IBM 80 Installation and operation manual

Customer Engineering

Manual

of

Instruction

Issued

to:

____________

_

Branch

Office:

__________

---:-_

Department:

___________

_

Address:

____________

_

Card

Sorting Machine

If this

manual

is

mislaid,

please

return

it

to

the

above

address.

MINOR REVISION (May 1957)

This edition, Form225-8766-4,

is

a minor revision of the preceding edition

but does not obsolete Form 22-8766-3. Principal changes in this edition are:

PAGE

SUBJECT

22 to end Deletion of all material that is

in

the

82-80-75

C.B.

Reference Manual

76 Added instructions for the 978 Card

Counting Unit

© 1952, 1953, 1956

by

International Business Machines Corporation

CONTENTS

IBM

82

CARD

SORTING MACHINE

FUNCTIONAL PRINCIPLES .......................................... 5

Principle of Sorting ................................................ 7

Operating Features .................................................. 8

Switches and

Fuses

......................................... 8

Card Brush ..................................................... 9

Contact Roll Cover .......................................... 9

Commutator ...................................................... 9

Declutching Hand Wheel ............... ................ 9

Card Runout .................................. ................ 9

Pocket Stop Device .......................................... 9

Machine Operation ......................... ................ 9

Current, Weight and Dimensions ... ................ 10

MECHANICAL

AND

ELECTRICAL PRINCIPLES ........

11

Chute Blades and Sort Magnet ................................

11

Card Brush Assembly ..............................................

13

Commutator ..............................................................

14

Drive Shaft and Motor ............................................ 16

Declutching Hand Wheel........................................

17

Reverse

Lock

............................................................

17

Feed Knives .............................................................. 18

Feed Rolls ................................................................ 19

Card Levers and Contacts ........................................

21

Pocket Stop Device ..................................................

21

CIRCUIT DESCRIPTION ................................................

22

Selenium Rectifiers ..........................................

22

Duo Relays ......................................................

22

Glossary of Terms and Abbreviations ..............

23

Time Delay Relay............................................

23

Relay Gate and Electronic Chassis ...........

_......

23

Tube Filaments ................................................

23

DC Machine Circuit ........................................

23

Star~ing

a!ld

~unning

Circuits ................................

25

SortIng Circuits ........................................................ 26

General Operation ............................................

27

Oscillator and Rectifier Tube ................

...

.......

27

Static Circuit Conditions ................................

28

Firing the Trigger Tube .................................. 29

Energizing the Sort Magnet .......................... 29

Restoring

Bias

..................................................

31

Miscellaneous Components ..............................

31

E,

F,

G

Suffix

Changes ....................................

31

PURPOSE OF RELAYS, CONTACTS AND SWITCHES

32

IBM

80

CARD

SORTING MACHINE

FUNCTIONAL PRINCIPLES ..........................................

Operating Features ..................................................

Mechanical and Electrical Principles ........................

CIRCUIT DESCRIPTION ................................................

Relay Cabinet .................................

__

...............

DC Machine Circuit ......................................

Starting and Running Circuits ................................

Motor Relay and Card Control Relay ..............

Drive Motor ....................................................

Sorti~U~~~~ui~a~.~~!.~~.~

..........

~~~~

......

~

........

~~

..................

~~

..

::::::::::::::

Purpose of Relays and Contacts ............................

IBM

75

CARD

SORTING MACHINE

33

33

34

35

35

35

35

35

35

37

37

37

FUNCTIONAL PRINCIPLES .......................................... 39

Operating Features .................................._............... 40

Switches ......................._.................................... 40

Counter Reset .................................................. 40

Current, Weight, and Dimensions

...

............... 40

Mechanical and Electrical Principles ...................... 40

Card Counters

..

................................................ 40

Reset Interlock Contact ....................................

41

Counting Commutators

..

......... ......................

41

Slate

Base

Relays ............................................

42

CIRCUIT DESCRIPTION ................................................ 45

~elay

~abi!lets

and Power Supply Rectifier .... 45

CountIng Circuits ....................................................

45

Card Lever Hold Relay.................................. 45

Counter Magnets and Relays

..

........................ 46

Transfer Set Up Relay.................................... 47

Count Control Relay and Reject Counter ...... 47

Total Counters ................................................ 47

Sorting Circuits ........................................................ 47

Purpose of Relays, Commutators, and Contacts .... 47

SPECIAL

DEVICES

AUXILIARY CARD

COUNTING

DEVICE ..................

50

Circuit Description ..................................................

51

SORT SUPPRESSION DEVICE ......................................

53

Circuit Description ..................................................

53

Sort Suppression Commutator ........................ 54

Energizing the Sort Magnet ............................ 54

CARD MATCHING DEVICE ..........................................

55

Circu?tPg:~~~?Pti~~··::::::::::::::::::::::::::::::::::::::::::::::::::

~~

Sorting Detail Cards ........................................

57

Sorting Master Cards ......................................

58

Purpose of Miscellaneous Circuit Components

51:!

MULTIPLE COLUMN SELECTION DEVICE ................

59

Control Panel' ..................................................

6J

Common Digit Select:on .................................. 60

Multiple Column Selection ..............................

61

Zero-Elimination ............................._................ 62

Normal Sorting ................................................ 63

Internal Controls ......................................................

6.3

Circuit Description .................................................. 64

Normal Sorting and Common Digit Selection 64

Multiple.

Col.umi?'

Select.i~n

.................................... 64

Static

CirCUit

Condltlons .................................. 64

Sensing a Selected Value ................................ 64

Sensing an Unselected Value .......................... 64

Zero Elimination .................................................... 68

Static Circuit Conditions ................................ 68

Operation of

.the

Zero-Eliminate Control Tube 68

Circuit Cutout Relay........................................ 69

GROUP SORTING DEVICE .......................................... 70

Internal Controls ....................................................

71

Circuit

I?esc~ipti?n

......:.:.........................................

71

Static

CirCUit

Condltlons ..................................

72

Firing the MCC Tube ....................................

72

Sorting the Master Card ...............................

_.

72

Sorting Detail Cards ..................................... 72

Trailer Card Operation ....................................

75

Single Master Card Operation ........................

75

Purpose of Miscellaneous Circuit Components

75

IBM 978 CARD COUNTING

UNIT

.............................. 76

Functional Principles .............................................. 76

Introduction ...................................................... 76

Reset .................................................................. 76

Counters ............................................................ 76

Tube and Relay Storage .................................. 76

Circuits ......................................................................

77

Powe~

.

Supply:

.....:........................................... 77

ConditiOning

CirCUits

...................................... 79

Sort

Only.......

................................................. 79

Count Only...................................................... 79

Sort and Count ................................................ 82

Purpose of Circuit Components .............................. 82

Wire Contact Relays ........................................ 82

Duo Relays ..................................... ................. 82

Cam Contacts ................................................... 84

Switches ............................................................ 84

Rectifier ............................................................ 84

Resistor .................. .......................................... 84

IBM

82

CARD

SORTING

MACHINE

IBM

82

CARD

SORTING

MACI-tINI:

FUNCTIONAL

PRINCIPLES

THE THREE machines necessary

to

perform the basic

operations required in punched card accounting are the

punch, the sorter, and the accounting machine. The

punch establishes the records, the sorter arranges or

classifies them, and the accounting machine produces

the printed reports.

In

punched card accounting systems, thousands of

cards may

be

involved daily in the

taJSk

of preparing

final reports.

In

most

cases,

these cards must

be

classi-

fied

properly prior to the preparation of each report on

accounting machines. Classification of such a large

number of cards manually would present an immense

task which would consume many man hours of work

and would

be

greatly subjected to human errors.

The Type 82 Card Sorting Machine affords a speedy

and accurate method of arranging cards into any desired

sequence. The operation of the Type 82 Sorter

is

Figure 1. Card Transport Through

the

Machine

6

CARD

SORTING

MACHINE,

TYPE

82

entirely automatic, except for the removal and replen-

ishing of cards in the machine.

Sorting cards on the Type 82 machine consists of

running the cards through the machine once for each

column in the field being classified. This

is

comparable

to scanning a series of printed figures with the human

eye, except here an electric sensing brush becomes the

eye.

This brush can sort on only one column at a time.

However, it

is

movable,

so

that the operator may posi-

tion the brush to sort on

anyone

of the 80 column

positions on the IBM card. The machine

is

equipped

with

13

pockets for dispersal of cards; one pocket for

each digit value 0 through

12

and one reject pocket

for cards unpunched in the column being sorted.

By

means of feed knives, cards are

fed

one at a time

from the bottom of the pack in the card magazine on

the right end of the machine (Figure

1).

After leaving

the card magazine, they are gripped between sets of

constantly revolving feed rolls and are fed from the

right to the left of the machine.

As

the cards travel

from right to left, they first

pass

the card brush station,

2

~

112

2 2

1 3

1 2

2 1)

1 3

2 2)

2 1

1 1

1 2

2,2

2 3

2 1

2 2

Cards

in

Magazin

(in miscellaneous

order)

12

22

12

23 22

21

13 12

21

13

22

11

--~

22

21

"3" Pocket "2" Pocket "1" Pocket

Cards

now

in

order

in

units position

FIRST

SORT

e

located between the first and second sets of feed rolls.

Here the punching in the card column being sorted

is

sensed

by

means of a brush projecting through the holes

in the card and making contact on a common roll.

Sensing of card punching

at

the card brush station sets

up the proper combination of raised or lowered chute

blades at the sort magnet station, located between the

second and third sets of feed rolls. This setup

is

accom-

plished

as

the leading edge of the card

is

traveling

under the chute blades. The chute blades, according

to

their setup, then direct the' card

to

its

proper pocket

(the card

is

still being carried

by

the feed rolls).

If

a 1 punch

is

sensed at the card brush station, the

chute blade combination setup will be such that the

card will be directed to the 1 pocket.

If

an 8 punch

is

sensed at the card brush station, the chute blade

combination setup will be such that the card will be

directed to the 8 pocket.

If

no punching

is

sensed

at

the card brush station, all chute blades will remain in

a raised position, and the card will be directed

to

the

reject pocket.

g)3

1 3

1 3

2 3

1 2

2 2

1 2

2 2

1 2

2 2

2 2

2 1

2 1

1 1

2 1

Cards in

order

in u

nits

position

(in

miscellaneous 0

rder

in

tens position)

23

23

22

22 13

22

13

22

12

21

12

21

12

21

11

"2" Pocket

"I"

Pocket

Cards

in

order

in

units and tens position (sub classification)

SECOND

SORT

Figure

2.

Principle

of

Sorting

FUNCTIONAL

PRINCIPLES

7

During the time that the punching in the card

is

sensed and the proper chute blade combinations are

set up, the card

is

continually moving from right

to

left under control of the constantly running feed rolls.

Speed

and

Capacity

The speed of the Type 82 machine

is

650 to 660

cards per minute.

The

capacity of the card magazine

is

550 cards.

PRINCIPLE

OF

SORTING

Numerical Sorting

Sorting multiple digit fields when only one column

may

be

sorted

at

a time is illustrated in Figure

2.

A

group of cards, punched

11

through 23 in a two digit

field, are arranged in miscellaneous order and placed

in the card magazine of the sorter.

The

units position

is

sorted first by positioning the card brush

on

that

column and running the cards through the machine.

All cards punched with a 1 in the units column will fall

into the 1 pocket, all cards punched with a 2 in the

units column will fall into the 2 pocket, etc.

When

all the cards have been run through the

machine for sorting on the units position, the card

brush

is

shifted to the tens column position and the

cards removed from the pockets. To remove cards from

the pockets in proper sequence, the

l's

are removed

first and placed

face

down in the card magazine, the

2's are removed next and placed face down on the

l's, the 3's

face

down on the 2's, etc. This

is

common

practice but cards may be removed in descending order

by

starting with the 9's and keeping the cards face up

in the palm of the hand instead of face down. The

important item during removal

is

to keep the cards

in sequence.

After all cards have been removed from the pockets

and replaced in the card magazine, and the card brush

has been located on the tens column position, the

machine

is

restarted and sorting of the tens position

takes place. Those cards punched with a 1 in the tens

position fall into the 1 pocket, the 2's into the 2 pocket,

etc.

By

removing the cards from the pockets in ascend-

ing order

as

was

done on the first sort,

(l's

ahead of

the 2's) the original group of miscellaneous cards will

be

found to be in numerical sequence froni

11

to 23.

The sorting process could be illustrated further

by

the

use

of a larger field, but from the foregoing example

it will

be

observed that, upon completion of the second

sort, all cards will appear in groups arranged in correct

numerical sequence.

The procedure for sorting cards to arrange them in

proper sequence according to major and minor classi-

fications follows the same general principle.

If

the above

mentioned two-digit numbers were subclassifications and

another one-column field were a major classification,

the next sort for major classification would bring these

groups together, and the subclassifications would be

in order within each group

as

illustrated in Figure 3.

A general rule to be kept in mind

is

that the sorts

for the minor

or

subclassifications are made first and

the

SOrts

for the major classifications are made last.

Alphabetic Sorting

Sorting cards containing alphabetic information into

alphabetic sequence necessitates the double sorting of

each column, since each letter

is

recorded by two holes

in a single column, one of which

is

12,

11

or 0 and

the other a digit from 1 to

9.

For example, the letter

A

is

indicated

by

punched holes in the 12 and 1 posi-

tions of a given column.

1523

522

1323

522 422 322

521

421

321

513 412 313

512 411 312

"5"

Pocket

"4"

Pocket

"3"

Pocket

Major! Sub

3)

! 2 3

5

12

3

1

5

12

2

4

12

2

3

12

2

1

12

2

4

'2

1 1

'2

, 1

3

12

1

: 1 3

i 1 3

: 1 2

: 1 2

,

, 1 2

4Y:

1 1

Cards

in

Maga

zine

by(cards

in

order

sub

classificatio

n

ne~us

but

in

miscella

order

by

major

classification)

Cards now

in

order

by sub

and

major classification

SORTING

BY

MAJOR

GROUPS

Figure

3.

Principie

of

Sorting

8

CARD

SORTING

MACHINE,

TYPE

82

The cards are sorted in the normal manner

accord-

ing to the digits 1 to 9 in the first column to

be

sorted.

The

zone

contact bar on the commutator (Figure

4)

is

then moved

to

the center of the commutator and

the complete sorting operation repeated on the

same

card column. Positioning the

zone

contact bar in this

manner suspends sorting for all values of punching

except 0,

11

and 12. Those

cards

which fall in the

12

pocket will contain the letters A to I

in

alphabetic

sequence; those in the

11

pocket, the letters J

to

R;

and those in the °pocket, the letters S to Z. Succeeding

columns are each sorted in the

same

manner

as

above;

the digits 1

to

9

first,

followed

by

sorting of the zone

punchings 0,

11

and 12. When cards

are

removed

from the pockets following a

zone

sort, the

12

zone

cards should be placed

face

down

in the card magazine,

the

11

zone

cards next; and the °

zone

cards

last in

preparation for digit sorting on the next column.

In

most

cases,

it

is

not necessary to sort on all columns

of a name field to place the cards in alphabetic order.

Usually sorting on the first three or four characters in

a group of names will

be

sufficient.

OPERATING

FEATURES

REFER

to Figure 4 for the location of the major oper-

ating features.

Switches

and

Fuses

There are 3 operating switches located on the front

right end of the machine. The main line switch, when

turned

on,

furnishes power to the machine and

com-

Fi4ure 4. Operatinl1 Features

FUNCTIONAL

PRINCIPLES

.,

pletes a circuit to the filaments of the tubes.

It

also

completes a circuit to the time delay relay.

The start button, when depressed, sets up circuits

which energize the drive motor, and it causes the

ma-

chine

to

operate. The start button

is

ineffective for

approximately 50 seconds after turning on the main

line switch because of the delay caused

by

the time delay

relay. This delay

is

necessary to allow the electron tube

filaments to reach proper operating temperature before

the machine

is

started.

The stop button causes immediate stopping of the

machine.

When

the

stOP

button

is

depressed, the run-

out feature of the machine

is

rendered inoperative, and

the machine stops

as

soon

as

its inertia

is

overcome

by

friction.

The fuses are located on the inner side of the right

hand lower cabinet assembly in the position shown in

Figure

1.

Card

Brush

The card brush senses the punching in the card.

It

may be set on any column to

be

sorted

by

rotating the

card brush lifting handle near the front of the card

magazine. Each rotation of the handle moves the brush

one column. The brush may

be

moved across several

columns

by

rotating the handle to the upper position

and sliding the brush holder to the desired column while

pressing down the finger lever at the top of the brush

assembly. A column indicator guide and pointer

is

located above the brush in a position readily visible

to the operator for convenient setting of the brush on

the column to be sorted.

Contact

Roll

Cover

The plastic cover.over the contact roll must

be

down

before the start key can become operative. This

is

a

safety cover which operates two microswitches. Open-

ing of these microswitches when the contact roll cover.

is

raised interrupts the running and sorting circuits.

Commutator

On

the front end of the first lower

feed

roll

is

a

commutator on which

12

contact bars (one for each

vertical position in the card) and an alphabetic zone

bar are mounted. The contact bars on the commutator

are accessible through the large hole

in

the switch plate.

When

all of the commutator contact bars are toward

the outside of the commutator, all holes punched in

the card column being sorted are sensed and cause the

card to sort to its proper pocket. However,

if

the 4 and

ocontact bars, for example, were moved to the center

of the commutator, sorting of 4's and

O's

would be

suspended. Any 4 or 0 punching in the card column

being sorted would not be sensed and the card would

feed

to the reject pocket just

as

though it were un-

punched. Sorting of all other digits would be normal.

1£

the zone contact bar (red bar)

is

moved to the

center of the commutator, sorting will be suspended

for all punching except 0,

11

and 12.

That

is,

those

cards that have no 0,

11

or

12

punching in the column

being sorted, will be fed to the reject pocket

as

though

they were unpunched.

Declutching Hand Wheel

A declutching hand wheel

is

provided for turning

the machine over

by

hand to check adjustments and

timings. This hand wheel

is

located on the right end

of the machine and, when rotated in a clockwise direc-

tion, causes the main drive shaft and its gears to revolve.

The handwheel must be pressed

to

the left while

it

is

being revolved before the main worm shaft will

rotate.

When

the machine

is

operating under power,

the handwheel

is

automatically declutched to keep

it from revolving and presenting a hazard.

Card Runout

When

the card magazine becomes empty while the

machine

is

in operation, a runout feature incorporated

in the machine keeps the drive motor running for a

long enough period of time to allow all cards to feed

to

their proper pockets.

On

older sorting machines

this

runout feature was not present, making it necessary in

many cases to depress the start

key

long enough to feed

the last

few

cards into their proper pockets.

Pocket Stop Device

Each pocket of the sorter

is

equipped with an auto-

matic pocket stop. This

is

a safety device which auto-

matically shuts

off

the current and stops the machine

when

anyone

of the thirteen pockets becomes filled to

capacity with cards. Each pocket has a capacity of

approximately 550 cards. Once the machine has been

stopped

by

the activation

of

the pocket stop device, it

can not be restarted

by

means of the start key until

the full pocket or pockets have been emptied.

Machine Operation

The main line switch should be turned on first to

allow time for the tubes to heat up while other prepara-

tions for starting are

being

completed.

10

CARD

SORTING

MACHINE,

TYPE

82

Prior

to

placing cards in the card magazine, they

should be carefully joggled against the glass top frame.

Cards are then inserted in the magazIne,

face

down with

the 9 edge to the left.

Do

not drop or force the cards

into the magazine. Check to

see

that the edges of the

cards are even to assure free movement within the

magazine. Place the card weight on top of the pack

to insure proper feeding

of

the last

few

cards.

After the cards have been placed in the card maga-

zine, the card brush should

be

positioned on the proper

, card column. The contact bars on the commutator

should

be

checked to

see

that they are in the contacting

or

OUT

position if desired,

so

that all holes punched in

the card column will be sensed

by

the card brush. The

contact roll cover must be down before the start

key

can become operative.

Assuming that all of the above conditions have been

satisfied, the start

key

may

be

depressed to cause the

machine

to

operate. This key must be held depressed

until the cards have reached the third set of upper feed

rolls, thus dosing all card lever contacts. Once cards

have reached this position in the machine, it will con-

tinue

to

operate automatically until the card magazine

has been emptied of cards, one or more pockets become

full, or the stop

key

is

depressed. The contact roll cover

----

Voltage Group Maximum

Operating Current

Amperes

Volts

Cycles

Phases

1/2

HP

1/3

HP

115

DC

5.0 5.0

230 DC 3.0 3.0

115 25 1 6.5 6.0

115 50 1 7.0 6.5

115 60 1 6.5 6.1

230 25 1 3.7 3.5

230 50 1 4.0 3.9

230 60 1 3.7 3.5

208 60 1 4.0 3.8

230 25 3

2.1

2.0

230 50 3 2.3 2.2

230 60 3 2.1 2.0

must not

be

raised while the machine

is

in operation

since this may

cause

mis-sorting

as

the machine comes

to a stop.

Care should be exercised when adding cards to the

card magazine while the machine

is

operating. Do not

jar the pack of cards already present in the machine

and do not add any cards jf the pack of cards present

in the machine

is

small; either procedure may cause

the machine

to

jam.

Current,

Weight,

and

Dimensions

See

the table below for the operating current, starting

current and

fuse

rating of the Type

82

machine.

NOTE:

Some Type 82 machines were produced using

Y2

HP

motors equipped with fusetrons instead of

fuses.

In

the

case

of these machines,

-the

fusetron racing listed

under the 1/3

HP

heading may be used

as

these values

give enough safety factor due to their time lag char-

aoreristJic.

Weight unpacked -

Weight packed

Length

Width

Height - - - - - - -

530 pounds

785

pounds

61

inches

16

inches

46 inches

Maximum

Starting Current Main

Fuses

Amperes Ampere Rating

1/2

HP

1/3

HP

1/2

HP

1/3

HP

Fuse

Fusetron

42.9 36.9

12

5.0

21.9 18.9 6 3.2

38.9 26.7

12

8.0

37.9 25.6

12

8.0

39.9 26.9

12

8.0

18.6 13.5 6 4.0

19.1 13.0 6 4.0

20.1 15.0 6 4.0

18.2 16.6 6 4.0

12.7 8.4 6 2.5

14.6

9.9

6 2.5

13.2

9.1

6 2.5

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

THE

REAR cover assembly and the covers on the right

and left ends of the machine are each held in place

by

means of concealed latches. These latches may

be

released

by

pressing on the latch cover plate.

The cover over the switch plate

is

hinged at the

bottom and held in place

by

a holding screw at the

upper right hand corner. The right end cover must

be removed before this holding screw

is

accessible.

Four adjustable levelers are furnished with each

machine for the purpose of leveling the machine and

to eliminate excessive vibration caused

by

an uneven

floor surface.

Chute Blades

and

Sort

Magnet

In

Figure 5, a card

is

shown passing between the

card brush and the contact roll just after it has been

fed

from the bottom of the pack in the card maga-

zine. The leading edge of the card

is

passing under

the tips of the chute blades and the card brush

is

wiping across the face of the card in search of punched

holes in the column being sorted.

The

chute blades are formed strips of tempered

spring steel, varying in length, from the opening of

each pocket to a position resting on the top of the

Fi~ure

5.

Sensin~

the

Card

11

sort magnet armature. There are two styles of chute

blades in

use.

The old style blade

is

.008" thick and

the new style blade

is

.009" thick. The .009" blade

has better wearing qualities than the .008" blade.

Each blade

is

numbered according to the pocket to

which it guides the card.

In

guiding a card to the

proper pocket, the card rides immediately over the

chute blade for that pocket.

Assume that a 4

is

punched in the column on which

the card brush

is

set. The chute blades are

so

arranged

that when the card has advanced to the position where

the card brush makes contact with the contact roll

through the 4 hole, the leading edge of the card will

have passed under the 9, 8, 7, 6, and 5 chute blade

tips

as

shown in Figure

6.

In

passing under the chute

blades, the card separates them from the sort magnet

armature.

As

soon

as

contact

to

the contact roll

is

made

by

the card brush, circuits are completed which energize

the sort magnet. Energization of the sort magnet at-

tracts the sort magnet armature. This armature

is

normally held in a raised position away from the

magnet cores (Figure

6)

by

means

of

a return spring.

As the armature

is

attracted, the 4,

3,2,

1,

0,

11, and

12 chute blades follow it down because of the spring

tension

on

the blades; but the 9, 8, 7, 6, and 5 chute

blades are held up by the card, thereby creating an

opening between the 5 and 4 blades (Figure

7).

The

feed rolls convey the card through this opening (over

the 4 blade and under the

5)

towards the 4 pocket.

As

the card nears the 4 pocket, travelling between the

4 and 5 chute blades, it strikes a formed ear on the

under surface of the 5 blade which guides the card

into the 4 pocket.

As

the card travels into the pocket,

a deflector spring (Figure

8)

is

pushed upward by

the card; then

as

the card leaves the feed rolls, the

tension of this spring deflects the card downward. This

action causes proper stacking of the card

as

it

is

free

of any drive which might cause it to stand on edge.

An armature knockoff screw insures the return of

the sort magnet armature to its normal position before

the next card

is

read (Figure

7).

The

knockoff screw

is

rotated counterclockwise (as shown by the arrow)

12

Pock.t

12

Pock.t

Card

Brush

insulated

Sort

Magnet Armatur.

·up·

just

before Magne

..

are

energized

Reject

Pocket

','

"

"

Fi~ure

6, Position

of

Chute

Blades Prior to

Sort

Magnet

Energization

Sort Magnet Armature energized

Reject Pock.t

Figure

'1,

Position

of

Chute

Blades

After

Sort

Magnet

Enerl1ization

12

" Hole

in

Card

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

13

Figure 8.

Cards

Entering the Pockets

and

is

mounted on the third lower feed roll shaft,

which

is

driven from the main worm shaft and makes

one revolution per card cycle.

It

is

timed

to

knock

off

the armature between the

12

position of one card

and the 9 position of the following card. Although

the return of the sort magnet armature

is

spring actu-

ated, the knockoff screw

is

provided to overcome any

residual magnetism present in the sort magnet.

If

the card fed

is

unpunched in the column being

sorted, the card brush fails

to

make contact with the

contact roll; therefore, the sort magnet

is

not ener-

gized and

its

armature

is

not attracted. Consequently,

the card

is

fed

under all the chute blades and deflected

into the R (reject) pocket.

Card

Brush

Assembly (Figure

9)

It

will

be

noted

by

referring to Figures 6 and 7

that the card brush makes contact on the contact roll

through the hole in the card. This sets up circuits

which cause energization of the sort magnet.

Figure 9.

Removing

the Card Brush' Assembly

14

CARD

SORTING

MACHINE,

TYPE

82

The card brush·may be positioned at

any

column

desired through manual operation of the card brush

lifting handle and the finger lever on the index head

rack holder (Figure

4).

During a sorting operation,

it

is

necessary that the card brush lifting handle be

in a position with

its

handle downward,

as

this allows

the card brush to rest on the contact roll for the pur-

pose of reading the card.

When

the card brush lifting handle

is

rotated one-

half turn from its normal downward position, the

card brush assembly

is

raised clear of the contact roll

by

means of a cam pinned on each end of the worm

screw (Figure

9).

These

cams

operate against rollers

to raise the worm

screw.

The worm

screw

is

normally

held down

by

means of a compression spring on each

end.

Rotation of the card brush lifting handle one-half

turn not only raises the brush to clear the contact

roll, but also disengages the index head stop locator

from the index bar rack. This

is

necessary if the brush

assembly

is

to be moved. For one column movement,

one complete revolution of the lifting handle

raises

the

brush, disengages the index head stop locator, moves the

brush one column through the lead of the worm, and

lowers the brush to the contact roll

as

the index head

stop locator seats in the adjacent index bar rack tooth.

Rotation of the card brush lifting handle in a clock-

wise

direction moves the brush toward the rear of

the machine. Rotation of the handle counterclockwise

moves the brush toward the front of the machine.

To move the card brush assembly a distance of

several columns or more, the lifting handle

is

rotated

one-half turn to

its

raised position.

As

stated above,

this raises the brush from the contact roll and disen-

gages the index head stop locator from the rack.

By

depressing the finger lever on the index head rack

holder, the index head locating nut

is

then disengaged

from the worm

screw.

This

is

a half nut and

is

nor-

mally held engaged with the worm screw

by

means of

a spring. Disengaging the index head locating nut

from the worm screw allows free movement, in either

direction, of the complete index head and brush holder

assemblies

as

a unit. Releasing the finger lever after

the desired movement has been completed again

en-

gages the locating nut with the worm

screw,

and

returning the lifting handle to

its

downward position

readies the brush for sensing the card.

Brush

Block

l!Iongated

Holes

Here

Brush

_----1-

Brush

Holder

F;~ure

10. Card

Brush

Holder

Assembly

A spring operated contact plunger (Figure 10)

provides the means of electrical connection between

the brush holder and an insulated contact rail. The

contact rail extends from front to rear over the entire

range of the card brush (Figure

9)

furnishing a con-

nection

to

the card brush regardless of the column

being sorted. A square end brush (part number 202)

is

used

and

is

held secure in the brush holder

by

means

of a locking screw (Figure

10).

Figure 9 indicates the procedure for removing the

card brush assembly. First, the lifting handle

is

turned

one-half revolution to

its

upper position. The locking

lever on the brush

is

then raised until it points

directly towards the left end of the machine. This un-

locks the brush assembly, allowing it

to

be removed

by

pulling it out to the left.

Commutator

The commutator assembly

is

mounted on the front

end of the first lower feed roll shaft. The function of

this assembly

is

to act

as

an electrical cam contact in

the card brush circuit and, in conjunction with the

card brush, to establish the timing of the impulses

which energize the sort magnet.

The commutator makes one complete revolution

for each card cycle; a card cycle being the distance

from the leading edge of one card to the leading edge

of the following card.

As

cards are

fed

from the maga-

zine they are separated

by

a distance of

%"

(Figure

11

).

The width of a tabulating card

is

3

~";

there-

fore, the distance from the leading edge of one card

to the leading edge of the following card

is

4".

The

distance between punching positions on a card

is

~",

center to center of the holes.

As

this distance of

~"

is

considered one point in the card cycle, the entire

card cycle then becomes a 16 point cycle (4-7-

~

=16).

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

15

Fillure 11. Card Spacing

However, the sort magnet can

be

energized only on

12 points of this cycle. These 12 cycle points corres-

pond

to

the 12 punching positions on the card. The

remaining four cycle points represent the distance

from the

12

hole of one card

to

the 9 hole of the

following card.

Figure

12

shows a commutator disassembled. Note

the

13

contact spots near the center. Twelve of these

spots, each adjacent to the other, are internally con-

nected

to

the twelve segments on the inner (lower)

ring. Nine of these spots, representing the digits 1

through 9, may be connected

to

the digit common on

the extreme outer (upper) surface of the commutator

by

means of the individual contact bars, the operation

of which

is

shown

in

Figure 12. 'The other three spots,

representing the

0,

11

and

12

values, may be con-

nected directly to the main common (outer) ring

by

means of their individual contact bars.

The thirteenth contact spot

is

internally connected

to

the digit common and,

by

means of its contact bar

(zone contact

bar),

maybe

externally connected to

Figure 12.

Commutator

Assembly

16

CARD

SORTING

MACHINE,

TYPE

82

the main (outer) common ring. Note that

if

the zone

contact bar

is

in its retracted position, the digit com-

mon

is

not connected

to

the main common.

By

re-

tracting the zone contact bar, sorting of all digit values

1 through 9

is

suspended and only 0, 11, and 12 values

are sorted.

There are three division points

on

the periphery

of

the commutator; the inner, center, and outer rings.

Three contact brushes ride on this periphery, one to

contact each ring (Figure

11).

The inner ring con-

sists of

12

insulated segments corresponding to each

value in the card and internally connected to the 12

contact spots

as

mentioned above. The commutator

is

timed to the machine in such a manner that, when

the card brush makes through the 4 hole in the card

for example, the inner commutator brush will be mak-

ing contact

on

the 4 segment. The center and outer

rings are commoned together. The outer (common)

ring extends around the complete circumference

of

the commutator. The center ring extends around

approximately three fourths of the commutator cir-

cumference; the other one fourth

is

insulation.

When

a hole

is

sensed in the card, a circuit

to

fire

the

OA4G

trigger tube

is

first completed through the

commutator from one of the 12 segments on the inner

ring to the outer

or

common ring through the com-

mutator contact brushes and the contact bar for that

position.

As

soon as the trigger tube has been fired, a

holding circuit

to

maintain conduction in the tube

is

completed from the center brush

to

the outer brush.

Firing the trigger tube removes the negative bias

on

the sort magnet control tubes and allows them to

energize the

SOrt

magnet. Furnishing a hold circuit to

maintain conduction

in

the trigger tube keeps the sort

magnet energized until the center brush breaks con-

tact

on

the center ring. This occurs after the 12

position on the card has passed under the card

brush, thus completing the sensing of any holes

in

that card column.

If

two holes are present in a column being sensed,

and no provisions are made by means of the contact

bars

on

the commutator to suspend sorting

of

one

value, the card will sort according to the first value

sensed by the brush.

When

the reading brush

is

resting on the bare con-

tact roll between cards, no circuit

is

available to fire

the trigger tube because both the inner and center

commutator brushes are

on

insulated portions

of

the

commutator.

Drive Shaft and

Motor

Mounted

on

the rear of the machine

is

a horizontal

drive shaft which transmits power from the motor to

drive the card feed mechanism, the feed rolls, and the

contaot roll.

The

drive motor is

10C3Jted

under the

base

on

the left end

of

the machine and

is

connected

Figure

13.

Main

Drive

Shaft

and

Pocket

Stop

Shaft

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

17

to the drive shaft

by

means of a V belt and pulleys.

Variations in machine speed are obtained

by

adjusting

the variable speed pulley on the drive motor. The

motor mounting

is

adjustable vertically and can be

pivoted in an arc for the purpose of regulating belt

tension and alignment. The complete motor and

mounting assembly

is

easily removed for repair or

renewal.

The drive shaft extends over the length of the

machine approximately on a level with the card line

(Figure

13).

Worms cut at intervals on the shaft

are used for the purpose of gearing to the

feed

roll

shafts, which run at right angles to the drive shaft.

Except for the first 3

sets

of feed rolls, only the lower

feed rolls are gear driven; the upper rolls are friction

driven from the lower rolls. Located at the right end

of the drive shaft (rear view)

is

a thrust bearing which

aids in absorbing the thrust developed in the shaft.

This bearing must be kept well lubricated.

Declutching Hand Wheel (Figure 14)

Mounted on the left end (rear view) of the drive

shaft

is

a hand wheel which

is

used

to turn the drive

shaft over manually when checking machine adjust-

ments and timing. The hand wheel

is

normally

dis-

engaged from the drive shaft

as

it

is

cammed

to

the

left (rear view)

by

the pin in the shaft striking the

ratchet teeth on the handwheel

as

the shaft revolves.

In

this manner, the handwheel

does

not turn when

the machine

is

in operation, thus eliminating a possible

safety hazard. To revolve the shaft

by

hand, it

is

necessary to push the handwheel farther onto the

shaft while turning it clockwise, causing the ratchet

teeth to engage the pin.

A housing over the end of the horizontal shaft

is

held in place

by

four

screws.

The handwheel

is

re-

tained in this housing

by

a ring type expansion spring

around its shank. This spring expands into a shallow

channel inside the housing when the shank of the

hand wheel

is

inserted in it. A beveled edge on the

housing

aids

in compressing the spring to facilitate

inserting the shank of the handwheel.

If

it

is

desired

to remove the hand wheel, a sharp rap to the left

(rear view) with a mallet or hammer handle will

cause compression of the retaining spring and allow

it to slip through the smaller opening at the end of

the housing. Figure 14 shows the housing removed

and the handwheel inserted over the end

of

the shaft.

Figure 14.

Declutching

Hand

Wheel

Reverse Lock (Figure 15)

Machines may be equipped with a reverse lock on

the pulley end of the drive shaft which prevents the

possibility of turning the drive shaft backwards and

caus-

ing damage to the commutator and card brushes. This

Figure 15.

Reverse

Lock

18

CARD

SORTING

MACHINE,

TYPE

82

reverse lock

is

in the form of a ratchet knurl cut on the

rim of the drive pulley. A locking pawl operates against

the pulley when the force of motion

is

in a clockwise

direction (viewed from the pulley

end),

thus preventing

any actual rotation of the pulley.

When

the direction of

rotation

is

counterclockwise (viewed from the pulley

end),

the locking pawl

is

held away from the knurled

edge through the action of the pawl operating arm.

The pawl operating arm

is

actuated

by

a friction contact

with the drive pulley. The knurled teeth on the rim

of the pulley are fine enough to prevent any appre-

ciable motion when the reverse lock operates. Any older

Type 80 machines which are not equipped with the

declutching type of handwheel should have a reverse

lock mechanism.

Feed

Knives

(Figures 16, 17, 17A)

The

feed

knives, in conjunction with the roller

throat assembly, are designed to feed one card at a

time from the card magazine. The roller throat

assem-

bly consists of a vertical knife whose lower edge

is

set parallel

to

a cylindrical steel roller. The throat

assembly

is

adjusted to allow the passage of only one

card at a time through an opening between the knife

. edge and the roller. The roller assembly

is

equipped

with small oil wicks for continuous lubrication.

Power to operate the

feed

knives

is

obtained from

the main drive shaft through the card

feed

worm gear

Figure

16.

Card

Magazine

Figure

17A.

Feed

Knife

Drive

located near the handwheel (Figure

13).

This large

gear drives a crank shaft which,

by

means of a con-

necting link, transforms the rotary motion of the

crankshaft to reciprocating motion of two feed levers.

One feed knife slide assembly

is

engaged with each

feed

lever and,

as

the

feed

levers reciprocate, the

feed

knife slide assemblies travel back and forth in porous

bronze guides. Their speed of travel

is

1300 strokes

per minute, thus enabling them to feed 650 cards

per minute, one with each stroke to the left.

The component parts of a feed knife slide

assem-

bly are shown in Figure 18. The knife holder

is

adjustable laterally in relation to the feed knife slide

and the

feed

knife

is

adjustable vertically' for the

proper projection. (Carbolloy

feed

knives are not

ad-

justable.) The knife slide pin furnishes the means of

engagement with the feed levers. The knife slide pins

are available in two

sizes;

a standard

size

and an over-

SIze

to

compensate for wear.

Since there

is

no latching point in the drive of a

sorter, the

feed

knives may come to rest at any stage

of their

feed

or return stroke when the machine

is

stopped. Upon starting of the machine, however,

that

feed

knife stroke which

was

interrupted will

be

completed and,

as

the

feed

knives make their first

full length stroke to the left, one card will be picked

up

from the bottom of the pack in the card maga-

zine. This card

is

fed

through the roller throat and

between the first set of

feed

rolls

by

the movement

of the feed knives to the left (Figure

17).

As

soon

as

the card

is

·firmly

gripped between the first set

of

feed

rolls, the

feed

knives start their return stroke

MECHANICAL

AND

ELECTRICAL

PRINCIPLES

19

Upper Front Card Guid" Throat

Knife

Rear Card Guide Post

__

J«---t-l1

Connecting

Link

Continuou.ly running Feed

RollI

Fi~ure

17.

Feed

Knife

Operation

to

pick another card from the bottom of the pack.

While the knives are returning, the

first

card con-

tinues its travel to the left under control of the

continuously running

feed

rolls. The stroke of the

knives

is

so

timed that,

as

the trailing edge of the

first

card leaves the magazine, the second card

is

Feed

Knife

SlideAssembly

Knife

Slide

Adjulting

Stud

~

~~~

cO

~j~

Card

Feed

Knife

Feed

Knife

Holder

Fi~ure

18.

Feed

Knife

Slide

Assembly

picked

up

by

the knives and

is

fed through the

throat, following the first card

by

a distance of

%0".

This

process

is

repeated for the feeding of all cards.

Feed

Rolls

(Figure 19)

The

feed

rolls furnish the means of recelvmg the

cards from the feed knives and transporting them

past the card brush and sort magnet stations and on

to their proper pockets. There are fifteen sets of feed

rolls in the machine. The

first

three sets nearest to

the card magazine differ somewhat from the other

twelve.

All the upper

feed

rolls consist of two rubber rolls

pressed on a steel shaft. The first 3 upper rolls are

driven

by

19-tooth worm gears meshed with the drive

shaft. The remaining

12

upper rolls are not direct

driven, but are driven

by

friction from their matching

lower rolls. Except for the second position, each lower

feed

roll consists of two steel rolls pressed on a steel

shafr. At the second position, the lower feed rolls con-

sist of two small auxiliary rolls mounted

on

separate

shafrs and bolted to the side frame. These auxiliary rolls

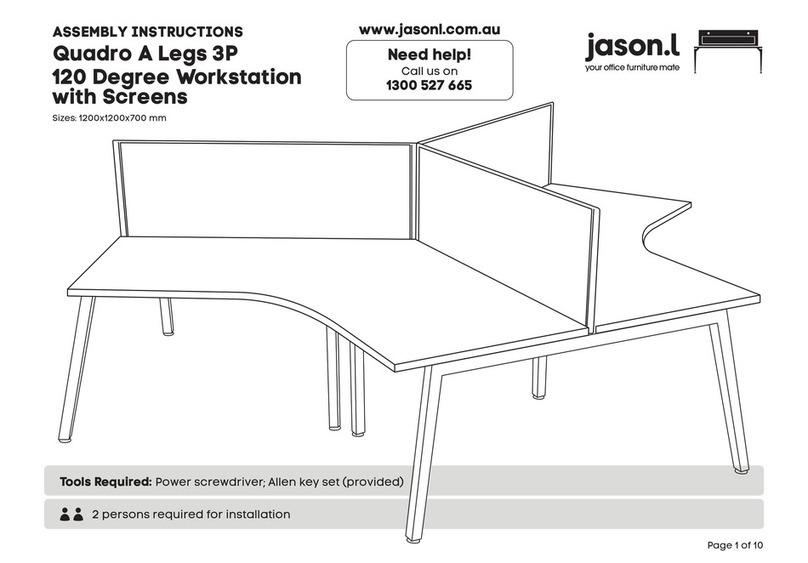

This manual suits for next models

2

Table of contents

Other IBM Office Equipment manuals

Popular Office Equipment manuals by other brands

Fellowes

Fellowes QuasarE 500 manual

Renz

Renz TC 20 quick start guide

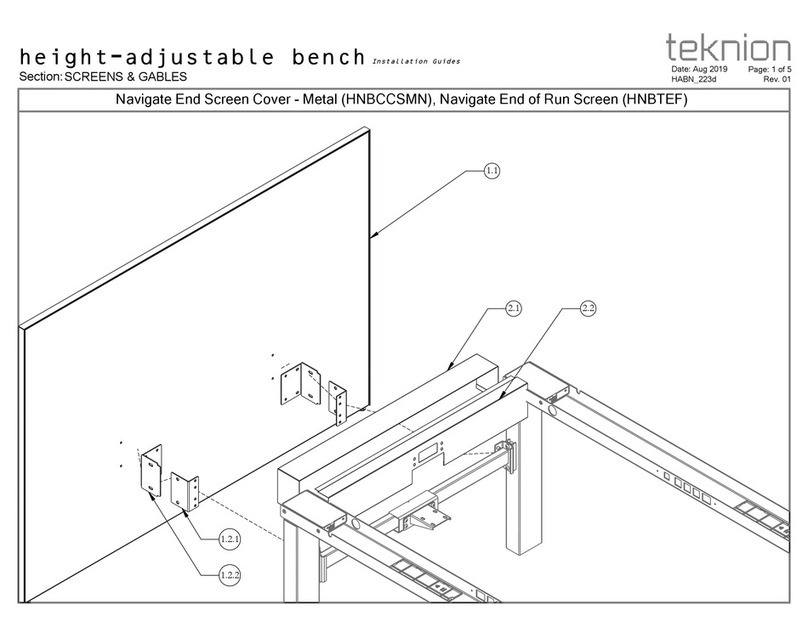

Teknion

Teknion HNBCCSMN quick start guide

Bush Business Furniture

Bush Business Furniture WC65570 Assembly instructions

Dauphin

Dauphin Syncro-Automatic @Just magic2 Series owner's manual

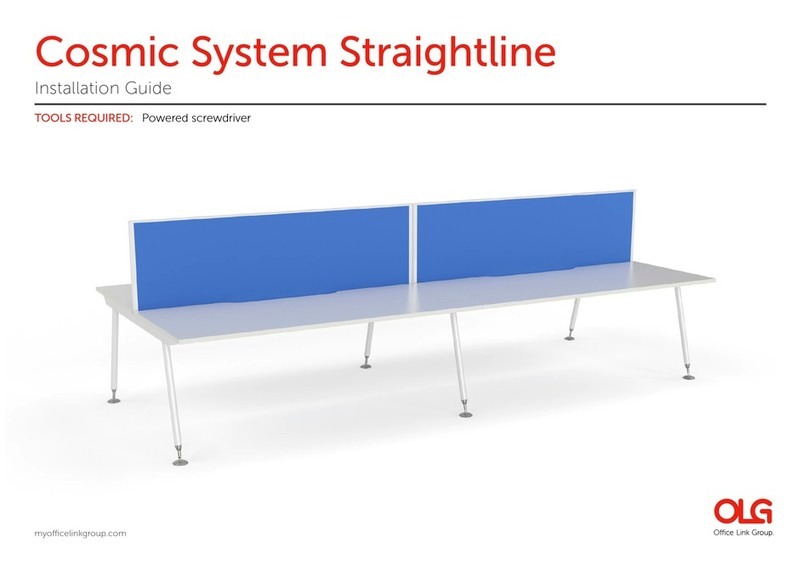

OLG

OLG COSMIC SYSTEM STRAIGHTLINE installation guide