© 2014 ICS, Blount International Inc. Specications are subject to change without notice. REV021414 F/N 566100

890 SERIES OPERATOR’S MANUAL

5

SAFETY

WARNING

THE FOLLOWING SYMBOL APPLIES TO ALL THE ITEMS LISTED ON THIS PAGE

A potentially hazardous situation exists which, if not avoided,

could result in death or serious injury.

Diamond chain breakage can result in high-speed ejection of parts, which can result in death

or serious personal injury to operators or bystanders. The items listed below are critical to

minimizing the risk of diamond chain breakage and injury.

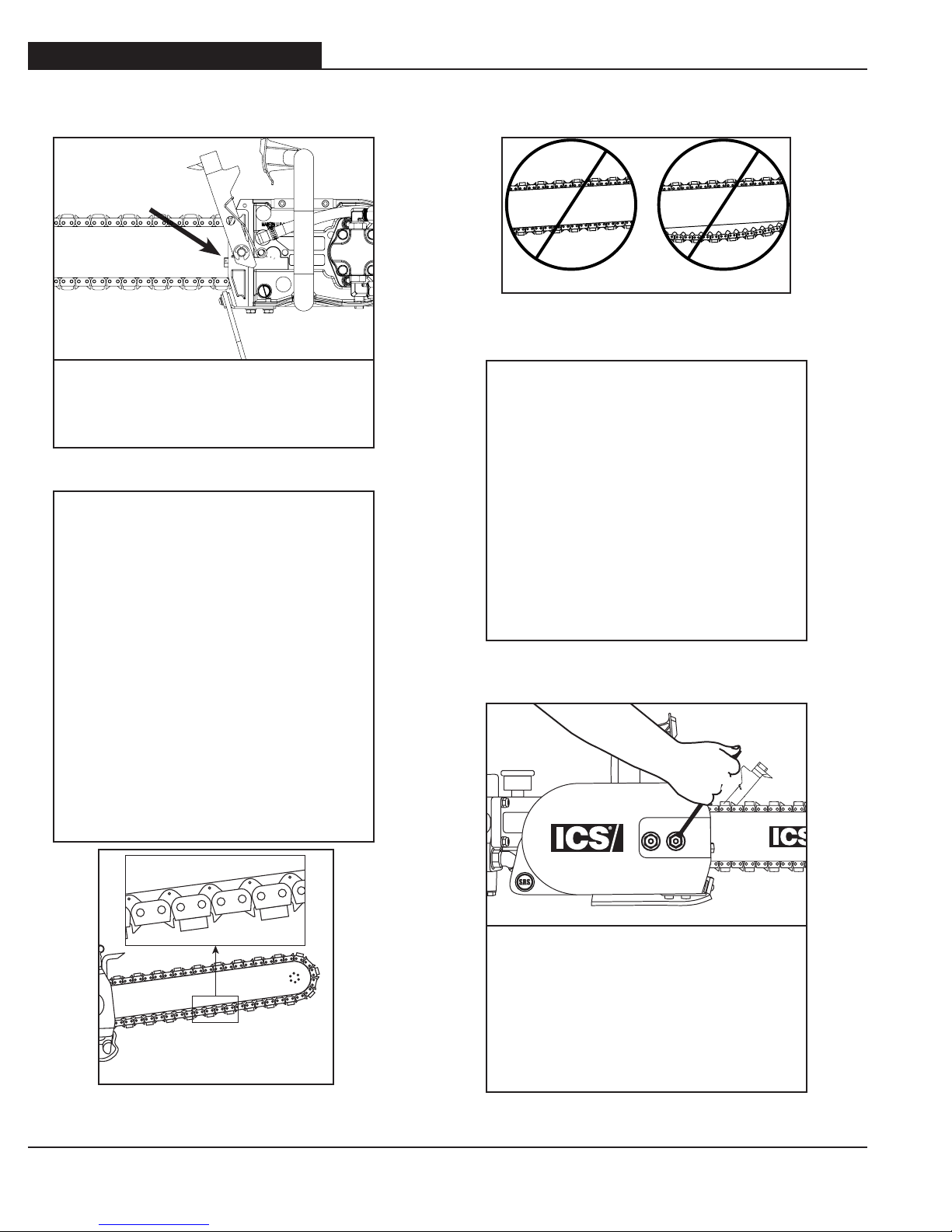

• DO NOT operate a diamond chain saw with a damaged, modified, broken or missing side

cover, bottom guard or guard flap. The side cover, bottom guard and guard flap provide

protection against contact with moving parts, ejected debris, broken diamond chain,

thrown water and concrete slurry.

• DO NOT operate saw with loose, missing, damaged or improperly repaired parts.

• DO NOT exceed the hydraulic flow for your saw model: 8 gpm (30 lpm) or 12 gpm (45 lpm)

at 2,500 psi (172.5 bar) hydraulic pressure.

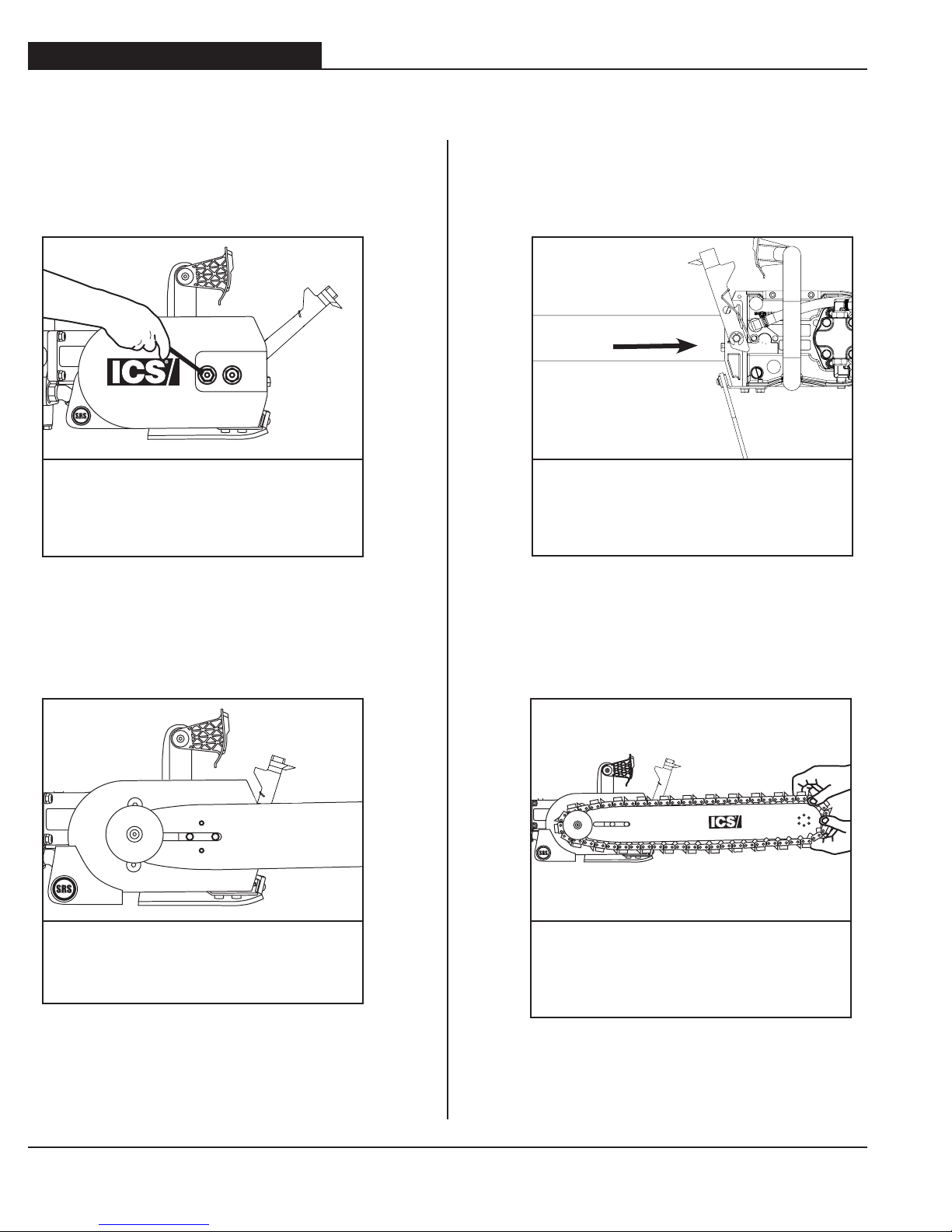

• DO NOT run the saw backwards. The chain should travel away from the operator on the

top of the bar and return on the bottom of the bar.

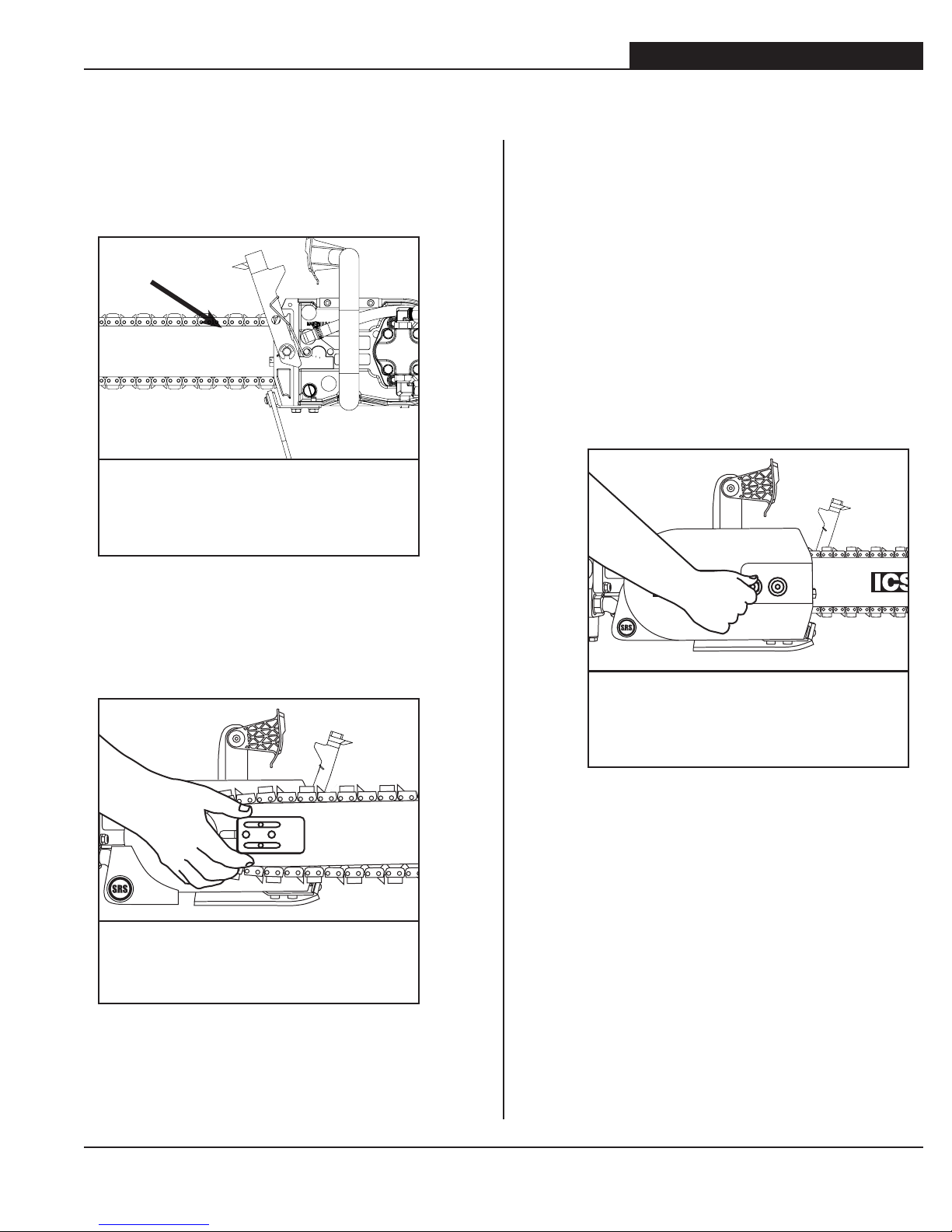

• DO NOT insert the saw into a slot narrower than the chain segments. Rapid pushback

might occur. Reference: Most diamond segments are .225 (5.72 mm) wide.

• DO NOT use the 890 Series side cover as a replacement cover for another saw.

• DO NOT use damaged, modified or improperly repaired chain.

• DO NOT run the saw upside-down. Concrete debris can fly back into the operator’s face.

• DO NOT use your hands to search for hydraulic leaks. Hydraulic fluid escaping under

pressure can penetrate skin. If any hydraulic fluid is injected into skin seek medical

attention immediately.

• Only use PowerGrit®Utility Saw Chain when cutting ductile iron pipe or like materials

with the saw. Using chain platforms not specifically designed for this type of material

may cause segment loss or diamond chain breakage.

• See page 13 for information about cutting with PowerGrit chain.