Idem KLTM-RFID User manual

Tongue Switch with Guard Locking & RFID Coding

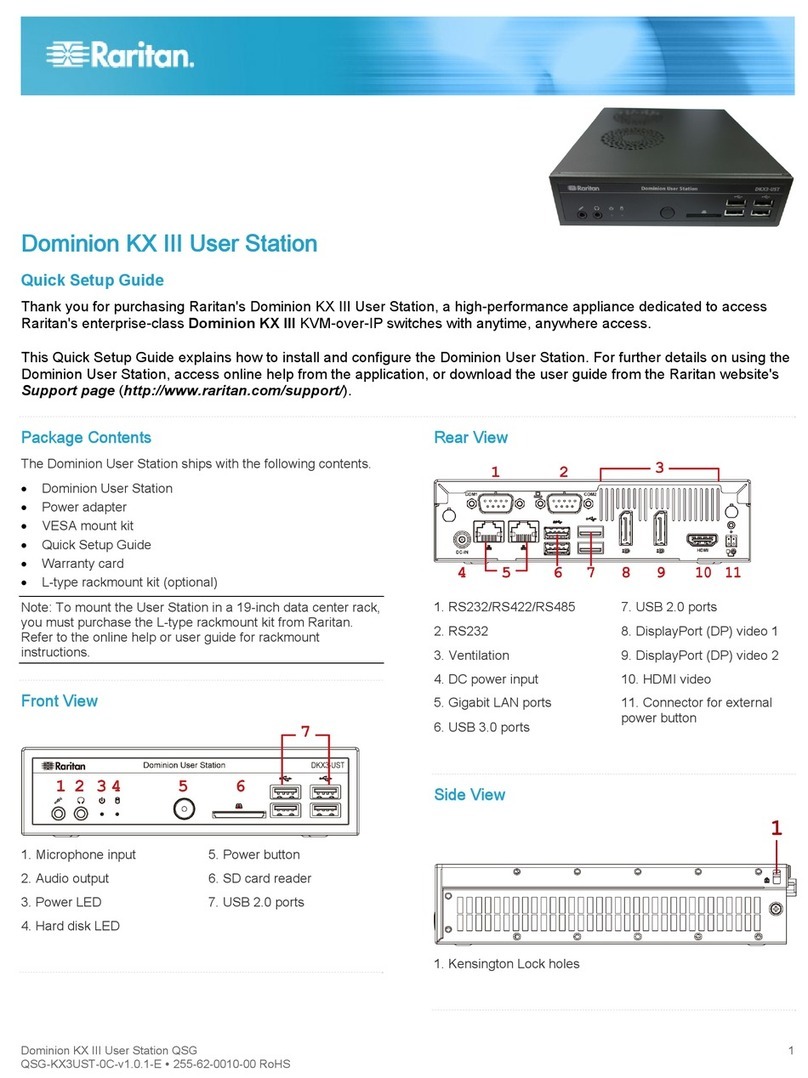

Quick Connect (QC)

M23 12 way

Male Plug

(Pin view from Switch)

Switch Circuit

1

0V

Su ly 0V.dc

2

R+ 24V.dc

Su ly 24V.dc

3

S+ 24V.dc

Unlock signal (solenoid) a ly +24V.dc

4 6

11/12

Safety out ut circuit

7 8

21/22

Safety out ut circuit

5

44

Guard o en signal +24V.dc out

9

34

Unlocked signal +24V.dc out

12

Earth bonding connection

IMPORTANT:

Record any RFID codes as required by factory rules or with reference to any risk assessment for the articular a lication.

The risk assessment for the articular a lication should include the risk of s are actuators. S are actuators should not be readily available and must be securely controlled.

The safety functions and mechanics must be tested regularly. For a lication where infrequent guard access is foreseeable, the system must have a manual function test to detect a ossible

accumulation of faults. At least once er month for PLe Cat 3/4 or once er year for PLd Cat 3 (ISO13849-1). Where ossible it is recommended that the control system of the machine

demands and monitors these tests, and sto or revents the machine from starting if the test is not done.(see ISO14119). It is the res onsibility of the user to ensure the correct overall

functionality of its systems and machines. IDEM, its subsidiaries and affiliates, are not in a osition to guarantee all of the characteristics of a given system or roduct not designed by IDEM.

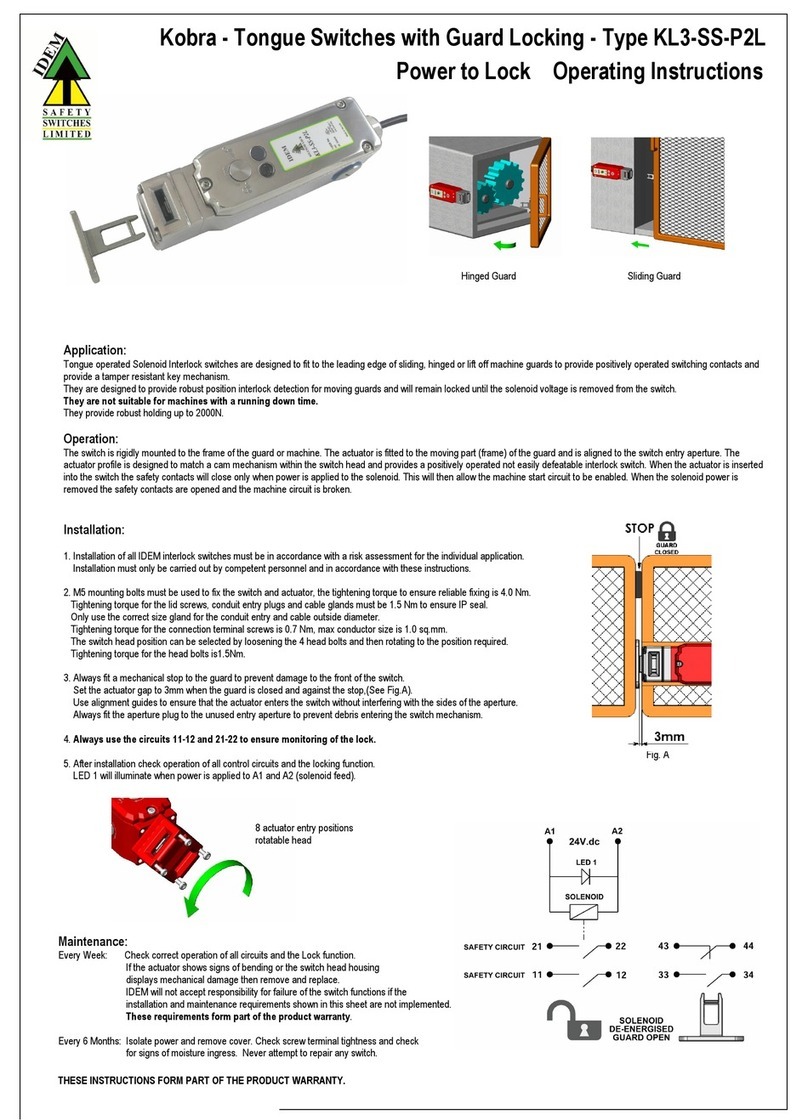

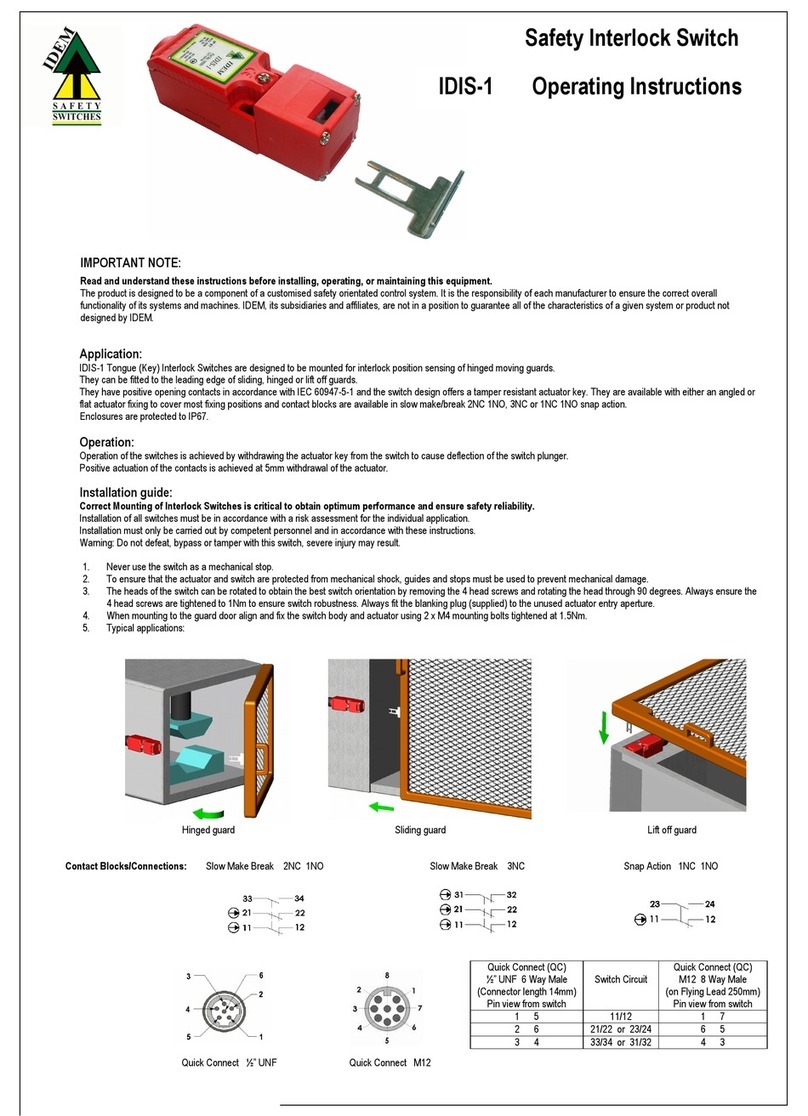

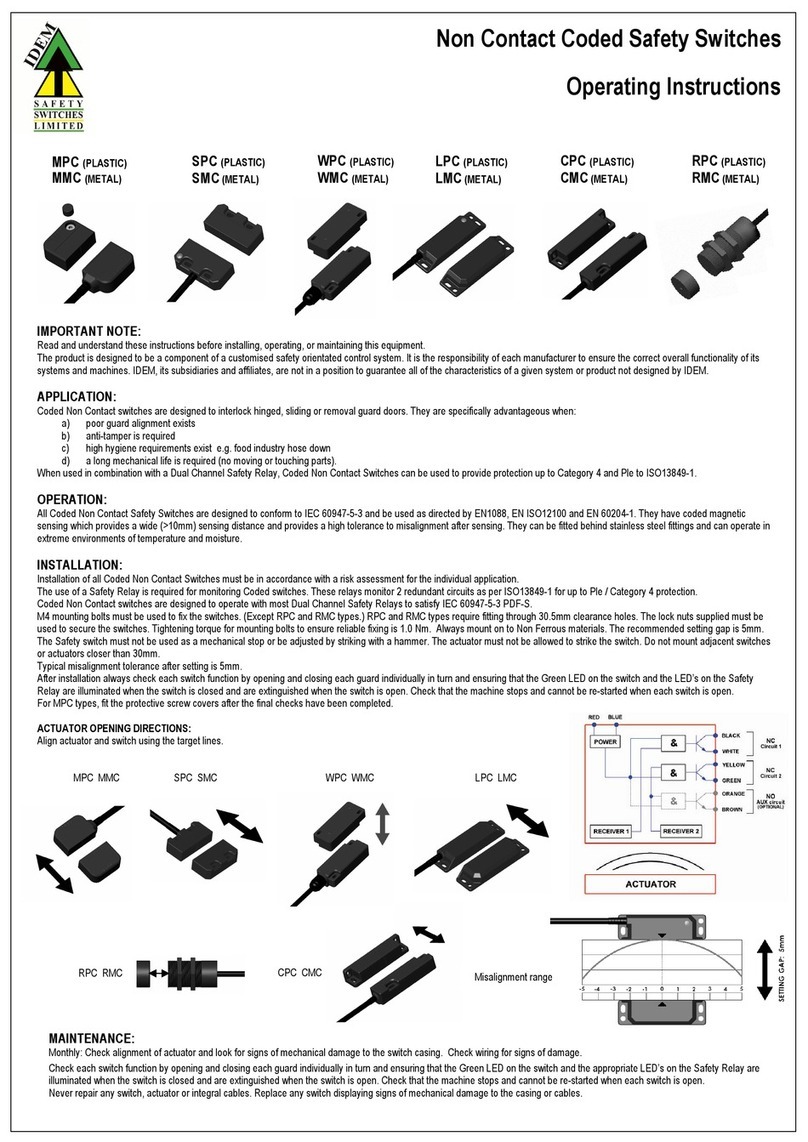

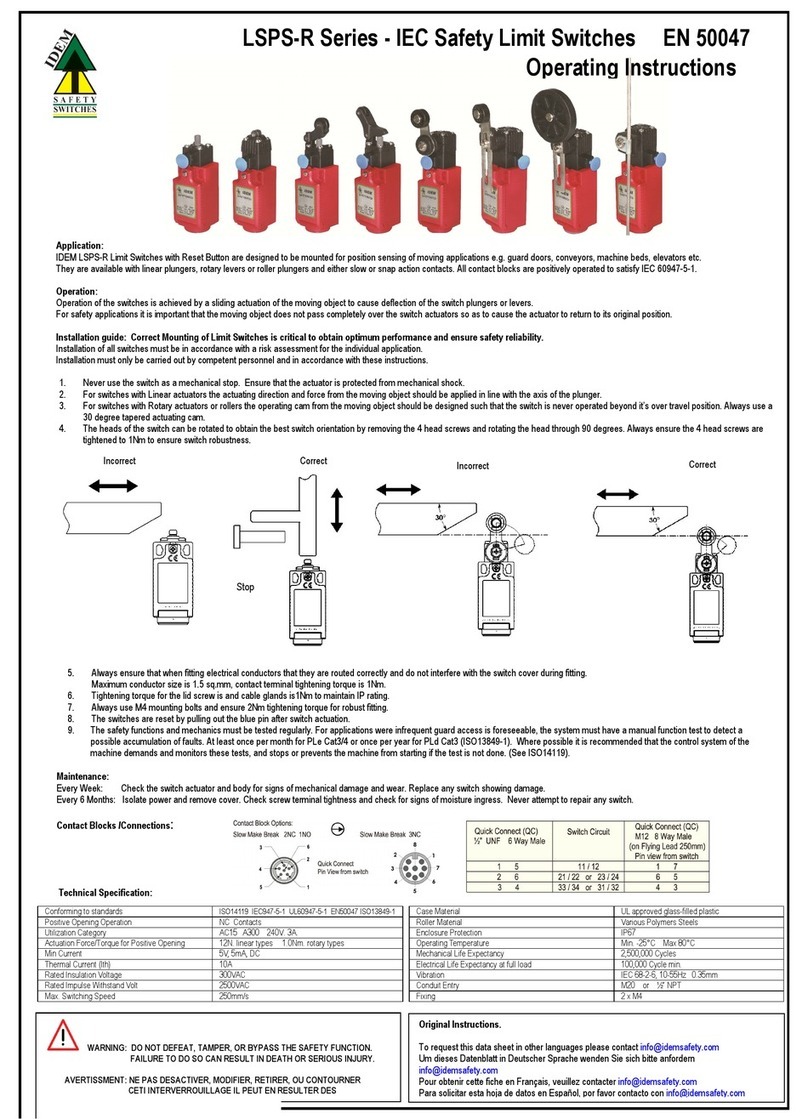

In tallation:

1. Installation of all IDEM interlock switches must be in accordance with a risk assessment for the individual a lication.

Installation must only be carried out by com etent ersonnel and in accordance with these instructions.

2. M5 (or a ro riate) mounting bolts must be used to fix the switch and actuator mounting lates. The tightening torque to ensure reliable fixing is 4.0 Nm.

Tightening torque for the lid screws and cable glands must be 1.5 Nm to ensure the IP seal. The actuator entry osition (Front or End) can be selected by using the internal

slide switch inside the switch cover (See Fig.1 on age 2). Do not mount adjacent switches or actuators closer than 100mm.

3. Always fit a mechanical sto to the guard to revent damage to the front of the switch.

Always ensure correct alignment of actuator and handle with front a ertures of the switch and guide. Use alignment guides to ensure that the actuator enters the switch

without interfering with the sides of the a erture.

If fitted, ensure access to at least one of the auxiliary release oints. The switch can be ositioned / shielded to revent unintended actuation of the auxiliary release.

The release function is achieved by use of a tool and is to be used in exce tional circumstances. If used the release can be rotected by use of a tam er coating to rotect

against unintended o eration. If o erated this tam er rotection must be restored.

Always fit the a erture lug to the unused entry a erture to revent debris entering the switch mechanism.

4. The RFID code is factory set. For instances where re lacement of the RFID actuator is required lease contact IDEM via e-mail: technical@idemsafety.com.

5. The switch is su lied with removable conductor links fitted 41/42 and 31/32. If required by the control circuit these may be removed to offer inde endent monitoring of the

solenoid locking function or the actuator osition.

6. After installation check o eration of all control circuits and the locking function.

For a lications with a run down time after removing ower, ensure that the correct timing allowance has been made before the solenoid is energised.

KLTM-RFID & KLT-SS-RFID Operating In truction

Maintenance:

Every month: Check correct o eration of all circuits and the Lock function. If the actuator shows signs of bending or the

switch head housing dis lays mechanical damage then remove and re lace. IDEM will not acce t res onsibility for

failure of the switch functions if the installation and maintenance requirements shown in this sheet are not im lemented.

Every 6 months: Isolate ower and remove cover. Check screw terminal tightness and check for signs of moisture

ingress. Never attem t to re air any switch.

THESE INSTRUCTIONS FORM PART OF THE PRODUCT WARRANTY.

Application:

The KLTM-RFID and KLT-SS-RFID Safety Interlock switches are designed to fit to the leading edge of machine guard doors to rovide robust

guard locking and rovide a double tam er resistant interlock mechanism.

They are designed to rovide robust osition interlock detection for moving guards and will remain locked until the solenoid voltage is a lied

to the switch. They can be used in conjunction with delay timers to rovide the solenoid energise signal only after a re-determined the time

has run down.

Operation:

The switch is rigidly mounted to the fixed frame of the guard or machine. The actuator is fitted to the moving art (frame) of the guard and is

aligned to the switch entry a erture. The mechanical tongue actuator rofile is designed to match a cam mechanism within the switch head

and rovides a not easily defeatable mechanical interlock. There is also an RFID coded actuator which aligns with a rogrammed receiver

inside the switch housing during closing of the guard. Only when both actuators are correctly aligned and the RFID coding is verified correctly

can the safety contacts close and allow the machine start circuit to be enabled. When the solenoid is energised the safety contacts are

ositively o ened and the machine circuit is broken.

KLTM

-

RFID

KLT

-

SS

-

RFID

Tongue Switch with Guard Locking & RFID Coding

IDEM SAFETY SWITCHES Ltd., 2 Orm ide Clo e, Hindley Indu trial E tate, Hindley Green, Wigan, WN2 4HR UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076

IDEM (USA) 4416 Technology Drive, Fremont, CA 94538 Tel:510-445-0751 Fax:1866-431-7064 email: ale @idem afety.com Web: www.idem afety.com

Doc.102540 Jan 18

LED Diagno tic

Switch State

LED 1 (Green

/Yellow

)

Comment

Solenoid State

LED 2

(Red)

Guard O en

Off

Energised

ON

Guard Closed + Locked

Steady Green

Safety out uts ON

De

-

energised

OFF

Guard Closed + Unlocked

Flashing Green

Guard Closed + Misalligned / Wrong Actuator

Alternate Flashing Green/Yellow

Fault

Steady Yellow

See reset rocedure

Special In truction: RFID actuator

–

RESET.

In the event that a Fault condition requires reset, follow the reset instructions:

1) Turn off all ower to the switch and o en the guard.

2) Remove the switch cover.

3) Using a 2mm terminal screwdriver hold down the RESET button inside the switch housing and turn on the switch

ower (see Fig.2).

4) Release the RESET button, the yellow LED will flash, close the guard and the yellow LED will turn steady yellow.

(If yellow LED continues to flash check for mechanical fault (e.g. damaged actuator or switch head)).

5) Turn ower off and then on, the green LED will illuminate.

6) Re-fit the switch cover.

7) O en and close the guard ensuring all safety functions are correct –refer to any risk assessment for the articular

guard a lication.

Slide Switch Po ition 2:

FRONT Entry

Slide Switch Po ition 1:

END Entry

Technical Data:

Standards : IEC60947-5-1 IEC60947-5-3 ISO14119 ISO13849-1 IEC62061 UL508

Entry Selector Switch

Select Front or End sensing. (See Fig 1)

RESET button

(If required ress and hold using a 2mm

terminal screw driver)

Su ly Voltage

24Vdc (+/

-

10%)

SELV

or Class 2

Power Consum tion

R+

(50mA Max.)

S+

(500mA Max.)

(Solenoid)

Safety Circuits

24

Vdc 200mA max. switching.

Auxiliary Circuits (34 & 44)

24Vdc

200

mA m

ax.

Out ut feed.

Rated Insulation Voltage

500VAC

Rated

Im ulse withstand

1000VAC

Holding Force

F1Max 3000N Fzh 2307

N

(ISO

14119)

Classification and coding level

Ty e 4 High (ISO14119)

Actuator insertion distance for assured locking

5mm

Sao (RFID)

10mm

Sar (RFID)

20mm

O erating Frequency

1Hz

Actuator entry minimum radius

175mm

Body Material

KLTM

-

RFID: Die cast

–

Painted red

KLT

-

SS

-

RFID: Stainless Steel 316

Head Material

Stainless Steel 316

Mechanical Actuator Material

Stainless Steel 316

Enclosure Protection

IP67

(

IP69K

S/Steel versions only).

O erating Tem erature

-

25°C to +40°C

Mechanical Life Ex ectancy

(B10d)

2

.5

x 10

6

c

ycles

at 100mA load

Vibration

IEC68

-

2

-

6, 10

-

55Hz+1Hz

Excursion: 0.35mm, 1 octave/min

Fig. 2. Cover

Removed

Safety Classification for Guard Position monitoring.

Characteristic data according to IEC62061 (used as a subsystem)

Safety Integrity Level

SIL 3

PFH (1/h)

4.8

E

-

10

Corres onds to 4.8% of SIL3

Proof Test Interval T

1

20a

Characteristic data according to EN ISO13849

-

1

Performance Level

e

If both channels are used in

conjunction with a SIL3/PLe control

device.

Category

Cat 4.

MTTF

d

1100a

Diagnostic Coverage DC

99%

(High)

Note: The Diagnostic coverage could

be reduced to lower than PL e if

multi le interlocking switches are

connected in series.

Information with regard to UL 508: Ty e 1 enclosure.

Maximum tem erature 40°C.

Use 16-28AWG co er conductors (rated 90°C). Terminal Torque 6 lb ins. (0.7Nm).

Intended for same olarity use. Safety Circuits (11-12 & 21-22) 24V.dc 200mA max.

Use one olymeric conduit connection. Not suitable for connection to rigid metal conduit.

(Earth bonding terminal inside enclosure if required – use 16-12AWG conductors).

WARNING:

DO NOT DEFEAT, TAMPER, OR BYPASS THE

SAFETY FUNCTION. FAILURE TO DO SO CAN

RESULT IN DEATH OR SERIOUS INJURY.

Original In truction

To request this datasheet in other languages lease contact

Um dieses Datenblatt in Deutscher S rache wenden Sie sich bitte anfordem info@idemsafety.com

Pour obtenir cette fiche en Francais, veuillez contacter info@idemsafety.com

Para solicitor esta hoja de datos en Es anol, or contacto con info@idemsafety.com

AVERTISSEMENT:

NE PAS DESACTIVER, MODIFIER, RETIRER, OU

CONTOURNER CETI INTERVERROUILLAGE IL

PEUT EN RESULTER DES BLESSURES

GRAVES DU PERSONNEL UTILISATEUR

END

FRONT

Head of

the s

witch

this way.

Fig. 1. Entry Selector Switch

Connection exam le to SCR31-42-TD-i Safety Relay (Timed delay to solenoid)

This manual suits for next models

1

Other Idem Switch manuals