Kobra - Tongue Switches with Guard Locking - Type KL3-SS-P2L

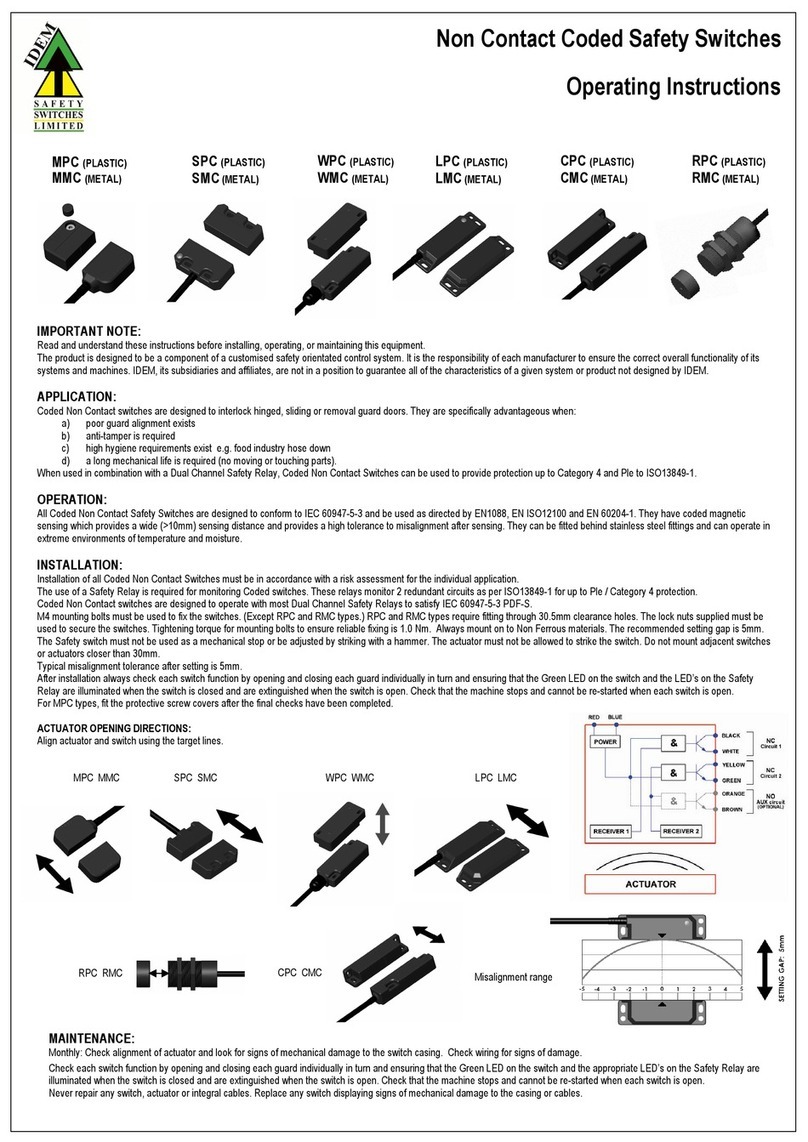

1. Installation of all IDEM interlock switches must be in accordance with a risk assessment for the individual application.

Installation must only be carried out by competent personnel and in accordance with these instructions.

2. M5 mounting bolts must be used to fi the switch and actuator, the tightening torque to ensure reliable fi ing is 4.0 Nm.

Tightening torque for the lid screws, conduit entry plugs and cable glands must be 1.5 Nm to ensure IP seal.

Only use the correct size gland for the conduit entry and cable outside diameter.

Tightening torque for the connection terminal screws is 0.7 Nm, ma conductor size is 1.0 sq.mm.

The switch head position can be selected by loosening the 4 head bolts and then rotating to the position required.

Tightening torque for the head bolts is1.5Nm.

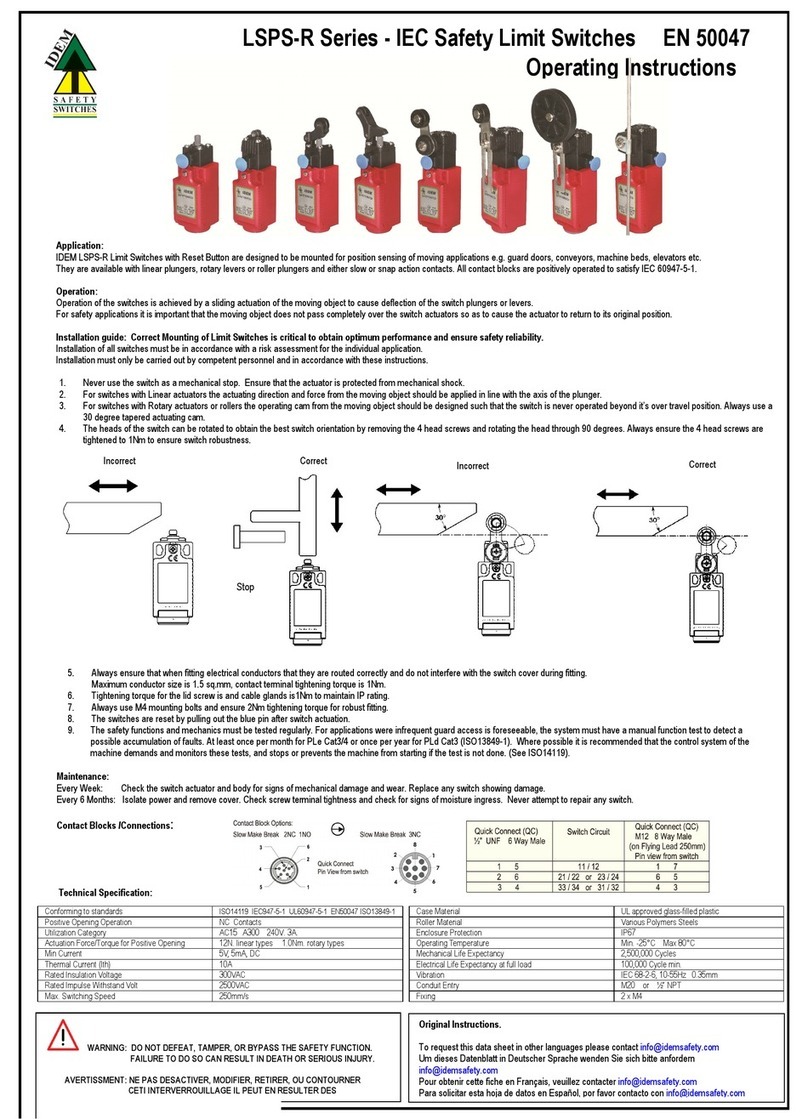

3. Always fit a mechanical stop to the guard to prevent damage to the front of the switch.

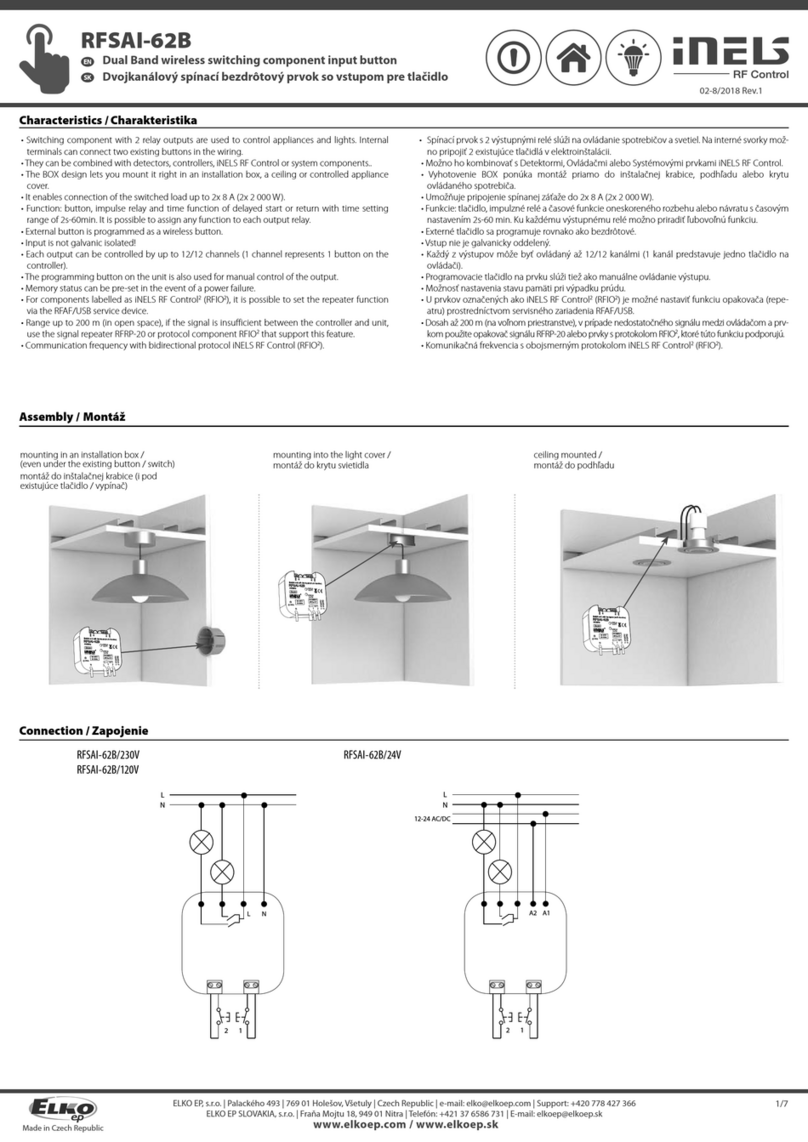

Set the actuator gap to 3mm when the guard is closed and against the stop,(See Fig.A).

Use alignment guides to ensure that the actuator enters the switch without interfering with the sides of the aperture.

Always fit the aperture plug to the unused entry aperture to prevent debris entering the switch mechanism.

4. lways use the circuits 11-12 and 21-22 to ensure monitoring of the lock.

5. After installation check operation of all control circuits and the locking function.

LED 1 will illuminate when power is applied to A1 and A2 (solenoid feed).

Every Week: Check correct operation of all circuits and the Lock function.

If the actuator shows signs of bending or the switch head housing

displays mechanical damage then remove and replace.

IDEM will not accept responsibility for failure of the switch functions if the

installation and maintenance requirements shown in this sheet are not implemented.

These requirements form part of the product warranty.

Every 6 Months: Isolate power and remove cover. Check screw terminal tightness and check

for signs of moisture ingress. Never attempt to repair any switch.

THESE INSTRUCTIONS FORM P RT OF THE PRODUCT W RR NTY.

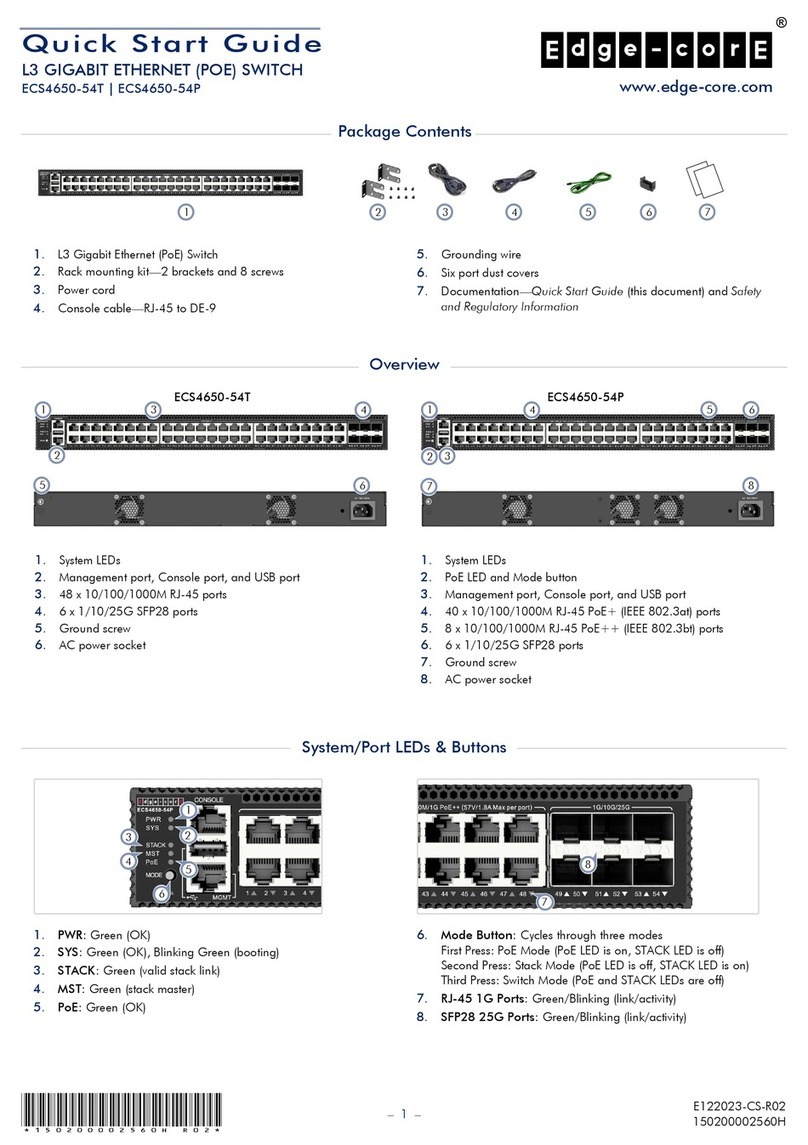

Hinged Guard Sliding Guard

Fig. A

8 actuator entry positions

rotatable head

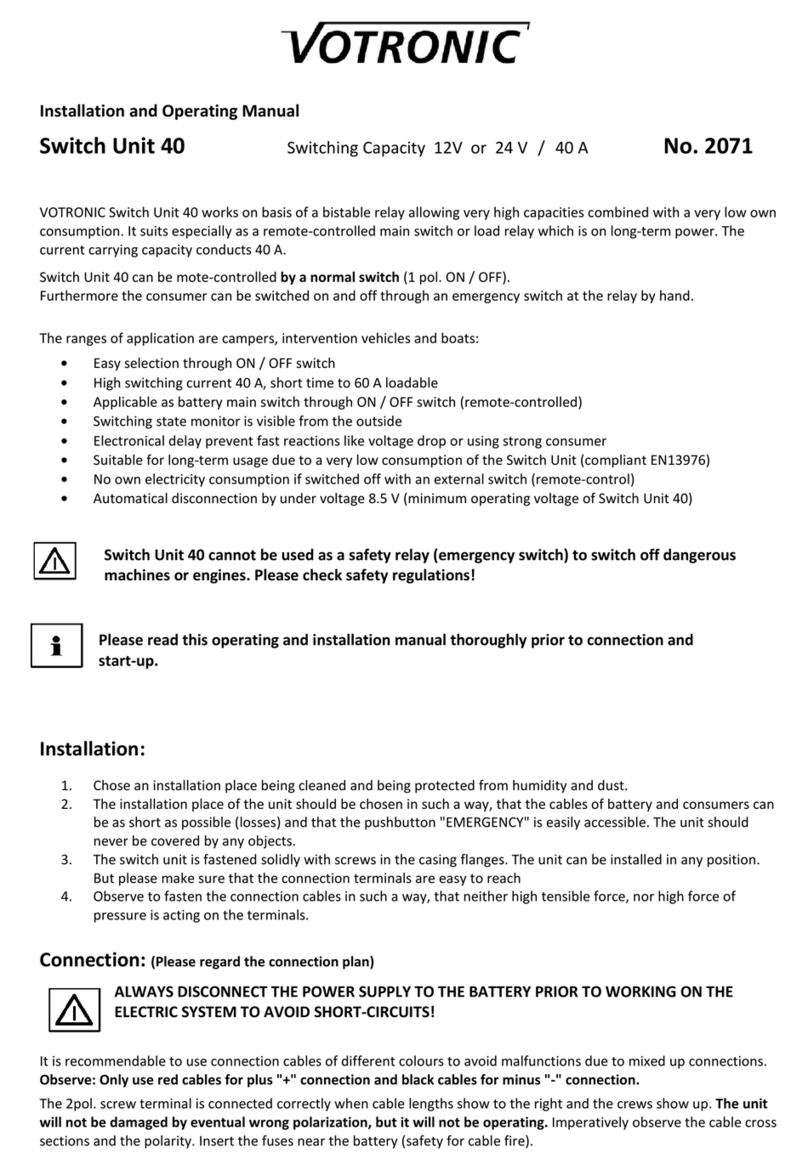

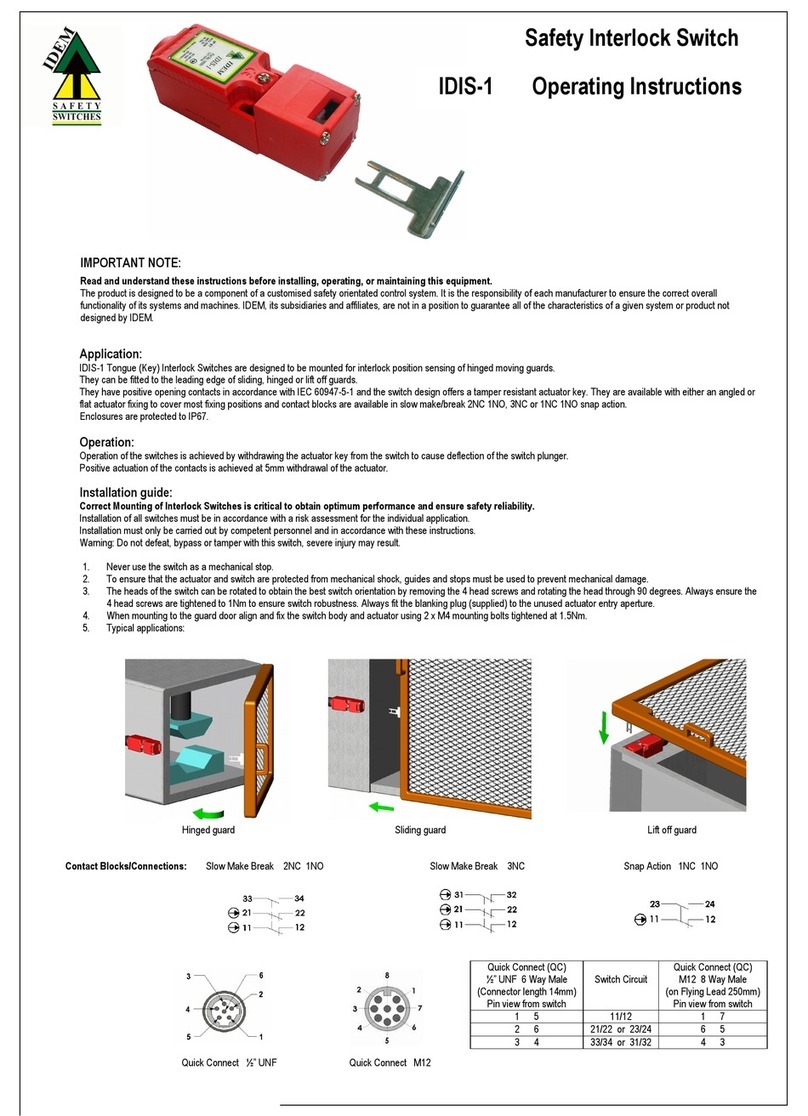

Power to Lock Operating Instructions

Tongue operated Solenoid Interlock switches are designed to fit to the leading edge of sliding, hinged or lift off machine guards to provide positively operated switching contacts and

provide a tamper resistant key mechanism.

They are designed to provide robust position interlock detection for moving guards and will remain locked until the solenoid voltage is removed from the switch.

They are not suitable for machines with a running down time.

They provide robust holding up to 2000N.

Operation:

The switch is rigidly mounted to the frame of the guard or machine. The actuator is fitted to the moving part (frame) of the guard and is aligned to the switch entry aperture. The

actuator profile is designed to match a cam mechanism within the switch head and provides a positively operated not easily defeatable interlock switch. When the actuator is inserted

into the switch the safety contacts will close only when power is applied to the solenoid. This will then allow the machine start circuit to be enabled. When the solenoid power is

removed the safety contacts are opened and the machine circuit is broken.