IDEM SAFETY SWITCHES Ltd., 2 Ormside Close, Hindley Industrial Estate, Hindley Green, Wigan, WN2 4H UK. Tel: +44 (0)1942 257070 Fax.: +44 (0)1942 257076

, Fremont, CA 94538 Tel:510

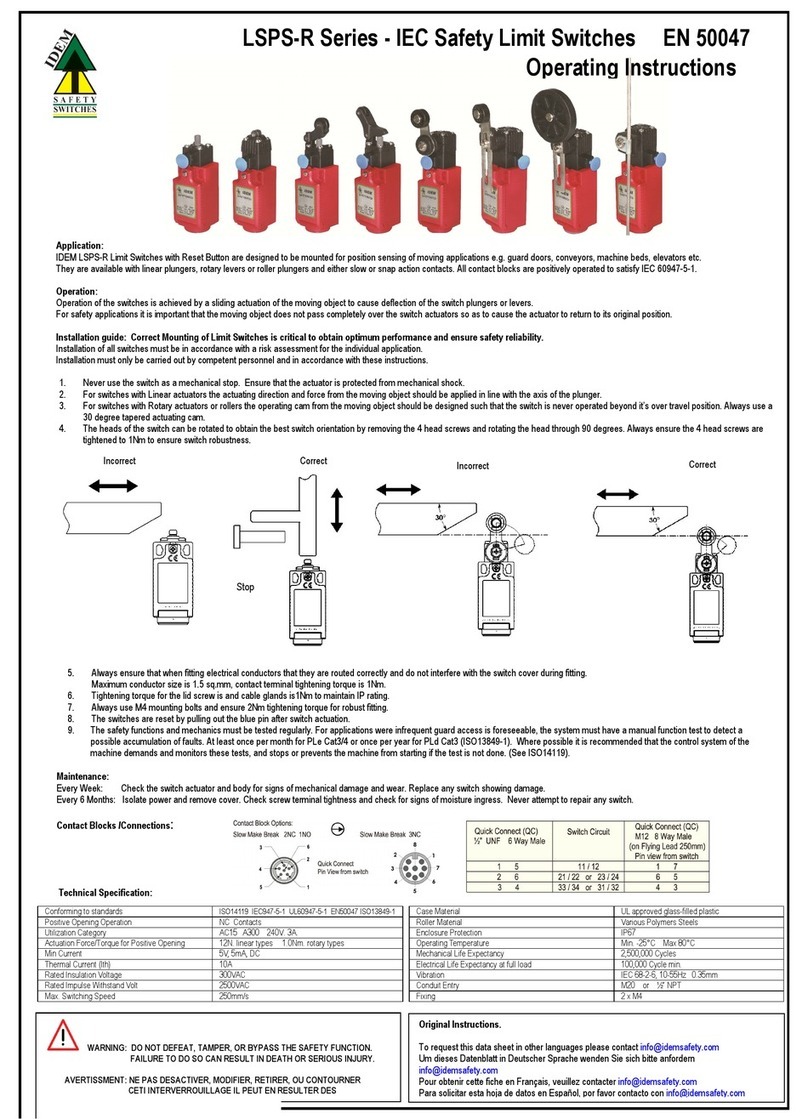

6. Always ensure that when fitting electrical conductors that they are routed correctly and do not interfere with the switch co er during fitting.

Recommended conductor size is 1.5 – 2.5sq.mm, contact terminal tightening torque is 1Nm.

7. Tightening torque for the lid screw and cable glands is1Nm to maintain IP rating.

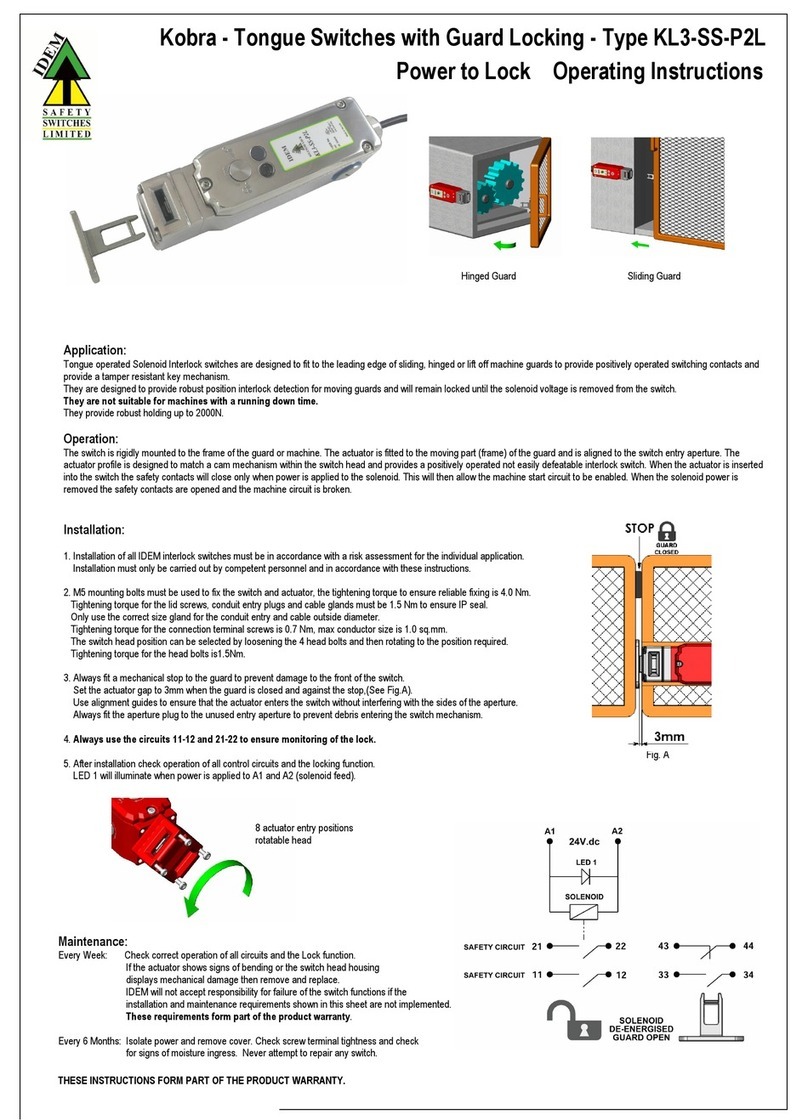

8. Check that the machine is stopped and cannot be started when the interlocked guard is open.

9. After installation apply tamper resistance paint or compound to the actuator and switch mounting bolts.

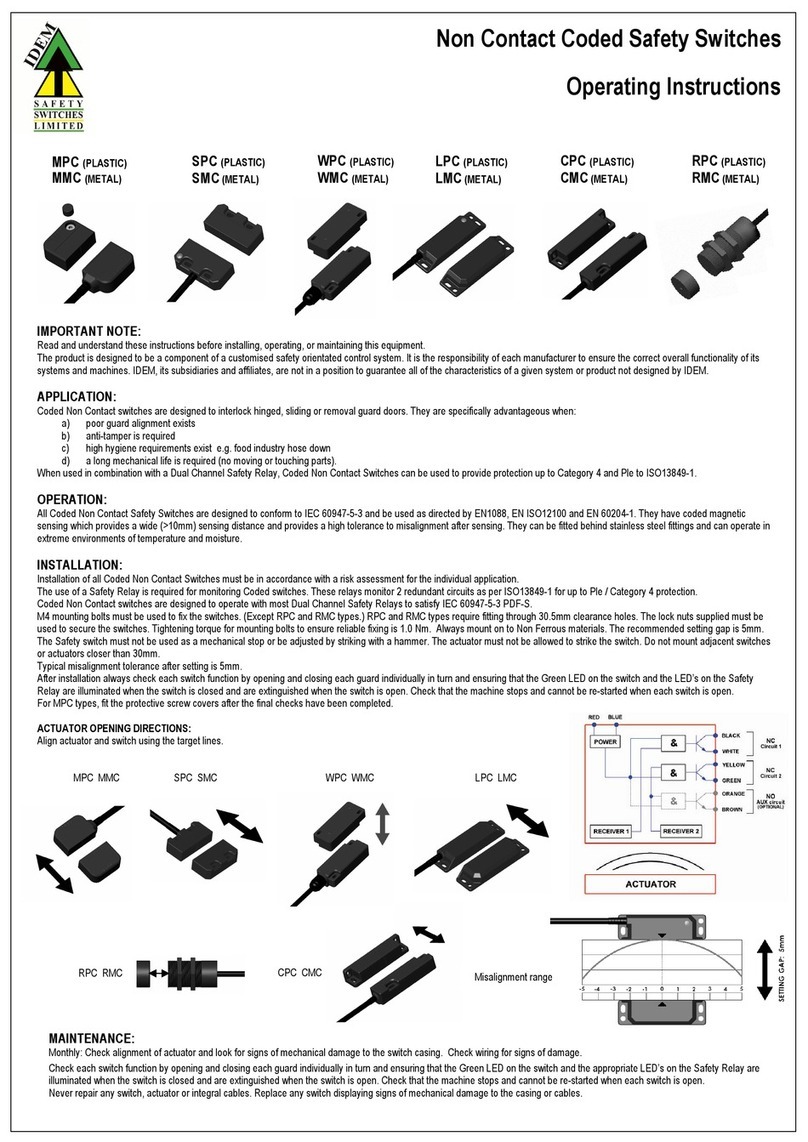

Maintenance:

E ery Week: Check the switch actuator and body for signs of mechanical damage and wear. Replace any switch showing damage.

Check that the machine is stopped and cannot be started when the interlocked guard is open.

E ery 6 Months: Check for mechanical damage to switch body or actuator. Replace any switch showing damage.

Isolate power and remo e co er. Check screw terminal tightness and check for signs of moisture ingress. Ne er attempt to repair any switch.

Standards:

EN1088, 50047, IEC 60947-5-1, EN60204-1

ISO 13849-1, EN62061, UL508

Safety Classification & eliability Data:

Mechanical Reliability B10d

2.5 x 106 operations at 100mA load

Up to Category 4 with Safety Relay

Up to PLe depending upon system architecture

Up to SIL3 depending upon system architecture

Proof Test Inter al (Life)

Rated Insulation/Withstand Voltages

Actuator Entry Minimum Radius

175mm Standard 100mm Flexible

Maximum Approach Withdrawal Speed

Excursion: 0.35mm, 1 octa e/min

Various (see sales part numbers)

R>=150mm

25 +/- 2mm

Minimum operating radius

is system shows interlock s

configured to allow dual circuit direct

feeds to contactor coils K1 and K2.

When the start button is pressed and then released, the auxiliary contacts (A) of contactors K1 and

K2 maintain the feed to the contactor coils.

Opening of the Interlock Switch or depressing the E Stop will isolate power to the contactor coils.

Re-start can only occur pro iding the Guard is closed and the E Stop is reset.

System is shown with the guards closed and the machine able to start.

Information with regard to UL 508:

Type 1 Enclosures.

Control Number 35NV

Use 16 - 12AWG copper conductors rated

90ºC minimum.

Intended for same polarity use and

one polymeric conduit connection.

Electrical Rating:

Max. Switching Current / Volt / Amp:

120V. 6A. (720VA break) PF 0.38

240V. 3A. (720VA break) PF 0.38

Operating Temperature 40ºC

Outline fixing dimensions mm