The

prime objective of any maintenance activity is

to

provide maximum machine availability to

the

cus-

tomer however; adjustments should not

be

made

un-

less necessary.

Section

2.

Preventive

Maintenance

cracks,

burnt

contacts, loose connections

and

clogged

filters.

The

three basic steps of preventive maintenance are

to clean, lubricate,

and

inspect.

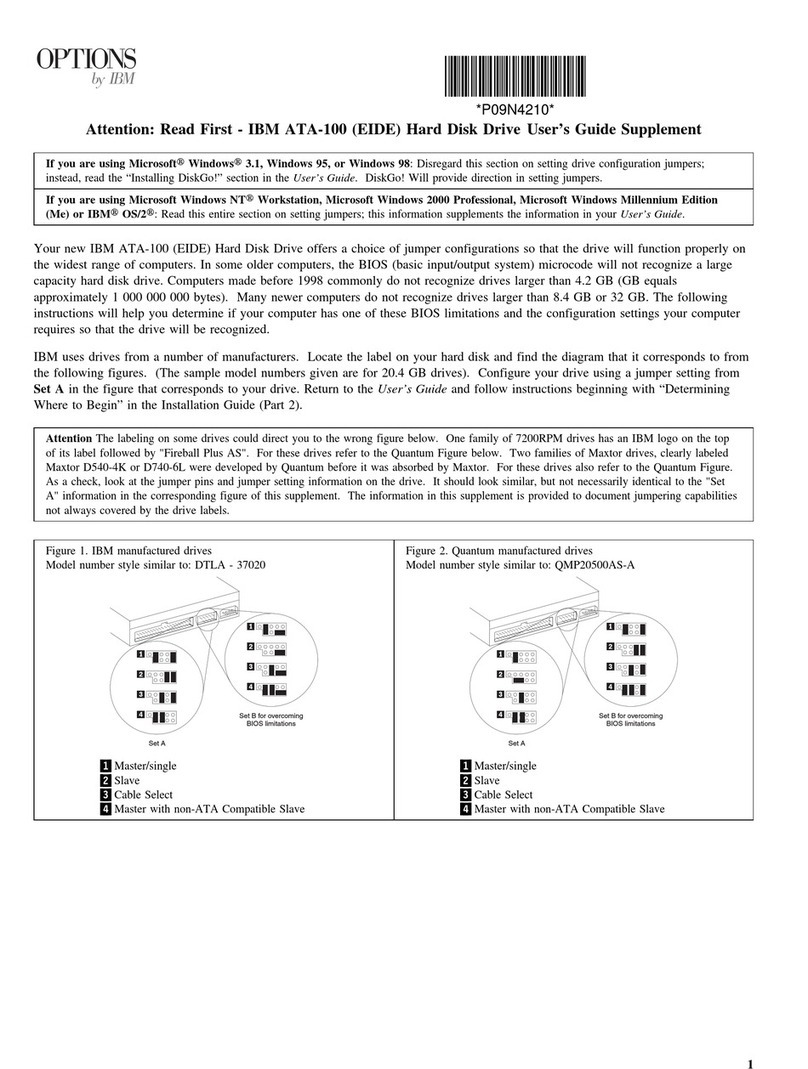

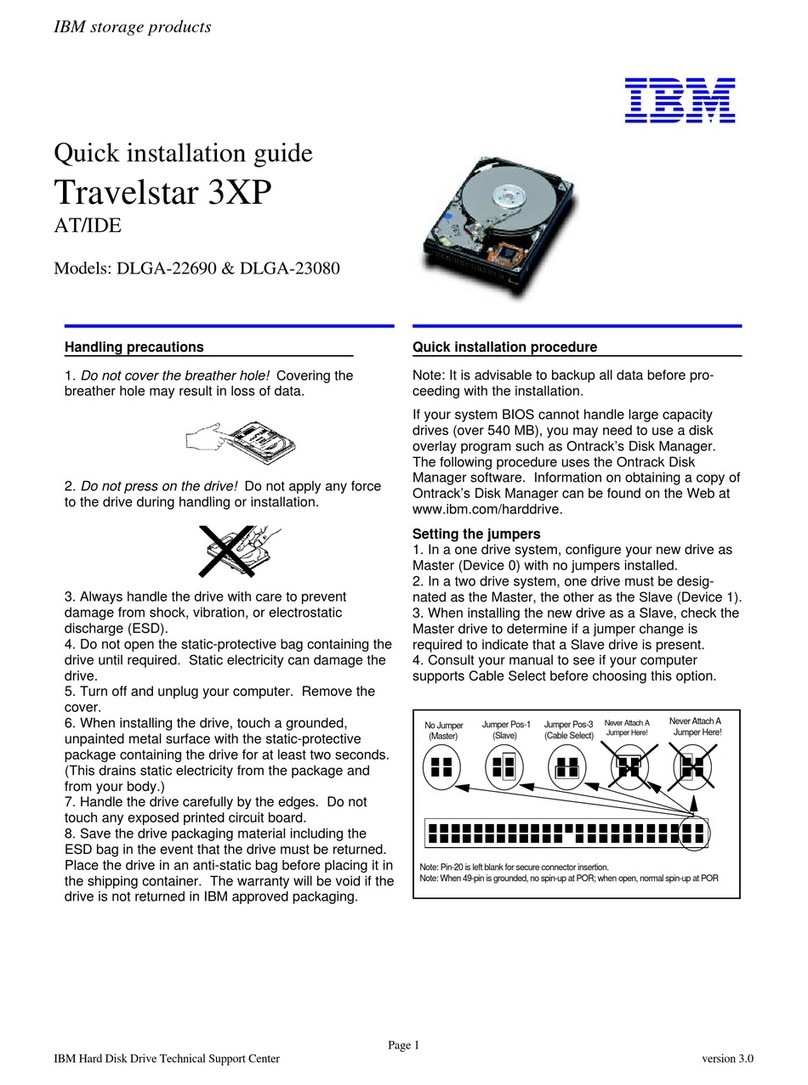

Figure

2-1 shows rec-

ommended

preventive maintenance routine.

Be visually alert for trouble indications any time

you service

tbe

machine. Look for corrosion, wear, Apply lubrication only in

the

quantity

necessary to

supply

the

immediate area involved.

Wipe

off excess.

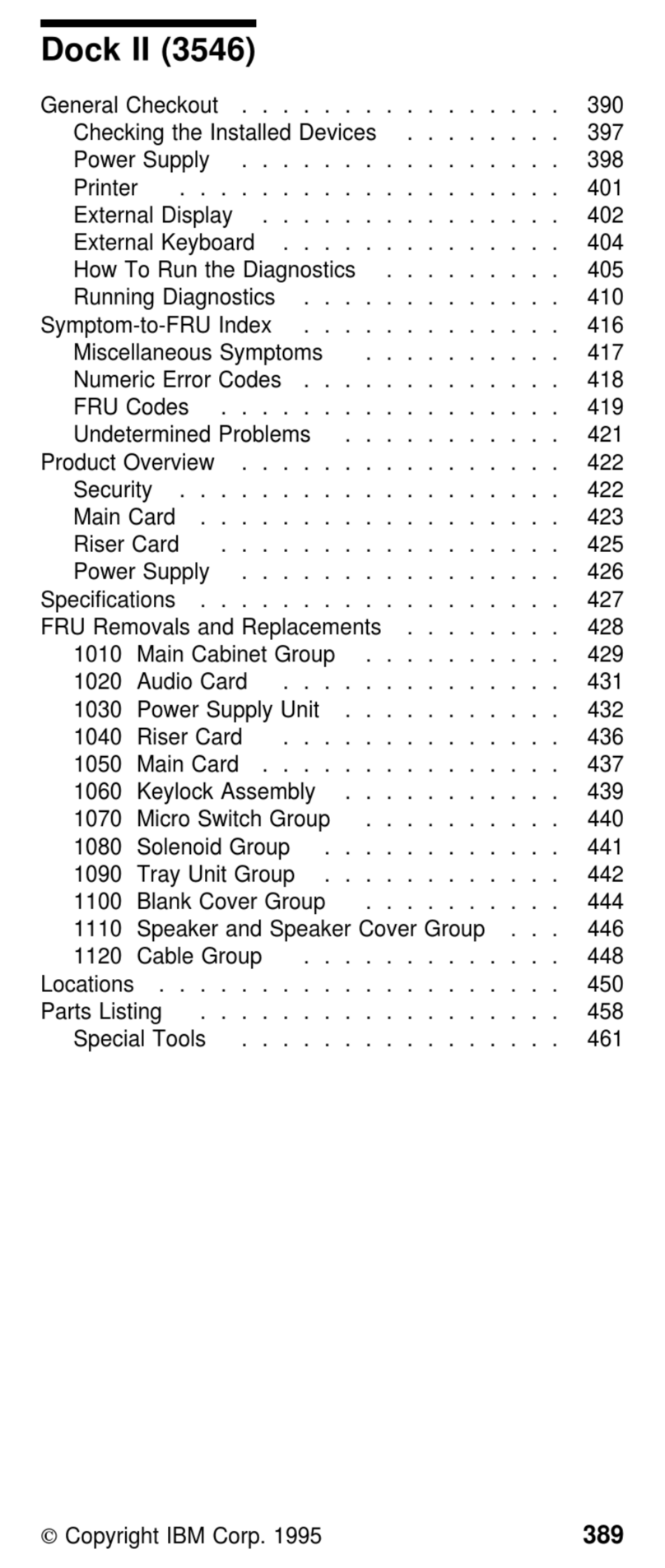

CODE

LOCATION

FREQ.

LUBRICATE

-CLEAN

OBSERVE

U R

OPERATION

MO.

PUNCH

CLEAN AND VACUUM

FEED.

LUBRICATE

CONTACT AND

BRUSH.fS

FOR

WEAR

AND DAMAGE

FEED

FEED

ROLL

HANGER

PIVOTS,

ALL

CLUTCH

PIVOTS

•••

• *9 HUSH TIMING

LOWERING

FRAME

SLIDING

SURFACES

AND

CAMS

...

•*17

PUNCH

REGISTRATION

LUBRICATE

GEARS,

ALIGNER CAMS.

FEED

ROLL

OPENING

BELT

WEAR

CAMS,

PICKER

KNIFE CAMS,

PUNCH

CLUTCH

LATCH

CAM, EXTENSION

SPRING

ENDS,

PUNCH

CLUTCH

4

ARMA

TURE

LATCH

PIVOT. . • • . • . • • • • • • • . .

•.

'17

STACKER

CLEAN

AND VACUUM

TRANSPORT.

LUBRICATE

CARD

BELT

WEAR

TRANS-

PUSHER

SLIDE

CAM

FOLLOWERS

•••••••••••••.

'9

PORT

LUBRICATE

CARD

PUSHER

SLIDE

SPRING

ENDS

AND

CAMS.

'17

LUBRICATE

STACKER

JOGGLER

CLUTCH

SPRING

GREASE

FITTING

.•..•••....•.••..••...••••.

*20

FILTER

REPLACE

IF

DIRT

IS

VISIBLE

FROM

INSIDE

0 MUFFIN

MODEL

1:

-20V

SUPPLY;

EARLY

FANS

STAGE

2, 3V

SUPPLY

MODEL

2:

-20V,

+12V

SUPPLIES

(ONE FAN), -12V

SUPPLY

3

MODEL

3:

PUNCH

MAGNET

DRIVERS

(SMS

GATE)

READ

LUBRICATE

ARMATURE

PIVOT

AND LINK

.....•.•..•

#6

DETENT

PAWL,

KEEPER,

LATCH,

CLUTCH

LUBRICATE

LATCH,

KEEPER,

LOAD

PAWL,

DETENT

PAWL,

AND

RATCHET

FOR

WEAR

AND

INTERMEDIATE

ARM

PIVOTS

..•••.•..•...

#17

EXCESSIVE

CLUTCH

BACKLASH

LUBRICATE

ARM,

KEEPER,

LATCH, AND

CLUTCH

RATCHET

WHILE

ENGAGED

WORKING

SURFACES

.•.••••

............

#17

CLUTCH

PULLEY

SHOCK

MOUNT

1

LUBRICATE

CLUTCH

NEEDLE

BEARING

AND

REVERSE

LOCK

FOR

LOOSENESS

GREASE

FITTINGS

..•.....•

. ...... .....

#17

READ

CLEAN

AND VACUUM

FEED.

LUBRICATE

FEED

ROLL

FEED

HANGER

PIVOTS

AND

ALL

OTHER

PIVOTS

.•..•...

#6

BRUSHES

FOR

WEAR

AND DAMAGE

LUBRICATE

GEARS,

PICKER

KNIFE

CAM, EXTENSION

BRUSH

TIMING

SPRING

ENDS

•..•.....••.••••••••

,

•.

#17

BELT

WEAR

FILE

LUBRICATE

CAM

FOLLOWER

ARM

JOGGLER

PIVOTS

.•..

#9

CLUTCH

OVERTHROW

FEED

LUBRICA

TE

ALL

OTHER

PIVOTS

.............

..

#6

BELT

WEAR

LUBRICATE

FRONT

JOGGLER

SPRING

ENDS,

GEAR

FEED

ROLLS

FOR

GLAZE

2 JOGGLER, CAMS, ADJUSTING

SCREW

SURFACES,

CLUTCH

LATCH

CAM

SURFACE,

SIDE

JOGGLER

SIDE

RETURN

SPRING

•.••••.••..•..••...

#17

CLUTCH

GREASE

FITTING

••••.•••••••••••••

'120

Figure 2-1. 1402 Preventive Maintenance Routine

Chart

2-1