IDEA VISION C3 VacuMount User manual

contact@idea-vision.de

The Right Choice!

GmbH

VISION

www.idea-vision.de

VacuMount

INSTRUCTION MANUAL

1

Office

IDEA VISION GmbH

Anzengruberstr. 16

83059 Kolbermoor

Germany

Directors

Gabriel Pecuch

Mark Fellinger

District Court of

Traunstein HRB 24094

USt-IdNr.: DE 298741089

Contact

Fon +49 (0)8031 90 85 795

Fax +49 (0)8031 90 85 796

email contact@idea-vision.de

www.idea-vision.de

www.idea-vision.de

Subject Page

Safety hints 3

The VacuMount System 4

Initial operation 5

Micro-controlled

Vacuum Pump System 6

Assembling 7- 12

Notes 13

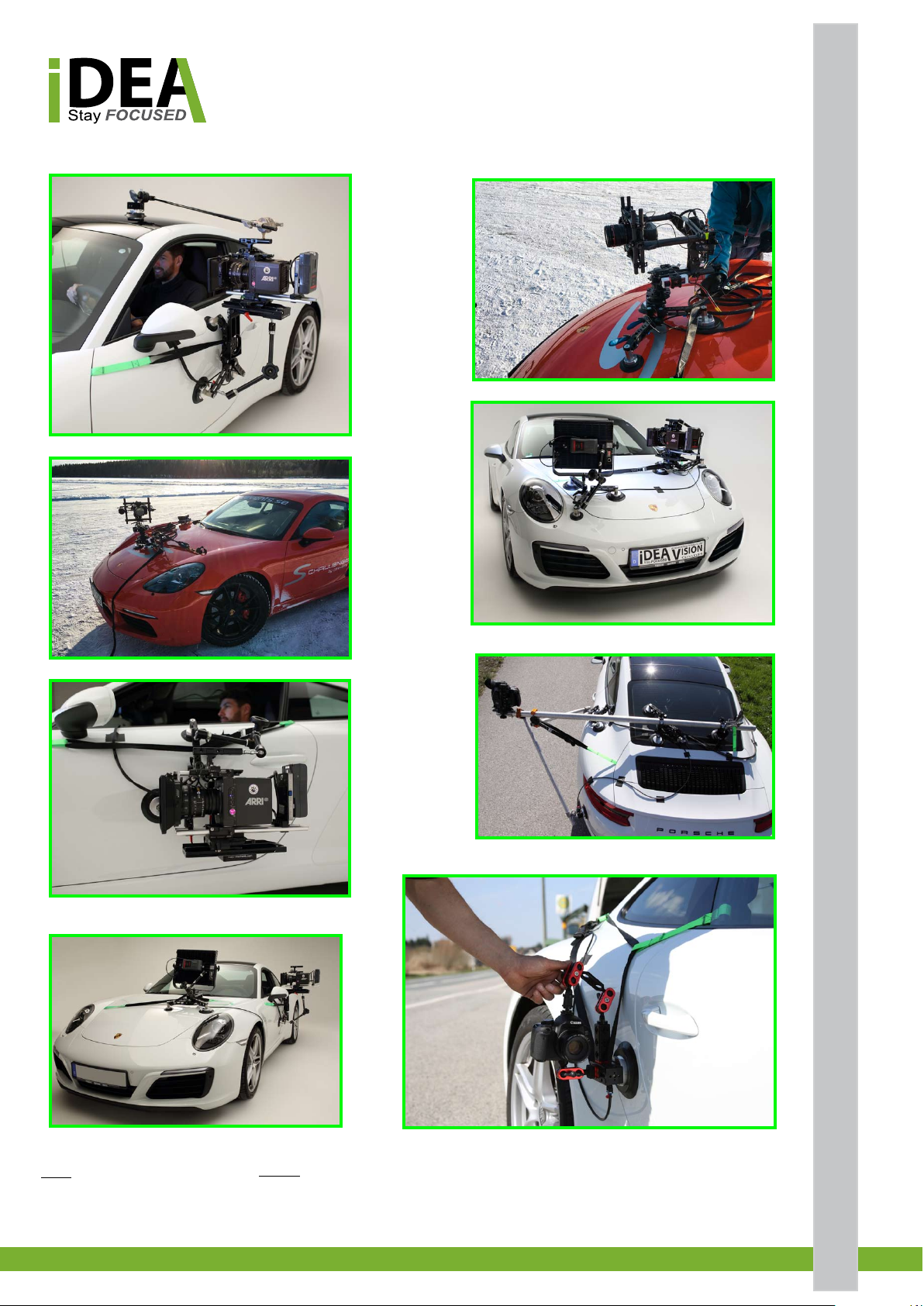

Examples 14 - 15

Table of contents

www.idea-vision.de

3

Safety hints

1. Do not start operating the VacuMount System until you have read and understood the

operating instruction. All safety hints and informations have to be observed.

2. The IDEA VISION VacuMount may only be operated by competent staff.

3. Cleanness and adhesion: To guarantee a proper adhesion of the suction cup it is most

important to make sure that the surfaces of both, the suction cup and the mounting sur-

face are clean. Please mount the device exclusively on smooth, even and suitable surfaces.

4. Attention: Although the holding force of the suction cups are high enough to carry the

camera, always use tension belts (safety straps)as a back up. Before using the VacuMount,

steadiness and holding force must always be tested before shooting or driving using the

maximum forces to be expected. Attention: With the construction the car is wider/higher

as normal. The horizontal and vertical areas must be kept free. Use only on secured roads/

areas. Do not use on public roads.

5. Do not switch on vacuum pump in dusty area. Clean car surface from dirt/dust. The suc-

tion cups work like a vacuum cleaner. During air suctioning, particle (e.g. sand)may dama-

ge inside parts like the pump.

6. Repair works should only be executed by the manufacturer or by well-trained staff.

7. When connecting the VacuMount to the power supply, the general VDE guidelines have

to be observed. The VacuMount needs to be protected against moisture.

8. Make sure that unauthorized personnel can not use the VacuMount

contact@idea-vision.de

4www.idea-vision.de

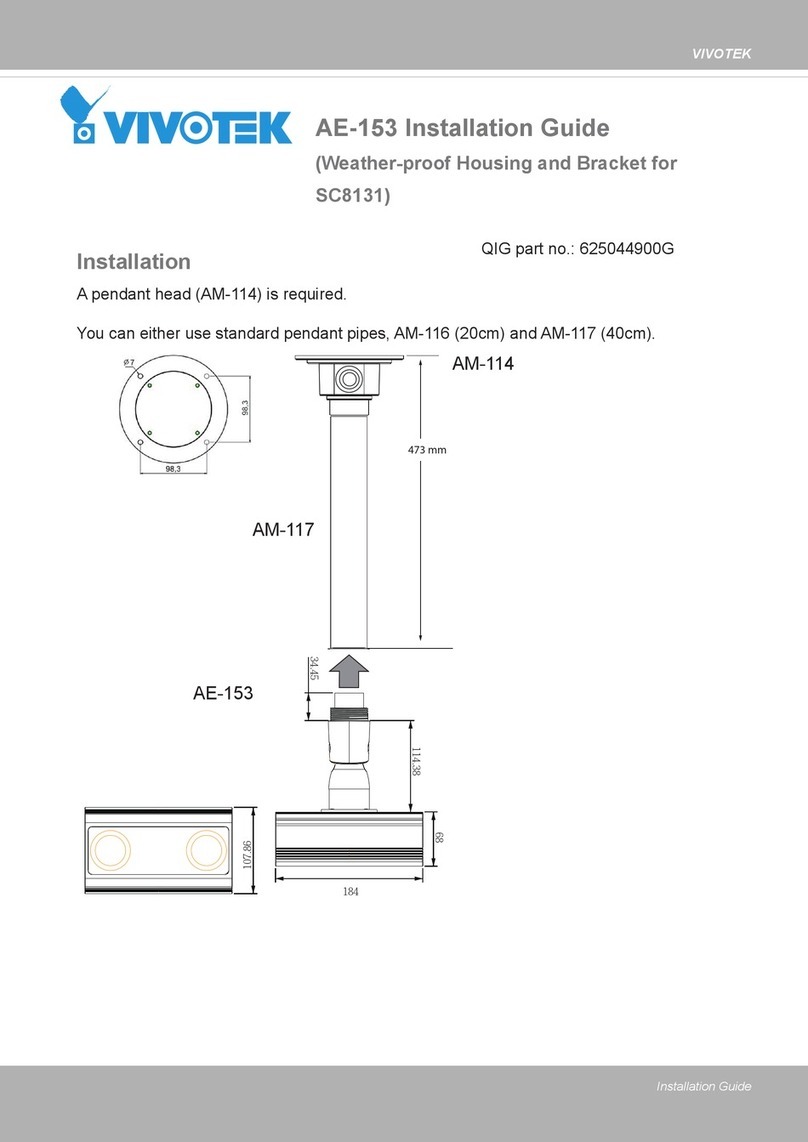

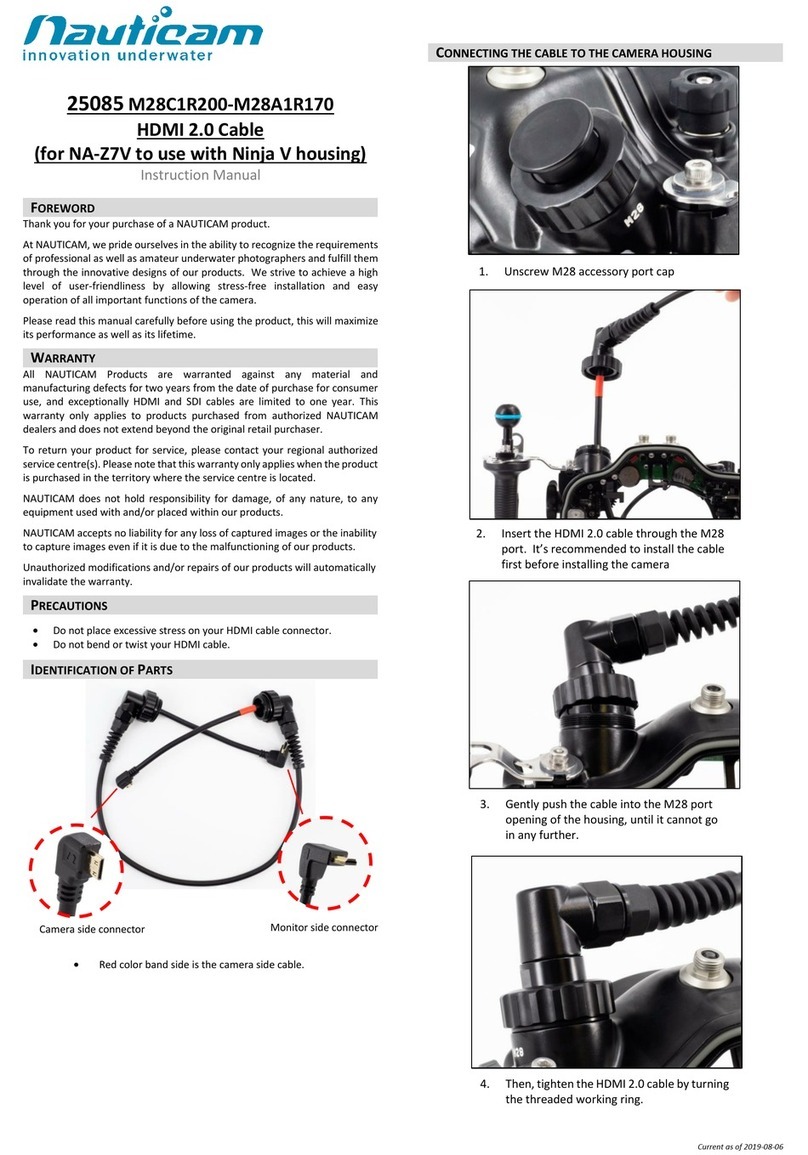

C3VacuMount Kit existing of:

1x C3structure

2x Suction cup 125 mm

1x Suction cup 80mm

1x Micro-controlled Vacuum Pump System

1x cable car power supply appr. 2m

1x cable air supply appr. 5m

C3VacuMount extension:

1x C3structure

2x Suction cup 125 mm

1x Suction cup 80mm

1x cable air supply appr. 5m

C1VacuMount extension:

1x C1structure

1x Suction cup 125 mm

1x cable air supply appr. 3m

The C3VacuMount System

MCU VacuMount Pump

1x VacuMount Pump

1x cable car power supply appr. 2m

5

contact@idea-vision.de

Initial Operation

pic

vacuum hose into

vacuum pump

1. Connect vacuum hose with the Micro-controlled Vacuum

pump and C3, C1structure.

Push the hose into the connections.

You can feel a distinct resistance during this process.

If there is a leak, the VacuMount system will not hold or the

vacuum pump will always pump.

2. Connect the Micro-controlled Vacuum pump system

with the power supply (11V –30V).

3. Check that the suction cups and the mounting

surface are clean.

To guarantee a proper adhesion of the suction cup it

is most important to make sure that the surfaces of

both, the suction cup and the mounting surface are

clean, dry and dust free.

4. Check the stability of the mounting surface.

Hoods, doors of modern cars are often weak.

Place the suction cups near edges, beadings,

seams, etc.

Keep in mind to find suitable mounting spots for

safety/tension belts.

1

2

3

4

6www.idea-vision.de

MANUAL

Vin 12.59 V

48.8

kpa

OK

AUTO

Hi

Lo

Vin

AUTO

OK

Lo

AUTOMAN

VacuMount

123

4

5

6

7

8

9

1 Power Supply Status

Power supply low

Power supply in working range

Power supply to high

2 Voltage indicating system

3 Operating Mode MANUAL

Operating Mode AUTO

4 Warning ! Slow stop! Check the system!

5 VacuumStatus

Vacuum pressure to low

Vacuum pressure in operating mode

6 Operating Range Vacuum

upper operating range

lower operating range

7 Negative Vaccum Pressure in kpa

8 Automatic Button

8.1 Mode Adjustment

Hold green Button for 3 seconds

12 Change into Mode Menu

13 Select with blue Button

Return with green Button

9 Manual Pump Button

10 Air supply

11 XLR Plug

10

11

PUSH

kPa

-70

-60-50

-40

-35 -45 -55 -65 -75

1

2

3

4

Modes

1 Low Vacuum pressure - light weight - low power

consumption - less pump cycles

2 Standard Vacuum pressure - standard power

consumption - standard pump cycles

3 Long Range Vacuum pressure - light weight - low power

consumption - less pump cycles

4 High Vaccum pressure - heavy weight - high centrifugal

force - raised power consumption

12 13

Vin 12.59 V

48.8

kpa

M

AUTO

2

Micro-controlled Vacuum Pump System

7

contact@idea-vision.de

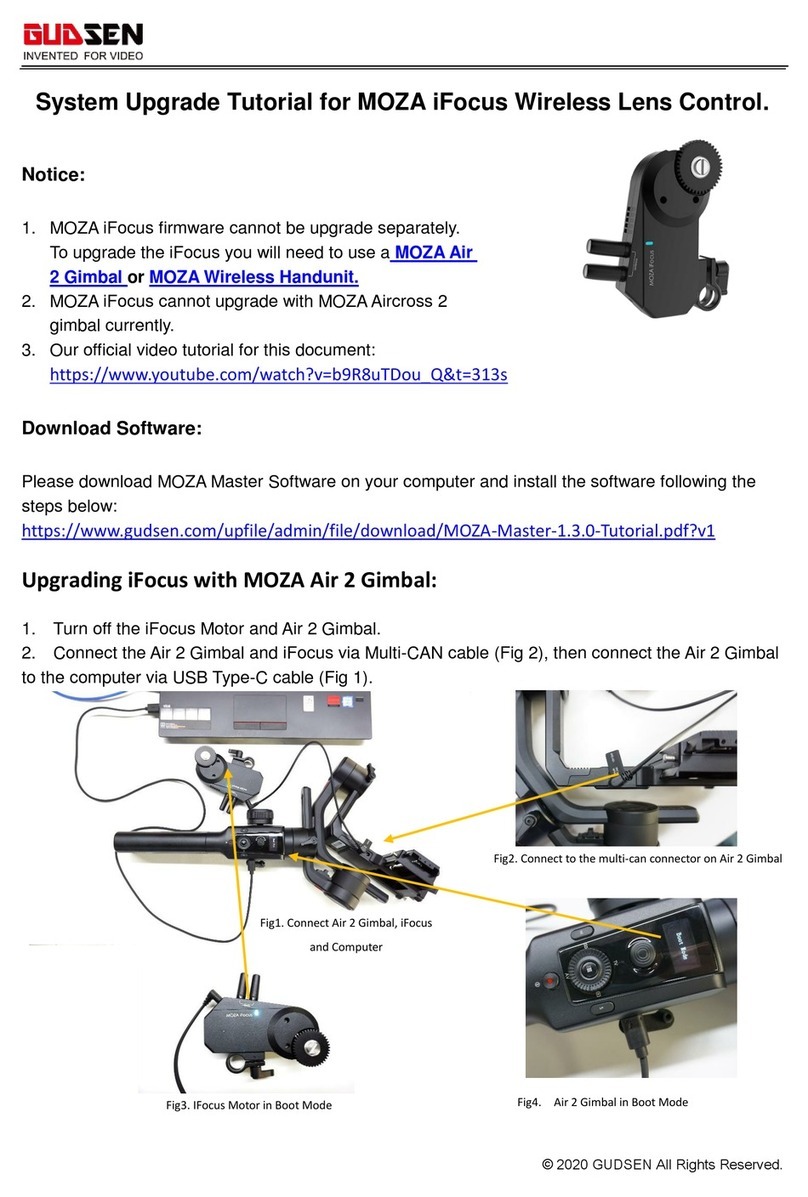

Assembling

1. Make sure all components are available

and in working order.

2. Clean car surface and suction cups.

Note: Clean, dry, dust free

4. Place C3VacuMount where you want

to shoot.

1

2

3

4

3. Safety: Although the C3VacuMount s holding

force is adequate for regular driving shots,

tension belts must be used for additional safety.

In any case, especially if mounted on cars or

overhead, the object attached to the

C3VacuMount (e.g. camera)has to be secured

additionally with a safety cable or a tensioning

strap.

Use pads to avoid dents and scratches on

carpaint. Tighten tension belts carefully to avoid

damages on the car.

Note: Tension belts give additional safty and

avoid vibrations, especially on thin metal

sheets.

8www.idea-vision.de

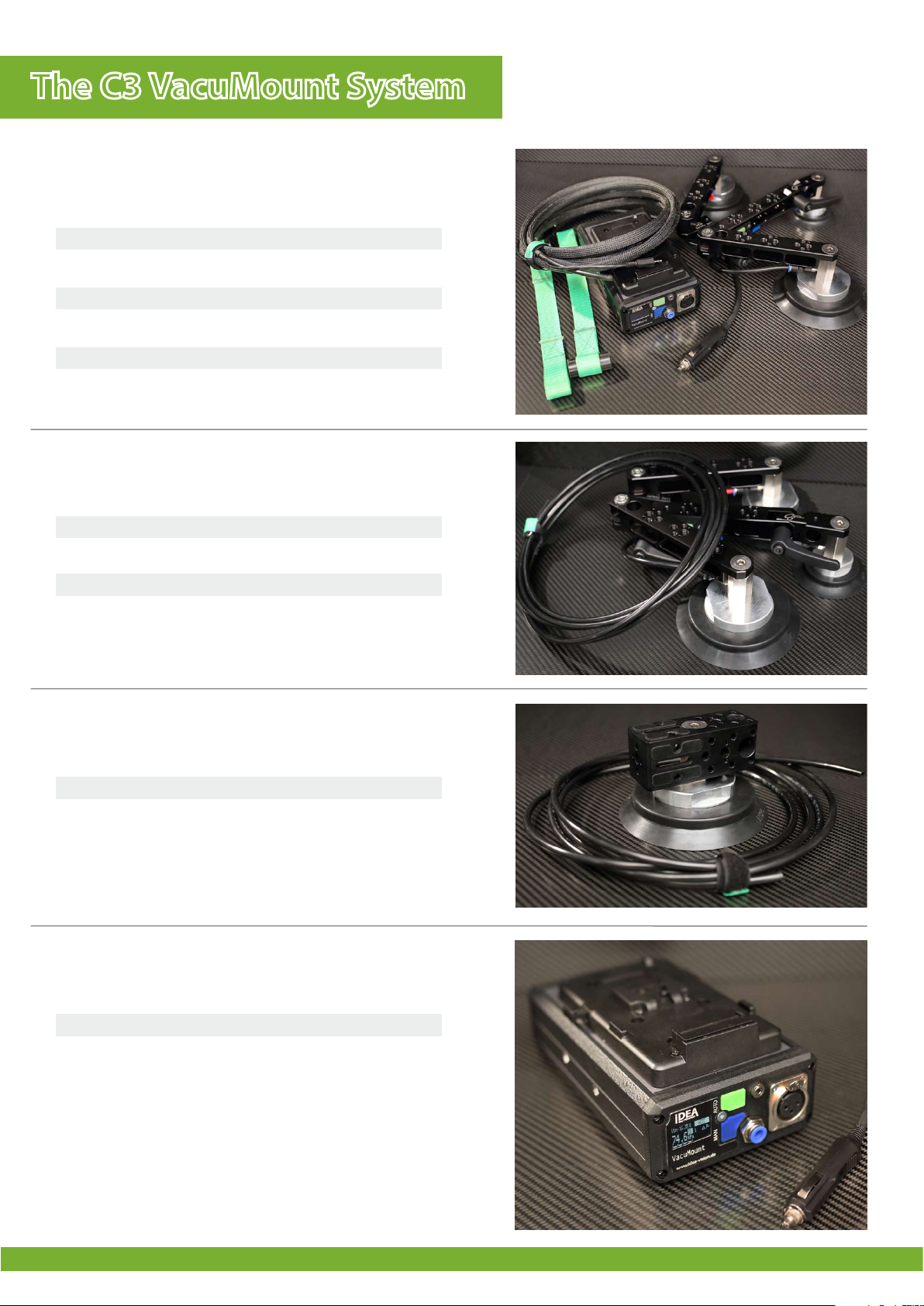

7. Adjust the C3to your requirements. Close

articulated links after all suction cups got vacuum.

8. Mount camera direct to C3structure using

M8, 1/4“ ,3/8 or use a wedge/tilt plate.

5. Open articulated links to level suction

cups to surface.

5

6

7

8

6. Press firmly suction cups down and push green

Button AUTO at the Micro-controlled Vacuum

pump or push green Button at the C3structure.

The vacuum pump starts working for appr. 3sec

Note: Assure that the Vacuum Pump System is

in Mode Automatic

9

contact@idea-vision.de

11. Fix vacuum hose with e.g. adhesive tape.

10. End of using:

Switch from Automatic into Manual Mode (push

green Button).

Push release Button at the Vacuum Pump System.

Note: You loose vacuum immediately.

10. Place vacuum pump system e.g. inside the car

and secure it properly.

9. Secure C3and camera with tension belt.

Note: Test fixture before driving.

9

10

11

12

VacuMount

10 www.idea-vision.de

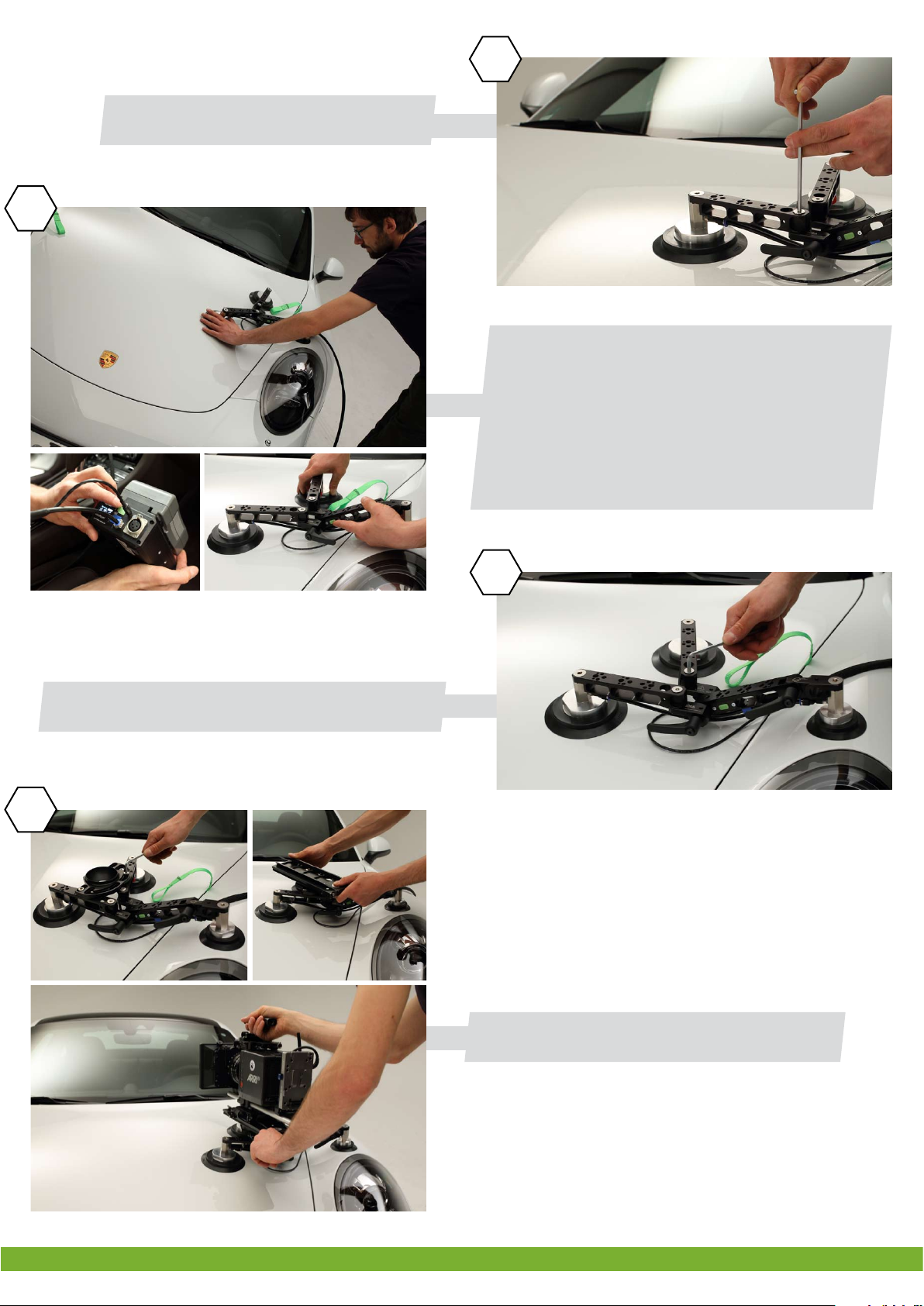

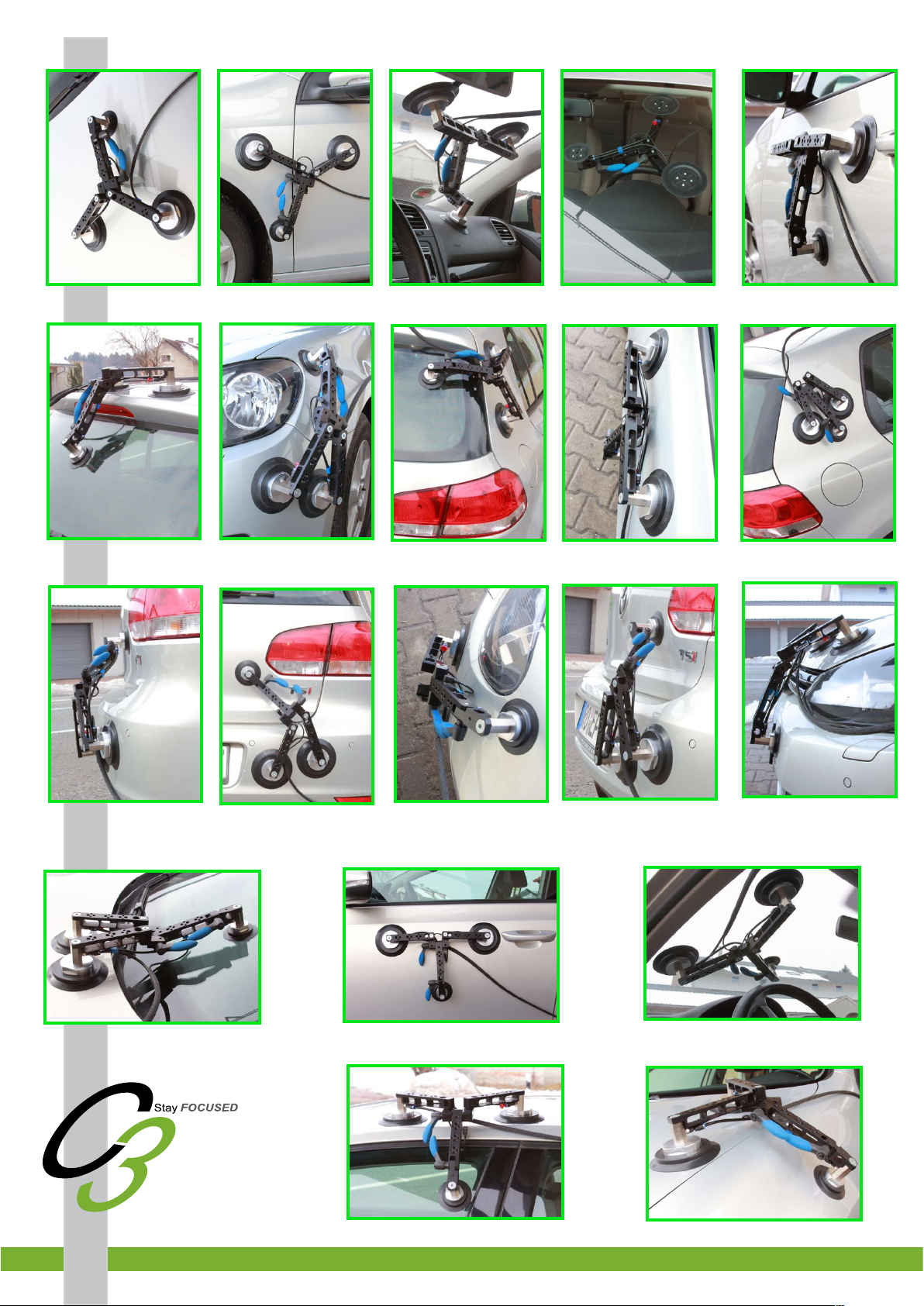

If you rigg the VacuMount e.g. on the

side of a car you have to keep in mind

same points as described

above. However, keep in mind that

the VacuMount will not hold on the

door without the vacuum.

Therefore, switch on the vacuum

pump system before you place it.

Vertical assembling

VacuMount

11

contact@idea-vision.de

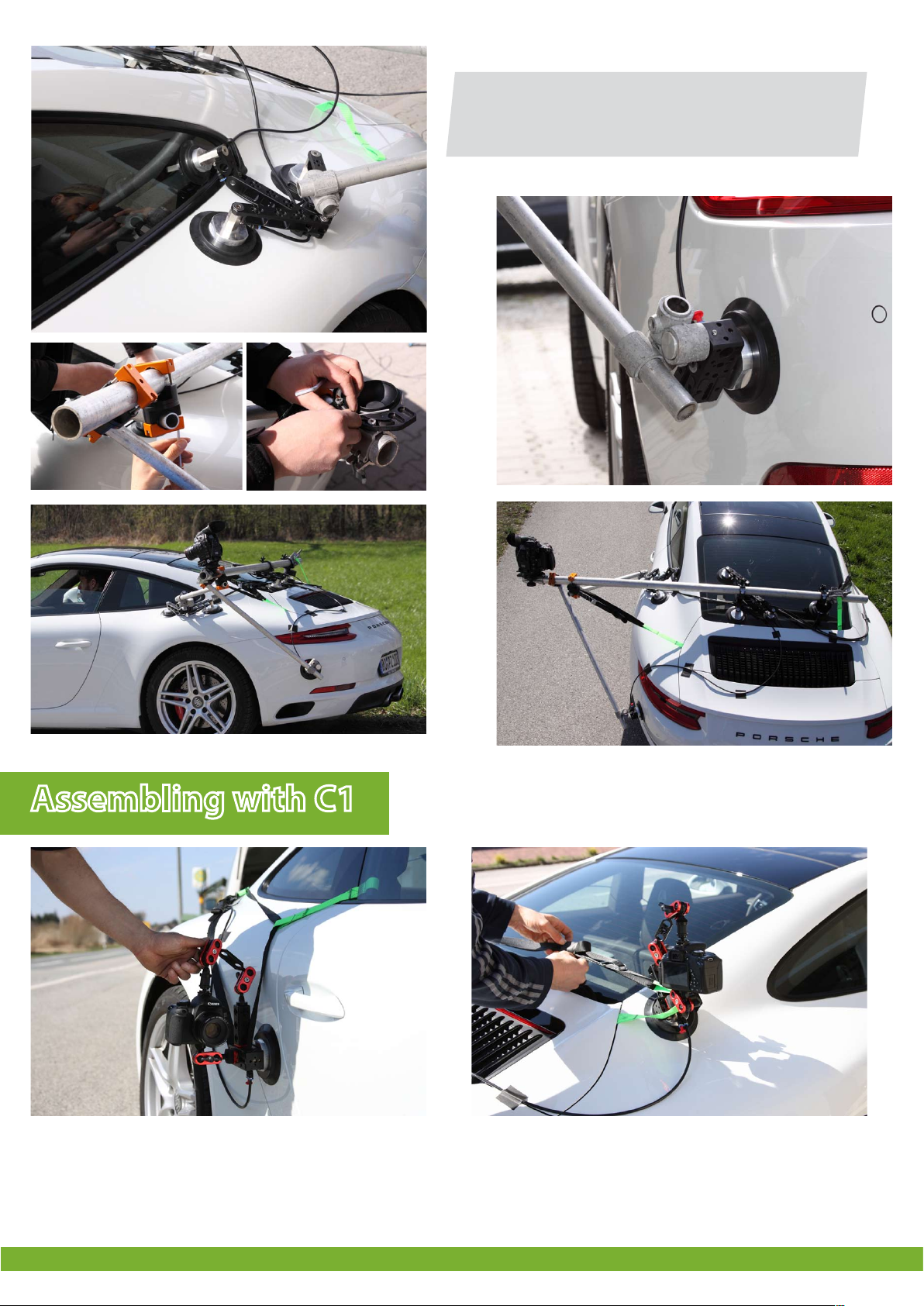

Use the Extension Kit if you want to place the

camera from more distance. You have to keep

in mind same points as described above when

mounting the VacuMounts with Extension Kit.

Individually place the VacuMounts to your require-

ments and connect them with the vacuum pumps

system. You can supply vacuum hoses serial.

Use Bowl Adapter to levell the camera. The camera

can be attached directly to Bowl Adapter or to a

camera wedge plate using 3/8 screws.

Assembling with C3, C1extension

1www.idea-vision.de

12 www.idea-vision.de

Note: In any case steadiness and holding force must always be tested before shooting or dri-

ving using the maximum forces to be expected. With the construction the car is wider/higher as

normal. The horizontal and vertical areas must be kept free. Use only on secured roads/areas. Do

not use on public roads.

Always use at least three mounting spots to get

adequate stability. The more mounting spots, C3s,

C1s you use the better stability you get.

Assembling with C1

Office

IDEA VISION GmbH

Anzengruberstr. 16

83059 Kolbermoor

Germany

Directors

Gabriel Pecuch

Mark Fellinger

District Court of

Traunstein HRB 24094

USt-IdNr.: DE 298741089

Contact

Fon +49 (0)8031 90 85 795

Fax +49 (0)8031 90 85 796

email contact@idea-vision.de

www.idea-vision.de

2

contact@idea-vision.de 13

contact@idea-vision.de

Notes

1. You lose vacuum immediately if you disconnect the vacuum hose!

2. Vacuum hose connection.

a. Disconnect vacuum hose.

i. Press down blue ring of connection.

ii. Pull hose at same time.

b. Connect vacuum hose.

i. Push hose into the connection. You can feel a distinct resistance during

this process.

c. If there is a leak, the VacuMount will not hold or the vacuum pump will always

pump.

3. Suction cups can be changed easily.

4. The Suction cups are designed in such a way that they still get vacuum on certain con-

vex and concave surfaces. However, use a suction cup with a different size or form, if the

surface is to much curved.

5. Normally, the suction cup is attached tightly and goes off easily. Nevertheless, the

suction cup should be regularly removed after 12-24 hours at the latest. Please clean and

maintain the device regularly using a special rubber-care product. This measure extends

the life of the suction cup and prevents it from sticking to the surface.

6. Clean surface after use to remove possible prints.

7. Cut vacuum hose right after the bend if the hose is cracked. You can repeat this

procedure until the vacuum hose becomes to short.

8. IDEA VISION recommends tubes with a size of 33mm (weight!).

14 www.idea-vision.de

VacuMount

15

contact@idea-vision.de

The Right Choice!

Office

IDEA VISION GmbH

Anzengruberstr. 16

83059 Kolbermoor

Germany

Contact

Fon +49 (0)8031 90 85 795

Fax +49 (0)8031 90 85 796

email contact@idea-vision.de

www.idea-vision.de

GmbH

VISION

www.idea-vision.de

Table of contents

Other IDEA VISION Camera Accessories manuals