Idem PSA User manual

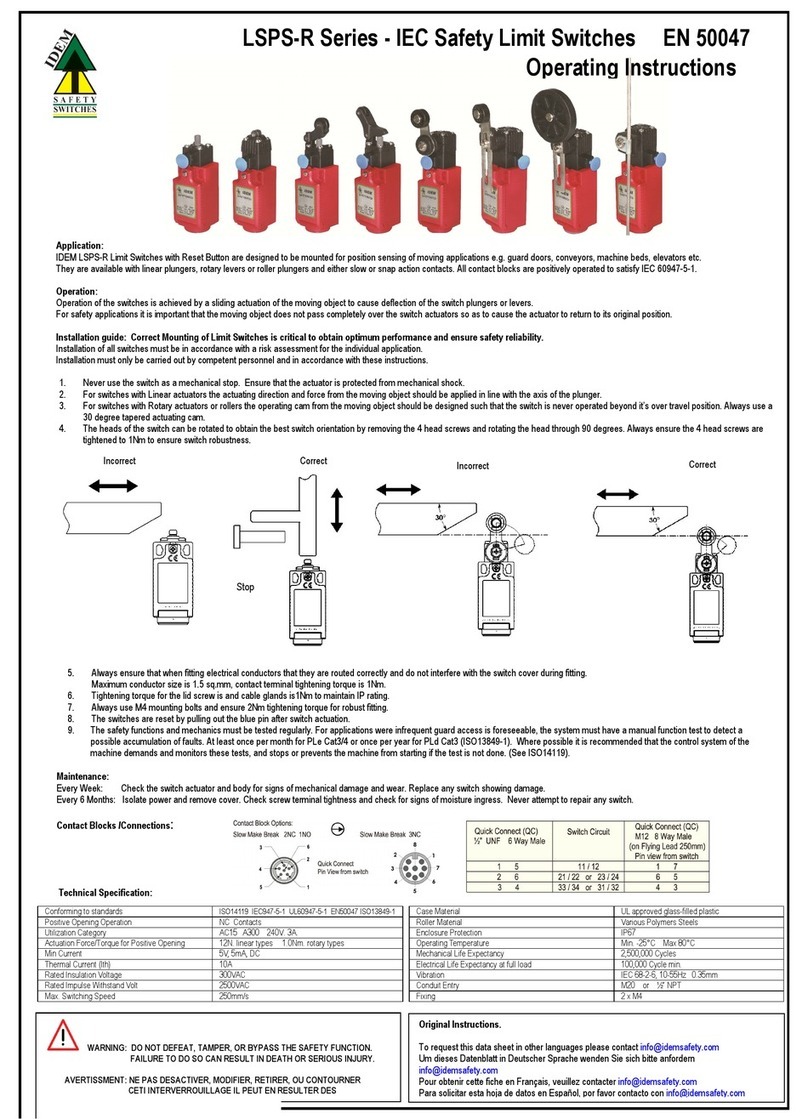

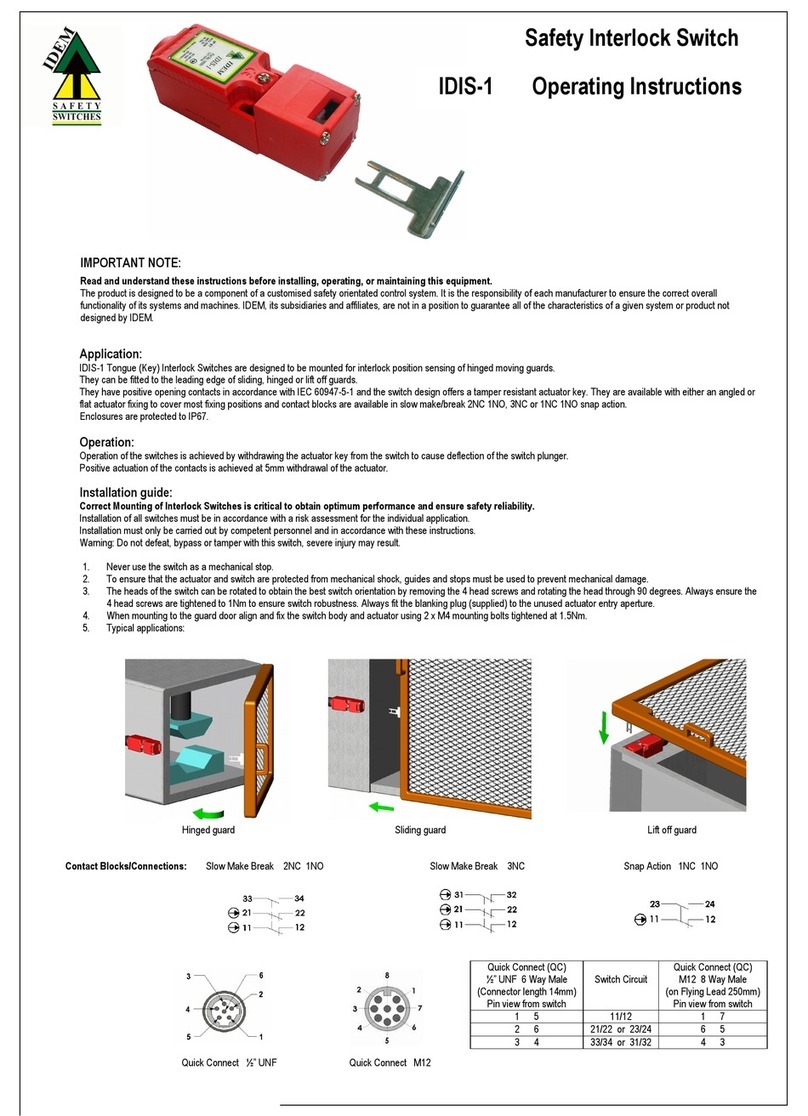

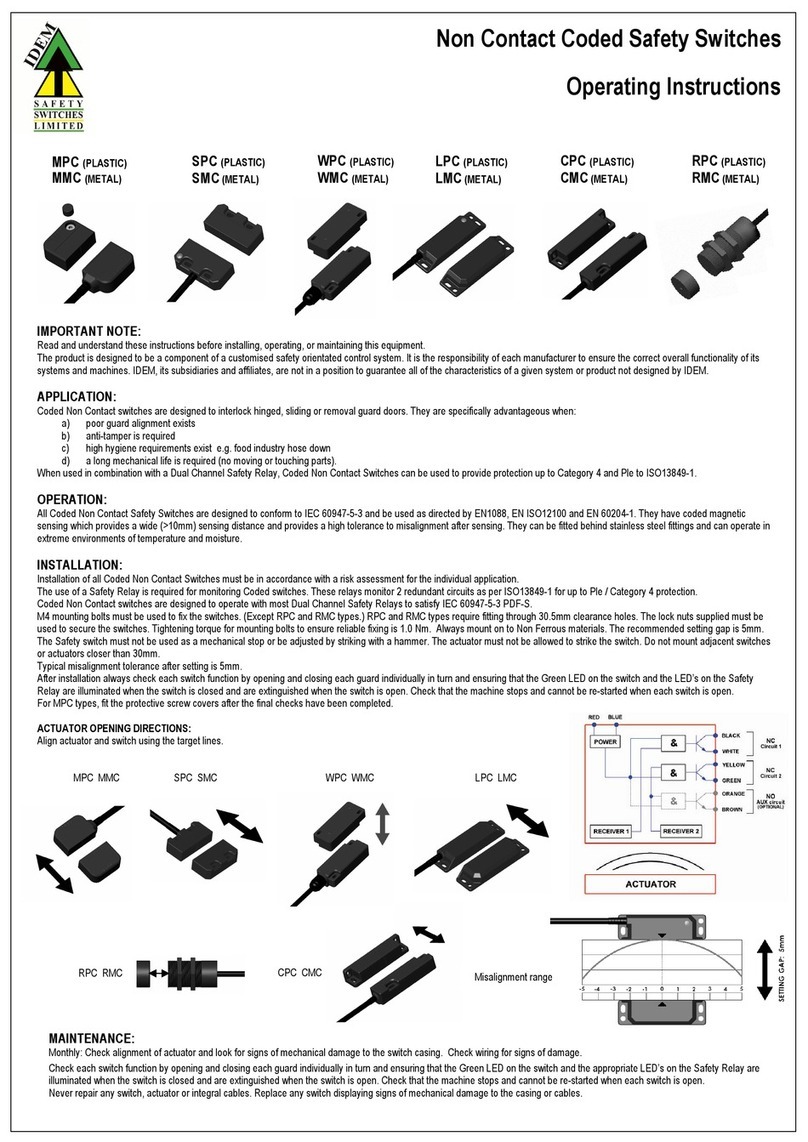

Non Contact Stand Alone Coded Safety Switches

MAINTENANCE:

Weekly: Check alignment of actuator and look for signs of mechanical damage to the switch casing. Check wiring for signs of damage.

Monthly: Check each switch function by opening and closing each guard individually in turn and ensuring that the Green LE on the switch is illuminated when the switch is closed and

extinguished when the switch is open. Check that the machine stops and cannot be re-started when each switch is open.

Never repair any switch, actuator or integral cables. Replace any switch displaying signs of mechanical damage to the casing or cables.

IMPORTANT NOTE

:

Read and understand these instructions before installing, operating, or maintaining this equipment.

The product is designed to be a component of a customised safety orientated control system. It is the responsibility of each manufacturer to ensure the correct overall functionality of its

systems and machines. I EM, its subsidiaries and affiliates, are not in a position to guarantee all of the characteristics of a given system or product not designed by I EM.

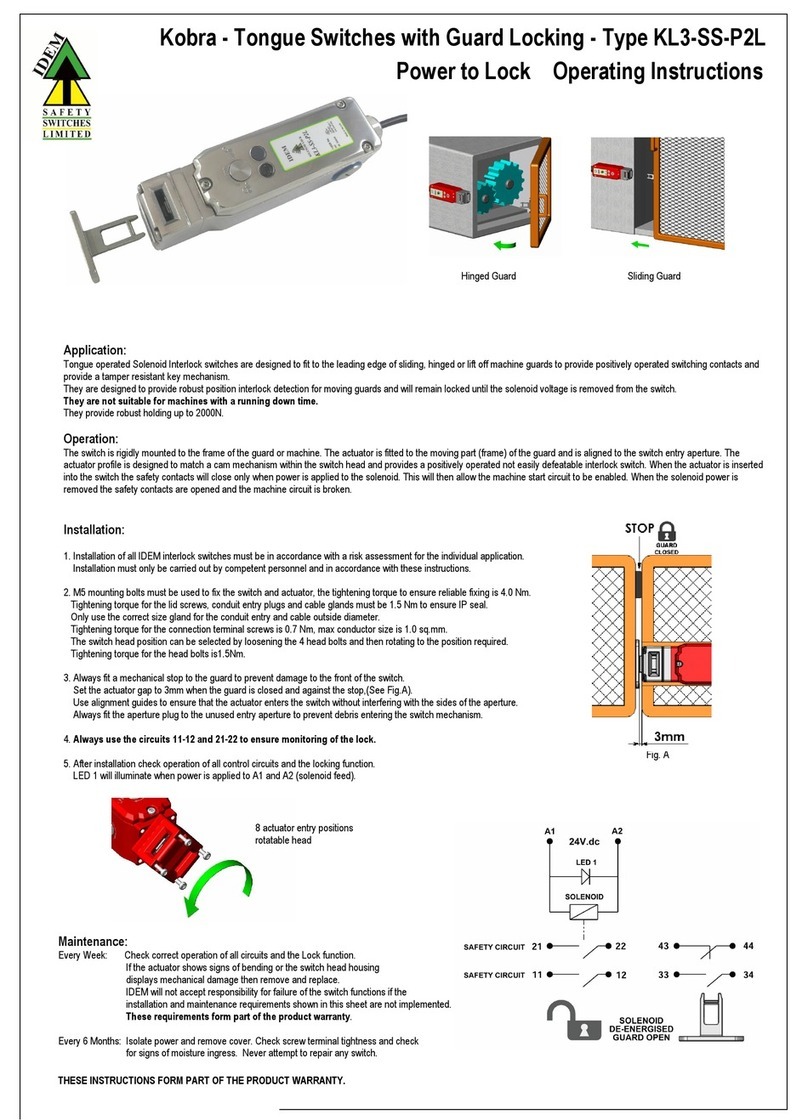

APPLICATION:

Coded Non Contact switches are designed to interlock hinged, sliding or removal guard doors. They are specifically advantageous when:

a) poor guard alignment exists

b) anti-tamper is required

c) high hygiene requirements exist e.g. food industry hose down

d) a long mechanical life is required (no moving or touching parts).

The PSA/MSA Coded Non Contact Switches can be used to provide protection up to Category 4 and Ple to ISO13849-1.

OPERATION:

All Coded Non Contact Safety Switches are designed to conform to EN60947-5-3 (P F-M) and be used as directed by EN1088, EN ISO12100 and EN 60204-1. They have coded

magnetic sensing which provides a wide (>10mm) sensing distance and provides a high tolerance to misalignment after sensing. They can be fitted behind stainless steel fittings and can

operate in extreme environments of temperature and moisture.

INSTALLATION:

Installation of all Coded Non Contact Switches must be in accordance with a risk assessment for the individual application.

The PSA/MSA internally monitor 2 redundant circuits as per ISO13849-1 for up to Ple/Category 4 protection.

M4 mounting bolts must be used to fix the switches. Tightening torque for mounting bolts to ensure reliable fixing is 1.0 Nm. Always mount on to Non Ferrou

s materials.

The recommended setting gap is 5mm. The Safety switch must not be used as a mechanical stop or be adjusted by striking with a hammer.

The actuator must not be allowed to strike the switch. o not mount adjacent switches or actuators closer than 30mm.

Typical misalignment tolerance after setting is 5mm.

After installation always check each switch function by opening and closing each guard individually in turn and ensuring that the Green LE on the switch and the LE ’s on the Safety

Relay are illuminated when the switch is closed and are extinguished when the switch is open. Check that the machine stops and cannot be re-started when each switch is open.

ACTUATOR OPENING DIRECTIONS: DIMENSIONS:

Align actuator and switch using the target lines. All dimensions in mm.

PSA MSA

O erating Instructions

MSA

PSA

Mirror Polished (Ra4)

Stainless Steel 316

Non Contact Stand Alone Coded Safety Switches

IDEM SAFETY SWITCHES Ltd., 2 Ormside Close, Hindley Industrial Estate, Hindley Green, Wigan, W

N2 4HR UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076

IDEM (USA) 4416 Technology Drive, Fremont, CA 94538 Tel:510-445-0751 Fax:1866-431-7064 email: [email protected] Web: www.idemsafety.com

Standards:

EN1088 IEC60947

-

5

-

3 IEC60947

-

5

-

1 EN60204

-

1

ISO13849-1 EN62061 EN954-1 UL508

Safety Classification and Reliability Data:

Power Supply

24Vdc +/

-

10% (Consumptio

n 15

0mA max.)

Safety Output Maximum Rating

24

0V

3A

ac/dc

Auxiliary Output Maximum Rating

24Vdc 0.5A

ielectric Withstand

4k

Vac

Insulator Resistant

100 Mohms

Recommended Setting Gap

5mm

Switching istance

Sao 10mm Close

(Target to Time)

Sar

15mm Open

Tolerance to Misalignment

5mm in any direction from 5mm setting gap

Approach Speed

600mm/m to 1000mm/s

Body Material

PSA High Specification Polyester

MSA Stainless Steel 316

Temperature

-

25C/45C

Shock Resistance

IEC 68

-

2

-

27 11ms

30g

Vibration Resistance

IEC 68

-

2

-

6 10

-

55Hz 1mm

Enclosure Protection

PSA: IP67 MSA: IP69K/IP67

Cable Type

PVC 10 core 7mm O

Mounting Bolts

2 x M4

Quick Connect (QC)

Flying Lead 250mm

M12 8 way Male Plug

(Pin view from switch)

Flying Lead

Colours

Circuit

2

Red

Supply +24Vdc

24Vdc +/- 10%

3

Blue

Supply 0Vdc

1

White

Safety Output 1 (Force guided relay)

AC15 250Vac 3A

C13 24Vdc 3A

7

Black

Safety Output 1 (Force guided relay)

4

Yellow

Safety Output 2

AC15 250Vac 3A

C13 24Vdc 3A

6

Green

Safety Output 2

8

Brown

Reset/Check Circuit

–

Output

Not Used

Orange

Reset/Check Circuit

–

Manual start

5

Pink

Reset/Check Circuit

–

Auto start

Not Used

Grey

Auxiliary Feed

Electronic +24Vdc 0.5

A

Saf

ety Integrity Level

SIL3

PFH (1/h)

3.95E

-

10

Corresponds

to 4.0% of SIL3

PF

3.46

E

-

05

Corresponds to 3.5

% of SIL3

Proof Test Interval T

1

20a

Performance Level

E

Category

Cat4

MTTF

d

446a

iagnostic Coverage C

99% (high)

oc: 1025

45

May 2013

CONNECTION EXAMPLE: Switches in series PLe Cat.4

Two switches connected in series to give dual circuit safety outputs to machine contactors.

Safety Circuit 1 (Black/White) utilises internally checked force guided relay contacts and is

connected in series with the corresponding Safety Circuit 2 (Yellow/Green) of the next

switch.

Allows minimal wiring and higher current switching to K1 and K2 contactors.

A manual start and contactor feedback check is achieved by connecting K1(Aux) and

K2(Aux) feedback contacts and momentary start button through the orange and brown

feedback check.

SAFETY PRECAUTIONS:

1. Installation and commissioning of the device must be performed only

by authorised ersonnel.

2. Observe the country specific regulations when installing the device.

3. The wiring of the device must comply with the instructions in this user

information - otherwise there is a risk that the safety function will be lost.

4. External fusing of the safety contacts (a slow blow or 6A quick action

must be provided).

5. All relevant safety regulations and standards are to be observed.

6. The overall concept of the control system in which the device is

incorporated must be validated by the user.

7. Failure to observe the safety regulations can result in death, serious

injury and serious damage.

8.

Always use Safety Output 1.

To req

uest this data sheet in other languages please contact

.

Pour obtenir cette fiche en Français, veuillez contacter inf[email protected].

Para solicitar esta hoja de datos en Español, por favor contacto con info@idemsafety.com.

EC Declaration of Conformity

MANUFACTURER: IDEM SAFETY SWITCHES LIMITED

Hindley Industrial Estate, Hindley Green, Wigan, Lancashire WN 4HR, United Kingdom

THE LISTED DEVICES CONFORM TO THE ESSENTIAL HEALTH AND SAFETY RE UIREMENTS OF THE FOLLOWING EUROPEAN DIRECTIVES

AND STANDARDS:

Machinery Directive ( 006/4 /EC)

Low Voltage Directive ( 006/95/EC)

DEVICES: NON CONTACT SAFETY SWITCHES:

PSA MSA Standalone Coded Safety Switches

STANDARDS (plus amendments):

EN 60947-5- : 007

EN 60947-5-3 1999 + A1: 005

EN ISO 13849-1: 008

M.Mohtasham Managing Director

1

st

May 2013

Characteristic Data according to

IEC62061 (used as a sub system)

Characteristic Data according to EN ISO13849

-

1

The calculation of the above values is based on the following assumptions:

Number of operating days per year: d

op

= 365d

Number of operating hours per day: h

op

= 24h

Number of operating cycles per day: n

cyc

= 1/d

B10

d

= 150,000 AC1 Load 3A

= 2,000,000 AC1 Load 0.5A

When the product is used deviant from these assumptions (different load,

operating frequency, etc.) the values have to be adjusted accordingly.

This manual suits for next models

1

Table of contents

Other Idem Switch manuals