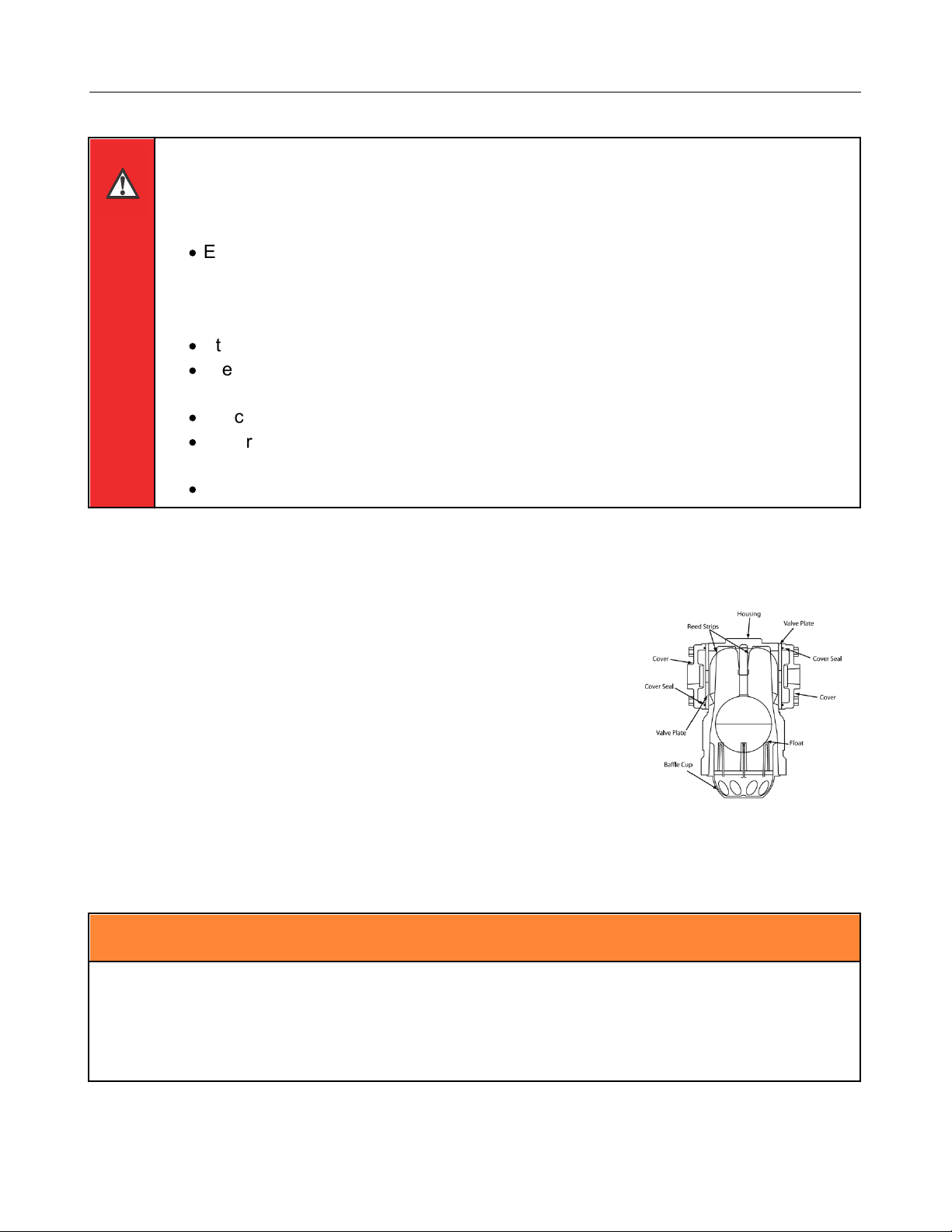

Orientation and Components

Liquid Controls mechanical air and vapor eliminators are

typically bolted, in an upright position, onto the top of a

strainer on the inlet side of the meter. Before operation, air

and vapor eliminators must be piped to a storage tank and–on

most meter systems– to an air-check (or differential) valve.

Installation and maintenance must be done by a qualified

technician. See Installation for Field Piping installation.

Air and Vapor Elimination

Liquid Controls mechanical air and vapor eliminators

eliminate air (or vapor) instantly and continuously as it enters

the meter system. Because air and vapor are lighter and less

dense than liquid, they are naturally pushed up above the

product flow. Air and vapor eliminators are set above the

product flow so that air in the system is pushed up into the

the cavity inside the air eliminator housing, out the valve plate

vent ports, through the piping, and into a storage tank (see

"Vent Ports Open" figure).

As air is evacuated from the system, the liquid level inside the

air eliminator cavity is allowed to rise and push the float up.

As the float moves up, it presses the reed strips against the

valve plate sealing the vent ports and preventing product from

passing through the piping and into the storage tank. If more

air enters the system, it will rise to the top of the air eliminator

cavity. The air will accumulate there and push the liquid level,

and the float, lower. As the float falls, the reed strips pull

away from the vent ports, and air can be vented before it

enters the system.