F/N 522803 Jul12 © 2012 ICS, Blount Inc.

814PRO SERVICE MANUAL

7

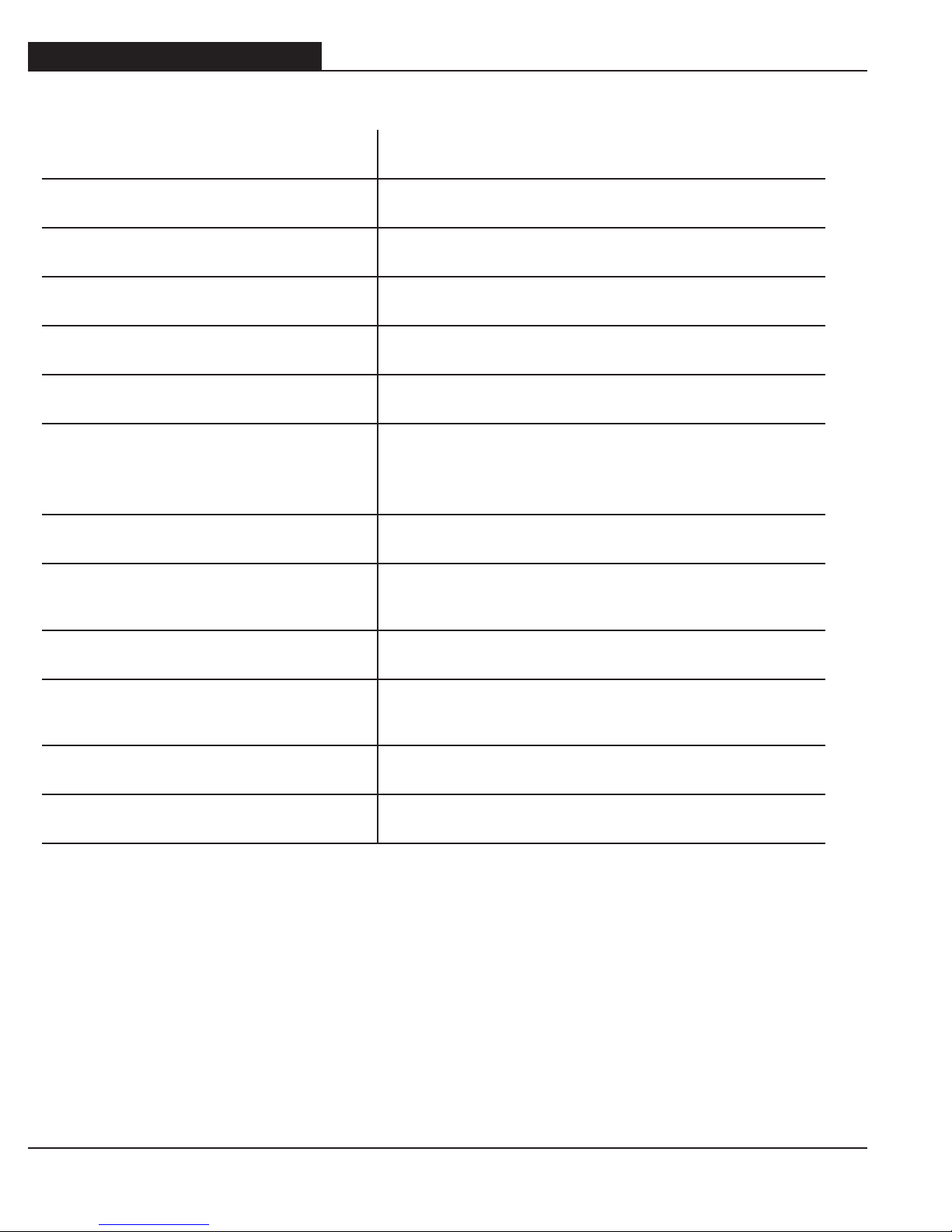

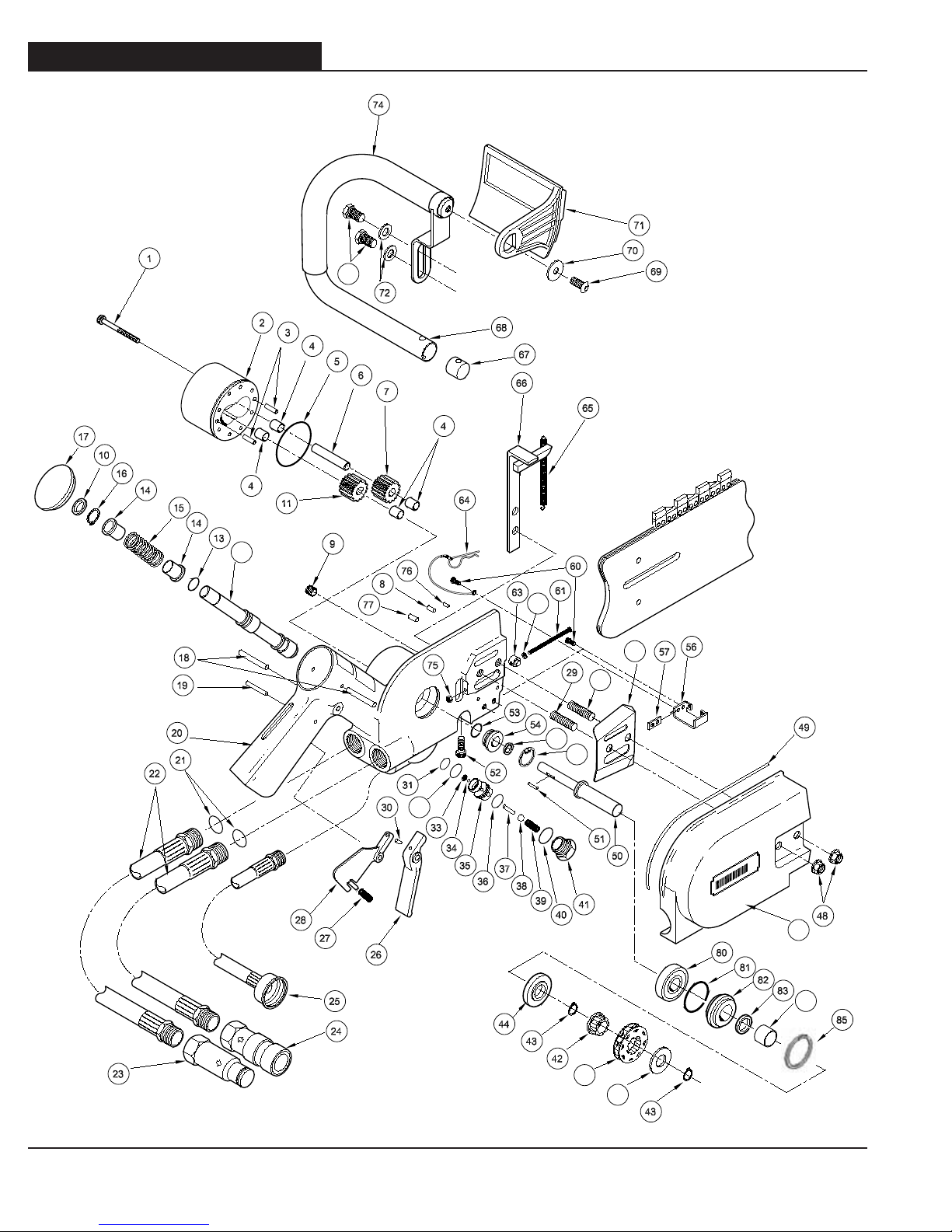

4. SPARE PARTS DIAGRAM

KEY P/N DESCRIPTION

174514 HSH Cap Screw 10-24 x 1 1/4

274515 Rear Gear Housing Assembly

374516 Dowl Pin

474517 Bushing (4)

574518 O-Ring

674519 Idler Shaft

774520 Idler Gear

874021 Wallwalker Pivot Pin

974597 1/8 NPT Plug

10 7459 6 Wiper Seal

11 74522 DriveGear(withKeyway)

12 74523 On-Off Valve

13 74524 Hydraulic Valve Seal

14 74525 Spring Washer

15 74526 Spring

16 74527 Retaining Ring 1/2 External

17 74528 Plug Button

18 74529 Roll Pin

19 74530 Roll Pin

20 74531 Valve Handle Assy (Includes: 31, 66)

21 74532 O-Ring

22 74533 Pigtail Hose Assembly

23 74534 1/2” Flush Face Coupler (M)

24 74535 1/2” Flush Face Coupler (F)

25 74536 Water Hose Assembly

26 74537 Trigger

27 74538 Spring

28 74539 Safety Catch (Trigger Lock-Out)

29 74540 Rear Stud

30 74542 Roll Pin

31 74543 O-Ring

32 74544 O-Ring

33 74545 Self Locking Retaining Ring

34 74546 O-Ring

35 74547 Water Valve Sleeve

36 74548 O-Ring

37 74549 Pin

38 74550 Steel Ball

39 74551 Spring

40 74552 O-Ring

41 74553 Seal Cap

42 71386 Splined Sprocket Adaptor

43 71384 External Shaft Retaining Ring

44 74497 Seal Spacer

45 71385 Rim Sprocket

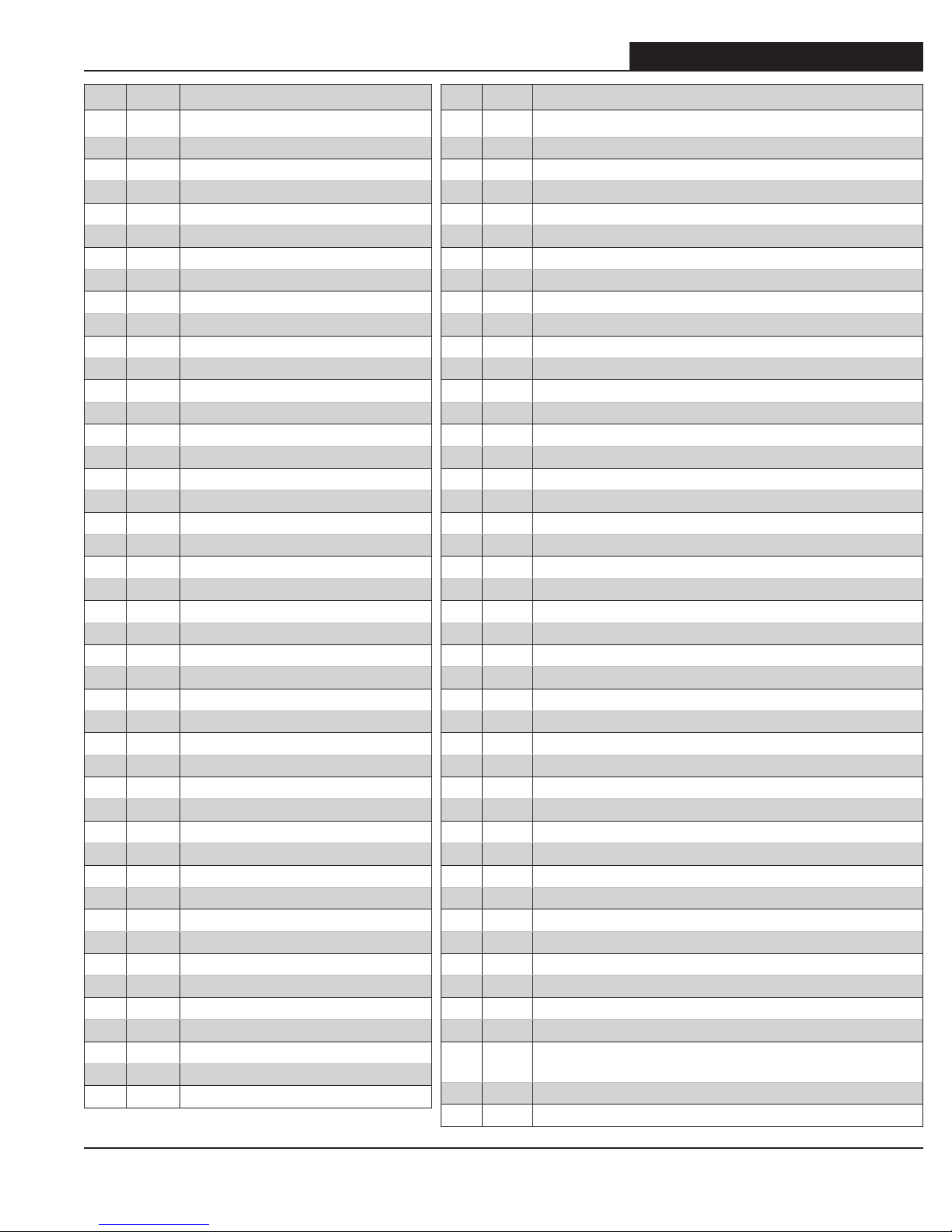

KEY P/N DESCRIPTION

46 71388 Tabbed Washer

47 71940 SideCoverReplacementKit

48 74558 Flange Nut (M10)

49 74559 Sprocket Side Cover Seal

50 71383 814PRO Motor Shaft Replacement

51 74561 Needle Roller

52 74562 HSH Cap Screw 5/15-18 x 3/4

53 74563 Shaft Seal

54 74564 Seal Back Up Washer

55 74591 Guard Flap Assembly (Not shown)

56 74566 Guard Flap Mount

57 74567 Spacer

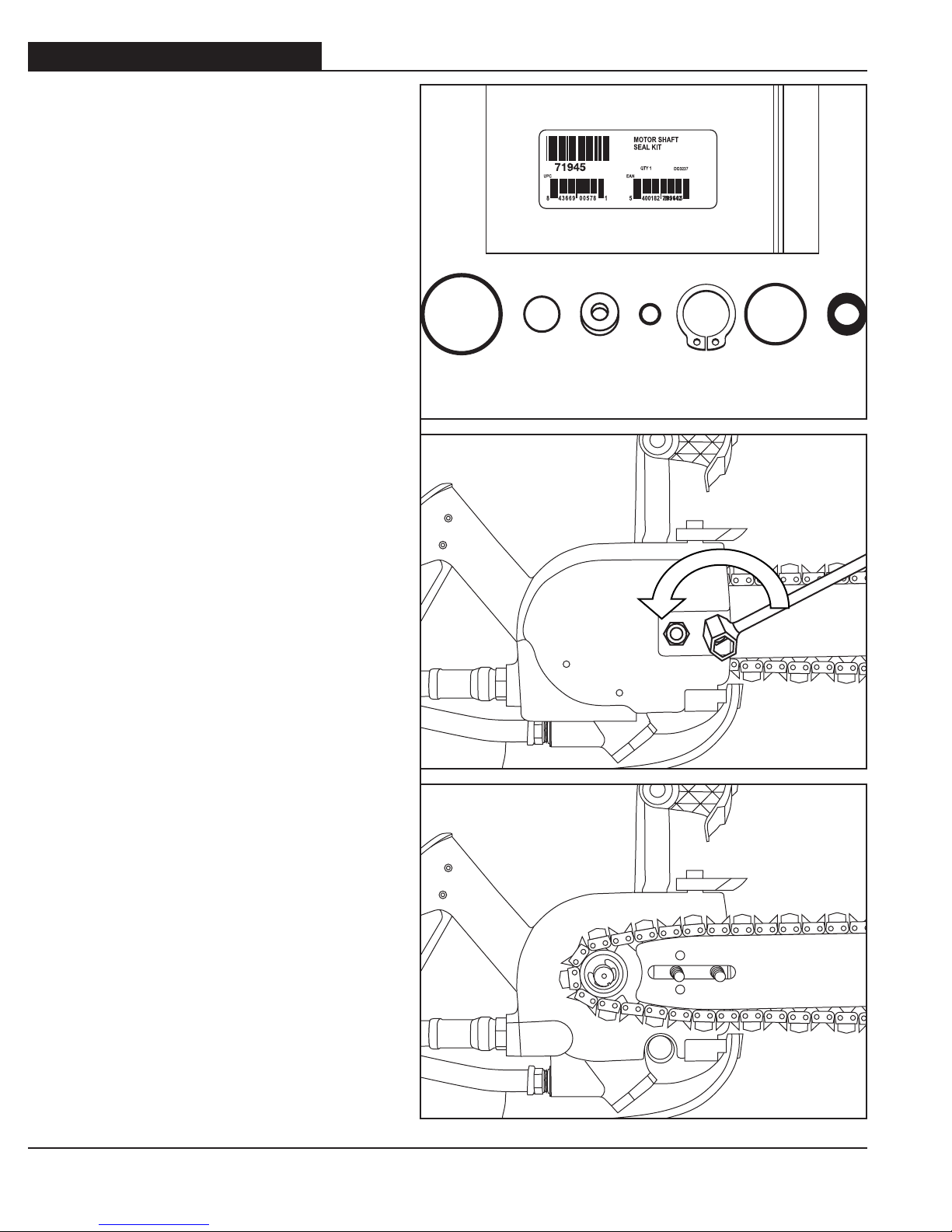

58 74568 Bar Mount Cover Plate

59 74569 Front Stud

60 74570 HSH Cap Screw 1/4-20 x 5/8

61 74571 Machine Screw

62 74572 Stat-O-Seal

63 74573 BarAdjustmentNut

64 74019 Lanyard Assembly

65 74582 WallWalker Spring

66 74583 WallWalker Arm (w/ Spring)

67 74574 Handle Bar Retainer

68 74575 Handle Bar

69 74584 Guard Mounting Bolt

70 74585 Guard Mounting Washer

71 74586 Front Handguard

72 74576 Washer

73 74577 HH Cap Screw 5/16-18 x 5/8, Zinc

74 74588 Handlebar Grip

75 74579 Nut 1/4-20 HHD LT SST

76 74580 Spiral Pin

77 74581 Spiral Pin

78 74493 Quad-Ring

79 74565 Retaining Ring

80 74554 Shaft Bearing Race

81 74498 O-Ring

82 74495 Seal Washer

83 74494 V-Ring

84 74496 Seal Ring

85 74555 Retaining Ring

71152 Tensioning Scrench, Hydraulic Saws (not shown)

71944 WaterValveSealKit(Incl:31,32,34,36)(notshown)

71945 MotorShaftSealKit(Incl:5,43,53,54,78,81,83)shownon

p.8

74061 Chain Tensioning Assembly (Incl: 61,62,63,75) (not shown)

75260 814RimSprocketUpgradeKit(notshown)