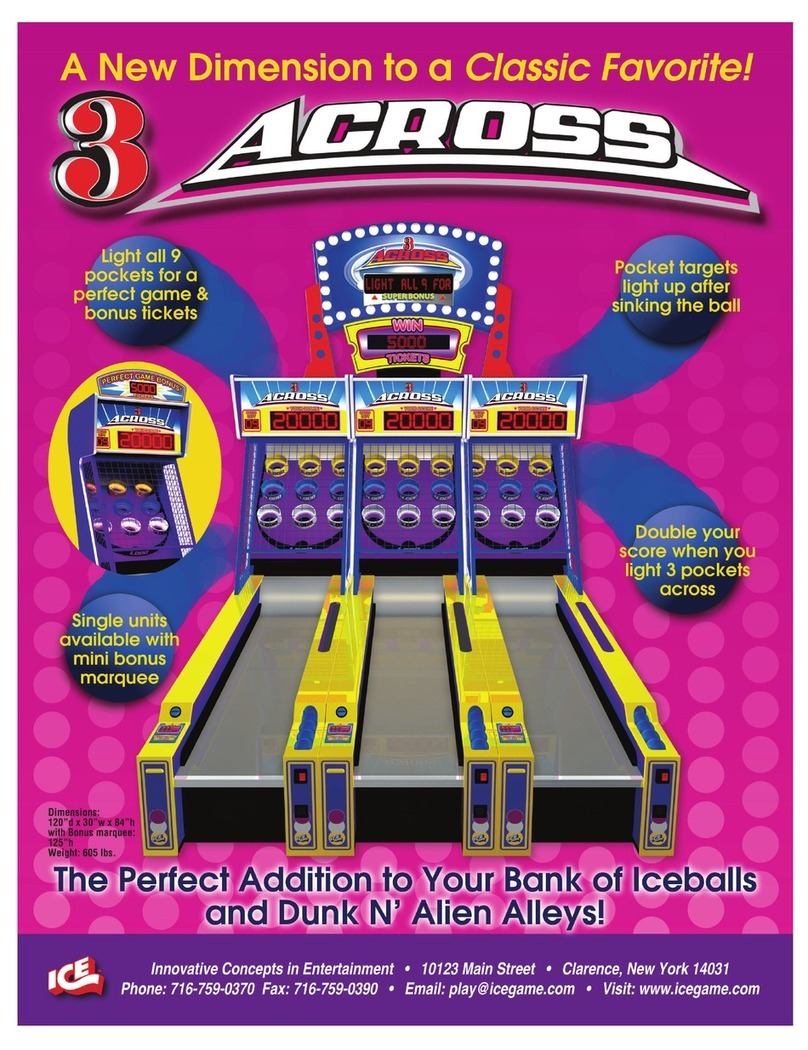

3

INTRODUCTION

GAME FEATURES

The brand new PLUSH BUS™ all metal crane game

by I.C.E. was designed with the operator in mind.

Reliability, low maintenance, themed cabinetry, and

all metal construction are the key design features,

exactly what is needed to ensure a combination of

long life and profit.

With nearly the entire construction made of metal, it

was only natural to Powder Epoxy Coat everything,

inside and out. This provides the owner – operator

with a game that will certainly outlast its wooden

counterparts. A few of the major advantages of all

metal construction include:

- Vault like security

- Long service life

- Low maintenance

- High Durability

All windows, of the PLUSH BUS™,are ¼” tempered

glass to provide an easy clean, maximum safety,

scratch resistant surface. Other features include, 40

strand conductor cables to prevent wire fatigue, full

range of operator adjustable software, and a newly

designed crane mechanism.

The first step in I.C.E.’s new crane design was to

select several leading cranes available on the

market today, observe and determine what problems

can be or are causes of failure and costly down time.

I.C.E. then surveyed operators nation wide,

requesting information like:

- What are the leading causes of crane

failures in your locations

- What are some problems in servicing

cranes

- What changes would you make to current

cranes to create a better machine

I.C.E.’s engineers then compiled all critical data,

addressed and corrected each problem and used

this information to create what we call the PLUSH

BUS™ .

This method of design ensures that the needs and

concerns of the owner-operators dictate the final

design parameters, for who knows a crane’s

attributes and faults better than a crane operator.

GAME PLAY

As coins are inserted into the PLUSH BUS™ all

metal crane game, the sound of a “BUS” starting is

heard. When sufficient coins have been inserted, the

engine starts, the claw clicks closed and re-opens,

which signals the start of the game. The crane will

position itself in the middle of the “play field” and

remain there, with the engine running, until the

player is ready.

When the player has moved the joystick or pressed

the buttons, to move the crane, the timer on the right

display will begin to count down. The player will

position the crane above the prize they are

attempting to win and press the drop button to lower

the claw.

If the nudging option is on, then the player will have

the ability to keep “nudging” the claw down each

time the button is pressed to home-in on the chosen

prize. If the nudging option is off, then the player will

have only one chance to drop the claw.

When the claw is fully dropped it will close and

retract to its upper most position. The crane will

then automatically position itself over the prize chute

at the rear of the cabinet. The claw will open,

releasing the prize into the prize chamber. The

player can now remove the prize from the chamber

through the prize door located in the front, lower left

corner of the game. The game is now in its home

position and is ready for the next player in line.

If you have any questions regarding Programming,

Troubleshooting or Repair, please call our Service

Department.

I.C.E. Parts/Service Dept.

Phone #: (716) - 759 – 0360

Fax #: (716) – 759 – 0884

NORMAL BUSINESS HOURS ARE:

MONDAY - FRIDAY, 9:00 AM TO 6:00 PM EST

*The crane will remain in the home position if game type (option 1) is set to 2 or 3. In this option the player has only two buttons, one for right travel

and one for forward travel. The crane will remain in the home position to allow the player access to the entire play field.