Idem UGB-NET-CS User manual

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions Contents

1. Contents

2. System Overview .......................................................................................................................1

UGB-NET Switch Body.........................................................................................................1

3. Safety Functions ........................................................................................................................1

4. Installation & Maintenance .......................................................................................................2

Principle..............................................................................................................................2

Fastening ............................................................................................................................2

Maintenance Activities .......................................................................................................2

UGB-NET with Rotary Handle..............................................................................................3

UGB-NET with Sliding Handle..............................................................................................3

5. Electrical Connection .................................................................................................................4

6. Protocol Setup ...........................................................................................................................5

Network Address –Setup/Initial Setting.............................................................................6

Setting via DIP Switch .........................................................................................................6

Setting via DHCP .................................................................................................................6

Studio 5000 Ethernet/IP Configuration...............................................................................8

Factory reset.....................................................................................................................10

Functional Tests................................................................................................................10

7. Data Map.................................................................................................................................10

8. Diagnostic Indication ...............................................................................................................11

9. Technical..................................................................................................................................12

Device Characteristics.......................................................................................................12

Electrical Data...................................................................................................................12

Mechanical Data ...............................................................................................................12

Environmental Data ..........................................................................................................12

Reliability / Safety Data (EN ISO 13849-1).........................................................................12

Reliability / Safety Data (EN 62061 / IEC 61508)...............................................................12

NOTES.............................................................................................................................................13

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 1

2. System Overview

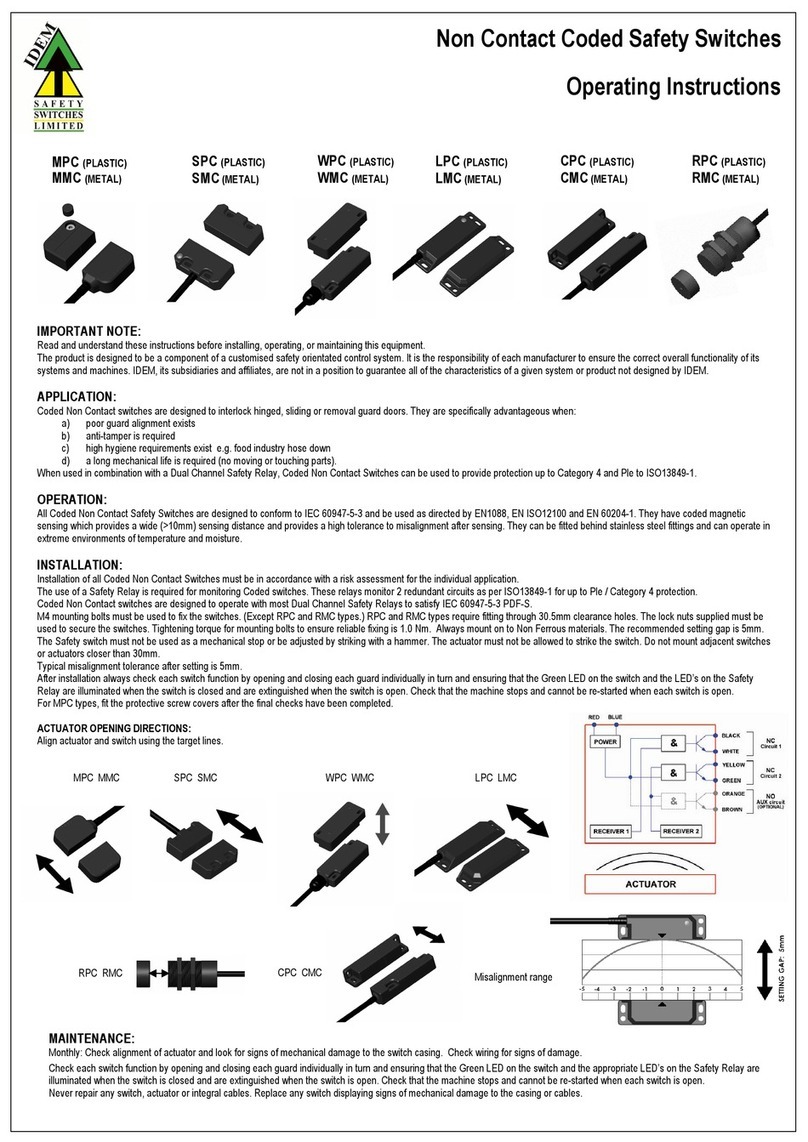

UGB-NET Switch Body

Key

1 –Pilot Devices

2 –Data Ports

3 –Power Ports

4 –Head End Entry

5 –Head Front Entry

6 –Manual Release

7 –Indication LEDs

8 –DIP Switch Cover

3. Safety Functions

IMPORTANT

•It is the responsibility of the user to ensure the correct overall functionality of its

systems and machines. IDEM its subsidiaries and affiliates are not in a position to

guarantee all of the characteristics of a given system or product not design by IDEM.

•All relevant safety regulations and standards are to be observed.

The UGB-NET-CS complies with the requirements of Cat. 4 / PL e and SIL 3 in accordance with ISO 13849-1,

IEC 62061 and IEC 61508. The device implements the following safety functions:

•Guard interlocking that complies with the requirements of IEC 60947-5-3 and is classified as a type 4

device with high coding in accordance with the application standard ISO 14119.

•Guard locking with lock monitoring for person protection.

•Emergency stop function (optional, see part number options)

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 2

4. Installation & Maintenance

Principle

The UGB-NET switch is mounted to the fixed frame of the guard or machine, the handle and actuator are

fitted to the moving guard with the actuator tongue aligned to the aperture of the switch head. The

mechanical tongue actuator profile is designed to match a cam mechanism within the switch head, the

cam and tongue together realise the specified holding force.

WARNING

DO NOT DEFEAT, TAMPER, OR BYPASS THE SAFETY FUNCTION.

FAILURE TO DO SO CAN RESULT IN DEATH OR SERIOUS INJURY.

NE PAS DESACTIVER, MODIFIER, RETIRER, OU CONTOURNER CETI, INTERVERROUILLAGE

IL PEUT EN RESULTER DES BLESSURES GRAVES DU PERSONNEL UTILISATEUR.

•Observe the county-specific regulations when installing the device.

•Repair or modification of the UGB-NET is not allowed unless authorised by IDEM

and carried out according to operating guidelines.

•Safety critical failures which do not lead to the safe state shall be reported to IDEM

immediately.

•Replace a malfunctioning UGB-NET immediately.

IMPORTANT

•Ensure that the static forces applied during normal operation do not exceed the

holding force (Fzh).

•Ensure that dynamic forces acting on the switch caused by bouncing of the guard do

not create an impact reaction force which exceeds the holding force (Fzh).

NOTES REGARDING :

•Maximum Temperature 40°C

Fastening

IMPORTANT

•If fitting rotary or sliding handles ensure the M6 mounting bolts are used to fix the

appropriate mounting plates.

•The tightening torque to ensure reliable fixing is 4.0Nm.

•The front and rear rotary handles can be adjusted for desired position by loosening

the locking bolt which fixes the handle to the switch body.

Maintenance Activities

IMPORTANT

•To achieve the target safety level, it is required to routinely check the safety

functions are operating correctly. For applications targeting PLe a check should take

place once per month, for PLd applications a check should take place once per year.

•If any part of the UGB-NET displays mechanical damage then remove and replace.

•IDEM will not accept responsibility for failure of the switch functions if the

installation and maintenance requirements shown in this document are not

implemented.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 3

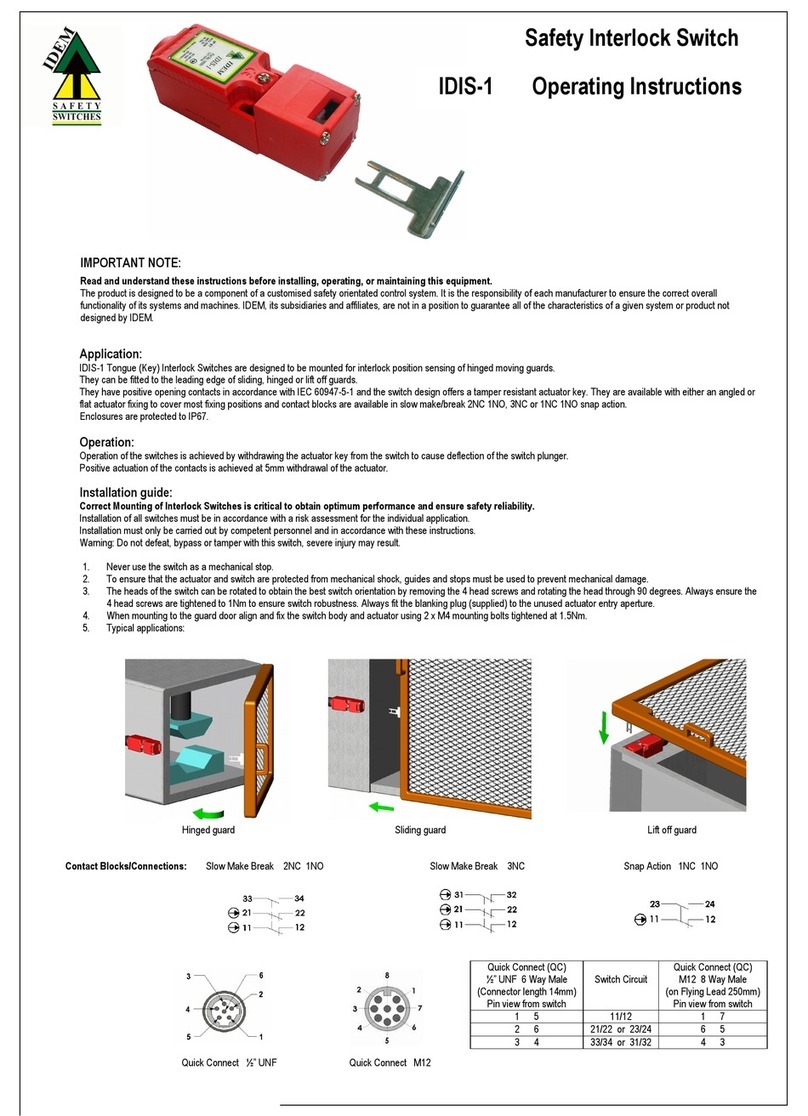

UGB-NET with Rotary Handle

Guard Front

Guard Rear

UGB-NET with Sliding Handle

Guard Front

Guard Rear

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 4

5. Electrical Connection

WARNING

•The device shall be supplied by a 24V SELV/PELV power supply acc. to IEC 61131-2

which limits the maximum voltage in case of failure to 60V.

•Function Earth must be connected.

NOTES REGARDING :

•To meet the requirements for UL a class 2 power supply must be used.

INFORMATION

•When multiple devices are used in a daisy-chain arrangement the power bus may be

forwarded via the UGB-NET device. Please see technical specification and ensure the

total current through each device does not exceed the specified maximum current.

INFORMATION

•Not all connections are required for all applications, the minimum requirement to

operate the device is one data connection and one power connection. All 4 ports are

utilised when the UGB-NET is used a ‘daisy chain’ configuration.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 5

6. Protocol Setup

IMPORTANT

•The minimum time between the change of a single safe digital input and the

transmission to the CIP Safety is 32ms for the Interlock/Lock and Estop. In the case

of an input level change at both safe inputs at the same time the maximum safe

application reaction time is 42ms for Interlock/Lock and Estop.

•Clear any pre-existing configuration from any safety device before installing it onto a

safety network.

•Commission all safety devices with IP address prior to installing it onto a safety

network.

•When a SIL3 device is configured directly from a workstation, the user should

compare the transferred SCID and configuration data with the SCID and

configuration data originally viewed in the workstation.

•The configuration software shall assume an ASYNC parameter value of 1.

•Configuring an originator with connection data and/or target configuration data

must be downloaded to the target so it can be tested and verified. Only then can

SCIDs from the target be confirmed.

•Status-Bits reported by the device via CIP Safety messages shall not be used to

trigger the safety function of a device or system.

•The safety-related parts of the EDS (Electronic Data Sheet) of the UGB-NET-CIP

device shall not be altered.

•Each safety device shall have a single physical address that is unique on the devices

segment.

•The maximum operation time (proof-test interval) of the UGB-NET shall not exceed

20 years. When reaching the proof test interval, the UGB-NET shall be replaced and

put permanently out of order.

•After the detection of a safety critical error, the UGB-NET shall not be kept in fail-

safe state for more than 1 hour.

INFORMATION

•The device EDS file can be found via the UGB-NET product page of the IDEM

website www.idemsafety.com/products or alternatively please contact

technic[email protected]m

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 6

Network Address –Setup/Initial Setting

The UGB-NET IP address can be set via DHCP server or statically via the device DIP switches.

The UGB-NET in its out-of-the-box state will have DHCP enabled (All DIP switches OFF, no IP address set).

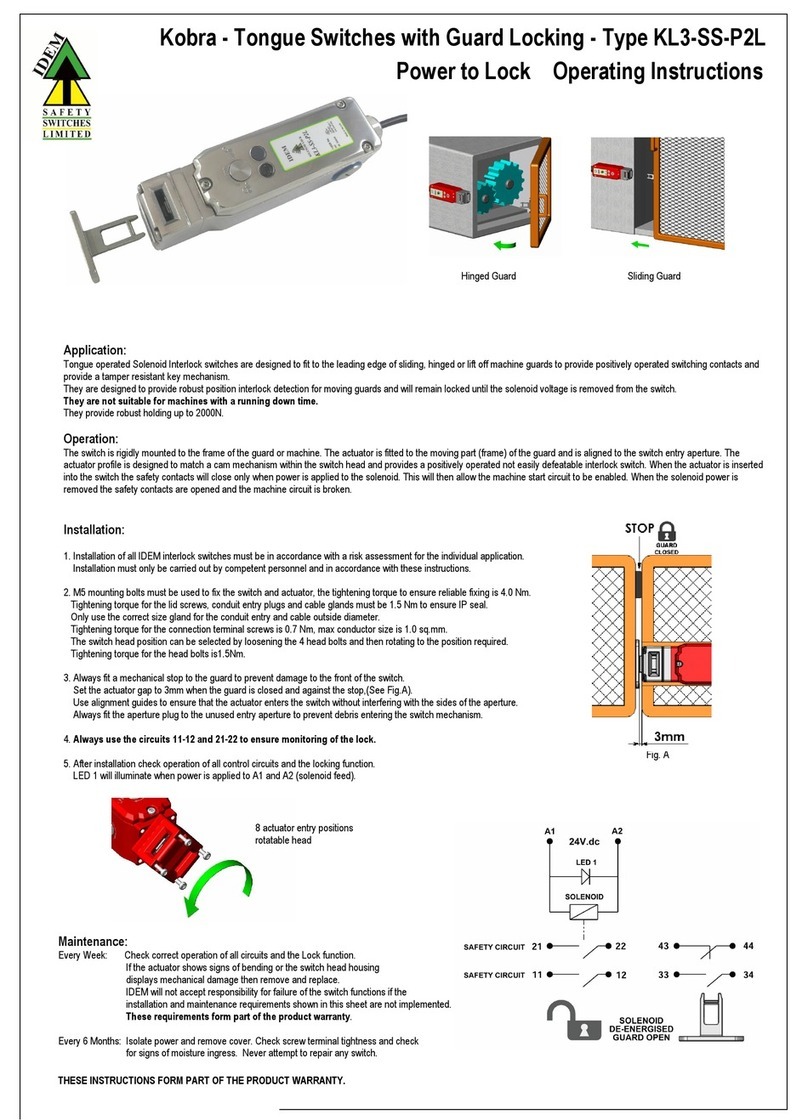

Setting via DIP Switch

To manually assign a static IP the DIP switches located on the lid of the UGB-NET are used. The following

steps can be performed with the device powered on or off, note the final step if the device is powered.

1. Locate the DIP switch cover on the UGB-NET body, remove the 2 cover screws and lift the DIP

switch cover to gain access to the DIP switches.

2. Using a small tool push the required switches to the ‘ON’ position to set the corresponding bit.

3. Cycle power to the UGB-NET or press and hold the reset button until the LEDs turn red then release to

reset the device. The UGB-NET will restart with the configured IP address and with DHCP disabled.

4. Replace the DIP switch cover and screws ensuring a tight seal to the switch housing.

INFORMATION

•The example given in the image above shows only switches 2, 16 and 64 set to

the ‘ON’ position. The resulting IP address is: 192.168.1.82

Setting via DHCP

1. Apply power to the UGB-NET, after a start-up period the ‘MS’ LED should be flashing green.

2. Using a PC station that is configured on the same network as the UGB-NET, run the BOOTP/DHCP tool.

3. Using the MAC address to identify the UGB-NET, select the UGB-NET in the ‘Discovery History’ window

and click ‘Add Relation’.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 7

4. Configure the required IP address setting in the pop-up window and click OK.

5. Open an internet browser and type in the IP address of the UGB-NET.

6. Navigate to ‘Configuration’ under the ‘NETWORK’ menu.

7. Set DHCP to ‘Disabled’ and click ‘Save settings’

8. Cycle power to the UGB-NET or press and hold the reset button until the LEDs turn red then release to

reset the device. The UGB-NET will restart with the configured IP address and with DHCP disabled.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 8

Studio 5000 Ethernet/IP Configuration

1. Download the EDS file for the UGB-NET and import to application control software.

2. Open or create a project with the PLC CPU, Partner and Ethernet/IP modules added.

3. Right click the Ethernet module and select ‘New Module…’

4. Find and select the UGB-NET-CIP (will only appear if EDS file imported correctly), click ‘Create’.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 9

5. Set the device name (customisable –‘UGB_NET_CIP’ used as example only) and set the

previously configured IP address.

6. Change the Safety Network Number (SNN) to match that of the controller/PLC.

7. On the ‘Safety’ tab, uncheck the ‘Configuration Signature’ box, press OK.

8. The UGB-NET can now be utilised in the PLC program according to the UGB-NET data mapping.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 10

Factory reset

Please consult the instruction manual of the application control software or for further assistance please

contact technical@idemsafety.com

Functional Tests

Once the device has been installed and setup within the EtherNet IP / CIP Safety application control

software the following checks are necessary to ensure correct operation of the system.

•Expected operation of all control circuits.

7. Data Map

See technical datasheet supplied with product. For assistance please contact:

technic[email protected]m

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 11

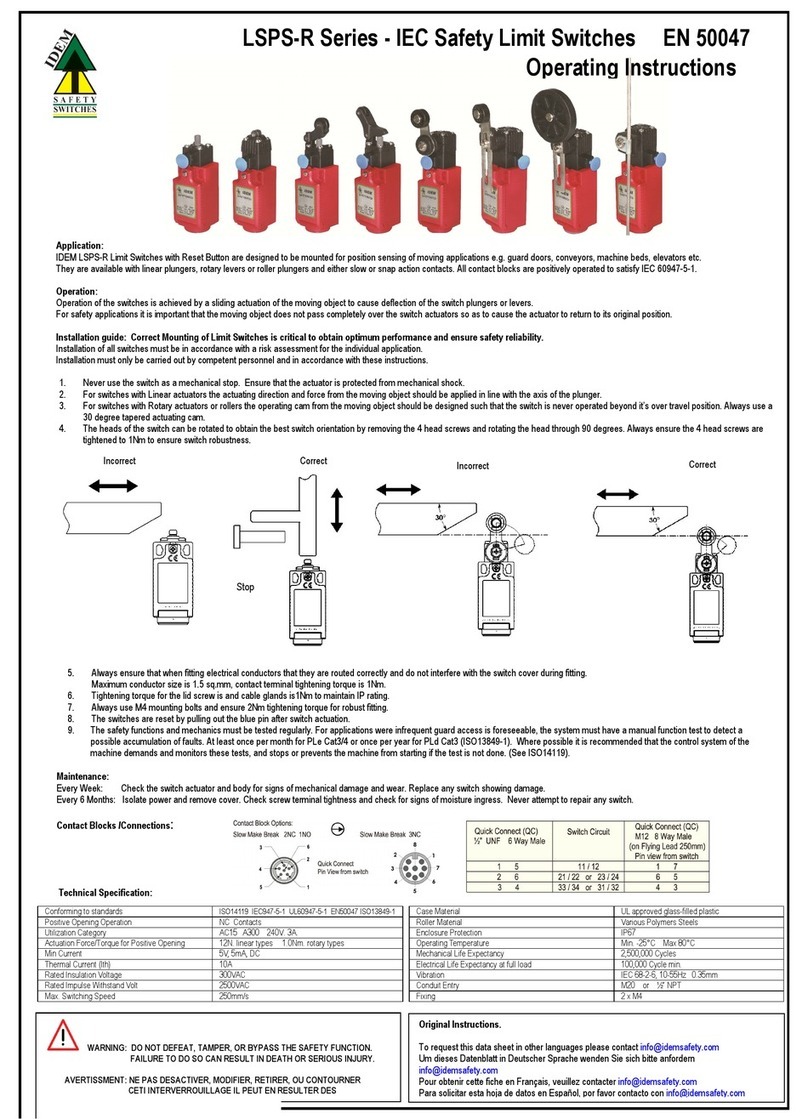

8. Diagnostic Indication

LED

Function

Colour

LS

Locking Switch Status

Red/Green

DS

Device Status

Red/Green

PS

Module Status

Red/Green

PN

Network Status

Red/Green

L1

Link 1

Amber/Green

L2

Link 2

Amber/Green

LED

LED State

Comment

LS

Off

Locking switch inactive, waiting for data connection

Green

Guard is closed and locked

Green flash

Guard is closed and unlocked

Red

Internal fault detected, reset required.

Red flash

Missing or incorrect RFID tag

Red double flash

Guard forced open, reset required.

Red/Green alternate

Reset in progress

DS

Green

Device running

Red

Internal fault detected

MS

Green

Connection to PLC, Run state

Green Flash

Connection to PLC, Idle state

Red

Major Fault

Red Flashing

Recoverable fault, check PLC/UGB-NET configuration

NS

Off

No IP address set

Green

Online, connection(s) established

Green flash 1Hz

Online, no connections established

Red

Network fault

Red flash

Connection timed out.

L1/L2

Off

No Ethernet link detected

Amber

Ethernet link detected

Amber flash

Ethernet data transfer

•Diagnostic LED’s are not reliable indicators and cannot be guaranteed to provide accurate

information. They should only be used for general diagnostics during commissioning or

troubleshooting. Do not attempt to use LEDs as operational indicators.

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 12

9. Technical

Device Characteristics

Actuator coding level

Type 4 (RFID), High (acc. to ISO 14119)

Assured sensing distance on (Sao)

10 mm

Assured sensing distance off (Sar)

20 mm

Assured locking distance

5 mm

Response time (E Stop)

36 ms max. (E-stop -> transmission to field bus)

Response time (Guard Interlock)

36 ms max. (Guard/Lock -> transmission to field bus)

Electrical Data

Operating voltage

24 V DC +10%/-15% (SELV/PELV)

Power Supply UL Requirements

Class 2 power supply must be used.

Current consumption, max.

600 mA (Lock solenoid enabled)

Allowed through current (daisy-chain)

5 A

Mechanical Data

Maximum holding force (F1)

3000 N

Rated holding force (Fzh)

2307 N

Body material

Die cast Aluminium

Head material

Stainless steel 316

Environmental Data

Operating temperature

-5 °C to 40 °C

Enclosure Protection

IP 65

Maximum operating altitude

2000 m

Shock and Vibration

Tested in accordance with:

IEC 60068-2-6 and IEC 60068-2-27

Pollution Degree (Storage and Operation)

Degree 2 (EN 60664)

Reliability / Safety Data (EN ISO 13849-1)

Category

4

Performance Level

e

MTTFd

High

DC

99%

Reliability / Safety Data (EN 62061 / IEC 61508)

Mission Time

20 years

SIL CL

SIL 3

PFHd (Guard Interlocking / Lock Monitoring)

7.3E-10

PFHd (Emergency Stop Function)

2.3E-9

Operating Instructions

IDEM Safety Switches

UGB-NET-CS

102620 2210 UGB-NET-CS Operating Instructions 13

NOTES

EC / EU Declaration of Conformity

MANUFACTURER:

EU REPRESENTITIVE:

ADDRESSES:

IDEM SAFETY SWITCHES LIMITED

IDEM SAFETY SWITCHES Ro SRL

Hindley Industrial Estate

Hindley Green

Bloc OD6, nr. 35

Wigan

Bulevardul Timișoara

Lancashire

București

WN2 4HR

061344

United Kingdom

Romania

DEVICE(s):

UGB-NET

THE LISTED DEVICES CONFORM TO THE ESSENTIAL HEALTH AND SAFETY REQUIREMENTS OF THE

FOLLOWING EUROPEAN DIRECTIVES AND STANDARDS

DIRECTIVES:

Machinery Directive

2006/42/EC

EMC Directive

2014/30/EU

STANDARDS:

EN 13849-1

:2015

EN 13849-2

:2012

EN 62061

:2015

EN 61508 (Parts 1-7)

:2010

EN ISO 14119

:2013

IEC 60947-5-3

:2013

THIRD PARTY APPROVALS:

TUV Rheinland Industrie Service GmbH

Am Grauen Stein

51105 Köln / Germany

(Notified Body for Machinery, NB 0035)

M.Mohtasham

Managing Director

Dec 2022

Other Idem Switch manuals

Popular Switch manuals by other brands

Matrix Switch Corporation

Matrix Switch Corporation MSC-2HD1624L product manual

Asco

Asco 7000 Series installation manual

Siemens

Siemens S3VA52T installation instructions

TP-Link

TP-Link JetStream L2 Lite TL-SG3210 Cli reference guide

D-Link

D-Link DES-3225G Series user guide

HP

HP 5830AF-96G Series Disassembly instructions