cam,

and the trip lever (Fig. 15).

The cam consists

of

a steel body with nylon molded

at

the

bear-

ing

point,

the

tai

I, and the shoe

that

contacts' the power

roll.

The cam

is

mounted to the cam lever by means

of

a shoulder

rivet.

It

is

free to

rotate

about the

rivet,

but the amount

of

rotation

is

limited

in

one direction by a steel stop which

pro-

jects

from

the

cam.

The stop contacts the side

of

the cam lever

and determines the rest position

of

the cam (Fig. 15). A cam

spring extends between a hook on

the

cam lever and a hook on

the cam and holds the cam

in

its rest position. The heel

of

the

nylon shoe contacts the cam lever when the cam

is

fully rotated

and limits rotation

in

this

direction.

Earlier steel bodied cams

did not have steel stops. The nylon heel

of

the cam was larger

and served as a cam stop

in

both

directions

of cam

rotation.

The st.eel stop was incorporated

to

minimize cam bounce when

the cam returned to its rest position.

The trip lever

is

mounted to the cam lever

by

a shoulder rivet

(Fig. 15).

An

elongated slot

in

the trip lever allows

it

to slide

front

to

rear

to

rotate around the

rivet.

A hook

on

the trip

lever mounts a sprint

that

extends to a hook on the cam

lever.

The tri I lever springs holds the trip lever

up

and to the rear

in

its rest position. The trip lever has two formed lugs. The top

lug

is

positioned

directly

under the lug on the key

lever.

The

boftom lug

is

directly

above the

cam.

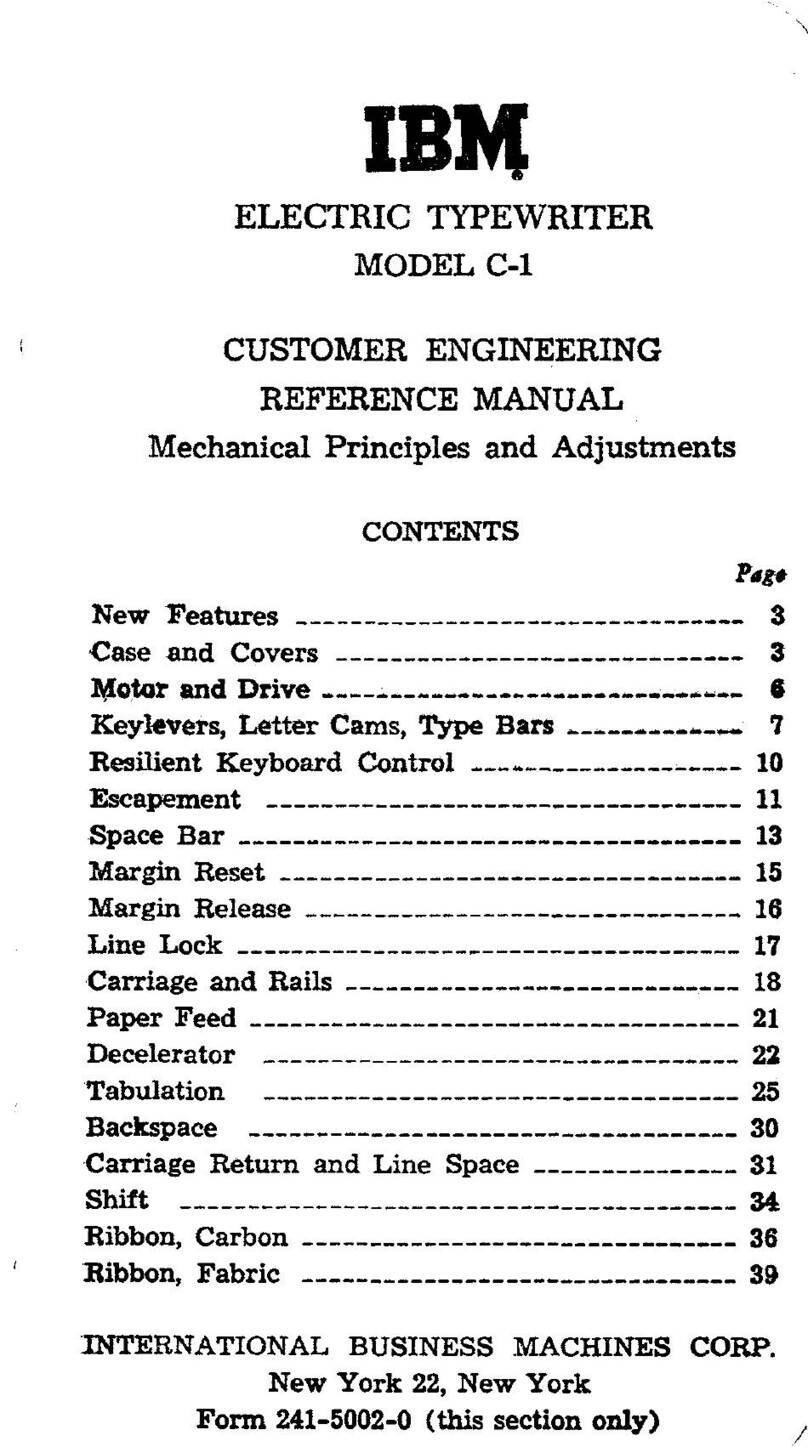

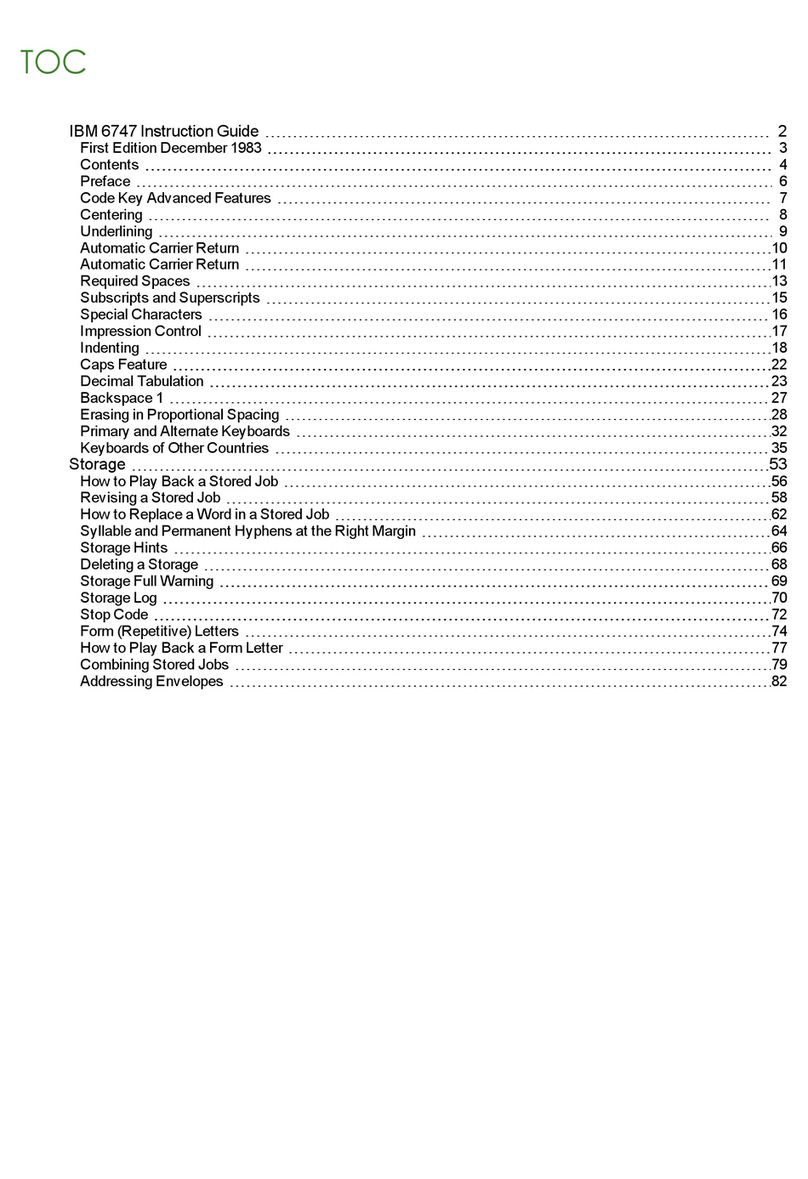

Impression Control Indicator

Figure

10.

Cam

Knockout

Bar

Assembly

The cam knockout bor assembly

is

an aluminum casting

to

which

two sets

of

flat knockout spring fingers are secured (Fig. 10).

There

is

one knockout finger for

each

cam lever assembly. The

height of

each

knockout finger, is controlled by individual

impression control screws which are located

in

the knockout bar

below the fingers. The knockout bar assembly pivots between

the left and right side frames on two pins

that

are

secured

by

set screws.

An

impression control

eccentric

shaft

is

positioned

beneath the

rear

of

the knockout bor and pivots in two bronze

bearings which

are

mounted to the left and right side frames

(Fig.

10). A plastic

gear

is

pinned

to

the left end

of

the shaft

and

meshes with the

teeth

on the impression control

indicator.

The impression control indicator pivots

on

a stud on the left

side frame. The rear

of

the

knockout bar

is

held down against

the impression control

eccentric

shaft

by

two springs.

4

Type

Bars

Type bars

are

mounted in a slotted segment

and

are

held by a

curved type bar fulcrum wire (Fig. 11). The lower end

of

the

type bor extends below the segment and has a hole in

it

for

the type bar link. Above the segment

is

the body

of

the

bar,

identified by

the

reinforcing

rib,

and the type head which

includes the type slug and

the

wider section

of

the bar

(Fig.

12). The part referred to as the throat extends

from

the

top

of

the reinforcing rib to the bottom

of

the

head.

A type mark,

used to identify the type

style,

is

located between the upper

and lower case type faces on the type slug.

An

anticlash

I

ug

prevents damage

to

the type face if one type bar

fo

Ilows

another to the

platen

before the first bar has gotten out

of

the

way.

The type face

is

curved

to

the same arc as the platen

so

that

all parts

of

the type face will strike

evenly.

A hole

is

provided

in

the

type head

to

facilitate

forming

of

the

head

during type alignment. A locater lug found on some type

styles

is

used

at

the factory

to

facilitate

soldering

of

the type

slug to the

bar.

Fulcrum

Wire

Ret.aining

Screws

Figure

11.

Type

Bar

Mounting

Changable type bars

are

available

to permit the operator

to

interchange type bars in specified positions, thus providing

a

greater

number

of

special

characters (Fig. 13). This feature

is

available

only

for positions

0,

32,36,

39,

40,

41,

42, 43,

and

the standard numerical type bar positions.

Changeable

type bars ore not porvided for

alphabetic

positions

or

position

#38. A special type bor link incorporating a spring

clip

is

.

used with changable type bars. This link will not drop

off

the

cain lever when

the

operator removes a type bar and drops

the.

link.

Each changable type bar is designated for one type bar

posi-

tion

only

and

is

to

be aligned

to

the

typewriter for which

it