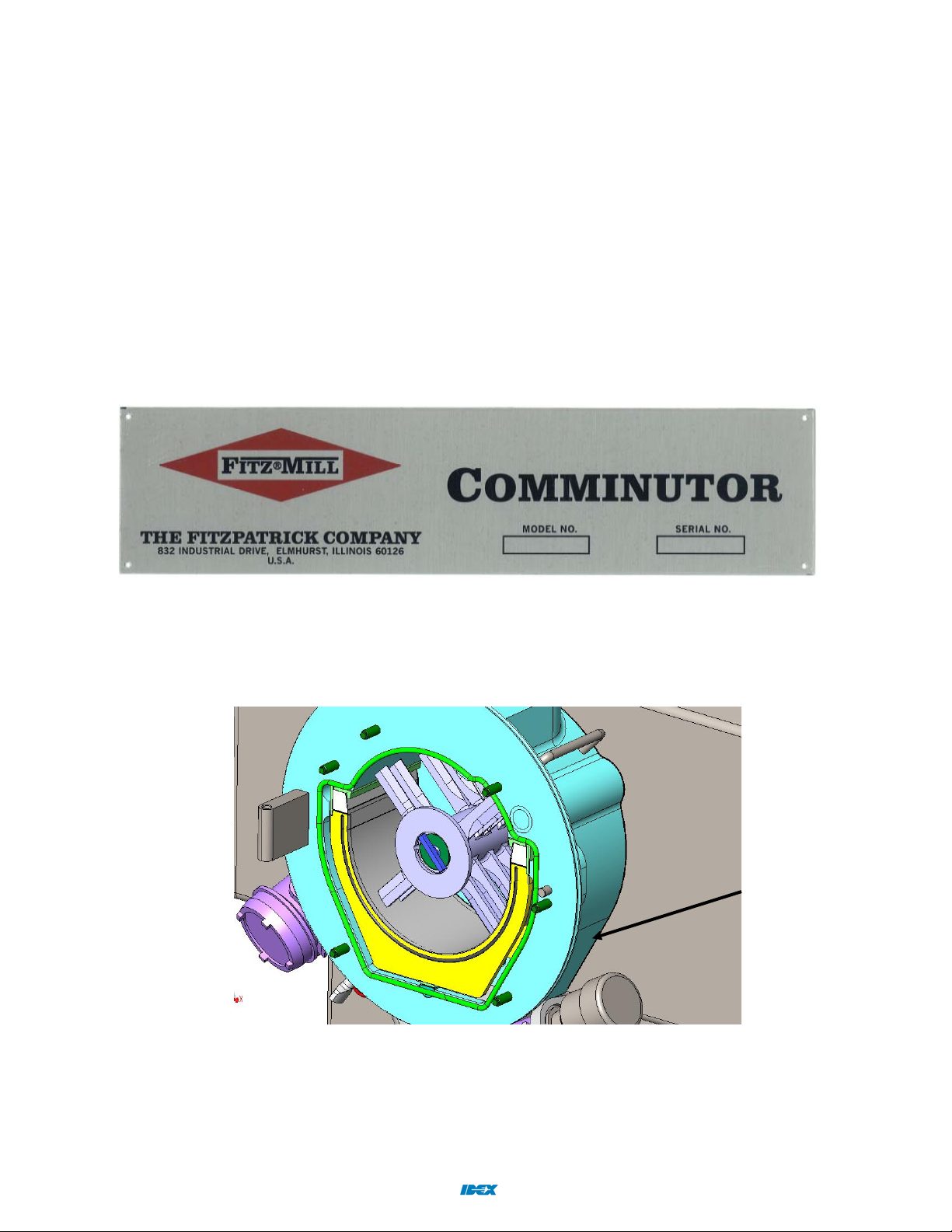

The Fitzpatrick Company D6B Manual Ver 1_24 Jan 2012-DRAFT.doc

A Unit of Corporation Page 20 of 49

SECTION 3: Machine Set Up

3.1 Operating Speeds

Motors are typically supplied with base speeds of 1800 or 3600 rpm for 60 hertz duty (1500

or 3000 rpm for 50 hertz). Actual slip speed, as stamped on the motor nameplate, will be

slightly less than these nominal ratings (e.g. 1750rpm, 3525 rpm, etc…). The Fitzpatrick

Company has designed your machine to meet the rotor operating speed(s) as defined in

your order documents and confirmed on the Comminutor Specification Sheet.

The typical operating range for the D6B Comminutor is:

1,000 – 4,600 RPM when using the conventional rotor

100 – 1,000 RPM maximum when using a bar rotor for gentle particle size reduction

With most model D6B machines, the mill rotor is directly coupled to the drive motor.

Therefore, motor speed = rotor speed. The D6B can also be supplied with a belt driven for

higher speed range when explosion proof or Atex motors are required. Normally these

motors are not allowed to exceed 1.5 times base motor speed. Most D6B machines are

equipped for operation over a working speed range (min-to-max) which is stated on your

Comminutor Specification Sheet. Motor speed is controlled by use of a variable

frequency drive (VFD). Depending upon the configuration of your specific D6B, speed

control through the VFD may be accomplished by one of three control devices:

1. A manually operated speed control potentiometer, located on the base of the

machine (older machines).

2. An electronic Human Interface Module (HIM) with digital readout.

3. Controlled by a PLC with touch screen. This option normally used for D6B

machines with advanced features such as Product Containment systems,

Nitrogen Inerting / Oxygen Sensing or where the D6B is integrated as part of a

Chilsonator granulating system.

See section 4 of this manual for additional information regarding machine controls.