Protege DIN Rail 8 PGM Output Expander | Installation Manual 3

Contents

1Introduction_______________________________________________________________ 5

2Installation Requirements___________________________________________________ 6

3Grounding Requirements ___________________________________________________ 7

3.1Safety Grounding ..........................................................................................................7

3.2Earth Ground Connection..............................................................................................7

4Mounting _________________________________________________________________ 9

4.1Removal.........................................................................................................................9

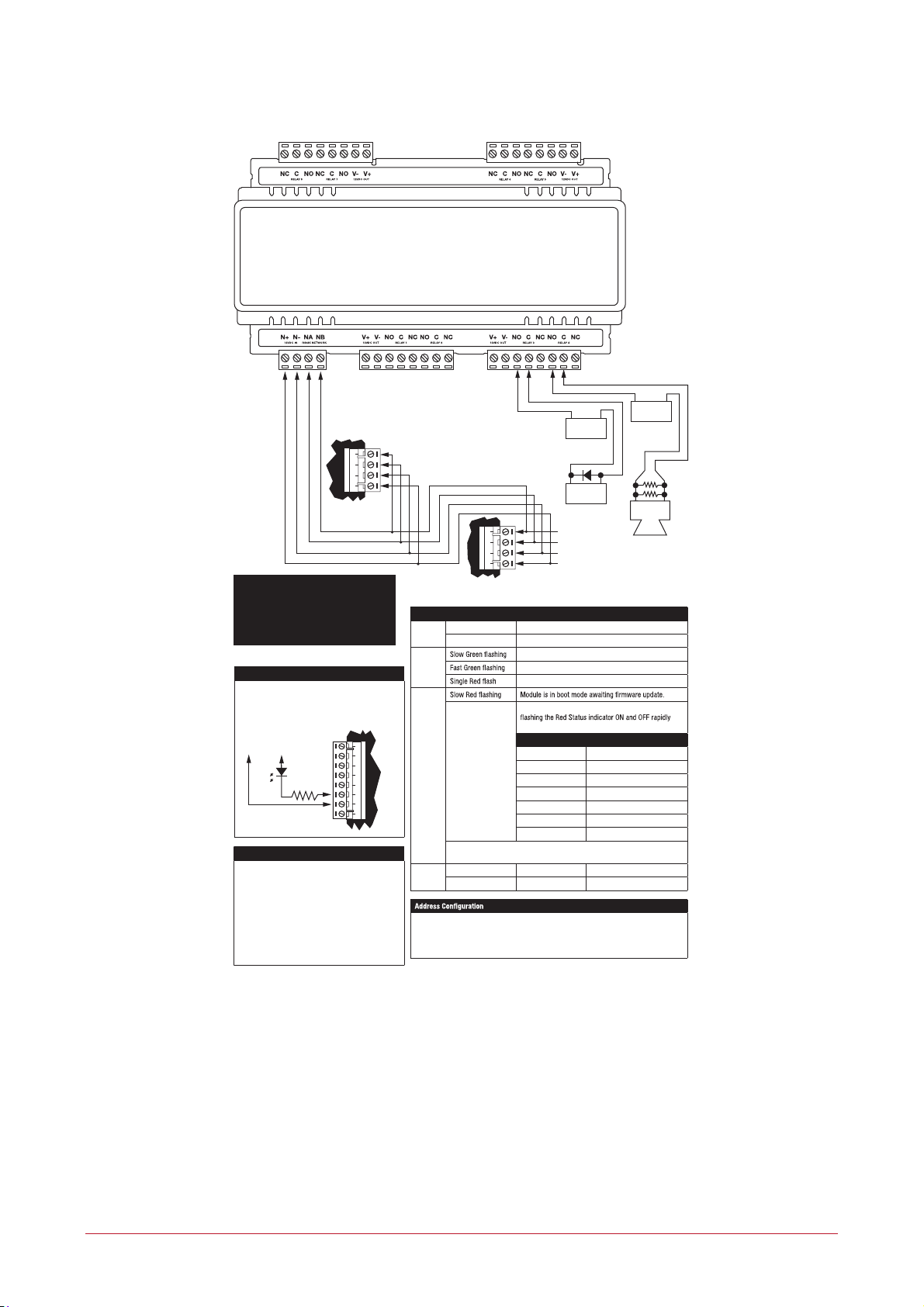

4.2Wiring Diagram............................................................................................................10

5DC Power & Encrypted Module Network ____________________________________ 11

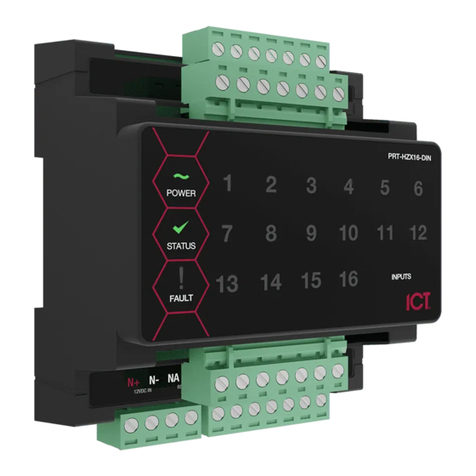

6Outputs _________________________________________________________________ 12

6.1PGM Outputs 1 to 8 ....................................................................................................12

7Address Configuration ____________________________________________________ 13

8LED Indicators ___________________________________________________________ 14

8.1Status Indicator ...........................................................................................................14

8.2Fault Indicator..............................................................................................................14

8.3Power Indicator ...........................................................................................................14

8.4Output Indicators.........................................................................................................15

9Error Code Indication _____________________________________________________ 16

9.1Error Code Display ......................................................................................................16

10Mechanical Diagram ______________________________________________________ 17

11Mechanical Layout _______________________________________________________ 18

12Technical Specifications___________________________________________________ 19

13New Zealand and Australia ________________________________________________ 20

14European Standards ______________________________________________________ 21

15UL and ULC Installation Requirements ______________________________________ 23

15.1UL/ULC Installation Cabinet Options ..........................................................................23

15.2ULC Compliance Requirements..................................................................................23

CAN/ULC-S304-06......................................................................................................23

CAN/ULC-S319-05......................................................................................................26