© 2010 ICS, Blount International Inc. Specications are subject to change without notice. REV0810 F/N 542025

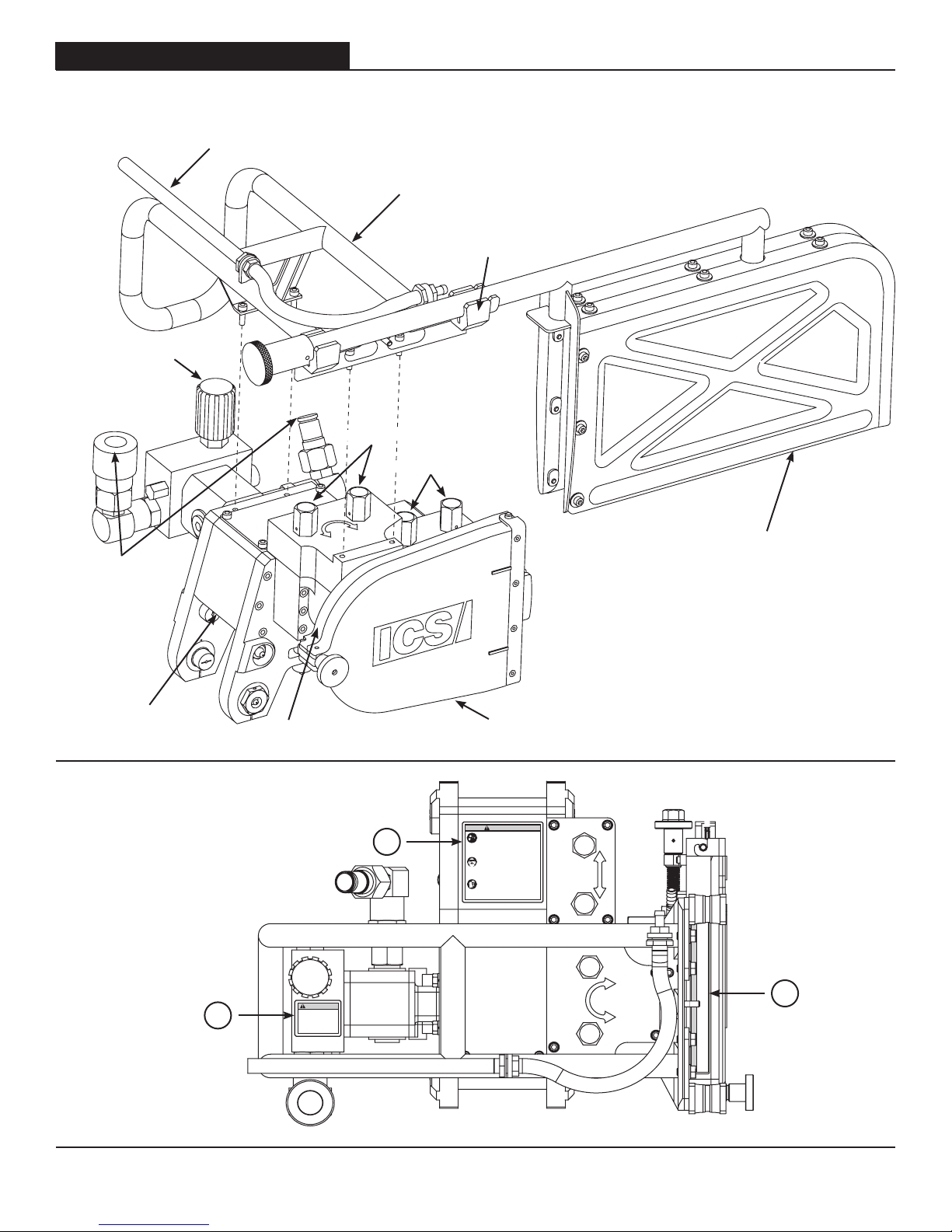

TITLECWS-200 OPERATOR’S MANUAL

7

SAFETY

CAUTION

THE FOLLOWING SYMBOL APPLIES TO ALL ITEMS LISTED ON THIS PAGE

A potentially hazardous situation exists which, if not avoided,

may result in minor or moderate injury or property damage.

• ALWAYS closely inspect the machine for worn, damaged or broken components that may

have occurred during use or due to an accidental impact or drop.

• Do NOT operate the machine if the diamond chain, guide bar and/or drive sprocket show

evidence of significant wear or damage. Replace if necessary.

• ALWAYS use genuine ICS® repair and replacement parts.

• Do NOT modify the machine or use components from other machines.

• ALWAYS ensure at least 20 psi (1.5 bar) water pressure is supplied to the machine.

• Avoid inserting the diamond chain into a slot narrower than the diamond segments.

Ref: The diamond segments used for the CWS-200 are .245" (6.45 mm) wide.

• ALWAYS complete the pre-cut checklist prior to each use (refer to p. 12).

• ALWAYS wear protective clothing, including hard hat, eye protection, hearing protection, and

appropriate gloves and boots.

• Avoid loose fitting clothing.

• NEVER use equipment that is poorly maintained or not functioning properly.

• ALWAYS operate and/or lift the machine with solid footing and proper positioning.

• Remove or control slurry to prevent slippery conditions in the working area.

• ALWAYS check for and remove any obstructions (plumbing, electrical conduit, air ducts, etc.)

that may interfere with the cut.

• Do NOT allow unnecessary bystanders within the working area.

• Set up a well-marked, properly organized working area with a roped boundary and clear

signs.

• ALWAYS ensure adequate ventilation when working in an enclosed area.