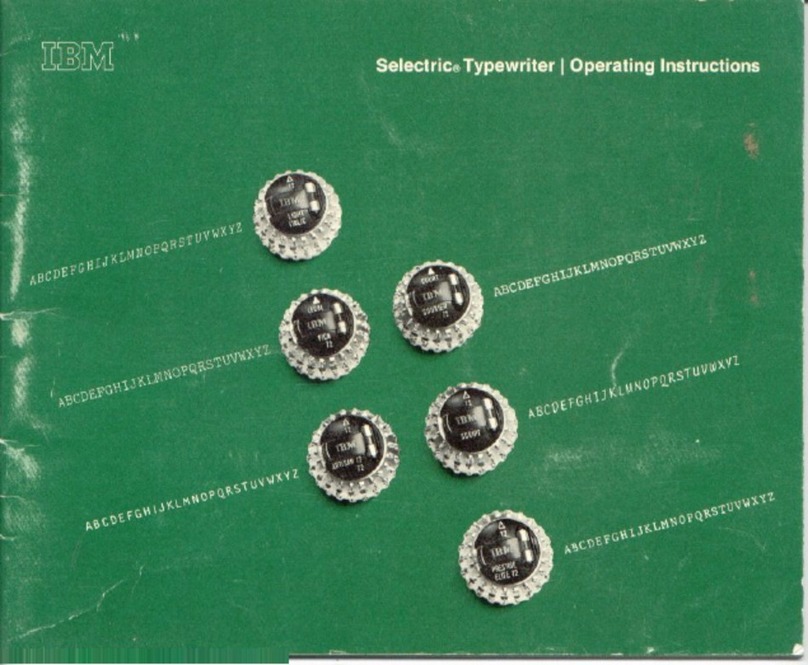

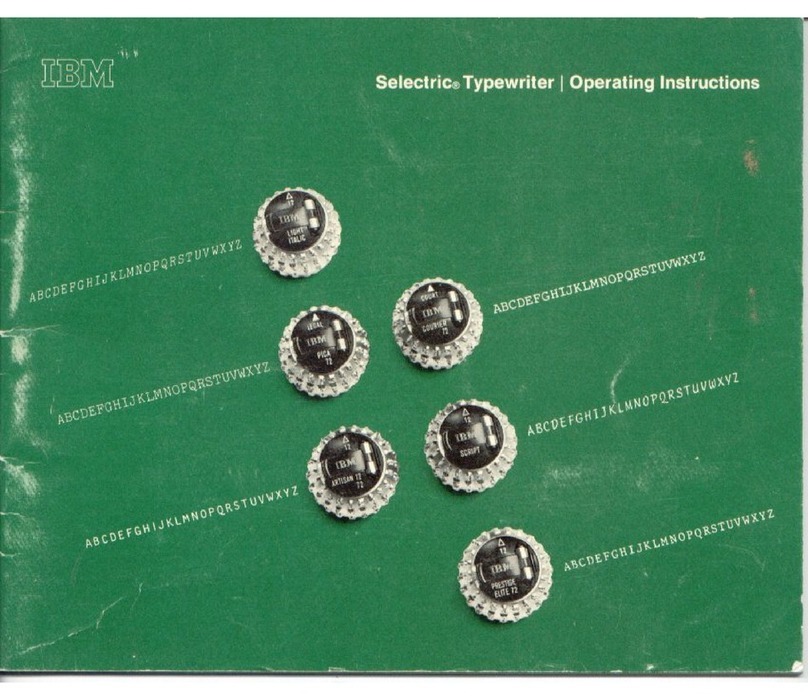

IBM Selectric User manual

Other IBM Typewriter manuals

IBM

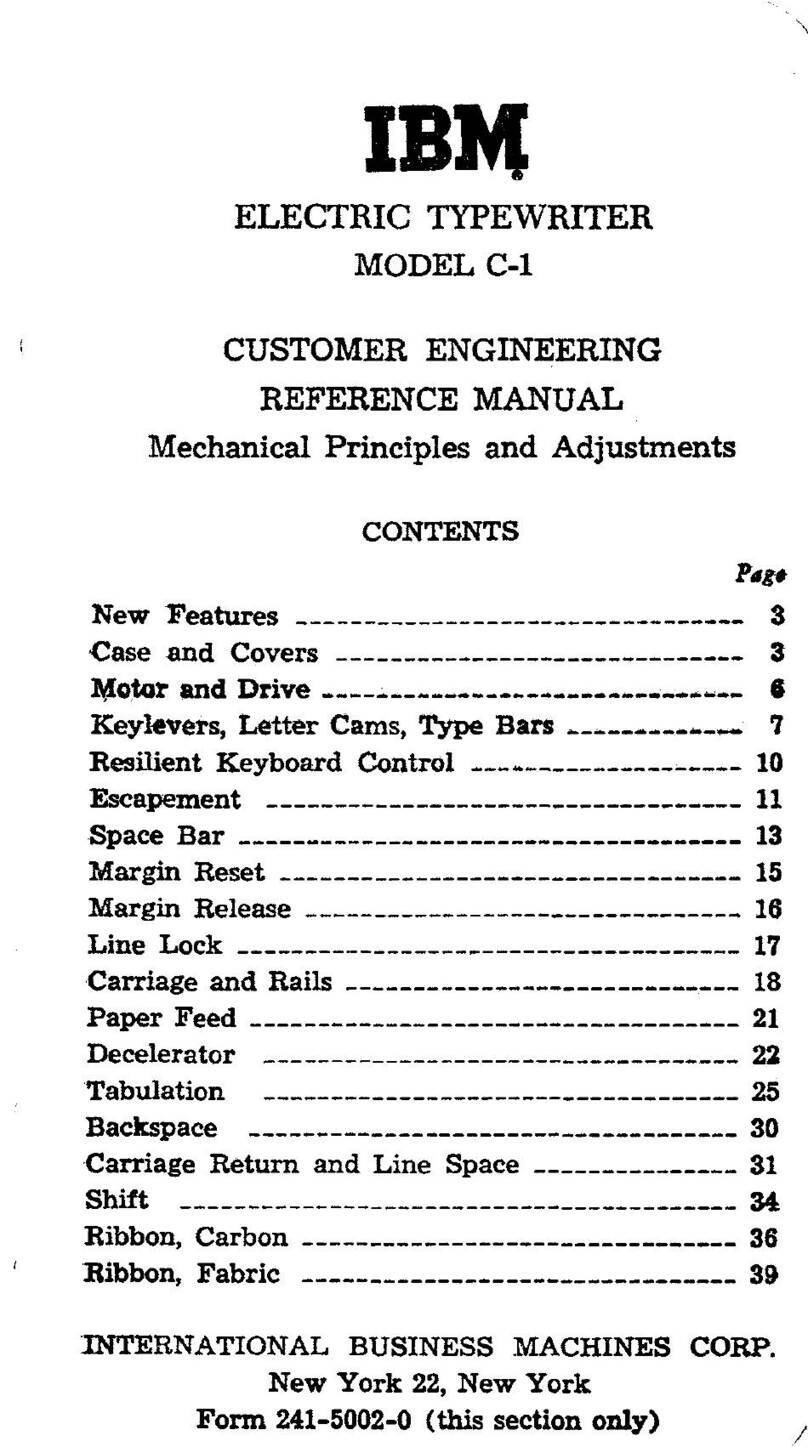

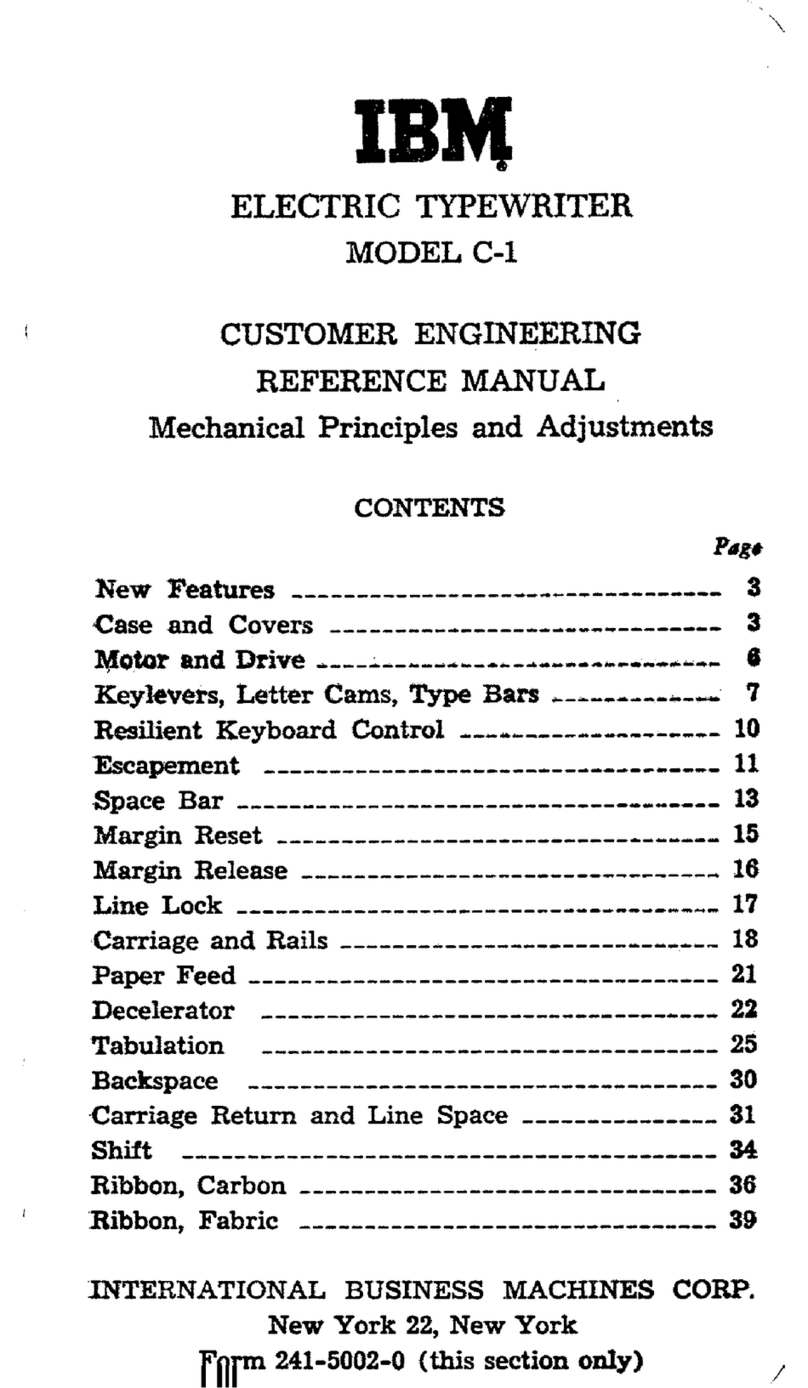

IBM C-1 User manual

IBM

IBM Selectric User manual

IBM

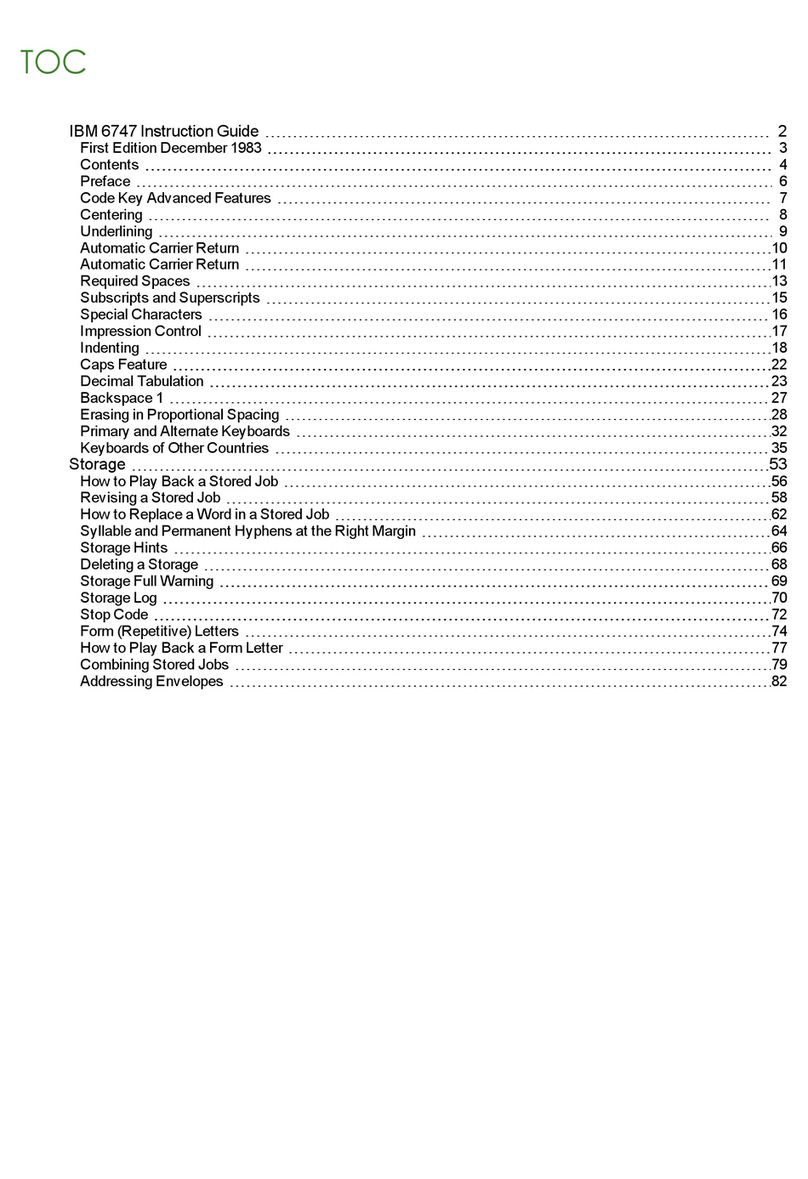

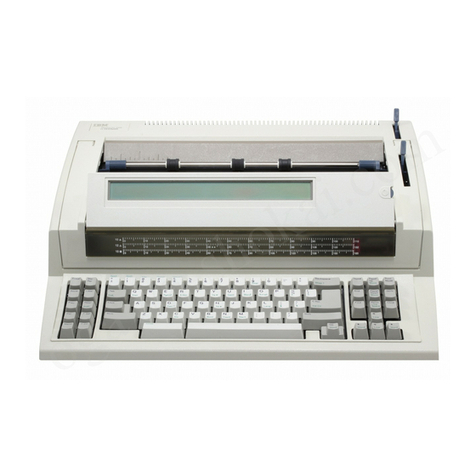

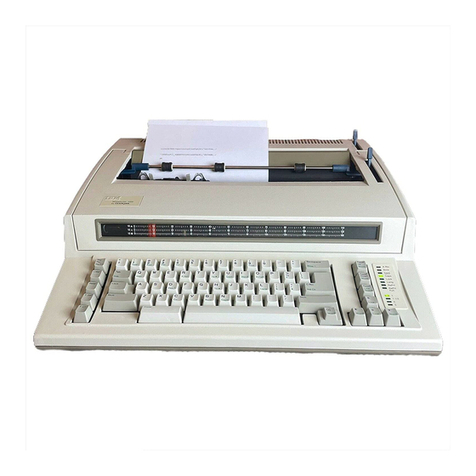

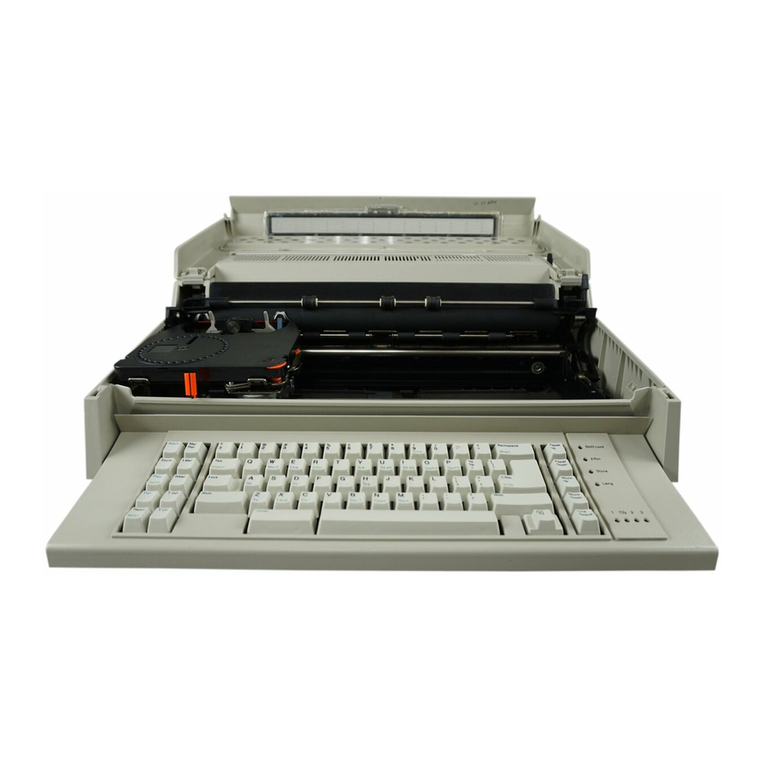

IBM 6 - Lexmark Wheelwriter 6 Professional... User manual

IBM

IBM Selectric User manual

IBM

IBM Selectric User manual

IBM

IBM Selectric III - Correcting Selectric III User manual

IBM

IBM Selectric Personal Typewriter User manual

IBM

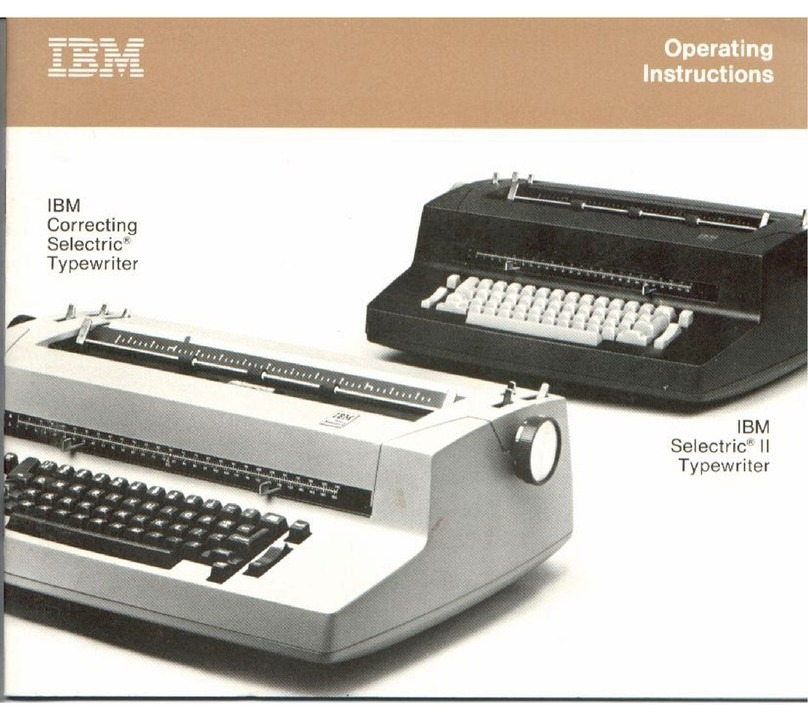

IBM Selectric II User manual

IBM

IBM Selectric II User manual

IBM

IBM Selectric User manual

Popular Typewriter manuals by other brands

Panasonic

Panasonic KX-R530 - Electronic Typewriter operating instructions

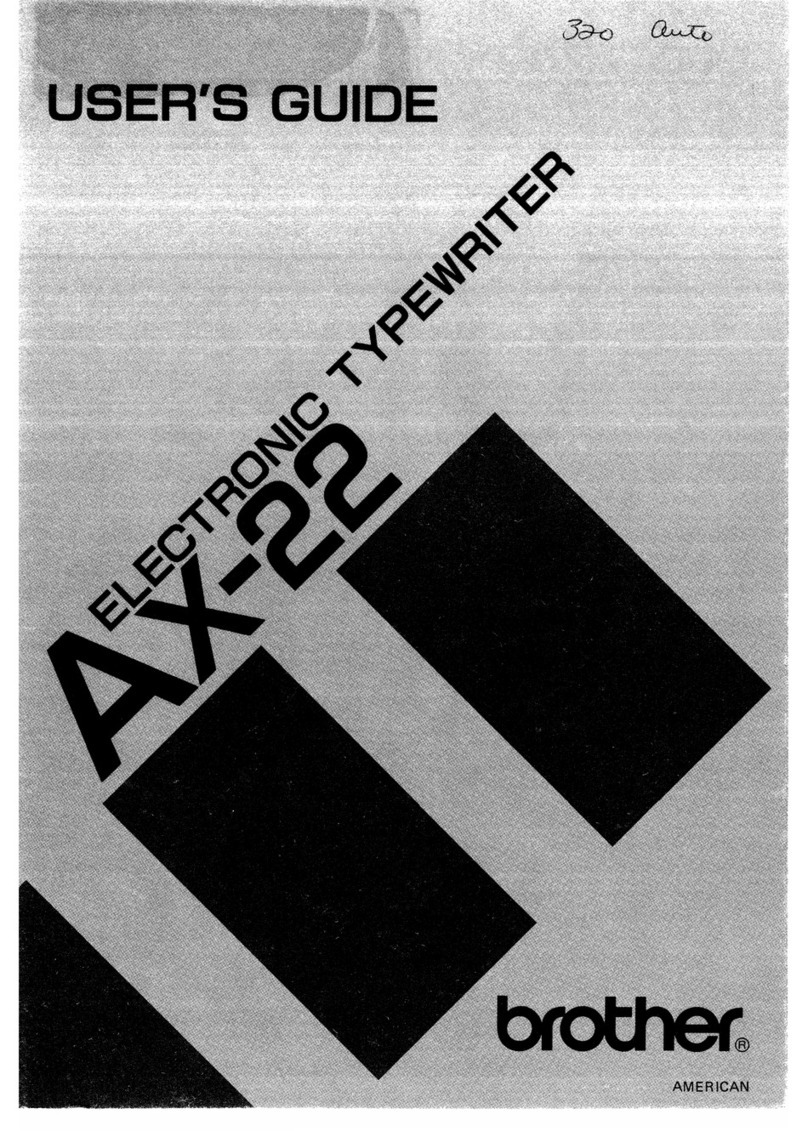

Brother

Brother AX-425 parts reference list

Remington Rand Inc.

Remington Rand Inc. Noiseless 10 Mechanical Instructions

Scheidegger

Scheidegger TYPOMATIC-TMS Instruction handbook

Siemens

Siemens 1000 CA operating instructions

Panasonic

Panasonic KX-E50 Operator's instruction manual