IBM 353 User manual

Other IBM Storage manuals

IBM

IBM Internal ZIP Drive User manual

IBM

IBM 3350-A2 User manual

IBM

IBM OPTIONS TR-7 User manual

IBM

IBM DS3950 Manual

IBM

IBM Elastic Storage System 3200 User manual

IBM

IBM DS8000 - ADDITIONAL INFORMATION User manual

IBM

IBM 8275-416 Reference guide

IBM

IBM totalstorage 200 User manual

IBM

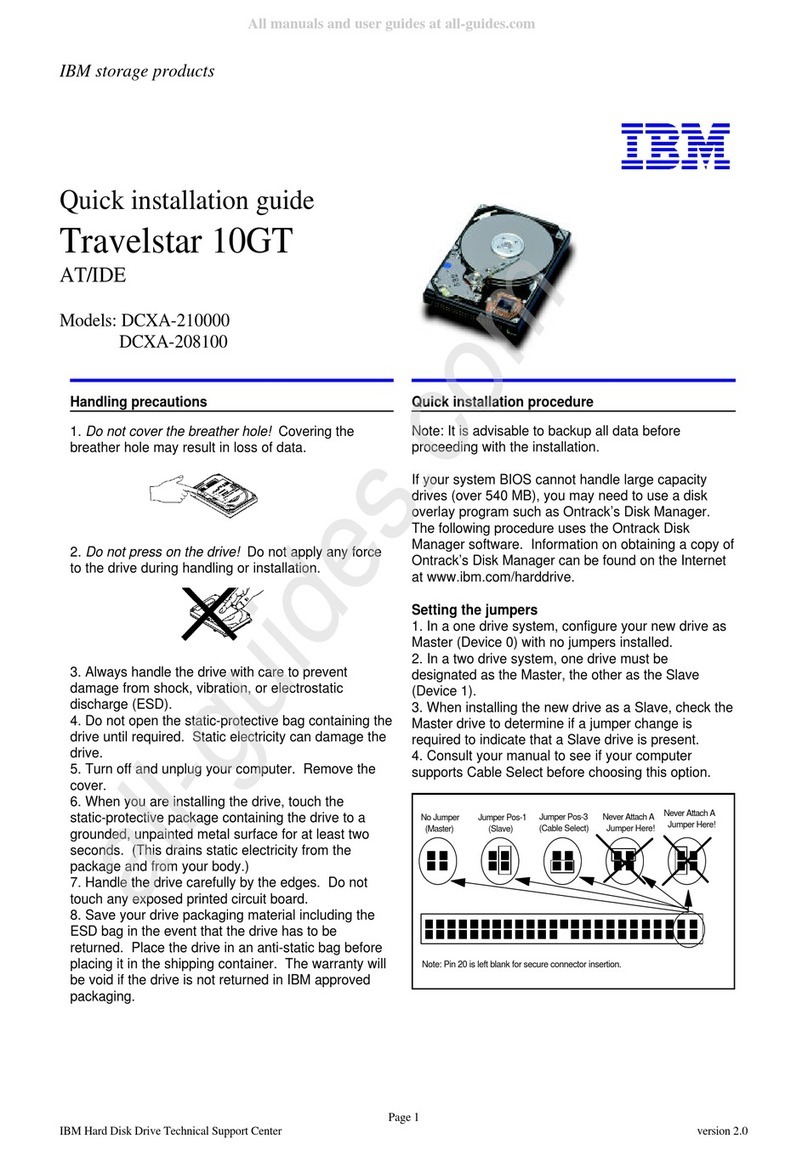

IBM DCXA-210000 User manual

IBM

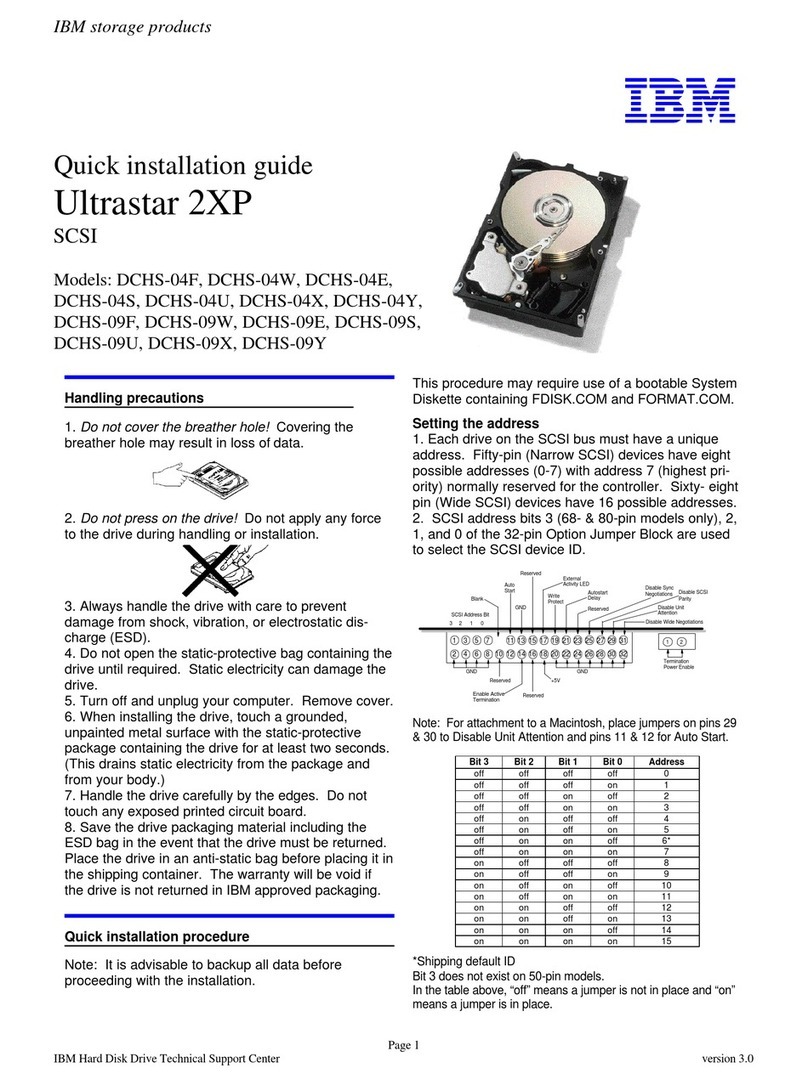

IBM Ultrastar 2XP User manual

IBM

IBM DTTA-350320 User manual

IBM

IBM System Storage TS2230 User manual

IBM

IBM Modbus Plus User manual

IBM

IBM 3420 User manual

IBM

IBM Elastic Storage System 3000 User manual

IBM

IBM Deskstar 16GP User manual

IBM

IBM 40/80 GB DLT User manual

IBM

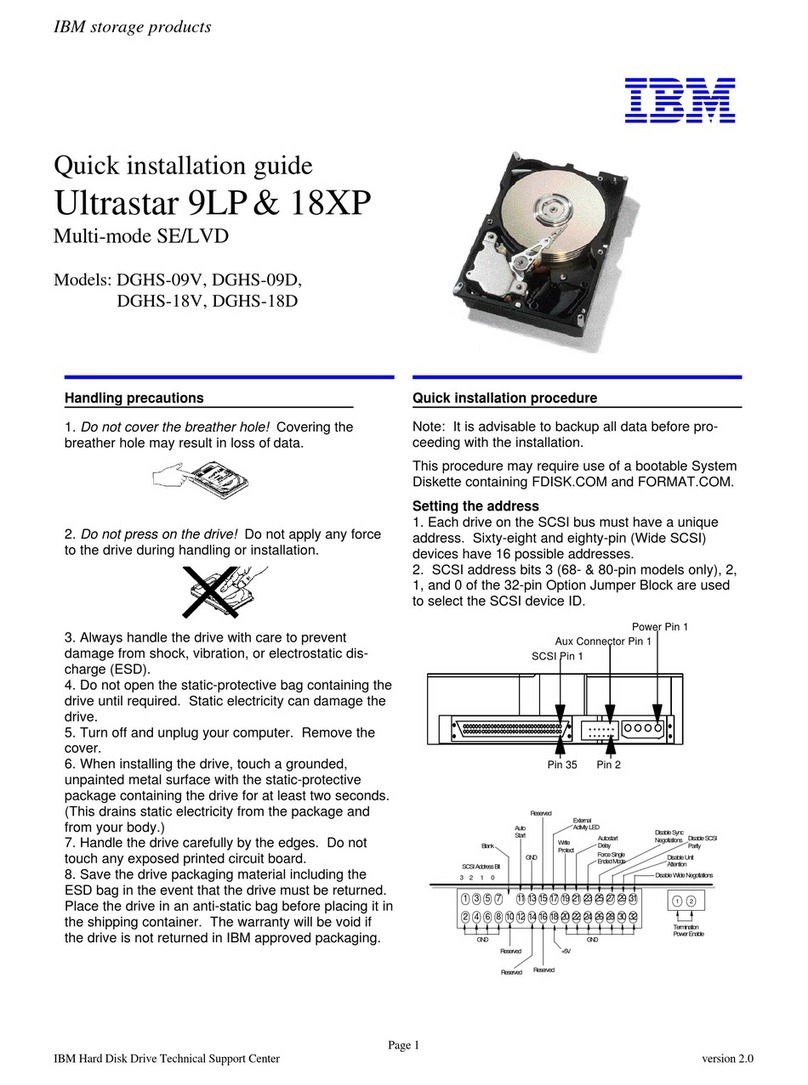

IBM Ultrastar 18XP User manual

IBM

IBM SAN768B-2 User manual

IBM

IBM LTO Library User manual