F/N 525746 Jan 09 © 2009 ICS, Blount Inc.

TITLE680GC OPERATOR’S MANUAL

7

SAFETY

IMPORTANT

THE FOLLOWING SYMBOL APPLIES TO ALL ITEMS LISTED ON THIS PAGE

A potential situation exists which, if not avoided, may result

in product or property damage.

Note: The chain-based cut-off saw is equipped with a two-stroke engine and must always be

run using a mixture of gasoline and ICS®two-stroke engine oil. It is important to accurately

measure the amount of oil to be mixed to ensure that correct mixture is obtained. When

mixing small amounts of fuel, even small inaccuracies can drastically affect the ratio of

the mixture.

• This engine is designed to be operated on premium unleaded gasoline.

• Use high quality, unleaded gasoline with a minimum octane rating of 90. If lower octane

gasoline is used, engine temperature will increase which will result in a piston seizure

and damage to the engine.

• Fuel mixture: 25:1 gasoline/oil mixture. Incorrect fuel mixture is the number one cause

of piston seizure.

• Use ICS®brand two-stroke engine oil.

• Never use two-stroke oil formulated for water-cooled two-cycle engines, such as

outboard motor oil.

• Never use motor oil intended for four-stroke engines.

• Use of water is required to cool bar and chain during break-in period.

ENGINE BREAK-IN

• It is very important to break-in a new engine to “seat” all moving parts, especially the

piston rings.

• To break-in the engine, run one full tank of 25:1 fuel at idle, cycling the throttle every

5 to 10 minutes to prevent loading.

• Failure to break-in an engine may result in piston seizure.

• Failure to break-in an engine at altitude will result in 50% loss of power output for the first

hour of operation making the initial cutting experience unsatisfactory.

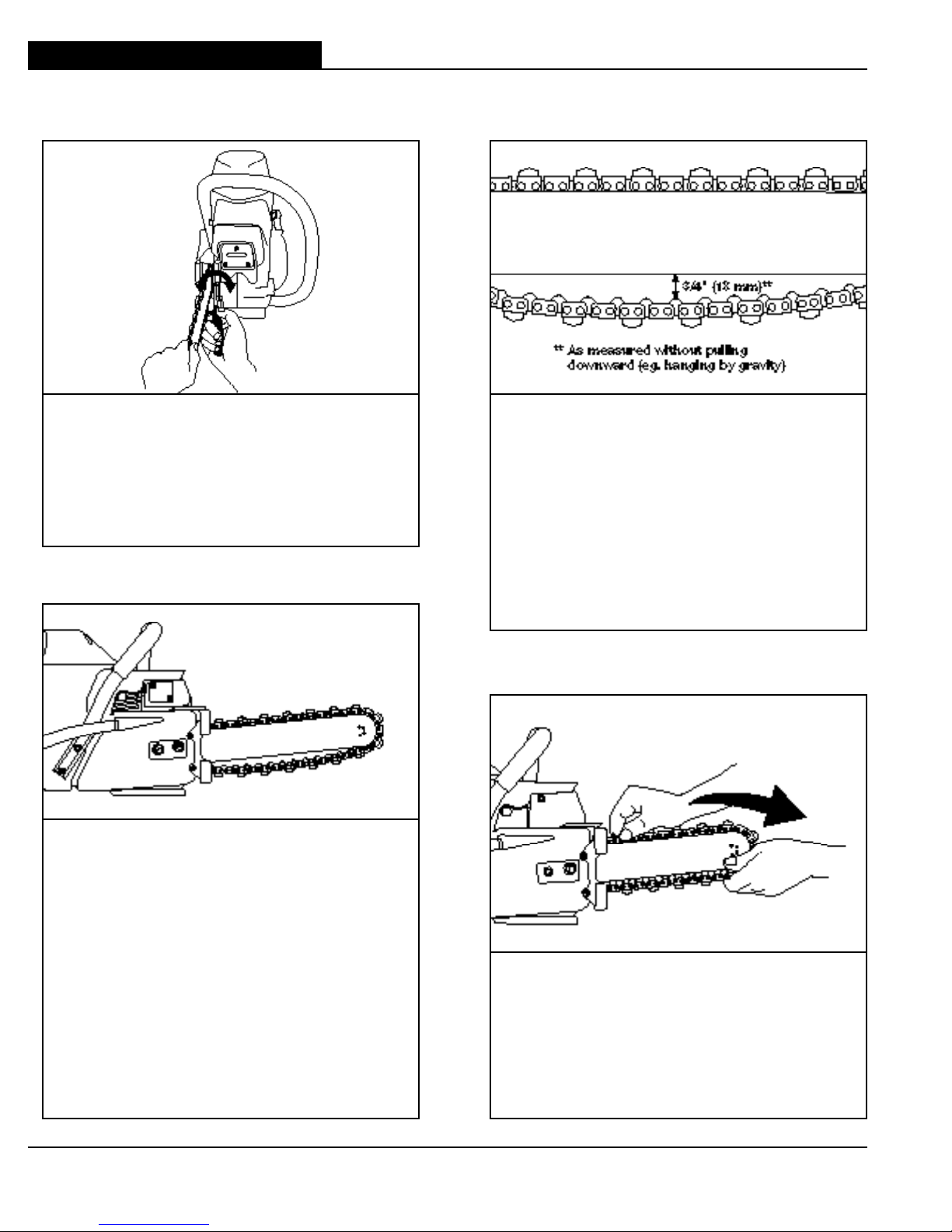

• Proper chain tension, especially for first cut, is extremely important. Over-tensioning of

bar and chain, especially at altitude, could result in severe loss of power output making

initial cutting experience unsatisfactory.