ICARO Page 4

INDEX

Pag.

1.0 INTRODUCTION…………………………………………………………..…6

1.1 INTRODUCTION…………………….…………………………..…....6

1.2 FORESEEN AND NOT FORESEEN USE………...….…….……...7

1.3 WAY OF CONSULTATION OF THE MANUAL…………………….8

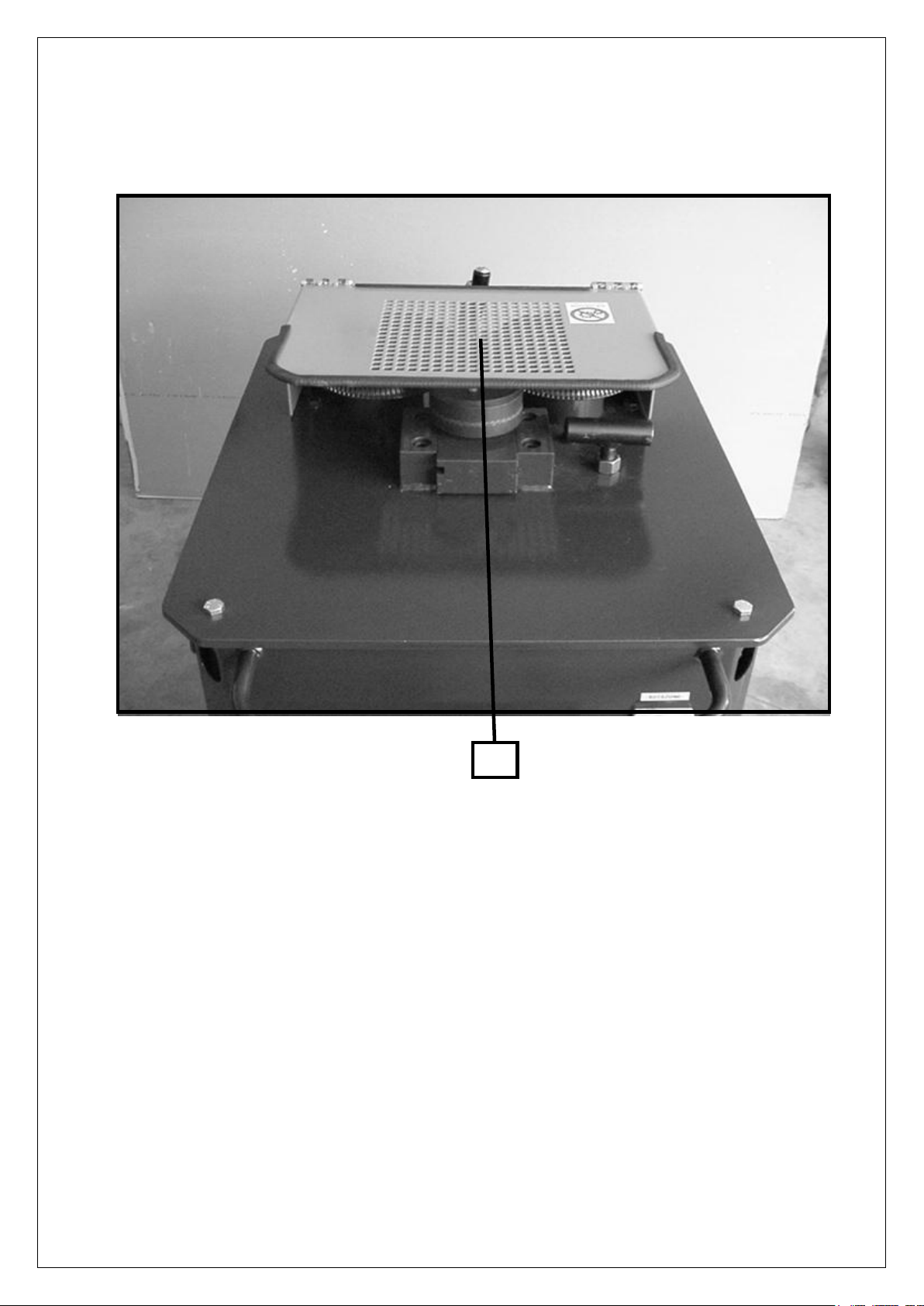

2.0 DESCRIPTION OF THE MACHINERY……………………..……………10

2.1 CHARACTERISTIC

TECHNIQUES………………………………………………………..11

3.0 SAFETY PRESCRIPTIONS………………..……………………………..13

4.0 SAFETY SYMBOLS…...……………….………………………………….16

5.0 SAFETY DEVICES…………………………………………………………18

5.1 PROTECTIONS OF THE ORGANS OF FOLDING..….……..…18

5.2 EMERCENCY STOP………………….…….…………..…………18

5.3 OPENING ELECTRIC PANEL……..……….…………………….18

5.4 COMMAND PEDAL…….……………….…… ……...……………18

6.0 PREPARATION OF THE INSTALLATION AREA……………..………20

7.0 MOVEMENT AND STOCKPILING RECEPTION……………………….20

7.1 SAFETY PRESCRIPTIONS FOR THE MOVEMENTS………....20

7.2 CONTROLS IMPLEMENTATION AT THE RECEPTION…........21

7.3 DISPOSAL OF PACKAGING MATERIAL...……..……………….21

7.4 STOCKPILING AND MAINTENANCE…...…………..…………...21

8.0 INSTALLATION……………………………………………..……………...22

8.1 ELECTRIC CONNECTION.….…………………………………….22

8.2 SENSE OF ROTATION CHECKING…….………………….…….24

8.3 SAFETY DEVICES CHECKING………………………..……..…..24

9.0 USE…...……………………………………………………………………...26

9.1 COMMANDS…....……………………………………………………26

9.2 REGULATIONS..……………………………………………..……..28

9.2.1 REGULATION SCREW..………….……………………..….28

9.2.2 REGULATION ROLLS….….………………………………..28

9.3 OPERATOR POSITION…………..………………………………..28

9.4 MACHINERY STARTING…………….………………………..…...29

9.4.1 PRELIMINARY CONTROLS…...…………………….……..29

9.4.2 STARTING…..……………………..……………….………...29

9.5 MACHINERY STOP………………………………………….……..29

9.6 REACTIVATION AFTER A FORCED INTERRUPTION………...29