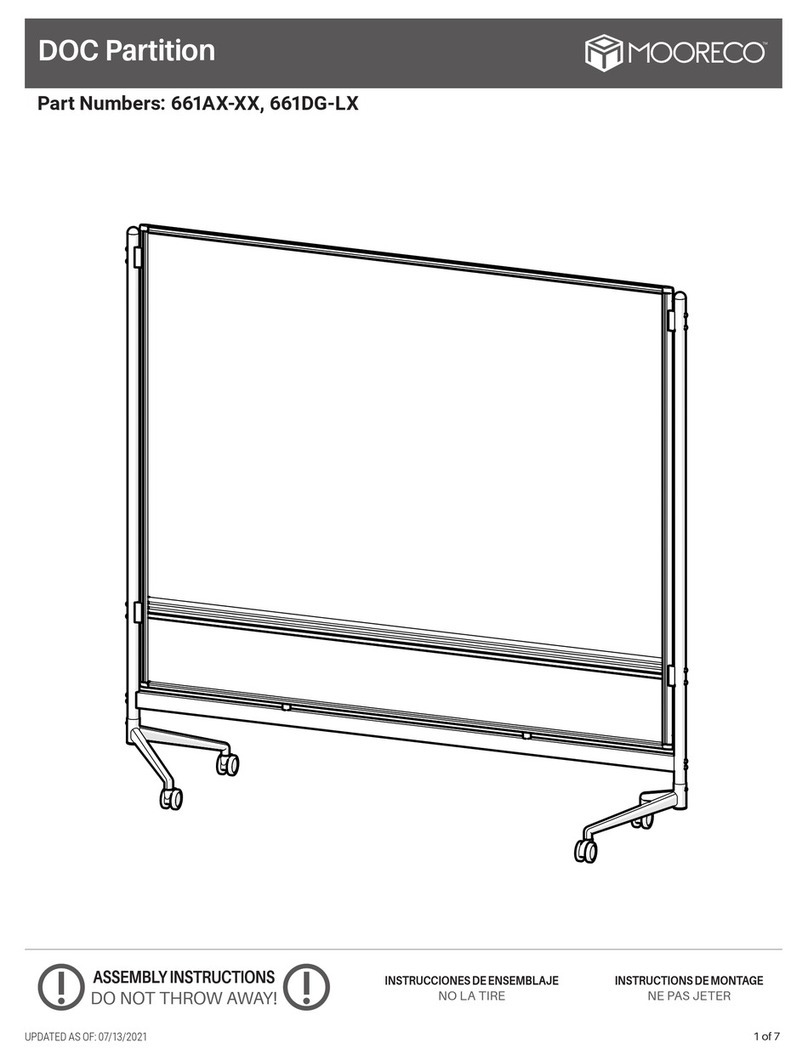

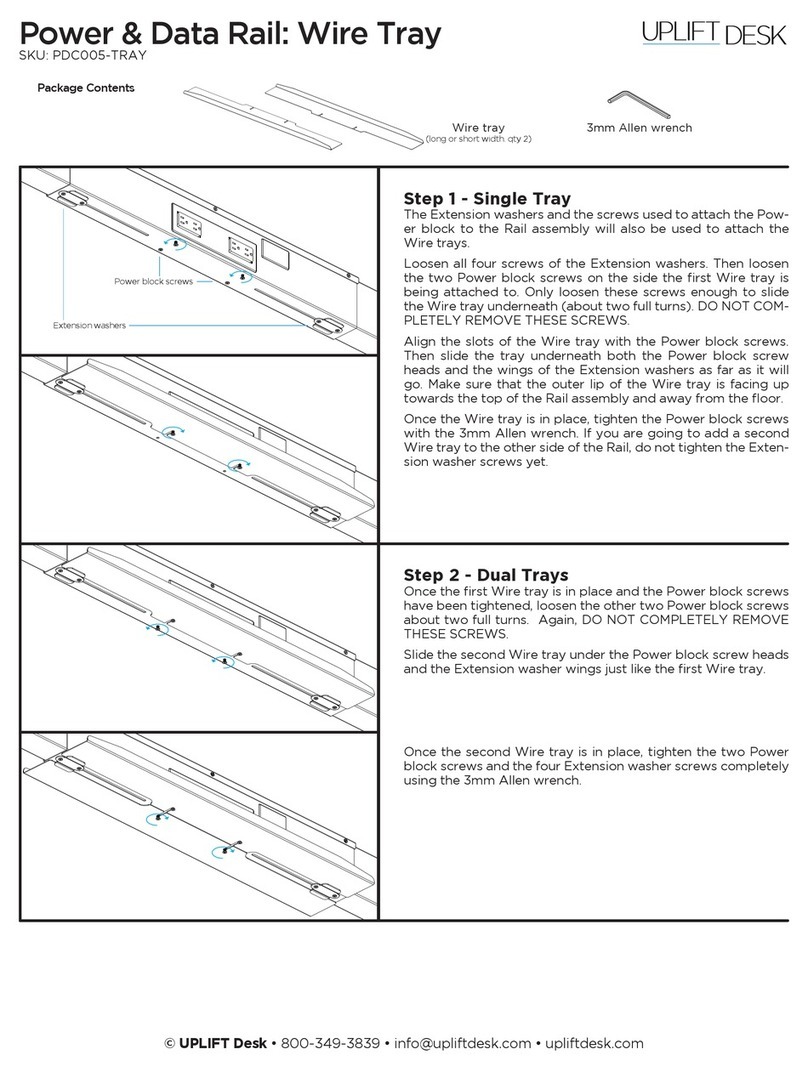

machine will be stopped automatically by the Figure 2 shows

a

control panel with the function

stacker stop switch. of each hub described.

Figure

2.

Control Panel-Explanation of Hubs

FUNCTIONAL PRINCIPLES

Multiplication

The Electronic Multiplier can multiply two

6-

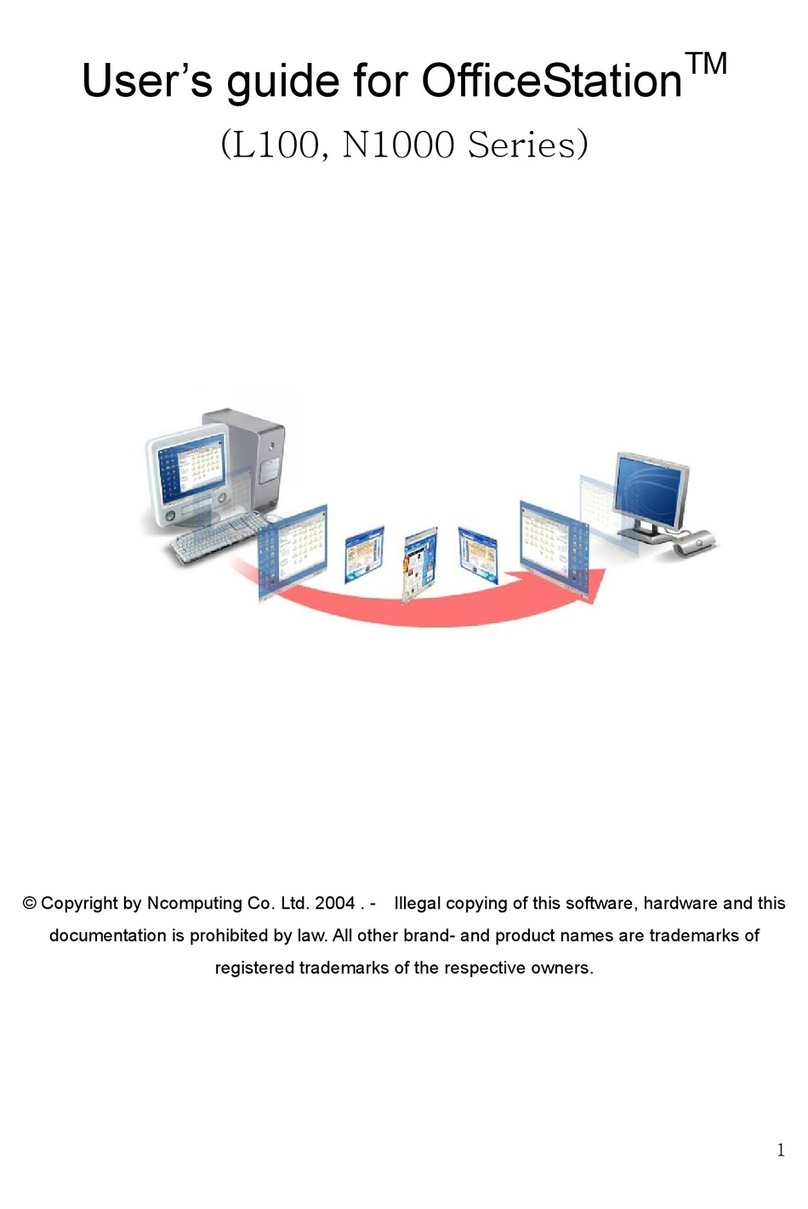

digit factors to produce a 12-digit product. Fig-

ure

3

shows control panel wiring for an individual

mulriplication problem. The multiplier and mul-

tiplicand are read from the card at the first read-

ing station, represented on the control panel by

the 80 exits labelled "Read for Entry and Con-

trol." They are wired to rhe multiplicand and

multiplier counter entries. The product is avail-

able for punching at Product Exit. The product

exit positions from which the product is read must

be wired

TO

the Punch Entry hubs representing the

columns in which the product is to be punched.

order. These positions are represenred on the con-

trol panel by the hubs labelled "Double Punch and

Blank Columh Entry." These hubs are supple-

mented by 10 control panel switches labelled

"Blank Column Switches" which correspond to the

10 DPBC entry hubs. The blank column switches

must be set

ON

for blank column checking.

Multiplication Check

In order thar the double punch and blank col-

umn feature may be used for checking multipli-

cation, it should be used on each original multi-

plying run to prove that only one hole has been

punched in each product column and that no coI-

Decimals

umns are unpunched. For this purpose, the product

When either of the two factors contains deci- field columns in Read for Checking should be

mals, the decimal in the product will wired ro Double Punch and

lank

column ~ntr~,

equal the sum of the decimal ~ositionsof .the fac- as shown in Figure

3.

tors. Only those decimal positions which are to When the punching has been checked in the

be retained in the product are wired from Product original run, the double punch and blank column

Exit to Punch Entry. detection feature may then be used in a separate

One-Half Correction

When some decimal places are dropped from a

product, rhe product can be corrected to the near-

est whole number or decimal position by adding

5

to the first position following the retained pro-

duct. In the Electronic Multiplier, this

'/2

cor-

rection can be made in any of rhe six right-hand

positions of the product counter. On the control

panel,

52

entries are located directly above the

product exits, and the

'/2

entry common is ad-

jacent. The

5

for

'/2

correction will be entered

inro the product counter during multiplication,

once for each card.

run to prove the calculation. The cards are re-run

through the machine with the wiring of .the mul-

tiplicand and multiplier counters reversed by

plat-

ing the factor reversal switch

ON.

During this

second operation the machine again multiplies and

punches the resulr in the product field. With the

product field wired from Read for Checking to

the DPBC Entry, any product punched in this

re-run which differs from the original product will

cause a double-punched column and will therefore

be sensed by double punch detection. If an error

is detected, the machine will srop and turn on the

red light at the front of the machine. The reset

button must be depressed to turn the lighr out.

Double Punch and Blank Column Detection

The start key must then be depressed for one card

The Electronic Multiplier is equipped with 10 cycle, at the end of which time the card in error

double punch and blank column detection posi- will be in the top position in the stacker and may

tions. Ten additional positions are available on be removed for review.

FUNCTIONAL PRINCIPLES

5

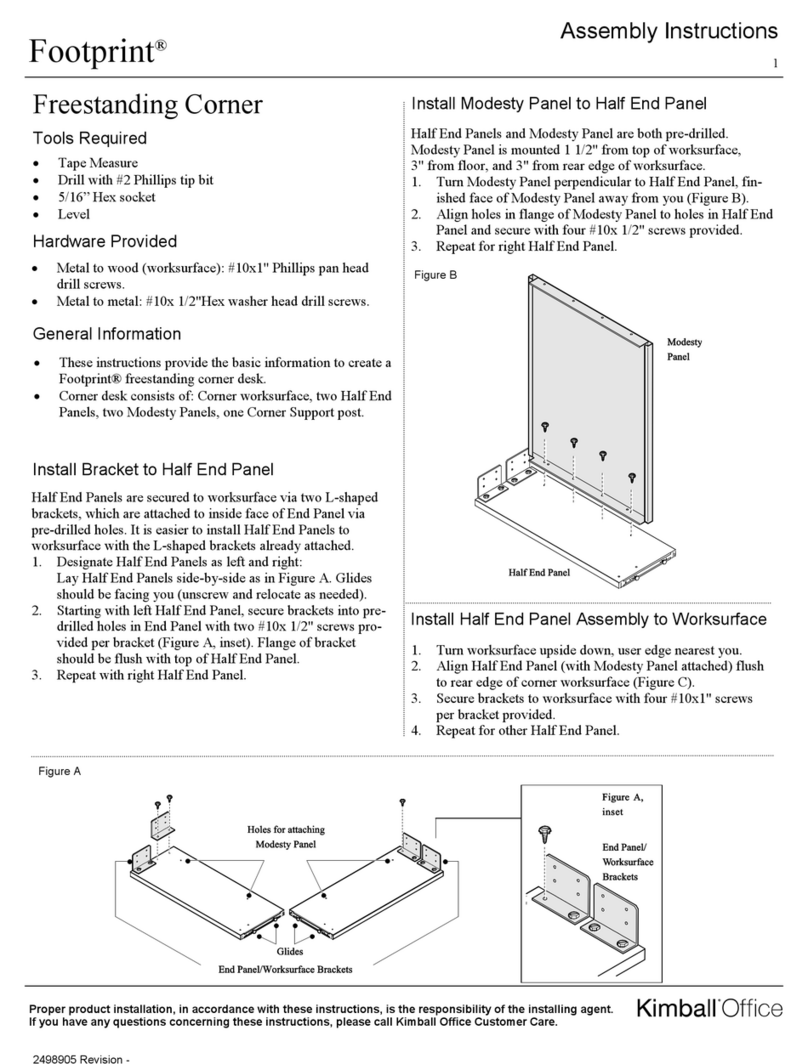

Figure

3.

Multiplication

The multiplier field (two decimal places) is entered in

the multiplier counter.

The multiplicand field (four decimal places) is entered

in the multiplicand counter.

Only two decimal positions are retained in the product;

5 is added to the third decimal position to correct the

product to the nearest whole cent.

The product (two decimal places) is punched in col-

umns

76

-

80.

The punched product field is checked for double punch-

ing.

The punched product field is checked for blank columns.

For group multiplication, this dotted wiring should be

added.

Only

5

positions are allowed on the card for punching

the product. If

a

product carries to six positions,

a 12

is punched in card column

70.

Wiring for checking is the same as for the orig-

inal run; the only difference is the reversal of the

factors by the factor reversal switch.

Group Multiplication

The Electronic Multiplier can be used for group

multiplication, in which one factor remains con-

stant for all cards in a group. The common factor

for group multiplication in the Electronic Multi-

plier must be wired to the multiplier counter. (The

multiplicand counter may be used to carry the

group multiplier if the factor reversal switch is

set

ON.)

The multiplier must be punched in a

card designated by a

9

punch and placed at the

front of each group. The multiplier counter will

not reset until a group is finished and the special

multiplier card for the next group is about to be

read.

For group multiplication, the group multiplier

control panel switch should be wired

ON.

The

column punched

9

in the group multiplier card

must also be wired from Read for Entry and Con-

trol to one of the group multiplier pickups labelled

"9".

The reading of a

9

by the pickup causes the

machine to reset the multiplier counter, read in the

new multiplier, and eliminate punching and check-

ing of the rate card.

With the group multiplier switch wired

ON,

the

reading of the

9

by the pickup hub causes only the

multiplier field to be read from the group multi-

plier card and only the multiplicand field to be

read from the detail cards. The basic wiring for

group multiplication is the same as for individual

multiplication. The additional wiring required is

shown dotted in Figure

3.

Product Overflow

Often the number of columns set aside on a

card to punch the product of a multiplication is

not large enough to permit punching the largest

products. However, if only a very small percent-

age of the total number of cards exceeds the capa-

city of the field, it may not be worth increasing

6

TYPE

603

ELECTRONIC MULTIPLIER

the size of the card field, thereby limiting the

number of columns available for other punching.

To take care of such cases, the product overflow

feature is furnished on this machine.

To place the product overflow feature in

opera-

tion, the product counver position

next

to

the

highest order wired to punch is wired to the Pro-

duct Overflow Entry hub. As long as the product

counter position wired to Product Overflow con-

tains 0, nothing happens. Any digit from 1

through

9

in this position causes the error light to

glow and the machine to stop when the card in

error is just ready to enter the stacker.

Since athe error light is used for other error sig-

nals, it is desirable to distinguish between errors

and overflow products. This is accomplished by

punching

a

12 hole in a card in which the product

exceeds the card field capacity. To punch the 12,

the Product Overflow 12 hub is wired to any

punch magnet, and

a

12 hole will be punched in

the overflow card.

With this arrangement,

a

card is examined after

an error light, and if

a

12 hole is punched, it is

apparent that the error was due to an overflow

product. This card can then be processed man-

ually.

The necessary control panel wiring is shown by

wiring

8

in Figure

3.

A 12 is punched in column

70 of the card with an overflow product (Figure

3).

Product Summary

Often it is desired

TO

accumulate several pro-

ducts before punching. This permits special oper-

ations, such as crossfooting on two cards, punching

the sum of several products, etc. To accomplish

this it is necessary to prevent reading out and clear-

ing of the product counter.

The product summary feature is placed in opera-

tion by wiring the

PROD

SUM

control panel switch

ON.

This feature may be either No

X

or

X

controlled. Digit control is also provided. If

it is desired to punch the product only in

X

Figure

4.

Use of Product Summary and Column Splits

I.

The multiplier field is entered in the multiplier counter.

2.

The multiplicand field is entered in the multiplicand

counter.

3. The product is half corrected by adding

5

to the 3rd

position.

4.

The product is punched in card columns

54

-

60 sub-

ject to the Product Summary Wiring.

5.

The Product Summary feature is placed

in

operation.

6.

X

punchings in the cards to be punched with the

products are sensed.

7.

When an X-punched card passes the die, the product

is punched in the card and the counter is cleared.

8. An X is punched in column 80 and an

0

in

column

I,

in all cards bymeans of the

0

and

X

and Column Split

features.

FUNCTIONAL PRINCIPLES

7

punched cards, the control panel wiring would be

as shown in Figure

4.

The standard wiring of the

multiplicand, multiplier, half-entry, etc. remains

the same as before. Of course, blank column check-

ing cannot be done in this case because many of

the cards are blank. However, double punch

checking may be used if desired.

If ir

is

desired to punch in No X (or digit)

cards, the

N

hub is wired to the

PROD

SUM

hub,

below it. In this case X punched cards will not

be punched, and the product will not clear.

A

blank card with the proper control punching

must precede a product summary run to insure rhe

clearing of the product counter provided a pro-

duct summary run is made immediately after turn-

ing the machine on. This card will insure the clear-

ing of any random figures from the product

counter, resulting from turning the power on. On

normal runs this is not necessary because the pro-

duct counter is cleared before starting the first

computation.

The 1 hub, which emits a 1 impulse during each

card cycle, may be used as a unit multiplier for

special crossfooring operations from card to card

in connection with the product summary feature.

Column Splits

Two positions of column split are available as

standard on this machine. The 0-9 hubs of the

column split are connected wirh the

C

hubs from

9 through

O

of the card, and the 11-12 hubs are

connected with the

C

hubs from 11-12. This de-

vice permits an X or 12 punching over a 0-9 digit

to be recognized independently or to be ignored.

Wiring

8

on Figure

4

shows a typical use of the

column splir device in connection with the

O

and

X

hubs for automatic punching of X's or 0's.

Punch Suppression

If it is desired to suppress punching in a card,

the card is either X punched or punched with a

control digit in a specified column. The control

punching $hen causes the suppression of punching

on that card with proper wiring of rhe control

panel. No X (or digit) control is also furnished,

so that the control punching can appear on the

cards to be punched. This feature permits stan-

dard group (or interspersed) gang punching oper-

a'tions on this machine.

The use of the punch suppression device in con-

nection with two special features, the distributor

and a class selector, is shown in Figure

5.

In this

example, an offset interspersed gang punching op-

eration is being performed.

If

No X (or digit) control is desired, rhe

N

hub

is wired to the

PCH

SUP

hub below. This setup

causes only X (or digit) punched cards to be

punched. Master cards would not be punched

with a control punching.

Class Selectors (Optional)

Class selectors are optional features on rhis ma-

chine. Two class selectors may be installed on

order.

The selectors are arranged for either X or

D

pickup and for normal or delayed operation. If it

is desired to transfer the selector during the cycle

following the reading of the X (or digit), the

GR

PLG

is wired to the Exit 1hub. Wiring the

GR

PLG

to the Exit 2 hub causes the selector to transfer

during the second cycle following the reading of

the X or

D

hole.

Figure

5

shows an example of class selector 1

picking up from a

3

punch in column 80 and

transferring during the second cycle following the

reading of the

3.

Distributor (Optional)

A

conventional 12-segment distributor can be

installed as an optional feature on this machine.

The distributor can be used as a digir emitter by

'

wiring the CB hub to the distributor

C

hub. The

individual hubs of the distributor then emit timed

impulses corresponding to rhe hub label.

The distributor can also be used as a digit selec-

tor by wiring from the brushes to the

C

hub of the

8

TYPE

603

ELECTRONIC MULTIPLIER

Figure 5. Use of Class Selector for OffsetGang Punching

1. A 3 in column 80 is sensed for punch suppression con-

trol and class selector pickup, using a digit selector.

2. Punching is suppressed as the 3-punched card passes

the die and stripper.

3. The class selector

I

transfers while the 3-punched card

passes the second set of brushes.

4.

The No

X

card following the 3-punched card is punched

in card columns 56

-

60 from columns 21 -25.

5. All No

X

cards gang punch in columns 56

-

60.

distributor. Then only the desired digit in any

card column can be recognized by proper wiring

of the

9-12

hubs of the distributor. Figure

5

shows

the distributor used as a digit selector.

Sign Control (Optional)

Sign control permits determination of the sign

(plus or minus) of a product by analysis of the

sign of its factors. Two factors having the same

sign produce a positive product, but if one factor

is positive and the other negative, the product will

be negative.

For multiplication, factors should always be

punched as true figures whether their sign is plus

or minus. In an IBM card the minus sign may be

indicated by an X punch. Any column may be

used forthe X punch, indicating the sign of a fac-

tor, but preferably it should be the unit column of

the factor field.

Wiring for sign control is shown in Figure

6.

To

place the sign control feature in operation, the

SIGN

CTRL

control panel switch must be wired

ON.

There are two sign control pickups on the control

panel, labelled

MCX

(multiplicand X) and

MPX

(multiplier X). One of the two common hubs,

MCX

should be wired from the column in Read for

Entry and Control containing the minus X for

,the multiplicand. One of the two common hubs

MPX

should then be wired similarly for the multi-

plier minus

X.

If only one of the sign control pickups reads an

X, the product should be negative. The machine

will punch the product in true figures, and to

designate the product as negative, will punch an

X in the units column of the product field. To

punch the minus

X

in the units column, the units

position of the product field must be wired from

the

PRX

PCH

hub to the Punch Entry hub (Fig-

ure

6).

The wiring is taken through the column

split to permit

X

punching over the units digit. If

it is desired, the negative product X may be

punched in any column of the card.

Sign Control Checking

When sign control is used in the original calcu-

lation, with a negative product indicated by an X

FUNCTIONAL PRINCIPLES

9

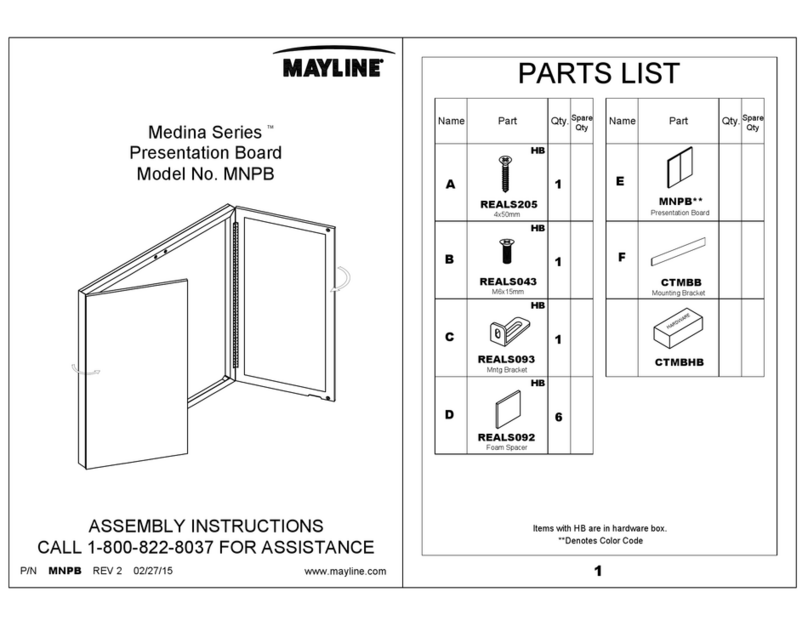

(All X's identifying negative amounts punched over

units position of corresponding field.)

The multiplier factor is entered in the multiplier coun-

ter; the units position is brought through the MPX

hubs to recognize negative multipliers.

The multiplicand factor is entered in the multiplicand

counter; the units position is brought through the MCX

hubs to recognize negative multiplicands.

The product is punched in card columns

74

-

80,

the

units position is taken through the column split to per-

mit both

a

digit and the sign control X to be punched

in the units position.

An

X

identifying

a

negative product is punched in the

units position of the product field through the column

split.

An

X

identifying

a

negative product is read when sign

control checking only.

The product is checked for double punchings and blank

columns; the units position of the product is taken

through the column split hub because of the

X

punched

over the units position in negative products.

Figure

6.

Multiplication

and

Checking with Sign Control

punch, the punching of this minus

X

for the pro-

duct may also be checked during the re-run. In

the re-run, the wiring of the two sign control pick-

ups, as well as wiring of rhe entries to multiplicand

and multiplier counters, is reversed by the factor

reversal switch. To check the minus

X

punch in

the product, the units column of the product field

from Read for Entry and Control is wired to one

of the two common hubs labelled

PRX

CHK

(Fig-

ure

6).

These

PRX

CHK

entry hubs should read an

X

when only one of the two sign control pickups

has read an

X.

If one of these conditions occurs

without the other, an error condition will be indi-

cated.

When checking multiplication with sign con-

trol for double punching, the

X

punched for nega-

tive products must be eliminared from the double

punch check, if it is punched over the product

field. This is done by means of the column split

device as shown in Figure

6.

MEC'H'ANICAL PRINCIPLES

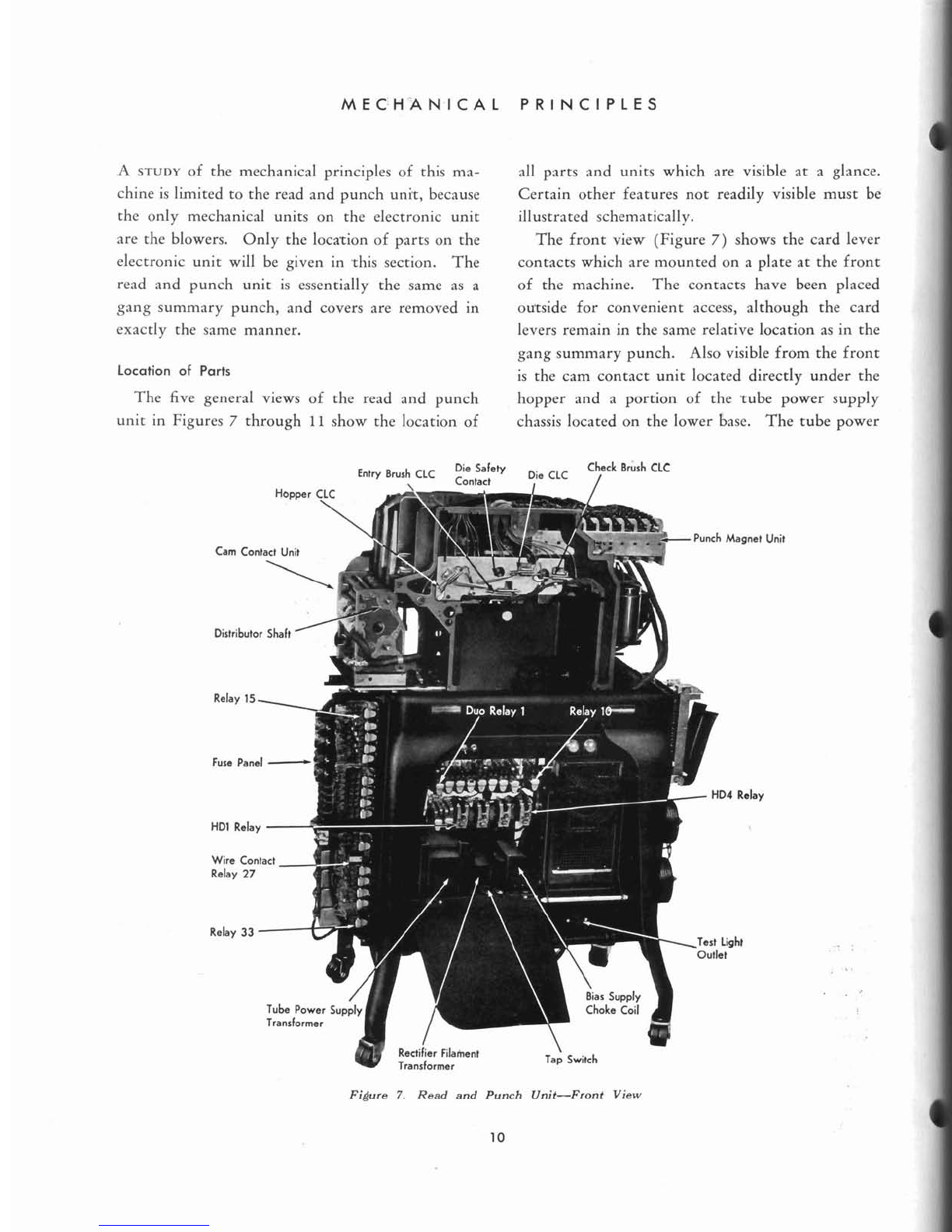

A

STUDY

of the mechanical principles of this ma-

chine is limited to the read and punch uni.t, because

the only mechanical units on the electronic unit

are the blowers. Only the locarion of parts on the

electronic unit will be given in ,this section. The

read and punch unit is essentially the same as a

gang summary punch, and covers are removed in

exactly the same manner.

Location

of

Parts

The five general views of the read and punch

unit in Figures

7

through

11

show the location of

all parts and units which are visible at a glance.

Certain other features not readily visible must be

illustrated schematically.

The front view (Figure

7)

shows the card lever

contacts which are mounted on a plate at the front

of the machine. The contacts have been placed

ourside for convenient access, although the card

levers remain in the same relative location as in the

gang summary punch. Also visible from the front

is the cam contact unit located directly under the

hopper and a portion of the rube power supply

chassis located on the lower base. The tube power

Check Brush

CLC

Entry

Brush

CLC

::nE:"

Die

CLC

/

Unit

Relay

Figure

7.

Read and Punch Unit-Front View

10

'

MECH.ANICAL

PRINCIPLES

'

11

Q

Terminal Punch Magnet

80

Terminal Punch Magnet

10

Selt

(Full

Common Terminal

Motor Starting

/

Capacitor

Connector Latch

miurn Rectifier

Figure

8.

Read and Punch Unit-Right Side View

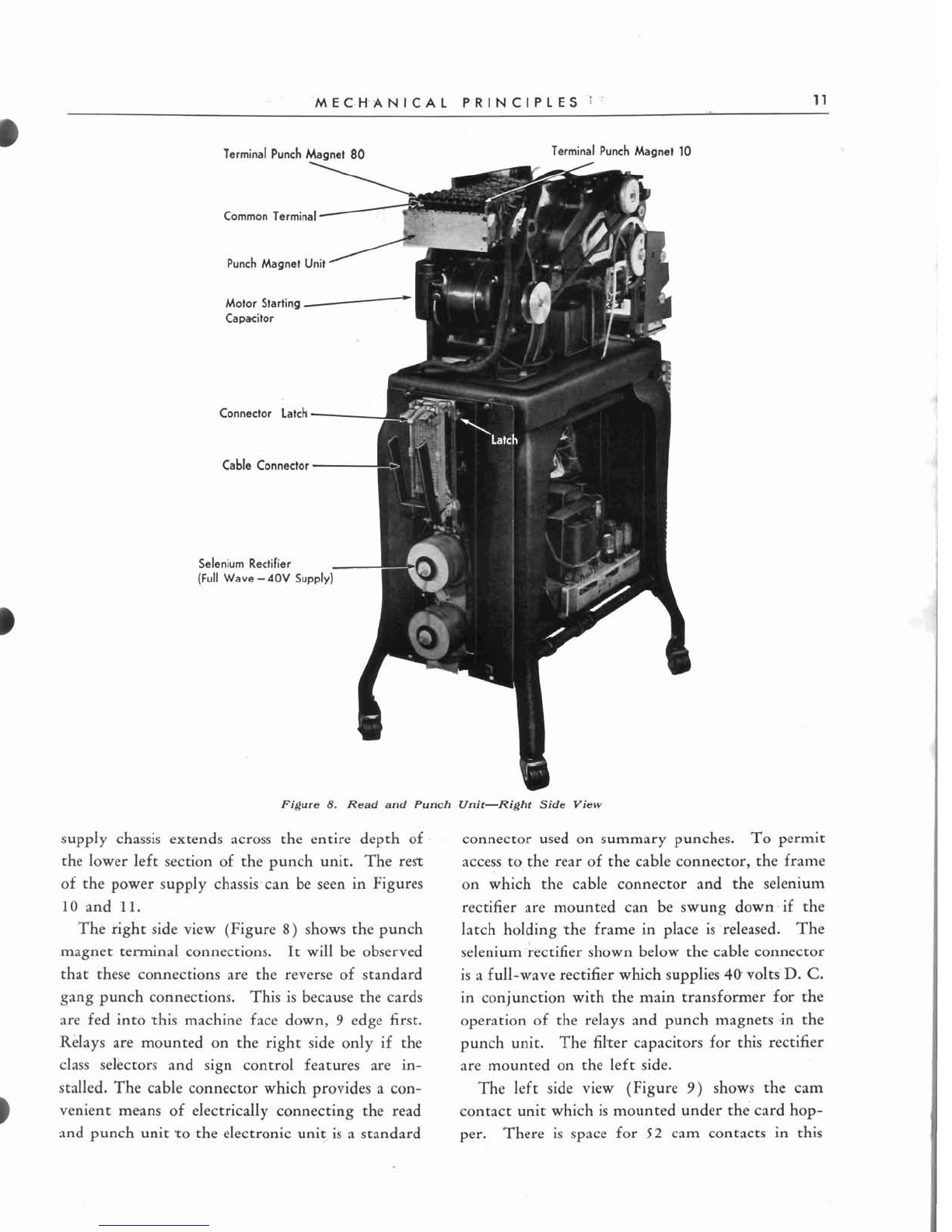

supply chassis extends across the entire depth of

the lower left section of the punch unit. The rest

of the power supply chassis-can be seen in Figures

10

and

11.

The right side view (Figure

8)

shows the punch

magnet terminal connections. It will be observed

that these connections are the reverse of standard

gang punch connections. This is because the cards

are fed into rhis machine face down,

9

edge first.

connector used on summary punches. To permit

access to the rear of the cable connector, the frame

on which the cable connector and the selenium

rectifier are mounted can be swung down.if the

latch holding %heframe in place is 'released. The

selenium rectifier shown below the cable connector

is a full-wave rectifier which supplies

40

volts'

D.

C.

in conjunction with the main transformer for the

operation of the relays and punch magnets .in the

Relays are mounted on the right side only if the punch unit. The filrer capacitors for this rectifier

class selectors and sign control features are in- are mounted on the left side.

stalled. The cable connector which provides a con- The left side view (Figure

9)

shows the cam

venient means of electrically connecting the read contact unit which is mounted under the card hop-

and punch unit ro the electronic unit is a standard per. There is space for

52

cam contacts in this

12

TYPE

603

ELECTRONIC MULTIPLIER

,Eccentric

Shah

P1

Cam Contact

P27

Cam Contact

200

mld

Capachrs

I140V

Supply)

Figure

9.

Reed and Punch Unit-Left Side View

I

unit, numbered from front

to

rear, top to bottom. bleeder resistor shown below the rectifier, supplies

I

However, no cams beyond P41 are used, and al-

though cams

9,

13, and 15 are not used, they retain

their numbers. The 12 amp fuses and 20 amp

fusetrons shown at the top of the fuse panel are in

the main transformer circuit. The glass fuses are

in the punch circuits and in the tube power supply

circuits. The conventional arc-suppressing capaci-

tors are mounted between the relay brackets and

above the half-wave selenium rectifier. This selen-

ium rectifier, together with its filter capacitors and

140 volts

D.

C.

for the read-out power tubes in

the electronic unit. The four 2000 mfd. capacitors

shown below the 140 volt

D.

C.

selenium rectifier

are the filter capacitors for the 40 volt

D.

C.

sup-

ply. Thedouble punch and blank column detection

relays

37

through 57 are mounted on the left rear

gate. If 10 additional positions of DPBC detection

are installed, relays

58

through 77 are mounted

just to the left of R37-R57.

a

MECHANICAL PRINCIPLES

13

Oil

Level

Crank

Stud Indicator

Gear Housing

\

Oil

Cup

Figure 10. Read and Punch Unit-Rear View

The rear view in Figure 10 shows the mechan-

ical features visible from the rear as well as the

main transformer and the tube power supply chas-

sis. The tube power supply furnishes

D.

C.

volt-

ages of

100

volts, 150 volrs, and 250 volts for the

operation of tubes in the electronic unit. The main

+

transformer supplies

A.

C.

of proper voltage to the

40 volt and 140 volt selenium rectifiers; it also

supplies -the filaments of all tubes except the gas-

filled rectifier tubes.

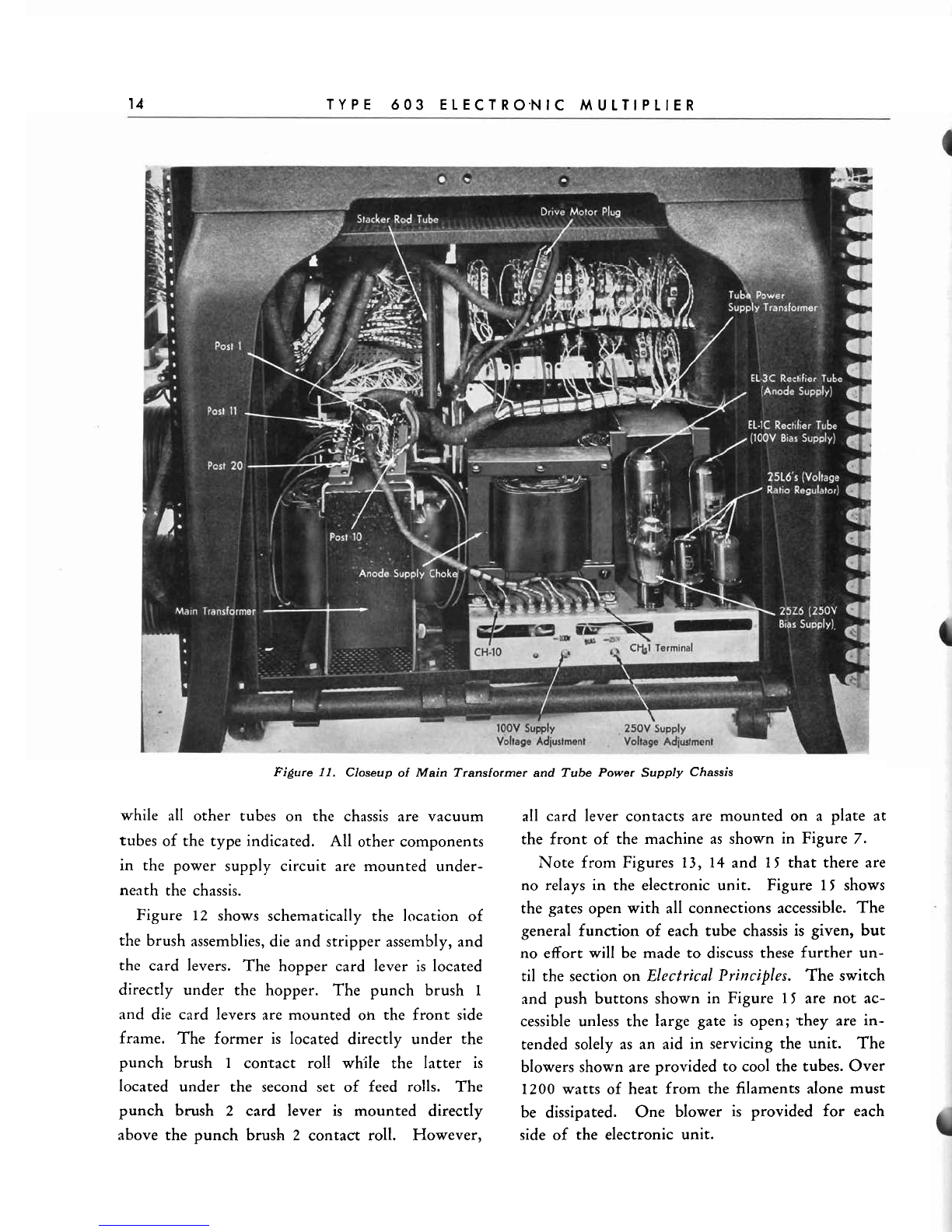

In the close-up view of Figure

11,

a better pic-

ture of -the main transformer and tube power sup-

ply chassis is shown. Note particularly the system

for numbering terminals on both the transformer

and the power supply chassis. The

EL-3C

and

EL-1C

tubes are gas-filled full-wave rectifier tubes,

14

TYPE

603

ELECTR0,NIC

MULTIPLIER

Figure

11.

Closeup

of

Main Transformerand Tube Power Supply Chassis

while

all

other tubes on the chassis are vacuum

tubes of the type indicated. All other components

in the power supply circuit are mounted under-

neath the chassis.

Figure

12

shows schematically the location of

the brush assemblies, die and stripper assembly, and

the card levers. The hopper card lever is located

directly under the hopper. The punch brush

1

and die card levers are mounted

oh

the front side

frame. The former is located directly under the

punch brush

I

con,tact roll while the latter is

located under the second set of feed rolls. The

punch brush 2 card lever is mounted directly

above the punch brush

2

contact roll. However,

all

card lever contacts are mounted on a plate at

the front of the machine as shown in Figure

7.

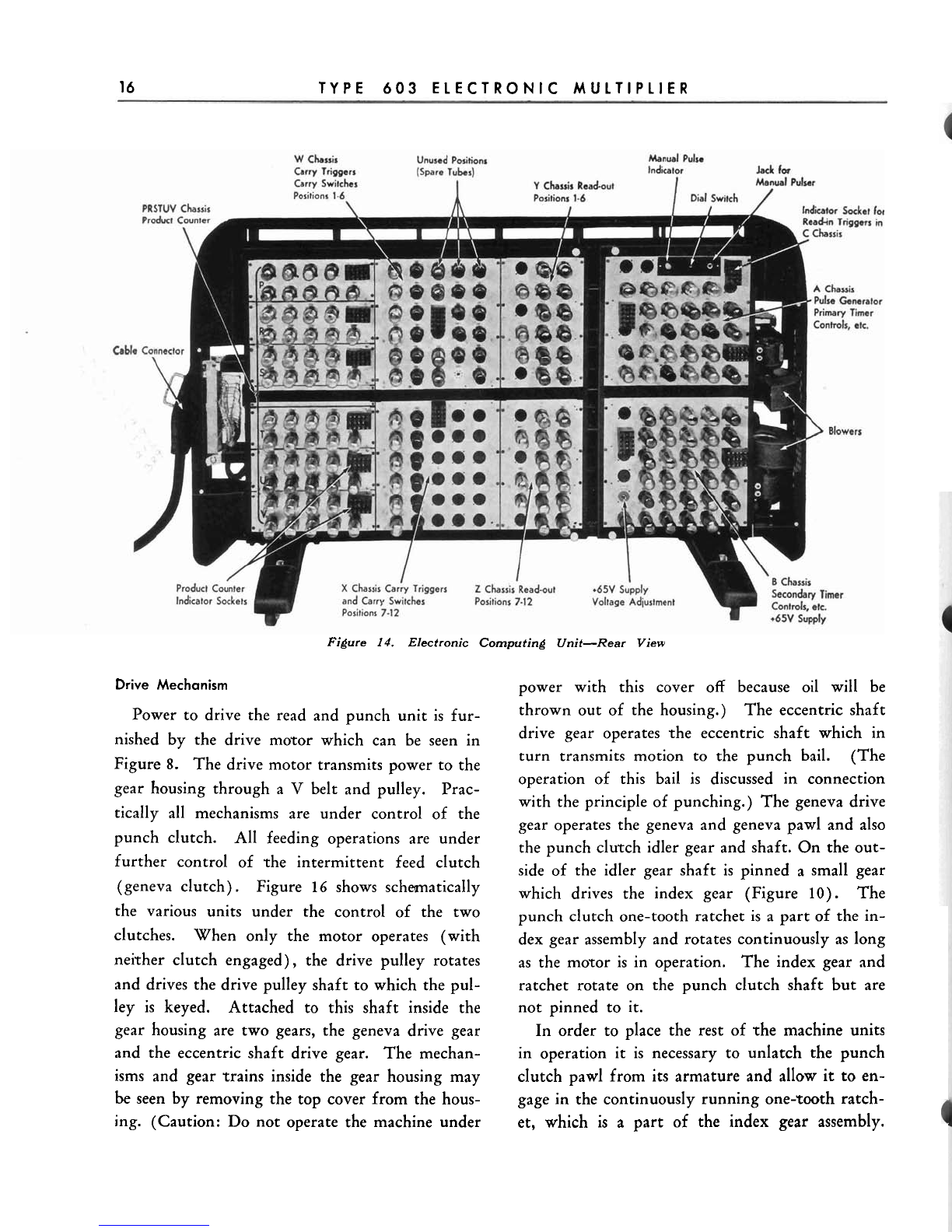

Note from Figures 13, 14 and

15

that there are

no relays in the electronic unit. Figure

15

shows

the gates open with all connections accessible. The

general function of each tube chassis is given, but

no effort will be made to discuss these further un-

til the section on

Electrical Principles.

The switch

and push buttons shown in Figure

15

are not ac-

cessible unless the large gate is open; rhey are in-

tended solely as an aid in servicing the unit. The

blowers shown are provided to cool the tubes. Over

1200

watts of heat from the filaments alone must

be dissipated. One blower is provided for each

side of the electronic unit.

MECHANICAL PRINCIPLES

15

Hopper

i

Reading Station

I

Punching Station

I

I

(Entry and Control)

I

I

Reading Station

(Checkingand

I

Gang Punching)

I

Figure 12. Schematic of Read and Punch Unit

Stacker

H

Chassis

M

Chassis

N

Chassis

Product Input lnverlers

Figure

13.

Electronic Computing Unit-Front View

16

TYPE

603

ELECTRONIC MULTIPLIER

Figure

14.

Electronic Computing Unit-Rear

View

Drive

Mechanism

Power to drive the read and punch unit is fur-

nished by the drive motor which can be seen in

Figure

8.

The drive motor transmits power to the

gear housing through a

V

belt and pulley. Prac-

tically all mechanisms are under control of the

punch clutch. All feeding operations are under

further control of the intermittent feed clutch

(geneva clutch). Figure

16

shows schmatically

the various units under the control of the two

clutches. When only the motor operates (with

neither clutch engaged), the drive pulley rotates

and drives the drive pulley shaft to which the pul-

power with this cover off because oil will be

thrown out of the housing.) The eccentric shaft

drive gear operates the eccentric shaft which in

turn transmits motion to the punch bail. (The

operation of this bail is discussed in connection

with the principle of punching.) The geneva drive

gear operates the geneva and geneva pawl and also

the punch clutch idler gear and shaft. On the out-

side of the idler gear shaft is pinned a small gear

which drives the index gear (Figure

10).

The

punch clutch one-tooth ratchet is a part of the in-

dex gear assembly and rotates continuously as long

as the motor is in operation. The index gear and

ratchet rotate on the ~unchclutch shaft but are

ley is keyed. Attached to this shaft inside the not pinned to it.

gear housing are two gears, the geneva drive gear In order to place the rest of -the machine units

and the eccentric shaft drive gear. The mechan- in operation it is necessary to unlatch the punch

isms and gear trains inside the gear housing may clutch pawl from its armature and allow it to en-

be

seen by removing the top cover from the hous- gage in the continuously running one-~00thratch-

ing. (Caution: Do not operate the machine under et, which is a part of the index gear assembly.

Table of contents

Other IBM Office Equipment manuals

Popular Office Equipment manuals by other brands

Safco

Safco Impromptu 5375 Assembly instructions

Safco

Safco Tuvi 5070 Assembly instructions

hushoffice

hushoffice hushwork.sit&stand HUS-BX-016/116 Maintenance and safety manual

Rexel

Rexel Optima 45 instruction manual

Levira

Levira FALDON Assembly instructions

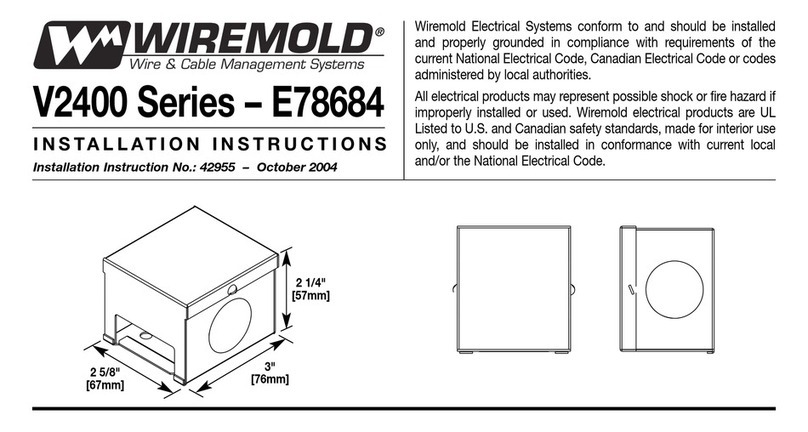

Wiremold

Wiremold V2400 Series installation instructions