Evolve EVPCP2 User manual

Evolve Customer Support available at 856/552-4000, 888/827-2500, from 8:30 Eastern through 6 Eastern time, or fax at 856/552-4001.

Page

Panels

Corner Connections – Equal Height (EVPCP2, EVPCP3, EVPCP4) 2

Corner Connections – Variable Height (EVPVP2, EVPVP3, EVPVP4) 3

Corner Connections – Corner Post Extension (EVPCEP2, EVPCEP3, EVPCEP4) 4

Inline Connection – Equal Height (EVPIC) 5

Inline Connection – Variable Height (EVPVC) 6

Notched Top Cap 7

Inline Connection – Panel Extension Module (EVPIEC) 8

End-of-Run Post Kit (EVPER) 9

End-of-Run Post Kit – Wall Mount Application 10

Electrical

Wiring Schematic 11

Power Distribution Housing (EVEPD) 12

Jumper Cables and Pass-Through Cables (EVECJ, EVECP) 13

Directional Floor Power Entry (EVEEFD) 14

Reversible Floor Power Entry (EVEEFR) 15

Ceiling Power Entry (EVEEC) 16

Duplex Receptacle (EVERD) 17

Worksurfaces

End Panel (EVHEP) 19

Corner Bracket (EVHCB) 20

Cantilever (EVHC) 21

Support Leg (EVHS) 22

Storage

Worksurface Supporting Pedestals (EVSBBF, EVSFF) 23

Overhead Flipper Door Storage Unit (EVSOF) 24

Corner Shelf (EVSSC) 25

Low-Profile Shelf (EVSSL) 26

Installation Manual – January 2001 1

Note: Any alterations to listed components will void the manufacturer's warranty. The manufacturer will

not be responsible for any damage or bodily harm caused by alterations in accordance with national or

local electrical codes and manufacturer's specifications.

In accordance with the manufacturer's policy of continual product improvement, the product presented in

this document is subject to change without notice or obligation.

Installation Sequence

Evolve Customer Support available at 856/552-4000, 888/827-2500, from 8:30 Eastern through 6 Eastern time, or fax at 856/552-4001.

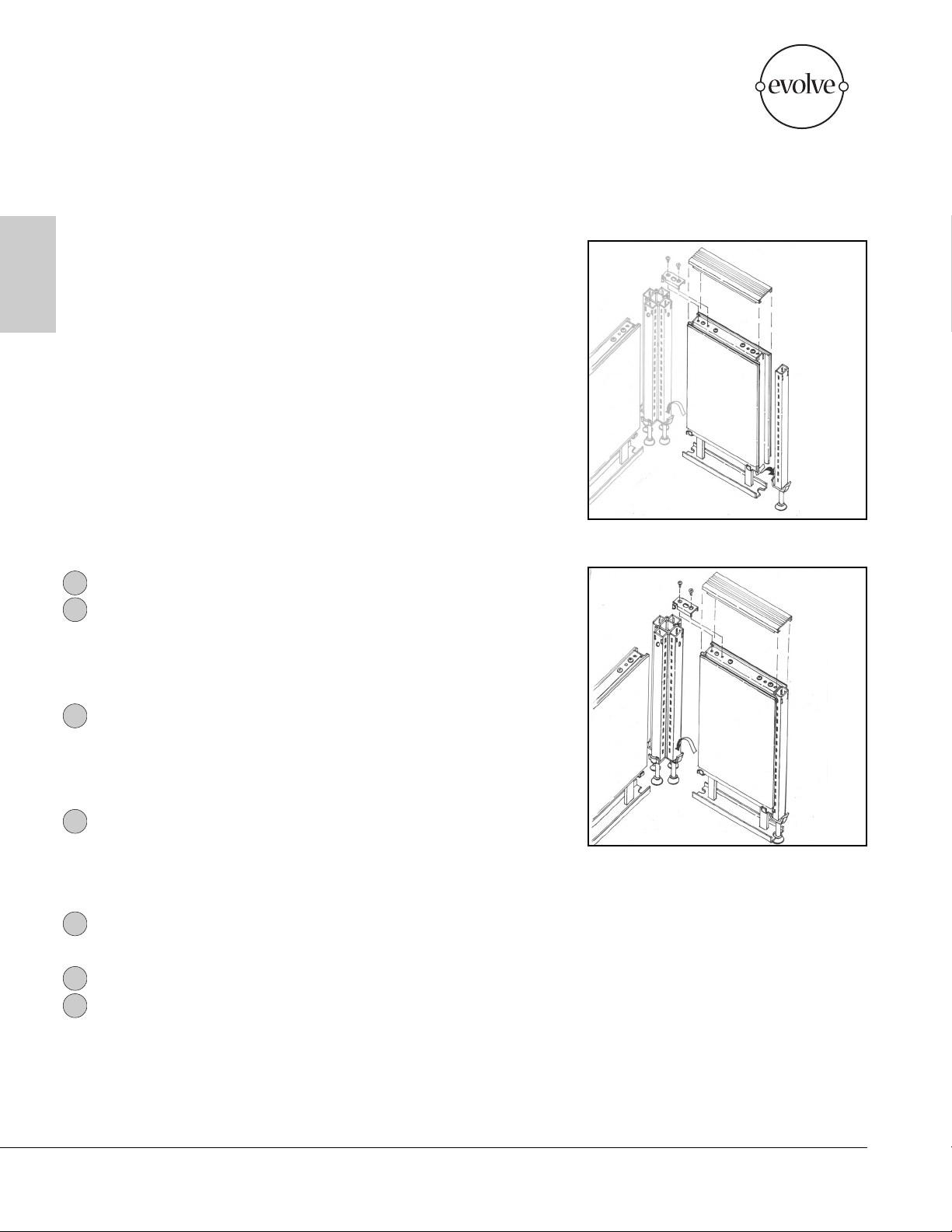

Corner Connections – Equal Height

Two-Way (EVPCP2), Three-Way (EVPCP3), and

Four-Way (EVPCP4) Corner Posts

Parts List:

1 Aluminum corner post

1, 2, 3 or 4 slotted posts with levelling glide

(attached to aluminum corner post)

1, 2, 3 or 4 single clamps

Appropriate trim

1 Top cap

Corner Posts are used to connect panels of equal height at a corner.

!

!Always start the installation of panels at a corner.

1. Remove the panel top caps.

2. Partially attach a slotted post to one end of the panel to be

installed. Do this by engaging the down-hook at the bottom of the

panel (above the raceway channel) over the up-hook on the slotted

post.

Attach the opposite end of this panel to one face of the Corner

Post by engaging the down-hook at the bottom of the panel (above the

raceway channel) over the up-hook on the slotted post. (The slotted

post is secured to the face of the Corner Post.)

3. Connect the top of the Corner Post to the panel by engaging the

single clamp through the slotted post and into the panel liner. Secure

the single clamp by bolting it to the top of the panel using two (2) quar-

ter 20 1/2" flat head screws.

4. Repeat the above procedure to attach the second, third and fourth

panel to the Corner Post.

5. Press fit the top cap down onto the top of the Corner Post.

6. Reattach the panel tops caps.

Installation Manual – January 2001

Note: Any alterations to listed components will void the manufacturer's warranty. The manufacturer will

not be responsible for any damage or bodily harm caused by alterations in accordance with national or

local electrical codes and manufacturer's specifications.

In accordance with the manufacturer's policy of continual product improvement, the product presented in

this document is subject to change without notice or obligation.

2

Panels

Panels

Installation Instructions

1

2

3

6

5

4

7

Evolve Customer Support available at 856/552-4000, 888/827-2500, from 8:30 Eastern through 6 Eastern time, or fax at 856/552-4001.

Installation Manual – January 2001 3

Panels

Note: Any alterations to listed components will void the manufacturer's warranty. The manufacturer will

not be responsible for any damage or bodily harm caused by alterations in accordance with national or

local electrical codes and manufacturer's specifications.

In accordance with the manufacturer's policy of continual product improvement, the product presented in

this document is subject to change without notice or obligation.

Panels

Installation Instructions

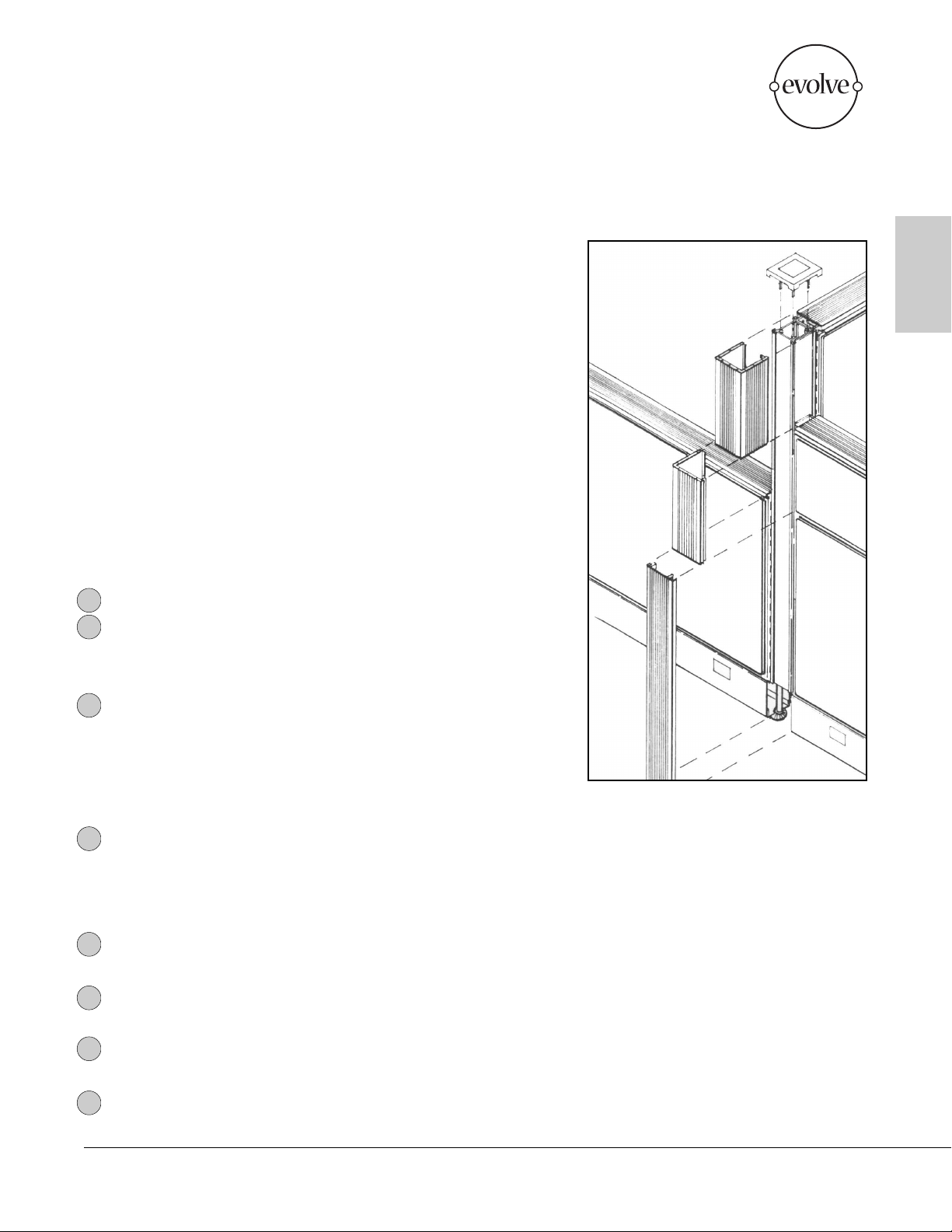

Corner Connections – Variable Height

Two-Way (EVPVP2), Three-Way (EVPVP3), and

Four-Way (EVPVP4) Corner Posts

Parts List:

1 Aluminum corner post

1, 2, 3 or 4 slotted posts of varying heights with levelling glide

(attached to aluminum corner post)

1, 2, 3 or 4 single clamps

Appropriate trim

1 Top cap

Variable-Height Corner Posts are used to connect panels of different heights

at a corner.

!

!Always start the installation of panels at a corner.

1. Remove the panel top caps.

Partially attach a slotted post to one end of the panel to be

installed. Do this by engaging the down-hook at the bottom of the panel

(above the raceway channel) over the up-hook on the slotted post.

2. Attach the opposite end of this panel to the corresponding face of

the Variable-Height Corner Post by engaging the down-hook at the

bottom of the panel (above the raceway channel) over the up-hook on

the slotted post. (The slotted post is secured to the face of the Variable-

Height Corner Post.)

3. Connect the top of the Variable-Height Corner Post to the panel by

engaging the single clamp through the slotted post and into the panel

liner. Secure the single clamp by bolting it to the top of the panel using

two (2) 1/2" flat head screws.

4. Repeat the above procedure to attach the second, third and fourth

panel to the Variable-Height Corner Post.

5. Snap the vertical corner trim pieces ("U", "L", and Flat) onto the

corner post. Start at the top and align corner trim with panel top cap.

Press fit the top cap down onto the top of the Variable-Height

Corner Post.

6. Reattach the panel tops caps.

1

2

3

6

5

4

7

8

Installation Manual – January 2001

Note: Any alterations to listed components will void the manufacturer's warranty. The manufacturer will

not be responsible for any damage or bodily harm caused by alterations in accordance with national or

local electrical codes and manufacturer's specifications.

In accordance with the manufacturer's policy of continual product improvement, the product presented in

this document is subject to change without notice or obligation.

4

Panels

Panels

Installation Instructions

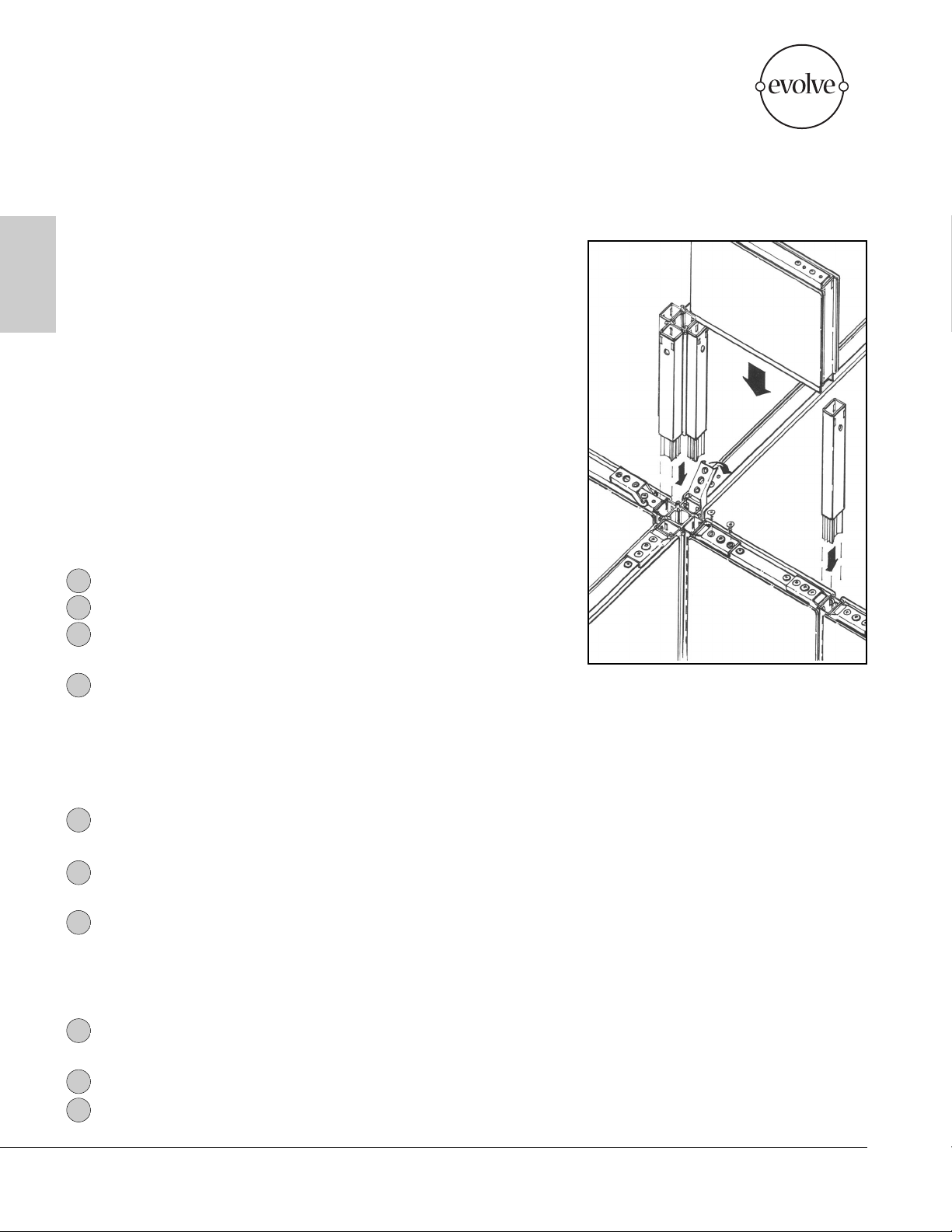

Corner Connections – Corner Post Extension

Two-Way (EVPCEP2), Three-Way (EVPCEP3), and Four-Way

(EVPCEP4) Corner Posts

Parts List:

1 Aluminum corner extension post

1, 2, 3 or 4 non-slotted posts (attach to aluminum corner post)

1, 2, 3 or 4 variable-height clamps

Appropriate trim

Corner Post Extensions are used to connect Panel Extension Modules at a

corner. The combination of one 66" panel and three 12" Panel Extension

Modules has been tested and U.L. approved. Special care should be taken

to ensure stability when exceding 90" in height.

1. Remove the post top cap.

2. Remove the panel top caps.

3. Remove the single clamp that attaches the panel to the ocrner

post.

4. Reconnect the top of the panels to the slotted corner posts by

engaging the variable-height clamps through the slotted post. Rotate the

variable-height clamps down onto the top horizontal tubes of the panels.

Secure the variable-height clamps by bolting each to a panel using two

1/2" flat head screws.

5. Insert the Corner Post Extension into the existing Corner Post,

making sure that it is fully seated.

6. Position the Panel Extension Module on top of the desired,

corresponding panel and against the Corner Post Extension.

7. Connect the top of the Corner Post Extension to the Panel

Extension Module by engaging the single clamp through the slotted

post and into the panel liner. Secure the single clamp by bolting it to the

top of the panel using two 1/2" flat head screws.

8. Repeat the above procedure to attach the second, third and fourth

panel to the Corner Post Extension.

9. Attach the Corner Post top cap.

10. Reattach the panel top caps.

1

2

3

4

5

7

6

9

8

10

Evolve Customer Support available at 856/552-4000, 888/827-2500, from 8:30 Eastern through 6 Eastern time, or fax at 856/552-4001.

This manual suits for next models

28

Table of contents

Other Evolve Office Equipment manuals

Popular Office Equipment manuals by other brands

hushoffice

hushoffice hushtwin HUS-BX-019 Maintenance and safety manual

silen

silen Space 2 Assembly manual

Middle Atlantic Products

Middle Atlantic Products LD Series instruction sheet

SHFL

SHFL DECK MATE BLACKJACK Service manual

VITRA

VITRA Stefan Hürlemann Dancing Wall Assembly instructions

BISLEY

BISLEY Glide V2 Assembly instructions