5

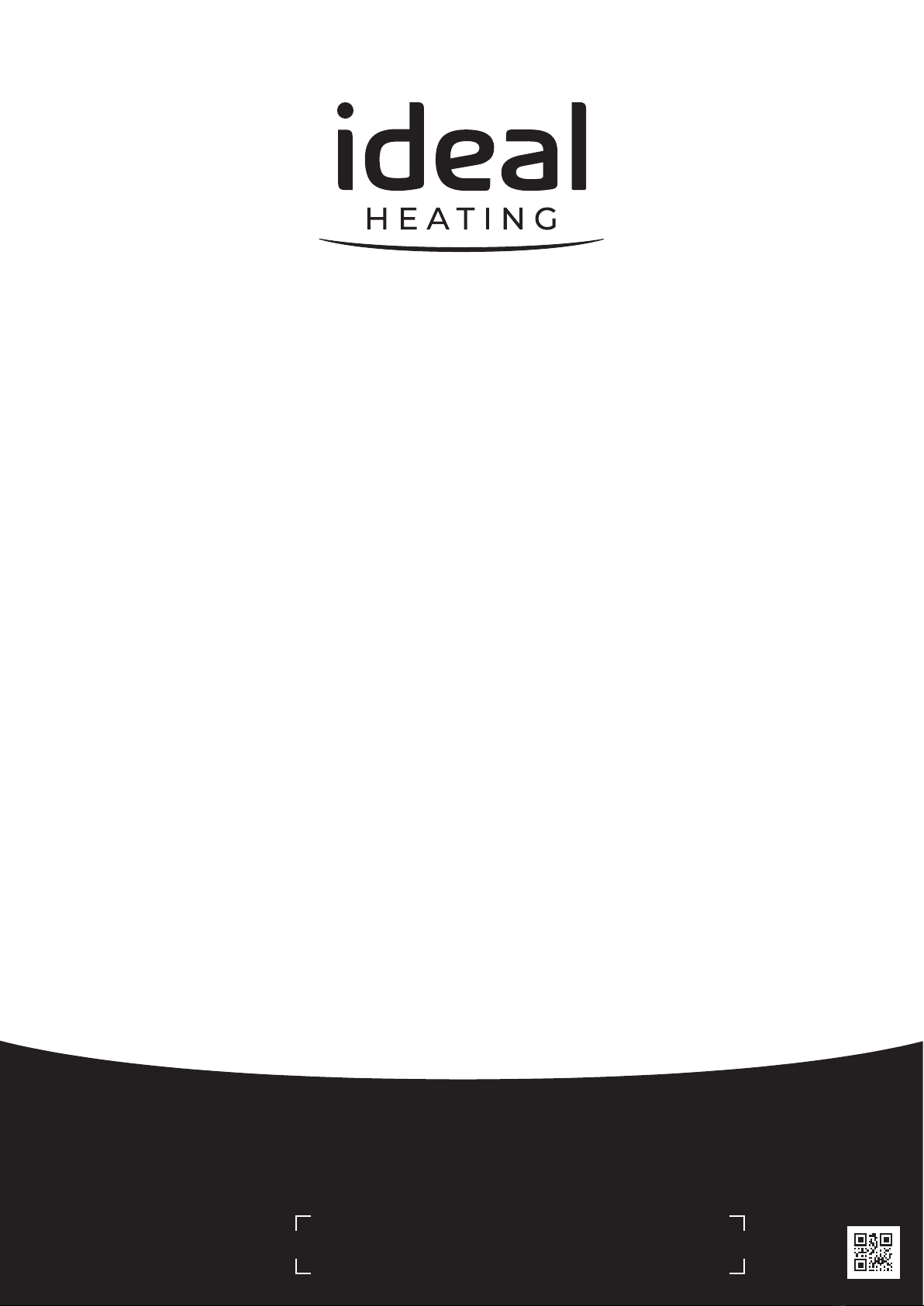

Plate Heat Exchanger Package

Section 2 - General Description

2.3 OUTPUT CONTROL

The package can be used with an optional accessory boiler

pump, available separately. The package can also be used

with compatible boilers having an internal boiler pump. Pumps

are designed to be wired to and controlled by the appliance to

allow a controlled pump over run.

2.4 GAS SUPPLY

Evomax 2 30, 40, 80, 60, 100, 120 & 150 boilers are

congured for use with natural gas. The 30P, 40P, 60P,

80P, 100P & 120P boilers are congured for use with LPG /

Propane.

The package requires the gas inlet to be made up to the gas

tap provided, connecting it to the appliance's inlet. Assembly

of the gas supply pipework and connection to the gas supply

must follow all the applicable regulations.

A purge valve with a test point is provided before the boiler

gas tap. This test point nearest the appliance gas inlet is

intended to be used as the appliance inlet pressure test point.

2.5 SAFE HANDLING

Take appropriate measures to ensure safe handling of this

appliance, use multiple operatives and or lifting equipment if

necessary.

Operatives should be knowledgeable in handling techniques

when performing these tasks and the following precautions

should be considered:

• Use appropriate handling points

• Be physically capable

• Use personal protective equipment as appropriate, e.g.

gloves, safety footwear

During all manoeuvres and manual handling actions, every

attempt should be made to ensure the following unless

unavoidable and/or the weight is light.

• Keep back straight

• Avoid twisting at the waist

• Avoid upper body/top heavy bending

• Always grip with the palm of the hand

• Use designated hand holds

• Keep load as close to the body as possible

• Always use assistance if required

2.1 PLATE HEAT EXCHANGER KIT

OPTIONS

This kit is provided with a plate heat exchanger suitable to

cover a single boiler installation from the range of available

Evomax 2 boilers.

The kit is based on a low height frame and allows hydraulic

separation of the boiler from the secondary system in a

compact envelope.

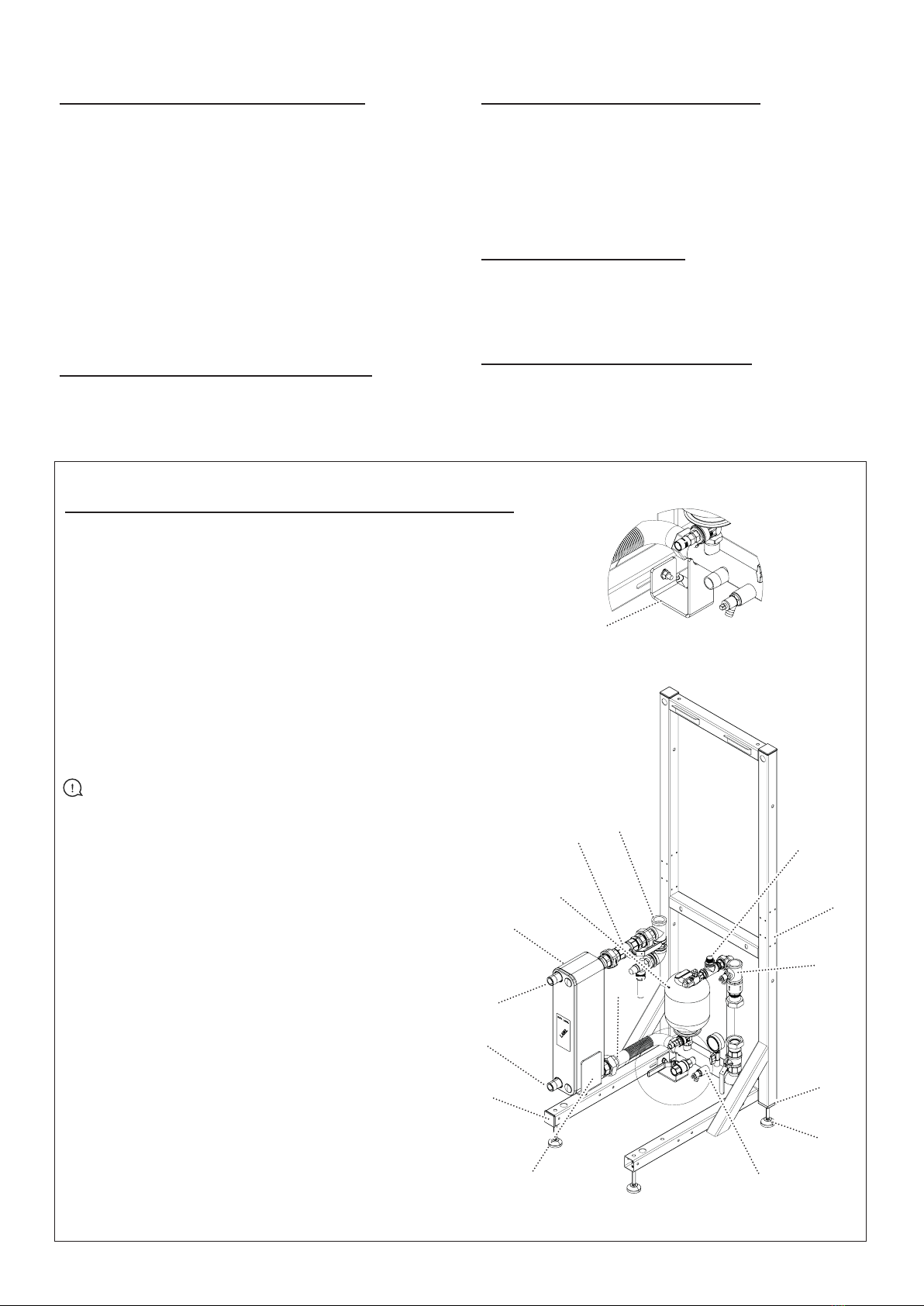

Consider the modulation range of the appliance and total

heat load requirements when sizing the boiler.

The package and the boiler pumps are intended to operate

with a temperature dierence of 20 °C across the appliance

to provide a 20 °C temperature dierence on the secondary

side of the plate.

Typical boiler and system side operating parameters are

85/65 °C and 75/55 °C respectively.

Available Evomax 2 Appliances

kW (NG) Product No.

Evomax 2 30 220814

Evomax 2 40 220815

Evomax 2 60 220816

Evomax 2 80 220817

Evomax 2 100 220818

Evomax 2 120 220919

Evomax 2 150 220820

kW (LPG) Product No.

Evomax 2 30 Propane 220823

Evomax 2 40 Propane 220824

Evomax 2 60 Propane 220825

Evomax 2 80 Propane 220826

Evomax 2 100 Propane 220827

Evomax 2 120 Propane 220828

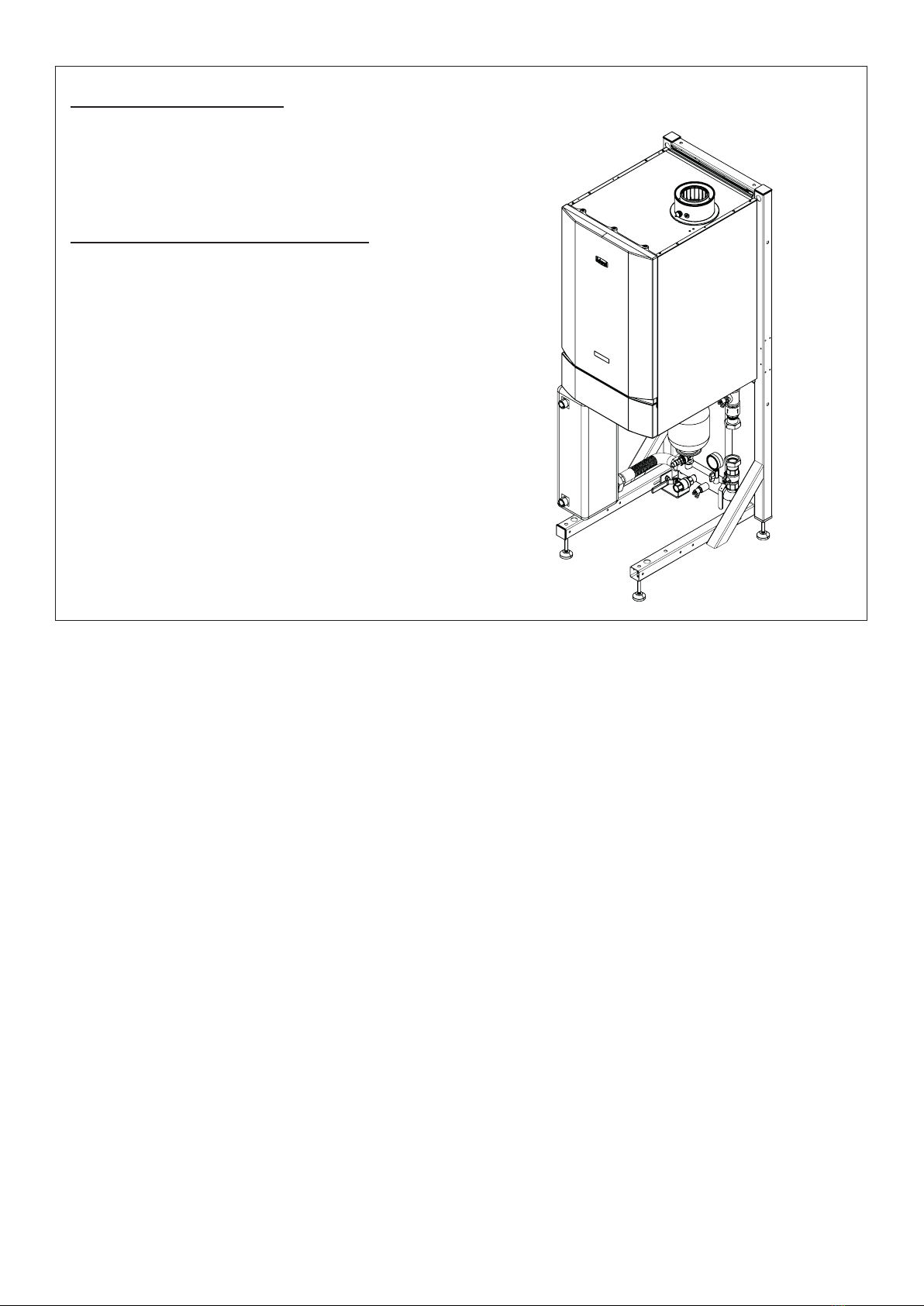

2.2 HYDRAULIC SEPARATION: PLATE

HEAT EXCHANGER

A plate heat exchanger supports hydraulic separation within a

hydronic system allowing two ows to operate independently

with their ow and pressure environments.

The brazed plate heat exchanger used within the package

ensures eective heat transfer and optimum eciency with low

ow resistance and a compact footprint.

The heat exchanger allows hydraulic separation between the

boiler and a heating circuit, covering duties up to 150 kW.

This enables the modern, high eciency condensing boilers

to operate under their optimum conditions, while the adjoining

heating circuit operates to its optimum controlled requirements.

The plate's design is based on standard components and a

modular brazed concept. Each unit is manufactured to the

highest standard and part of the AHRI certied program that

ensures thermal performance under the product specications.

Benets:

• Compact design

• No gaskets

• Easy installed within the plate heat exchanger package

• Low maintenance/ self-cleaning

• All plates are pressure tested during manufacture

CAUTION: Caution should be exercised during these

operations.