© 2010 ICS, Blount International Inc. Specications are subject to change without notice. REV0910 F/N 545067

TITLE 695GC / 695F4 OPERATOR’S MANUAL

10

SET-UP

GUIDEBAR AND DIAMOND CHAIN INSTALLATION

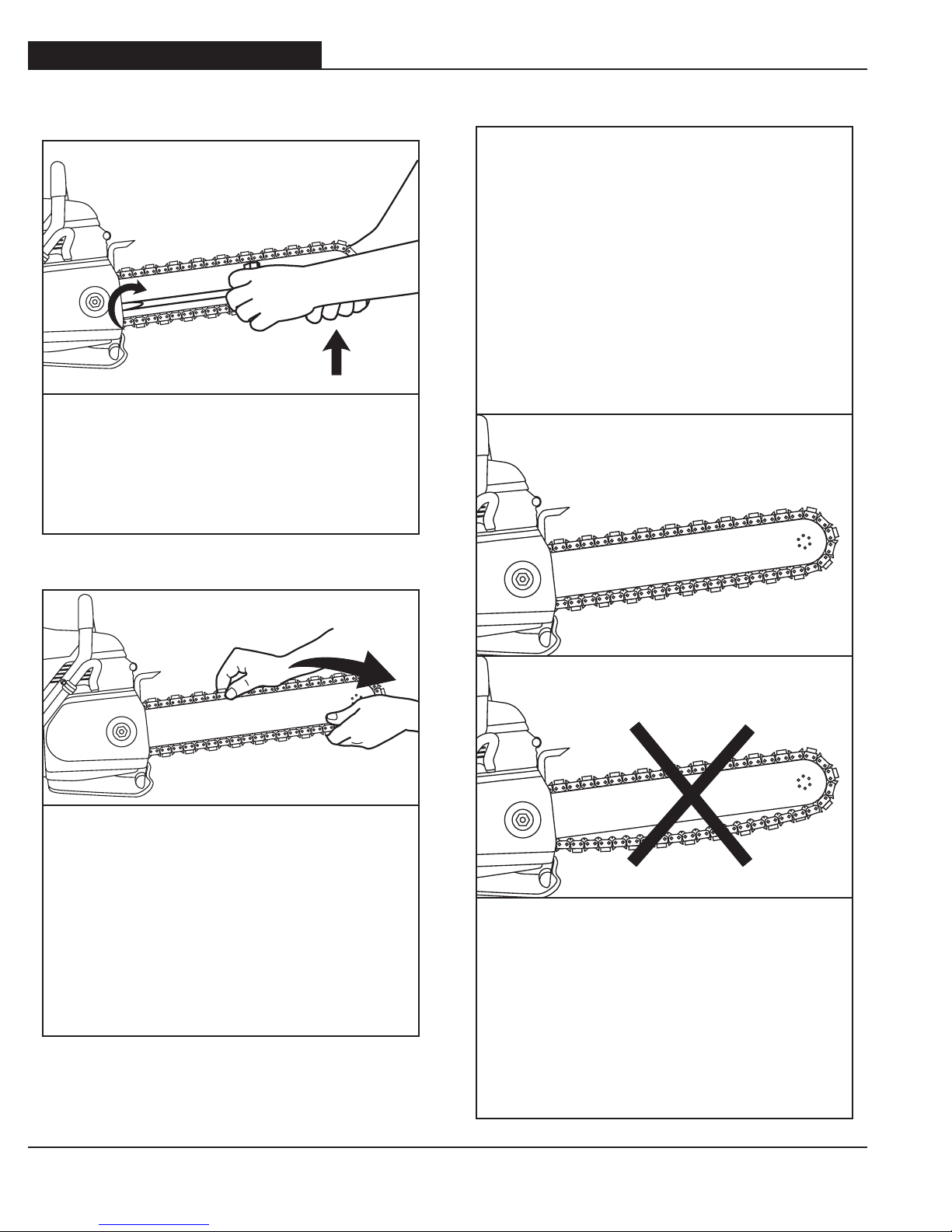

STEP 6

Before cutting, check for proper tension by

pulling the chain around the bar by hand. If

you cannot easily pull by hand, the chain is

too tight and needs to be loosened slightly.

CAUTION: Be aware that the guidebar

rails may develop sharp edges over time

so always pull the diamond chain by the

diamond segments.

STEP 5

Make sure all the drive links are inside

the guidebar groove then lift the bar nose

and tension the chain by turning the screw

clockwise.

CORRECT CHAIN TENSION

All chains have a tendency to stretch

when used. Diamond chains stretch more

than wood cutting chains because of the

abrasive materials they are cutting.

If the chain is too tight, a lot of the saw's

power goes into turning the chain rather

than into the cut. In extreme over-tightened

cases, the saw may not be able to turn the

chain at all. In addition, damage can occur

to the bar nose and premature stretch may

oc cur.

CHAIN TOO LOOSE

If the chain is too loose, it could come off

the bar, or it will allow the drive sprocket to

spin without turning the chain, which can

chew up drive links.

When a chain stretches to a point where

the drive links are hanging approximately

1/2 in (12 mm) to 3/4 in (18 mm) below the

bar, it is time to tension the chain.