IDEC WB1F Series User manual

B-1775(6)

WB1F Fix Linear CCD Scanner

User’s Manual

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

i

Introduction

Introduction

Attention

zIDEC Corporation holds all rights related to this manual. Unauthorized duplication, reproduction, sales, transfers, or leas-

ing without the express consent of IDEC is prohibited.

zThe content of this manual may change without prior notication.

zWe have taken all possible measures with the content of this product, but if you notice any portions that are unclear, or

any mistakes, please contact the dealer where purchased or an IDEC sales representative.

Applicable standards

The applicable standards that this product supports are listed below.

zIEC/EN 60950-1 (2005)

zIEC/EN 61000-6-1 (2007)

zIEC 62471 (2006)

zIEC 61000-6-3 (2006)

zEN 61000-6-3 (2007)

zEN 55022 (2010) Class B

zEN 55024 (2010)

zUL 60950-1, 2nd Edition, 2011-12-19

zFCC Part 15 Subpart B Class B (Verication)

zCSA C22.2 No.60950-1

zICES-003 Class B (self-declared)

zVCCI Class B (compliance conrmed)

FCC Regulations

This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions:

(1) This device may not cause harmful interference, and

(2) this device must accept any interference received, including interference that may cause undesired

operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not

installed and used in accordance with the instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does

cause harmful interference to radio or television reception, which can be determined by turning the equipment

o and on, the user is encouraged to try to correct the interference by one or more of the following measures;

- Reorient or relocate the receiving antenna.

- Increase the separation between the equipment and receiver.

- Connect the equipment into an outlet on a circuit dierent from that to which the receiver is connected.

- Consult the dealer or an experienced radio/TV technician for help.

Canadian Department of Communications Compliance Statement

• CAN ICES-3(B) / NMB-3(B)

For details on the applicable standards, please inquire with the distributor where purchased.

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

ii

Introduction

Version up information

New function has been added to WB1F. Please check the applicable models and the main application version of rmware

before using. Method for version acquisition refers to FP. 5-7 "No.39 Get version" of “Control commands list”. In

addition, the initial release version is“A-002.000.00”.

The rmware of WB1F is available on the IDEC website.

You can use WB1F Support Tool to upgrade the version of rmware. About the method of version upgrade, please check

the user’s manual of WB1F Support Tool (WB1F-SOFT-SUPPORT-TOOL-MANUAL-E, B-1767).

New Function

Main application version

RS-232 type USB type

WB1F-100S1B WB1F-100S1S

PLC Connection function*1 A-002.010.00 –

Menu Sheet support

A-002.010.00

External trigger input lter time

Reading start when power on

No response when reading failed

GS1-128 2016 year edition

Compliant AI A-002.020.00

RS-232 Setting Communication speed

Addition of 600bps

High speed upload and download

supported

A-002.030.00

GS1-128 2017 year edition

Compliant AI A-002.040.00

GS1-128 2018 year edition

Compliant AI A-002.050.00

Number of decoding times addition

A-002.060.00

GS1-128 2019 year edition

Compliant AI

*1 USB type does not support PLC connection function.

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

iii

General terms, abbreviations, and terminology used in this manual

General terms, abbreviations, and terminology used in this manual

The general terms, abbreviations, and terminology used in this manual are as follows.

Item Details

WB1F An abbreviation for the WB1F-100S1B and the WB1F-100S1S.

RS-232 type

The type that uses RS-232 for the communication interface. (The cable end must be fabri-

cated.)

(WB1F-100S1B)

USB type The type that uses USB for the communication interface.

(WB1F-100S1S)

Communication interface Refers to the RS-232 interface and the USB interface.

Prevention time of same

read

The wait time to prevent reading the same barcode twice when reading barcodes consecu-

tively.

Number of characters Refers to the total number of 1-byte codes that are sent and received from the RS-232 inter-

face and the USB interface.

AIM ID An abbreviation for AIM-compliant symbology identication ID.

AI An abbreviation for Application Identier which GS1 standardized.

Pitch Refers to the rotation angle of the barcode symbols for the axis parallel to the bar height.

For details, refer to FP. 5-3 "5. 2. 2 Angular characteristics".

Skew Refers to the rotation angle of the barcode symbols for the axis parallel to the barcode sym-

bol length. For details, refer to FP. 5-3 "5. 2. 2 Angular characteristics".

Tilt Refers to the rotation angle of the barcode symbols for the axis perpendicular to the bar-

code symbol. For details, refer to FP. 5-3 "5. 2. 2 Angular characteristics".

Light receiving axis The axis that provides the image of the reected light from the barcode to the WB1F inter-

nal CCD.

Reading timeout

The time after a reading request turns on until reading is automatically turned o. This time

is applied when a factor does not occur that is supposed to turn reading o such as reading

succeeded, external trigger input o, and the stop reading command.

Receive buer A storage area that temporarily stores received data.

Send buer A storage area that temporarily stores send data.

Quiet zone The margins to the left and right of the barcode.

Control characters ASCII codes 00H to 1FH and 7FH. In this manual, they are expressed using . For details,

refer to FP. 5-11 "5. 7 ASCII code table".

Prex Character data that is added to the beginning of output data and communication com-

mands.

Sux Character data that is added to the end of output data and communication commands.

Output Output is the general term for communication output, OK output, NG output, PWM output,

and the indicator LED.

Input Input is the general term for the Operation button, external trigger input, and communica-

tion input.

IDEC website www.idec.com

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

iv

Graphic symbols used in this manual

Graphic symbols used in this manual

The following graphic symbols are used in this manual to simplify the explanations.

Notes

Graphic symbol Meaning

WarningWarning

Warning notices are used to emphasize that improper operation may cause severe personal injury or

death.

CautionCaution

Caution notices are used where inattention might cause personal injury or damage to equipment.

Information that requires special attention. Failure to operate the product in accordance with the in-

formation provided can lead to serious injury or damage.

Useful information relating to a function.

Product series name

Graphic symbol Meaning

RS-232 Type

RS-232 Type

This symbol (

RS-232 Type

) indicates functions that can be used with the RS-232 type, and the other

symbol (

RS-232 Type

) indicates functions that cannot be used.

USB Type

USB Type

This symbol (

USB Type

) indicates functions that can be used with the USB type, and the other sym-

bol ( USB Type ) indicates functions that cannot be used.

Examples

Symbols for the product series names are listed in this manual as follows.

RS-232 Type USB Type : Can be used with all product series.

RS-232 Type USB Type

: Can be used with the RS-232 type. Cannot be used with USB type.

RS-232 Type USB Type

: Can be used with the USB type. Cannot be used with RS-232 type.

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

v

SAFETY PRECAUTATIONS

SAFETY PRECAUTATIONS

zBefore installing and wiring this product, operating it, or performing maintenance and inspection, please read this

manual carefully and use the product correctly.

zThe degree of possible danger that may occur if the product is mishandled is classied as "Warning" and "Caution".

The meaning of each is as follows.

WarningWarning

Warning notices are used to emphasize that improper operation may cause severe personal in-

jury or death.

CautionCaution

Caution notices are used where inattention might cause personal injury or damage to equip-

ment.

Safety precautions

WarningWarning

zThis product is not designed for use in medical equipment, nuclear power, railways, aircraft,

passenger vehicle equipment, or similar applications requiring a high degree of reliability and

safety. Do not use the product for these applications.

zWhen using this product in a system that may impact human life, such as in the management

of chemicals, take the utmost care with a redundant design and safety design so that there is

no possibility of impacting human life when data is mistaken.

zDo not modify, disassemble, or repair this product. There is a risk of serious accidents such as

electric shock, damage, re, malfunction, and other heave accident.

zWhen using this product in situations where it is not built into other equipment, do not use

an integrated power supply. Otherwise there is a risk of re or electric shock.

zDo not directly look at the reading window (red transparent section) or expose any person to

it while the LED is illuminated (performing reading operation). There is a risk of danger to the

eyes.

zThis product is for general electronic equipment. Do not use it for applications where there is

a direct threat to the body or to human life due to malfunction or failure.

zAlways turn off the power supply before wiring, maintaining, and inspecting the product.

Otherwise there is a risk of electric shock or failure.

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

vi

SAFETY PRECAUTATIONS

CautionCaution

zDo not connect the product to a power supply outside the rated power supply voltage range

or to an AC power supply. Otherwise there is a risk of explosion or burnout.

zMistakenly wiring the product may cause the internal circuit to be damaged. Wire the input

and output circuits by referring to the connection examples in FP. 2-5 "2. 3. 1 Wiring the

RS-232 type". This product is not equipped with a protection circuit for a reversed power sup-

ply connection, so there is a risk of damage when the power supply connection is reversed.

Use extreme caution when connecting the power supply.

zAvoid parallel wiring of the product's wires in the same conduit or duct with high voltage

lines or power lines (inverter power lines in particular) as this may cause malfunction or dam-

age due to the eect of induction noise.

zIf the wires are long and when there is a risk of being aected by power sources or solenoids,

independently wire the product as a general rule.

zAvoid installing or using the product in the following locations as there is a risk of malfunc-

tion or damage.

-Near induction equipment or heat sources

-Locations with many vibrations or shocks

-Dusty and dirty locations

-In an atmosphere with hazardous gases such as suldizing gas

-Locations in direct contact with water, oils, or chemicals

-Outdoors

zThis product is not an explosion-proof product. Conrm that explosion-proof capabilities are

not required when installing the product.

Precautions for Use

CautionCaution

zUse the product in the environment listed in the catalog and manual. If this product is used

in locations with high temperatures, high humidity, condensation, corrosive gas, or excessive

vibration/shock, there is a risk of electric shock, re, and malfunction.

zThe usage environment pollution degree for this product is "pollution degree 2". Use the

product in a pollution degree 2 environment. (Based on the IEC 60664-1 standard)

zThe power supply reset time is 300 ms, so perform operations 300 ms after turning the power on.

zAt initial startup, perform operations 10 s after turning the power on.

zWhen the load and the unit are connected to dierent power supplies, always turn on the unit's power

supply rst.

zInstall the product so that the reading window is not directly exposed to sunlight or uorescent light.

zThe non-volatile memory equipped on WB1F can be overwritten 100,000 times.

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

vii

SAFETY PRECAUTATIONS

Cleaning

zCleaning the reading window

If dust, dirt, or water drops get on the reading window or if it gets scratched, this

will aect barcode reading performance.

Periodically inspect the reading window to see if there is anything on it, and when

you nd something, clean it o.

Cleaning methods

zTo clean the reading window, blow o dust/dirt with an airbrush, and then gently wipe it o with a soft-tipped item

such as a cotton swab.

zIf there are water drops on the reading window, wipe them o with a soft cloth.

zAlways turn o the power supply before cleaning the product.

PMMA is used for the reading window material, so do not use organic solvents (such as alcohol, thinner, or

benzine), ammonia, or sodium hydroxide. Otherwise this may change the properties of the reading window.

zCleaning the unit

zPlease wipe the dust o a body of the WB1F with a soft, dry cloth.

zWhen that body is very dirty, please wipe it with a cloth soaked in a neutral detergent diluted with water and wrung out

thoroughly, and then wipe it with a soft, dry cloth.

Do not use organic solvents such as alcohol, thinner, or benzine.

This may alter the case or strip the paint.

Reading

window

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

viii

Related manuals

Related manuals

Manuals related to the WB1F are as follows. Please refer to them together with this manual.

Type Manual name Details

B-1775 WB1F Fix Linear CCD Scanner

User’s Manual (this manual)

Explains an overview and functions of the WB1F, plus basic operat-

ing methods.

B-1741 Instruction Sheet WB1F series Included with the product.

B-1768 WB1F Fix Linear CCD Scanner

Support Tool User's Manual

Included with the support tool.

Explains about support tool.

B-1782 WB1F Fix Linear CCD Scanner

Menu Sheet Explains about menu sheet.

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

ix

Contents

Introduction........................................................................................................................................................i

Attention ................................................................................................................................................................................i

Applicable standards .........................................................................................................................................................i

Version up information ....................................................................................................................................................ii

General terms, abbreviations, and terminology used in this manual..........................................iii

Graphic symbols used in this manual......................................................................................................iv

Notes..................................................................................................................................................................................... iv

Product series name........................................................................................................................................................ iv

SAFETY PRECAUTATIONS ..............................................................................................................................v

Safety precautions .............................................................................................................................................................v

Precautions for Use.......................................................................................................................................................... vi

Cleaning.............................................................................................................................................................................. vii

Related manuals........................................................................................................................................... viii

Contents.............................................................................................................................................................ix

1

Overview 1-1

1. 1 Checking the packaged product and the product conguration...............................1-1

1. 2 Part names and functions..........................................................................................................1-2

1. 3 System conguration ..................................................................................................................1-3

2

Installation & wiring 2-1

2. 1 Installation precautions..............................................................................................................2-1

2. 2 Mounting methods ......................................................................................................................2-3

2. 2. 1 WB1F mounting methods ..................................................................................................................... 2-3

2. 2. 2 Setup barcode position.......................................................................................................................... 2-4

2. 3 Wiring................................................................................................................................................2-5

2. 3. 1 Wiring the RS-232 type........................................................................................................................... 2-5

2. 3. 2 Wiring the USB type................................................................................................................................. 2-8

Contents

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

x

Contents

3

Function 3-1

3. 1 Overview..........................................................................................................................................3-1

3. 1. 1 Operation mode........................................................................................................................................ 3-1

3. 1. 2 Operation mode switching operation and status......................................................................... 3-2

3. 2 Slave mode......................................................................................................................................3-3

3. 2. 1 Switching operation to slave mode................................................................................................... 3-3

3. 2. 2 Barcode reading........................................................................................................................................ 3-4

3. 2. 3 Output data additional information................................................................................................3-11

3. 2. 4 Output data editing...............................................................................................................................3-16

3. 2. 5 Comparison-Matching..........................................................................................................................3-18

3. 2. 6 Analysis.......................................................................................................................................................3-23

3. 2. 7 Command alias........................................................................................................................................3-24

3. 2. 8 Communication command.................................................................................................................3-26

3. 3 Setup support mode................................................................................................................. 3-29

3. 3. 1 Switching operation to setup support mode (setup support function) ............................3-29

3. 3. 2 Setup support function........................................................................................................................3-31

3. 4 Maintenance mode ................................................................................................................... 3-33

3. 4. 1 Switching operation to maintenance mode.................................................................................3-33

3. 4. 2 Maintenance support............................................................................................................................3-35

3. 4. 3 Firmware updating.................................................................................................................................3-35

3. 5 Conguration item table......................................................................................................... 3-36

4

Support tool 4-1

4. 1 Overview..........................................................................................................................................4-1

5

Appendix 5-1

5. 1 Product specications.................................................................................................................5-1

5. 2 Field of view/characteristics......................................................................................................5-2

5. 2. 1 Field of view................................................................................................................................................ 5-2

5. 2. 2 Angular characteristics ........................................................................................................................... 5-3

5. 3 Dimensional outline drawings.................................................................................................5-4

5. 4 Troubleshooting............................................................................................................................5-5

5. 5 Control commands list................................................................................................................5-6

5. 6 Check digit calculation method............................................................................................ 5-10

2. Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

xi

Contents

5. 7 ASCII code table.......................................................................................................................... 5-11

5. 8 AIM symbology ID table .......................................................................................................... 5-13

5. 9 GS1-128 Application Identier.............................................................................................. 5-15

5. 10 Conguration barcode............................................................................................................. 5-16

5. 11 Sample labels............................................................................................................................... 5-17

5. 12 Installing the USB driver (USB type) .................................................................................... 5-19

5. 13 Setting check digit..................................................................................................................... 5-20

5. 14 Setting margin rate ................................................................................................................... 5-23

5. 15 Index............................................................................................................................................... 5-25

Revision history ........................................................................................................................................... A-1

1-1

1

Overview

This chapter describes the product conguration of the WB1F, the names and functions of its parts, and the basic system

conguration during operation.

1. 1 Checking the packaged product and the product conguration

RS-232 Type USB Type

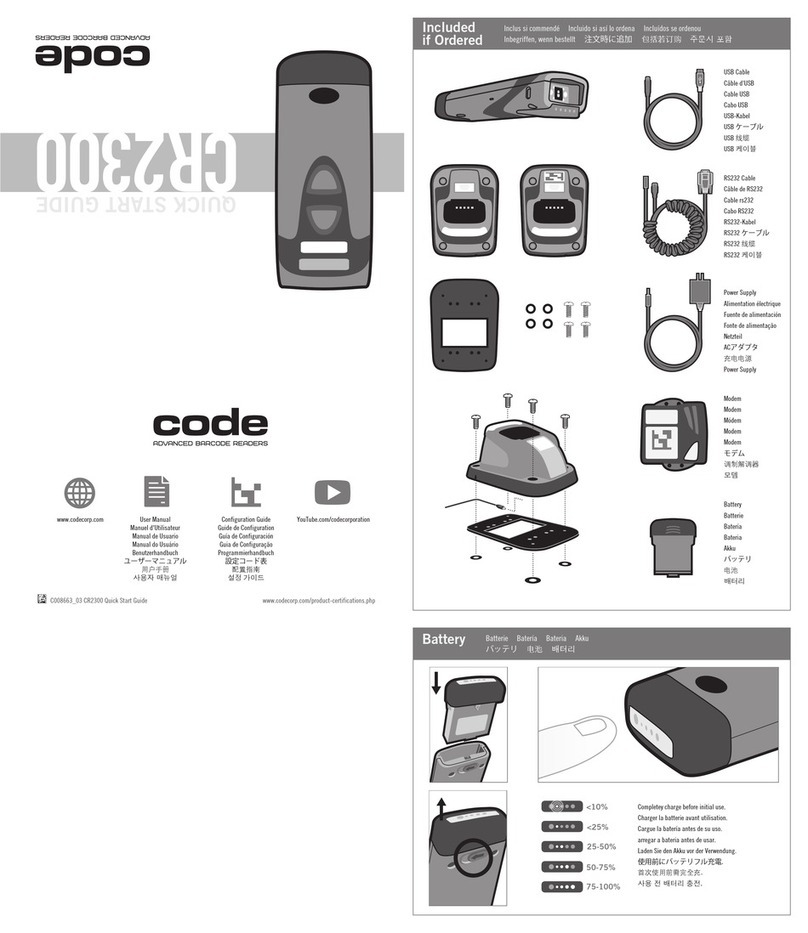

The WB1F is packaged with the following items.

Before using the WB1F, please check that the unit and accessories are present and that they have suered no damage.

Unit: 1

* The illustration is the WB1F-100S1B.

Product mounting screws (M3): 2 Instruction Manual: 1

2. Installation & wiring 3. Functions 4. Support tool 5. AppendixOverview

1-2

Part names and functions

1. 2 Part names and functions

RS-232 Type USB Type

This section describes the names and functions of WB1F parts.

(4) Connecting cable

(1) Reading window

(2) Operation button

(3)Indicator LED

(Green)

(Orange)

(Red)

* The illustration is the WB1F-100S1B.

No. Name Function

(1) Reading window The unit reads barcodes through the reading window.

While the unit is reading barcodes, the internal emitter LED turns on.

(2) Operation button Use the operation button to turn on the barcode reading request and to switch the opera-

tion mode.

(3) Indicator LED

The indicator LED indicates the operating status of the unit.

(Green): Turns on when reading has succeeded and the read image is matched on comparison.

(Orange) : Turns on during a reading operation.

(Red): Turns on when reading fails and the read image is not matched on comparison.

This operation may dier due to the settings.

The status of the indicator LEDs also changes due to the unit's operating status.

(4) Connecting cable

RS-232 type

zThis type communicates via the RS-232 interface.

zPerforms control of OK output, NG output, and PWM output.

zJudges the external trigger input status and turns the reading request on and o.

zConnect to the power supply (5V DC).

USB type

zThis type communicates via the USB interface (USB virtual COM).

2. Installation & wiring 3. Functions 4. Support tool 5. AppendixOverview

1-3

System conguration

1. 3 System conguration

The basic system conguration when operating the WB1F is as follows.

RS-232 type

RS-232 Type USB Type

Host device

Separately-excited buzzer

PLC

Sensor

5V DC power supply

Power supply

OK output

NG output

PWM output

External trigger input

RS-232

USB type

RS-232 Type USB Type

Host device

USB

When connecting a computer, refer to FP. 5-19 "5. 11 Installing the USB driver (USB type)".

2-1

2

Installation & wiring

This chapter describes WB1F installation locations, mounting methods, and wiring the WB1F to peripheral devices.

2. 1 Installation precautions

RS-232 Type USB Type

zInstall the unit so that ambient light such as sunlight, uorescent light, and photoelectric switches does not enter the

reading window.

Otherwise the unit may not be able to read barcodes or it may erroneously read them.

Example

Take measures to block ambient light or to change the position of photoelectric switches.

Block

the light

zDo not install a reective body (metal or mirror) along the light receiving axis.

Otherwise the unit may not be able to read barcodes or it may erroneously read them.

Example

Prevent reections by applying black tape to the reective body.

Light

receiving

axis

Mirror

Light

receiving

axis

Black tape

Mirror

For the light receiving axis, refer to FP. 2-4 "2. 2. 2 Setup barcode position".

Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

2-2

Installation precautions

zWhen installing WB1F units in a series, install them so the emitted LED light does not overlap (so they do not interfere

with each other).

Otherwise the unit may not be able to read barcodes or it may erroneously read them.

Example

Install the WB1F units by increasing the spacing between them.

Interference

zInstall the WB1F so that two or more barcodes do not enter the reading area.

The WB1F cannot simultaneously read multiple barcodes.

Example

Use the WB1F by increasing the spacing between barcodes.

2 barcodes 1 barcode

Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

2-3

Mounting methods

2. 2 Mounting methods

RS-232 Type USB Type

2. 2. 1 WB1F mounting methods

1 Check the dimensions of the mounting holes and drill holes in the mounting plate.

For the dimensions of the mounting holes, refer to FP. 5-4 "5. 3 Dimensional outline drawings".

2 For a plate thickness of 0.8 to 2.3 mm, use the two included product mounting screws and secure the WB1F to

the plate.

The tightening torque for the product mounting screws is 0.4 to 0.5 N·m.

Included product

mounting screws

M3 SEMS x 6 (2 screws)

Plate thickness 0.8 to 2.3 mm

When using the included product

mounting screws

zFor a plate thickness other than 0.8 to 2.3 mm, do not use the included product mounting screws.

Instead, use two M3 screws with an eective thread length of 3 to 5 mm and secure the WB1F to the

plate.

zWhen using the WB1F, remove the protective lm on the reading window.

zFor a plate thickness other than 0.8 to 2.3 mm, do not use the included product mounting screws.

zDo not over tighten the mounting screws or hit the product with a hammer or the protective construc-

tion will be damaged.

Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

2-4

Mounting methods

2. 2. 2 Setup barcode position

Install the unit so that barcode skew θ is in the range of -20° ≤ θ ≤ 0° and +20° ≤ θ ≤ +40°.

For the reading area, refer to FP. 5-2 "5. 2. 1 Field of view". For other angular characteristics, refer to FP. 5-3 "5. 2. 2

Angular characteristics". For detailed dimensions, refer to FP. 5-4 "5. 3 Dimensional outline drawings".

+20 to +40°

10°

-

20 to 0°

Barcode

Light receiving axis

Mirror reflection area (dead zone)

Setup barcode position range

θ

+

-

Do not read barcodes in the skew range 0° < θ <

20°.

* The light receiving axis is the path where the reected

light from the barcode travels to create an image on

the WB1F internal CCD. The unit reads barcodes that

are on the light receiving axis.

zSkew in a range of 0° < θ < 20° is in the mirror reection area (dead zone), so reading performance may dras-

tically decrease in ways such as the unit not being able to read or misreading barcodes.

zInstall the unit so the light receiving axis is in the center of the barcode.

zThe unit may not be able to read barcodes that are short in height as they will not be in the light receiving

axis.

Ensure that the barcode height is 3 mm or higher.

FP. 3-31 "3. 3. 2 Setup support function" to adjust the istallation position while checking the barcode read-

ing rate.

Installation & wiring 3. Functions 4. Support tool 5. Appendix1. Overview

2-5

Wiring

2. 3 Wiring

2. 3. 1 Wiring the RS-232 type

RS-232 Type USB Type

zWire colors

The wires with the following colors are drawn out of the connecting cable.

Wire the cable according to the usage and application.

Conductor

color Signal name Function

Black 0 V Power supply- (combined SG)

Red 5V DC Power supply+

Yellow NG_O NG output

Purple OK_O OK output

Blue CTS RS-232 control signal

Orange RTS RS-232 control signal

White RXD RS-232 receive data

Green TXD RS-232 transmission data

Gray Ex_trig External trigger input

Brown PWM_O PWM output

The shield wire is not connected inside the unit.

Connect it to FG or 0 V depending on the ambient noise.

Other manuals for WB1F Series

1

This manual suits for next models

2

Table of contents

Other IDEC Barcode Reader manuals

Popular Barcode Reader manuals by other brands

Mindeo

Mindeo FS580 user manual

Tysso

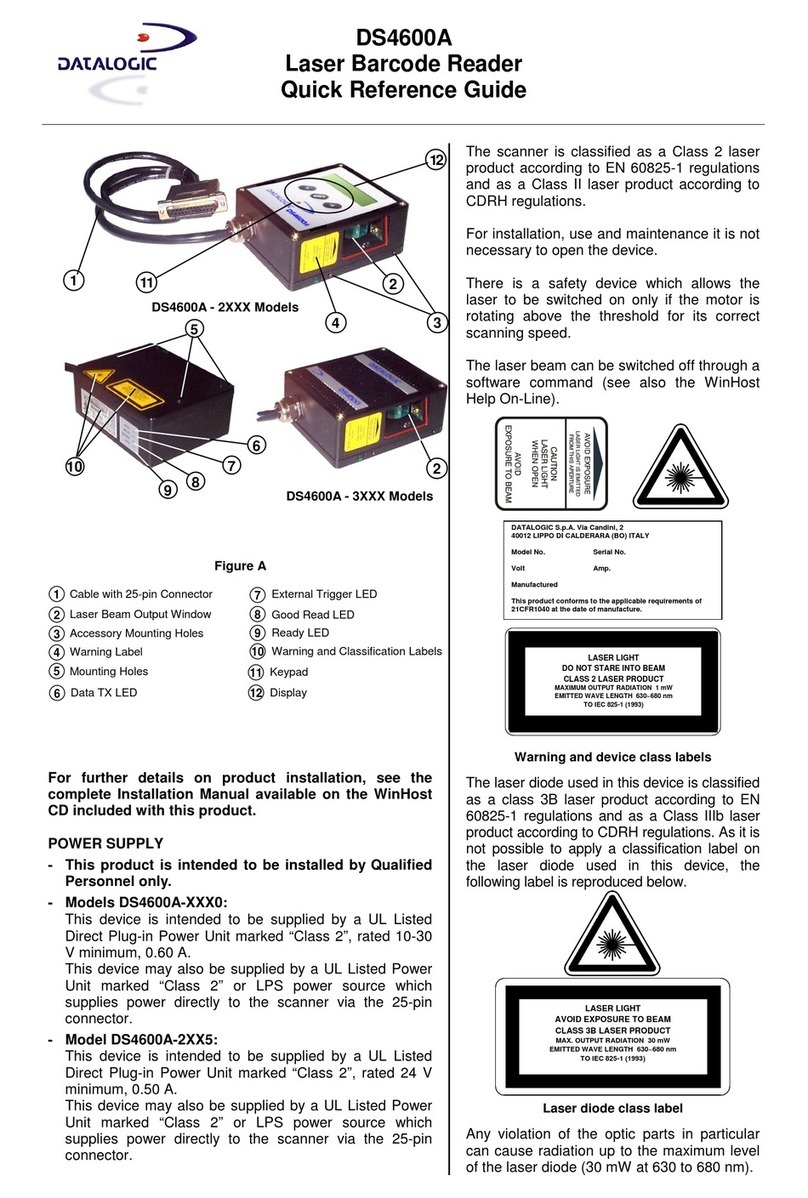

Tysso Fixed Mount CCD Barcode Scanner user manual

Steren

Steren COM-595 instruction manual

Datalogic

Datalogic POWERSCAN 7000 2D Imager Quick reference guide

Datalogic

Datalogic DS5100-X200 Reference manual

Leuze electronic

Leuze electronic VisionREADER 2300 Technical description