idronaut Ocean Seven 314 User manual

OCEAN SEVEN 314

Multi-parameter On-line module

Copyright @ 1982 –2019 Idronaut S.r.l. All rights reserved.

OCEAN SEVEN and Idronaut are registered trademarks of Idronaut S.r.l.

Other products and services mentioned in this document are identified by the trademarks or service marks of their respective companies

or organisations. No part of this publication, or any software included with it, may be reproduced, stored in a retrieval system, or

transmitted in any form or by any means, including photocopying, electronic, mechanical, recording or otherwise, without the prior

written permission of the copyright holder. Idronaut S.r.l. provides this document as is without warranty of any kind either expressed or

implied including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose. Idronaut S.r.l. may

make changes of improvements in the equipment, software, firmware, or specifications described in this document at any time and

without notice. These changes may be incorporated in new releases of this document. This document may contain technical inaccuracies

or typographical errors. Idronaut S.r.l. waives responsibility of any labour, materials, or costs incurred by any person or party as a result

of using this document. Idronaut S.r.l. shall not be liable for any damages (including, but not limited to, consequential, indirect or

incidental, special damages, or loss of profits or data) even if they were foreseeable and Idronaut S.r.l. has been informed of their potential

occurrence arising out of or in connection with this document or its use.

IDRONAUT S.r.l.

Via Monte Amiata, 10 –Brugherio (MB) –ITALY

Tel. +39 039 879656 –883832 Fax. +39 039 883382

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

IMPORTANT REMARKS

INTERNAL BATTERY REPLACEMENT/RECHARGING

1) To gain access to the battery pack, remove the screws in the OS314 top cover. However,

before doing this, please ensure to have removed any water droplets around the screw

heads, to prevent them from running down inside the housing.

ON-LINE MODULE Top-Cover removal, please follow the instructions in

Appendix “A”

2) Rechargeable battery: disconnect the battery pack from the top cover and connect it

to the battery charger.

3) If the OS314 is not to be used for long periods (some months), remove the internal

battery pack from the OS314. This eliminates the possibility of damaging the electronic

circuitry in case of battery leaks because a small amount of energy is drawn from the

internal batteries by the OS314 electronic circuitry even if OFF. This phenomenon

causes batteries to run down and they may be damaged (leak) in a very long time

SELF-RECORDING USE

➢The ON-LINE MODULE internal Real-Time Clock (RTC) keeper is powered by the ON-LINE

MODULE main battery. If the battery run-off energy or is disconnected, the RTC loses date

& time. It is mandatory to set up the ON-LINE MODULE date & time or/and check that

the ON-LINE MODULE date & time are correct before starting a self-recording data

acquisition cycle.

➢The ON-LINE MODULE is equipped with a rotary magnetic power ON/OFF switch,

installed on the top cover. The ON-LINE MODULE is ON when the switching arm is

positioned over the red dot marker. Once the ON-LINE MODULE self-recording

configuration is completed, the ON-LINE MODULE can be switched OFF and then ON again

at the sampling site, when ready for the deployment. This procedure is indispensable to run

self-recording data acquisitions, as described in the dedicated section of this manual.

VERY IMPORTANT: Allow a 10-second interval between each ON/OFF cycle.

CONDUCTIVITY MEASUREMENT

➢To obtain the best accuracy, the conductivity sensor and therefore the ON-LINE MODULE

sensor head, must be immersed in clean seawater or freshwater for at least 15 minutes before

measurements.

➢When the conductivity sensor is not in use, it is kept dry. Therefore, when the conductivity

sensor is placed in water, very small bubbles may remain attached to the platinum ring

electrodes (seven). If such a thing happens, the measured value of conductivity will be lower

than the true one. To remove these air bubbles, degrease the inside of the conductivity cell

using cotton buds wetted with the Conductivity Sensor Cleaning Solution or with liquid soap.

Gently rotate the cotton bud against the whole internal surface of the quartz cell. This will

wet the platinum electrodes, thus reducing the surface tension of the cell and considerably

decreasing the risk of trapped air bubbles.

OXYGEN MEASUREMENT

Most polarographic oxygen sensors take 5 to 10 minutes after they have been switched on

to polarize and become stable. To overcome this limitation, the OS314 has been fitted with

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

a small internal rechargeable device, to maintain polarization of the oxygen sensor

continuously for about three days. However, if the OS314 is not used for several days, the

polarization device may become completely discharged. It is recommended that the OS314

should be switched ON (and streaming real-time data) for at least few minutes, to fully

recharge the polarization device in a healthy condition before starting the measurements.

BLUE CAP OPTICAL DISSOLVED OXYGEN SENSOR

A black cap is provided to protect the membrane from light. When the ON-LINE MODULE

is not used protect the membrane by installing the black cap.Please, remove the black cap

before calibration and before deploying the ON-LINE MODULE in water.

pH MEASUREMENT

The pH and reference sensors should never be allowed to dry out. For short-term storage of

up to one day, the OS314’s sensor head can simply be immersed in water. If the OS314

remains unused for periods longer than one day, always place the hydrating caps on both

sensors. The pH sensor cap should be filled with the pH7 Buffer Solution (or simply with

clean water). The reference sensor cap should be filled with the Idronaut Reference Sensor

Storage Solution.

ON-LINE MODULE CTD SENSORs RE-CALIBRATION & CHECKING

A dedicated Windows software described at section E.7.3 allows to correctly capture data

from the ON-LINE MODULE CTD sensor during a re-calibration procedure or ON-LINE

MODULE sensors performance checking cycle. Captured data can be saved in a txt file. The

“OceanSevenCalibration” software is freely distributed with the IDRONAUT ITERM

software.

OS314 WASHING

After use, the OS314 must be always washed with fresh water to remove any salt water

residual or dirtiness.

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

COPYRIGHT STATEMENT

Copyright IDRONAUT S.r.l.

OCEAN SEVEN and IDRONAUT are registered trademarks of IDRONAUT S.r.l. All rights reserved.

This document may not, in whole or in part, be copied, photocopied, reproduced, translated, or reduced to

any electronic medium or machine-readable form without prior consent in writing from IDRONAUT S.r.l.

ABOUT THIS MANUAL

This manual will serve as a guide to you when you use the OCEAN SEVEN 314

❖Use it to understand the purpose of each of the OS314 components and functions.

❖It will help you to understand the OS314 behaviour.

❖It will guide you through the OS314 capabilities.

❖It will serve you as a reference when some problems arise when using the OS314.

HOW TO USE THIS MANUAL

The following topics are covered by this manual:

Section 1 A description of the OCEAN SEVEN 314.

Section 2 Installation and start-up operations.

Section 3 Data acquisition functions and data processing capabilities.

Section 4 Data storage functions.

Section 5 Sensor calibration functions.

Section 6 Service functions (configuration, diagnostics).

Section 7 OS314 maintenance.

Section 8 Troubleshooting

Appendix A Internal and external battery pack description.

Appendix B Data Processing Function Priming.

Appendix C OPTIONAL Sensor

Appendix D Advanced configuration

Appendix E IDRONAUT Windows Terminal Emulation Programme.

Appendix F Wireless “Bluetooth™” –WiFi interface.

Appendix G Submersible connectors and cable care.

GETTING STARTED

To become familiar with the OCEAN SEVEN 314 ON-LINE MODULE capabilities and operation, we

suggest reading through sections 1 and 2. It is necessary to also read sections 3 and 5 and section 7 before

starting to deploy the OS314. The remaining sections and appendices could be consulted only when needed.

If the OS314 is supplied with external sensors, deck unit or the IDRONAUT Portable Reader, useful

information can be found in each dedicated Operator’s Manual.

Operator’s Manuals of all IDRONAUT products and software can be found on the USB-data storage key

included with this product in the “Literature&Manuals\OperatorManual” folder.

NOTATIONAL CONVENTIONS

Throughout this manual, the following conventions are used to distinguish the various elements of the text:

[OS314 COMMANDS] They always appear in uppercase and between [ ] or < > brackets.

OS314 messages, user inputs They always appear in italics.

DEFINITION OF TERMS

Throughout this manual, the following terms are used:

Cast As a whole of the data set collected in the same way in a determined

sampling point.

Data set As a whole of configured parameters expressed in physical or

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

chemical units and acquisition date and time, collected at

programmed sampling interval, (i.e. once per second, once per

depth increment).

Raw data –ADC Counts As a whole set of data acquired by means of the ADC and the

conditioning circuits, from the configured sensors and are

expressed in numeric decimal or hexadecimal format.

Non-verbose mode This term refers to a OS314 that has been configured to use a

communication protocol (computer oriented) to communicate with

the operator.

Verbose mode This term refers to a OS314 that has been configured to use the MMI

functions to communicate with the operator.

ON condition This term refers to a fully operative OS314, waiting for commands

from the operator or running the requested command.

OFF condition This term refers to a OS314 electronically switched off. In this state,

the OS314 draws negligible amount of current from the battery.

MMI This term refers to the set of common rules, which the operator must

follow during the operation of OS314 in verbose mode.

QAM Quadrature Amplitude Modulation.

IDRONAUT DOCUMENTS PERTAINING TO THE OCEAN SEVEN 314

The following documents are available in the “Literature & Manual” folder on the USB-data storage key

distributed with the OCEAN SEVEN 314 ON-LINE MODULE.

❖OCEAN SEVEN OS314s Data Transmission Protocol Description

❖REDAS-5 Condensed Manual

SOFTWARE UPDATES AND TECHNICAL SUPPORT

Please visit our website download area for software updates and technical support:

http://www.idronaut.it/download.

WARRANTY

The OCEAN SEVEN 314 ON-LINE MODULE is covered by a one-year limited warranty that extends to all

parts and labour and covers any malfunction that is due to poor workmanship or due to errors in the

manufacturing process. The warranty does not cover shortcomings that are due to the design, nor does it cover

any form of consequential damage because of errors in the measurements. If there is a problem with your

OCEAN SEVEN 314, first try to identify the problem by following the procedure outlined in the

troubleshooting section of this manual. Please contact your representative or IDRONAUT Sr.l. if the problem

is identified as a hardware problem or if you need additional help in identifying the problem. Please make

sure to contact IDRONAUT S.r.l. to obtain the relevant instructions before the OCEAN SEVEN 314 or any

module is returned to IDRONAUT (see cleaning instructions).

For systems under warranty, IDRONAUT S.r.l. will attempt to ship replacement parts before the

malfunctioning part is returned. We encourage you to contact us immediately if a problem is detected and we

will do our best to minimize the downtime. Every effort has been made to ensure the accuracy of this manual.

However, IDRONAUT S.r.l.makes no warranties with respect to this documentation and disclaims any

implied warranties of merchantability and fitness for a particular purpose. IDRONAUT S.r.l.shall not be liable

for any errors or for incidental or consequential damages in connection with the furnishing, performance or

use of this manual or the examples herein. The information in this document is subject to change without

notice.

CLEANING INSTRUCTIONS

Before the returned OCEAN SEVEN 314 can be serviced, equipment exposed to biological, radioactive, or

toxic materials must be cleaned and disinfected. Biological contamination is presumed for any instrument,

OS314, or other device that has been used with wastewater. Radioactive contamination is presumed for any

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

instrument, OS314 or other device that has been used near any radioactive source. If an OCEAN SEVEN 314,

or other part is returned for service without following the cleaning instructions, and if in our opinion it

represents a potential biological or radioactive hazard, our service personnel reserve the right to withhold

service until appropriate cleaning, decontamination has been completed.

When service is required, either at the user's facility or at IDRONAUT, the following steps must be taken to

insure the safety of our service personnel.

➢In a manner appropriate to each device, decontaminate all exposed surfaces, including any containers.

70% isopropyl alcohol or a solution of 1/4 cup bleach to 1-gallon tap water are suitable for most

disinfecting. Instruments used with wastewater may be disinfected with 5% Lysol if this is more

convenient to the user.

➢The user shall take normal precautions to prevent radioactive contamination and must use

appropriate decontamination procedures should exposure occur. If exposure has occurred, the

customer must certify that decontamination has been accomplished and that no radioactivity is

detectable by survey equipment.

➢Any product being returned to the IDRONAUT S.r.l. laboratory for service or repair should be packed

securely to prevent damage.

➢Cleaning must be completed on any product before returning it to IDRONAUT S.r.l.

DISPOSAL OF WASTE EQUIPMENT BY USERS IN THE EUROPEAN UNION

The recycling bin symbol on the product or on its packaging indicates that this product must not be disposed

of with your other waste. It is your responsibility to dispose of your waste equipment by handling it over to a

designated collection point for the recycling of waste electrical and electronic equipment. The separate

collection and recycling of your waste equipment at the time of disposal will help to conserve natural resources

and ensure that it is recycled in a manner that protects human health and the environment. For more

information about where you can drop off your waste equipment for recycling, please contact your local city

office, your waste disposal service.

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

TABLE OF CONTENTS

1INTRODUCTION .............................................................................................................................. 1

1.1 OS314 DESCRIPTION ....................................................................................................................... 1

1.2 SAMPLING MODES.......................................................................................................................... 1

1.3 REAL-TIME COMMUNICATIONS ................................................................................................ 2

1.4 WIRELESS COMMUNICATION MODULE "BLUETOOTH®”, “WiFi”................................... 2

1.5 INTERNAL BATTERIES ................................................................................................................... 2

1.6 MAGNETIC POWER ON/OFF SWITCH........................................................................................ 2

1.7 MANAGEMENT PROGRAMMES.................................................................................................. 2

1.8 STANDARD SENSOR SPECIFICATIONS ..................................................................................... 3

1.9 OPTIONAL SENSOR SPECIFICATIONS....................................................................................... 3

1.10 ELECTRONIC SPECIFICATIONS................................................................................................... 3

1.11 PHYSICAL CHARACTERISTICS .................................................................................................... 4

1.12 THE STANDARD SENSORS............................................................................................................ 4

1.12.1 LIFETIME AND HOW TO REPLACE THE IDRONAUT SENSORS......................................... 4

1.12.2 The pressure sensor........................................................................................................................... 4

1.12.3 The temperature sensor .................................................................................................................... 5

1.12.4 The conductivity sensor equipped with the "IDRONAUT seven-ring cell".............................. 5

1.12.5 The oxygen sensor ............................................................................................................................. 6

1.12.6 The oxygen sensor maintenance-free version - 5 bar only.......................................................... 7

1.12.7 The Blue-cap optical dissolved oxygen sensor.............................................................................. 7

1.12.8 pH and reference sensors ................................................................................................................. 9

1.12.9 The redox sensor.............................................................................................................................. 11

1.13 CALCULATIONS............................................................................................................................. 12

1.13.1 Polarographic Oxygen sensor ........................................................................................................ 12

1.13.2 pH calculation and pH correction in relation to the sample temperature............................... 12

1.13.3 Conductivity compensated at 20 °C.............................................................................................. 13

1.14 FIRMWARE OVERVIEW................................................................................................................ 14

1.14.1 User interface.................................................................................................................................... 14

1.14.2 Menu & submenu structure ........................................................................................................... 15

1.14.3 Menu header structure.................................................................................................................... 15

1.14.4 OS314 Access Rights........................................................................................................................ 16

1.14.5 Data transmission protocol ............................................................................................................ 16

1.14.6 Data transmission protocol: PTP Point-to-point ......................................................................... 16

1.14.7 Acquired data processing and post-processing .......................................................................... 17

1.14.8 Low power consumption................................................................................................................ 17

1.14.9 Configuration ................................................................................................................................... 17

2INSTALLATION AND START UP............................................................................................... 19

2.1 SHIPPING LIST ................................................................................................................................ 19

2.1.1 RS232C connection cable ................................................................................................................ 19

2.2 INSTALLATION .............................................................................................................................. 19

2.2.1 Internal battery................................................................................................................................. 19

2.2.2 Measuring flow cell ......................................................................................................................... 19

2.3 START-UP ......................................................................................................................................... 20

2.3.1 RS232C interface - OS314 power ON............................................................................................ 20

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

2.3.2 Standard start-up messages ........................................................................................................... 20

2.4 THE MAIN MENU .......................................................................................................................... 21

2.5 LOW POWER CONSUMPTION.................................................................................................... 21

3DATA ACQUISITION .................................................................................................................... 23

3.1 THE DATA ACQUISITION MENU.............................................................................................. 23

3.2 ACQUIRED PARAMETERS........................................................................................................... 23

3.3 COMMON RULES TO SET UP THE DATA ACQUISITION CYCLE...................................... 23

3.4 COMMMON RULES TO STORE ACQUIRED DATA................................................................ 23

3.5 ON-LINE ACKNOWLEDGEMENT.............................................................................................. 24

3.6 UNATTENDED ACKNOWLEDGEMENT .................................................................................. 24

3.7 UPLOADING DATA STORED IN THE On-Line module MEMORY...................................... 24

3.8 UNATTENDED ACQUISITIONS –IMPORTANT TIPS............................................................ 25

3.8.1 Power consumption reduction....................................................................................................... 25

3.8.2 Warm-up........................................................................................................................................... 25

3.8.3 ON/OFF cycles ................................................................................................................................. 25

3.9 SHIPPING CONDITIONS .............................................................................................................. 25

3.10 SENSORS........................................................................................................................................... 25

3.11 REAL TIME DATA ACQUISITION .............................................................................................. 25

3.12 TIMED DATA ACQUISITION....................................................................................................... 26

3.12.1 Terminate a timed data acquisition............................................................................................... 27

3.12.2 Automatic power OFF procedure ................................................................................................. 27

3.12.3 Accidental power ON cycle............................................................................................................ 28

3.12.4 Magnetic power ON/OFF switch................................................................................................... 28

3.12.5 Step-by-step procedure................................................................................................................... 28

3.13 CONDITIONAL DATA ACQUISITION ...................................................................................... 29

3.13.1 Terminate the Conditional data acquisition ................................................................................ 30

3.14 CONTINUOUS DATA ACQUISITION........................................................................................ 31

3.14.1 Step-by-step procedure................................................................................................................... 32

3.14.2 Routine operations to perform unattended continuous profiles .............................................. 32

3.14.3 Terminate the Continuous data acquisition................................................................................. 33

3.15 BURST DATA ACQUISITION ....................................................................................................... 33

3.15.1 Field operations................................................................................................................................ 34

3.15.2 Ending the unattended data acquisitions..................................................................................... 34

4DATA STORAGE............................................................................................................................. 35

4.1 MEMORY ORGANIZATION......................................................................................................... 35

4.1.1 Cast area............................................................................................................................................ 35

4.1.2 Data records...................................................................................................................................... 35

4.1.3 Data Sets............................................................................................................................................ 35

4.2 MEMORY MANAGEMENT........................................................................................................... 36

4.3 SHOW MEMORY STATUS ............................................................................................................ 36

4.4 SHOW STORED DATA................................................................................................................... 36

4.5 MEMORY DELETE DATA ............................................................................................................. 37

4.6 INITIALIZE DATA MEMORY....................................................................................................... 37

5SENSOR CALIBRATION ............................................................................................................... 39

5.1 CALIBRATION STORING LAYOUT............................................................................................ 39

5.1.1 Parameter/Sensor logical codes ..................................................................................................... 39

5.2 CALIBRATION GLP (GOOD LABORATORY PRACTICE)...................................................... 39

5.3 SENSOR CALIBRATION FUNCTIONS....................................................................................... 39

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

5.3.1 Updating the calibration information........................................................................................... 40

5.4 CALIBRATE THE SENSORS.......................................................................................................... 40

5.4.1 Selecting a wrong sensor ................................................................................................................ 40

5.5 CUSTOMIZED CALIBRATION PROCEDURE........................................................................... 40

5.5.1 Pressure sensor................................................................................................................................. 41

5.5.2 Temperature & Conductivity sensor calibration......................................................................... 41

5.5.3 Simple check of conductivity sensor calibration......................................................................... 42

5.5.4 Oxygen sensor calibration .............................................................................................................. 42

5.5.5 pH sensor calibration ...................................................................................................................... 45

5.5.6 Redox sensor calibration................................................................................................................. 46

5.6 CALIBRATING LOGGING ............................................................................................................ 50

6SERVICE, DIAGNOSTICS AND CONFIGURATION ............................................................... 51

6.1 THE SERVICE MENU ..................................................................................................................... 51

6.1.1 Raw data acquisition in ADC counts or mV................................................................................ 51

6.1.2 OS314 diagnostic functions ............................................................................................................ 51

6.1.3 OS314 configuration ........................................................................................................................ 53

7OS314 MAINTENANCE................................................................................................................. 58

7.1 OXYGEN SENSOR........................................................................................................................... 58

7.1.1 Important remark on oxygen measurement ................................................................................ 58

7.1.2 Green membrane ............................................................................................................................. 58

7.1.3 Refilling oxygen sensor cap with electrolyte ............................................................................... 59

7.1.4 Membrane replacement (oxygen membrane cap)....................................................................... 59

7.1.5 Replacement of membrane(s) using the OXYGEN SENSOR MAINTENANCE KIT: ........... 59

7.1.6 Oxygen sensor cleaning .................................................................................................................. 60

7.1.7 Oxygen sensor check in the absence of oxygen........................................................................... 61

7.1.8 BLUE CAP MEMBRANE STORAGE............................................................................................ 61

7.1.9 BLUE CAP DEPLOYMENT ........................................................................................................... 61

7.1.10 BLUE CAP CLEANING.................................................................................................................. 61

7.2 REFERENCE SENSOR..................................................................................................................... 61

7.3 pH SENSOR ...................................................................................................................................... 62

7.3.1 To etch the sensor, perform the following: .................................................................................. 62

7.3.2 Important remark on the pH measurement................................................................................. 62

7.4 CONDUCTIVITY SENSOR............................................................................................................. 63

7.4.1 Important remarks on conductivity measurement..................................................................... 63

7.4.2 Conductivity sensor cleaning......................................................................................................... 63

7.5 REDOX SENSOR.............................................................................................................................. 63

7.6 TEMPERATURE SENSOR .............................................................................................................. 63

7.7 PRESSURE SENSOR ........................................................................................................................ 63

7.8 INTERNAL BATTERY .................................................................................................................... 64

7.8.1 Internal battery pack endurance.................................................................................................... 64

7.8.2 Oxygen sensor polarization device ............................................................................................... 64

7.9 ROUTINE MAINTENANCE SCHEDULE ................................................................................... 64

8TROUBLESHOOTING.................................................................................................................... 65

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

APPENDIX

Appendix A Internal & external battery pack description 66

Appendix B Data Processing Function Priming 67

Appendix C Optional sensors 69

Appendix D Advanced configuration 71

Appendix E IDRONAUT Windows Terminal Emulation Programme 73

Appendix F Wireless “Bluetooth™” Interface 74

Appendix G Submersible connectors and cable care 75

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

1

1INTRODUCTION

This section describes the main components of the OCEAN SEVEN 314 multi-parameter on-line module.

1.1 OS314 DESCRIPTION

The OS314 On-line module is housed in a sealed POM cylinder provided with a transparent acrylic flow

cell which is easily removed for sensor cleaning and maintenance. The sample volume of the measuring

chamber is only 450 ml, which ensures a very fast response time. The measurement sensors installed in

the On-line module are manufactured by IDRONAUT. The On-line module is controlled by an

advanced miniaturized and very low power electronics that store measurements in non-volatile

memory or transmit them in real-time at sampling rate of up to 28 Hz. The On-line module can be

directly connected to a data logger or personal computer by means of a wired or wireless interface.

Optional interfaces allow the connection of external fluorometer, turbidity meter and a remote

thermometer.

The OCEAN SEVEN 314 is equipped with the well-known and proven IDRONAUT pressure balanced

full ocean depth, pump free and long-term stability sensors. Central to which, is the high accuracy

seven-platinum-ring conductivity sensor, which can be cleaned in the field without the need for re-

calibration. Furthermore, an optional UV-LED (280nm) integrated into the conductivity cell, sterilize

the sample under measurement, thus avoiding the early growth of biofouling inside the quartz

measuring cell. For added flexibility, the OCEAN SEVEN 314 on-line module multi parameter OS314

can be operated in either verbose or non-verbose modes, the latter being especially convenient for

system integrations on buoys data loggers. Data is output using the standard RS232C interface, in

alternative the wireless (Bluetooth, WiFi) interface can be optionally installed. Submersible bulkhead

connectors, installed on the top cover, provide optional external power supplies and data exchange with

a suitable system. The response time constant is 50ms for the CTD sensors and 3/5s for oxygen, pH and

redox (see sensors specification table). Software compensation is provided for changes in the internal

temperature of the on-line, to guarantee both high performance and long-term stability. The electronic

boards are fitted in a sealed housing made of either PPS white plastic.

The OCEAN SEVEN 314 on-line module in its basic configuration is equipped with three sensors:

pressure, temperature and conductivity. Other bulkhead sensors can be optionally added, like:

dissolved polarographic oxygen, optical dissolved oxygen, pH, redox, reference electrode. It is possible

to interface external sensors or equipment like: a second remote temperature sensor, Turbidity meter,

Fluorometers.

The following equipment is currently interfaced:

❖IDRONAUT –Blue Cap Dissolved Oxygen sensor.

❖IDRONAUT –Remote temperature sensor.

❖CHELSEA - Unilux and Trilux Fluorometers.

❖SEAPOINT - Fluorometers.

❖TURNER DESIGNS –Cyclops-7 Fluorometers.

Other equipment or sensors can be interfaced upon request.

1.2 SAMPLING MODES

The OS314 is microprocessor-controlled and can be programmed to acquire and process data by various

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

2

methods. Processed or raw data can be either transmitted in real time or stored inside the instrument.

Data acquisition methods includes:

➢Timed.The OS314 collects a series of samples and then sleeps for the configured time interval

before waking up again and repeating the acquisitions. Time interval can be configured from 5s

up to 1 day. Battery power is conserved while the OS314 is in sleep mode.

➢Conditional. Data is sampled at configurable sampling rates starting when the selected parameter

overcomes the configured boundary. Sampling continues until the selected parameter falls below

the configured boundary. Whenever the acquisition cycle starts, a configurable sampling rate

0.1..28Hz is used. Monitoring of the selected parameter occurs at the configurable interval

between 5s up to 1 day.

➢Continuous. Data is sampled at configurable sampling rates starting when the operator switches

on the OS314. Sampling continues until the OS314 is switched off. Multiple cycles can be obtained

by switching the ON-LINE MODULE ON and OFF.

➢Burst. Burst sampling carried out at configured intervals: 5s up 1 day.

➢Real-time.Data is sent to the control system at the chose sampling rates.

1.3 REAL-TIME COMMUNICATIONS

The OCEAN SEVEN 314 multi-parameter on-line module communicates with a computer via a

standard RS232C interface. Real-time data can be acquired by means of the REDAS-5 Windows software.

The RS232C cable maximum length is 200 m. It is important to mention that the OCEAN SEVEN 314 is

insulated with respect to the communicating device, independently of the kind of interface that is used.

Insulation guarantees that the sensors are not affected or disturbed by ground loops or stray currents.

1.4 WIRELESS COMMUNICATION MODULE "BLUETOOTH®”, “WiFi”

The OCEAN SEVEN 314 can be optionally equipped with a wireless adapter which allows bidirectional

full-duplex communications between the OCEAN SEVEN 314 and a personal computer (Desktop,

Laptop) or PDA devices equipped with a compatible wireless device. A thorough description of the

wireless adapter can be found in the dedicated appendix.

1.5 INTERNAL BATTERIES

The OCEAN SEVEN 314 housing has in its upper part enough space to accommodate an internal battery

pack. This is used whenever the OS314 carry-out unattended acquisition cycles without the connection

in real time with a surface unit (PC). Different types of battery can be installed inside the housing:

➢1x Size “A” Li-SOCI2 Lithium-thionyl chloride non rechargeable battery 3.6V, 2.4Ah

➢3x Size “AA” 1.5V Alkaline non rechargeable battery assembled in a single pack 4.5V

➢1x Size “C” Li-SOCI2 Lithium-thionyl chloride non rechargeable battery 3.6V, 8.4Ah

➢1x Li-Ion rechargeable IDRONAUT custom battery pack 3.7V,4.5 Ah

Whenever the OS314 operates in Timed, Burst and Conditional modes, the battery endurance is

considerably extended because the on-line module enters a deep sleep mode between acquisitions.

When the OS314 is not used for long periods (e.g. 2 weeks or more), we suggest disconnecting the

internal battery pack connector from the OS314 electronics or removing the internal battery pack from

the OS314 to prevent the internal batteries from damaging the OS314 due to battery acid leakage.

1.6 MAGNETIC POWER ON/OFF SWITCH

The OCEAN SEVEN 314 is equipped with a magnetic power ON/OFF switch,

which allows the operator to effectively switch ON and OFF the on-line

module. The on-line module switch on and off by itself whenever it performs

self-recording acquisition cycles and uses the internal battery pack.

When switching ON/OFF the OS314 by means of the magnetic switch, please

wait at least 10 seconds between consecutive ON/OFF cycles.

1.7 MANAGEMENT PROGRAMMES

IDRONAUT programmes designed for the Windows 32/64bit operating systems allow the operator to

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

3

communicate with the OCEAN SEVEN 314 to perform attended or unattended data acquisitions.

Programmes include functions to upload data from the internal non-volatile data memory when the

OS314 acts as a logger. The available programmes are:

ITERM –WTERM:

IDRONAUT Terminal Emulation program and on-line module management to easily

communicate with the OCEAN SEVEN 314 multi-parameter OS314. Diagnostic and

dedicated functions are present.

REDAS-5: Real-time data acquisition, processing and presentation program, which allows the

numerical display and plotting of the standard sensors and the derived variables such as

salinity, sound speed, density, according to the UNESCO formulas and recommendations.

1.8 STANDARD SENSOR SPECIFICATIONS

The OS314 multiparameter on-line module can be equipped with the following sensors to measure:

1.9 OPTIONAL SENSOR SPECIFICATIONS

Among others, the OCEAN SEVEN 314 can be optionally equipped with the following sensors:

1.10 ELECTRONIC SPECIFICATIONS

Real-time and logging: up to 28 Hz

Interfaces RS232C, Wireless: WiFi/Bluetooth

Real-time clock accuracy: 3 ppm/year

Power supply: Battery: 2.9..5.0 VDC; running: 90 mA @ 3.6VDC; standby 8 µA @3.6VDC

External power: 9..32 VDC; running: 67 mA @ 12VDC; standby 8 mA @12VDC

Parameter Range Accuracy Resolution Time Constant

Pressure 0..10 dbar 0.05 % FS 0.0015 % FS 50 ms

Temperature -5..+50 °C 0.0015 °C 0.0001 °C 50 ms

Conductivity salt water 0..90 mS/cm 0.0015 mS/cm 0.0001 mS/cm 50 ms (1)

fresh water 0..7000 µS/cm 5 µS/cm 0.1 µS/cm 50 ms (1)

Oxygen (polarographic) 0..50 ppm 0.1 ppm 0.01 ppm 3 s 2)

0..500 %sat. 1 %sat. 0.1 %sat. 3 s 2)

Oxygen (optical) 0..45 mg/l 0.1 mg/l 0.025 mg/l 5 s

0..250 %sat. ±0.2 %sat. 0.05 %sat. 5 s

pH 2..12 pH 0.01 pH 0.1 mpH 3 s 3)

Redox -1000..+1000 mV 1 mV 0.1 mV 3 s

(1) At 2 litre/min flow rate. (2) From nitrogen to air. (3) Differential pH preamplifier, 10131014 ohm input impedance.

The fundamental properties of seawater like: Salinity, Sound Speed, Water Density, Oxygen ppm are obtained using the algorithms described

in the UNESCO “Technical papers in marine science no. 44”. The fresh water properties like: TDS (Total Dissolved Solids), Fresh Water

Conductivity corrected at 20°C and 25°C are automatically calculated.

Parameter Range Accuracy Resolution Time Constant

Remote temperature sensor -3..+50 °C 0.01 °C 0.001 °C 3s

Turbidity meter 0..>2500 FTU 0.1 FTU 0.025 FTU 3s (1)

Fluorometer 0..150 µg/l 0.02 µg/l 0.01 µg/l 3s (1)

UNILUX (single-channel) 0..100 µg/l (2)

TRILUX (three-channel) 0..100µg/l (2)

CYCLOPS fluorometers 0..100 µg/l (2)

(1) Provided with auto-range ,25,125,500, >2500 FTU; 5,15,50,150 µg/l.

(2) Chlorophyll a, Phycocyanin, Phycoerythrin for algae monitoring; Rhodamine WT or Fluorescein for dye tracing applications;

Nephelometer for turbidity monitoring.

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

4

1.11 PHYSICAL CHARACTERISTICS

Fluidics Flow cell volume: 450 ml

Fluidic ports: male connector ¼” OD x 1/8” MT PVDF for hard tubes

Type of tubes: Tygon B-44-3 BEV grade tubing

Size of tubes: ¼” OD and 1/8” ID

Flow rate: ~ 2 litre/minute

Working pressure: 0.02 up to 1 bar

Dimensions: sealed container: POM cylinder Ø 75mm x 400mm (including bulkhead connectors)

Measuring chamber: Acrylic transparent Ø 100mm x 170mm

Weight: 3.5 Kg

Bulkhead connectors: wet-pluggable MCBH-6-MP

1.12 THE STANDARD SENSORS

This section provides a detailed presentation of the OCEAN SEVEN sensors.

LIFETIME AND HOW TO REPLACE THE IDRONAUT SENSORS

The IDRONAUT sensors are all pressure compensated and, in particular, the physical sensors (pressure,

temperature and conductivity) can last many years, if properly used. They are high-quality sensors, as

they are well known by oceanographers to measure salinity with great accuracy. If thoroughly

maintained by their respective hydrating caps and solutions, the IDRONAUT pH and reference sensors

can last several years. The sensor replacement requires that the closure screws on the top head of the

OS314 be unscrewed with a common screwdriver and the cylindrical housing be removed (this takes

very few minutes). The wire sensors are tin soldered on their respective connection points placed on the

printed circuit board. All sensor heads have a standard 12 mm diameter and are provided with two O-

rings (Parker 12-2) for sealing. This means that every sensor can be fitted in any of the five sensor head

holes. The pressure sensor is a high-quality transducer, which lasts many years if properly used. Its

replacement is not very easy and, moreover, it requires a Dead Weight Tester System to obtain the

factory calibration accuracy of 0.05% full scale.

The pressure sensor

The pressure sensor is a high quality strain gauge, centrally mounted on the OS314 base, capable of

generating a linear signal output, thus giving a resolution of 0.03% over the whole measuring range of

0 - 10 dbar

Type: strain gauge

Measurement range: 0...10 dbar

Accuracy: 0.05%FS

Resolution 0.002%FS

Response time: 50 ms @1 m/s

Measurement bridge resistance: @ 25°C Ω 3500 ± 20%

Excitation current: 0.6 mA

Insulation: @ 50 VCC MΩ 100

Operating temperature: °C -30…100

Sensor body: AISI 316L

Compensation: automatic compensation for temperature variations; not

compensated for the barometric pressure variations.

Life: unlimited.

Calibration frequency: monthly.

Maintenance: offset calibration in air.

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

5

The temperature sensor

The temperature sensor consists of a platinum resistance thermometer (type Pt 100 ohms at 0°C), fitted

on a thin stainless-steel housing, able to withstand up to 700 bar. The sensor has a very low response

time (50 ms) and a high stability of reading with ageing. The drift of reading (sensor plus associated

electronics) is less than 0.0003 °C per year.

Type: Pt100@0°C

Measurement range: -3..+50 °C

Accuracy: 0.003 °C

Resolution: 0.0002 °C

Response time: 50 ms @1 m/s

Maximum pressure: 700 bar

Sensor body: AISI 316L

Life: unlimited

Calibration frequency: yearly

Compensation: none.

Maintenance: none.

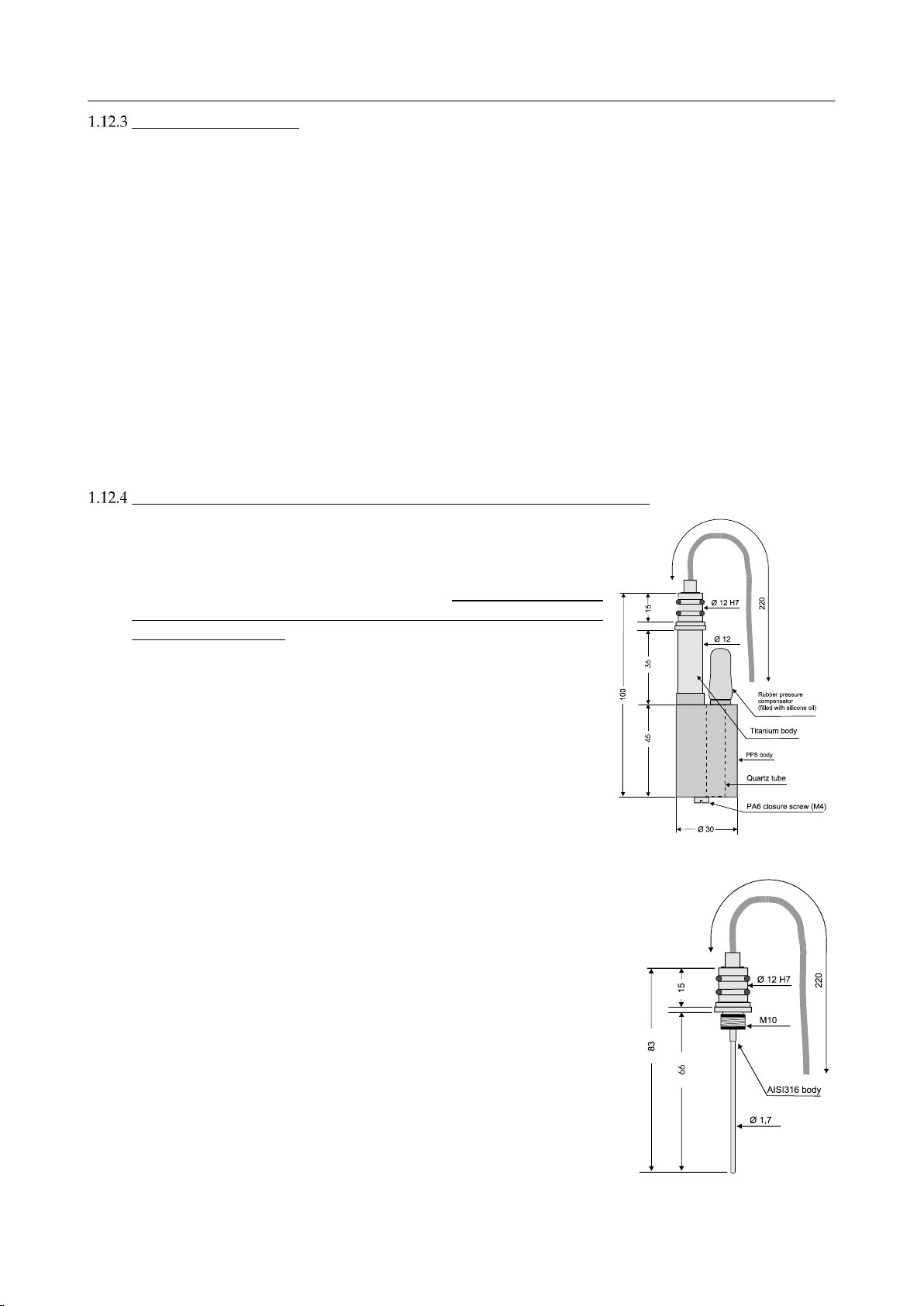

The conductivity sensor equipped with the "IDRONAUT seven-ring cell"

The conductivity sensor is a unique flow-through self-flushed cell

with seven platinum ring electrodes. The central ring is excited with

alternate current flowing to both the outermost rings. The two

adjacent pairs of rings sense the relative drop in voltage due to the

electrical conductivity of the measured water. The outermost pair of

rings is grounded to shield the measuring cell from any outside

electrical interference. The cell is mounted in a special cylindrical

plastic body, which guarantees thermic insulation and is filled with

silicone oil and provided with a rubber bellow to achieve pressure

compensation. The IDRONAUT conductivity sensor and its

associated electronics are designed to work both with plain and black

platinised platinum electrodes These electrodes have the advantage

that, they can be used in both clean and dirty water without the fear

of contamination. Should electrode contamination occur, they can be

easily cleaned (even with up to 30% hydrochloric acid) without

affecting the OS314 performance or requiring re-calibration.

Measurement cell: 7 platinum rings deposited inside a quartz tube. Internal diameter

8mm, length 45mm.

Measurement range: 0..70 mS/cm

Accuracy: 0.003 mS/cm

Resolution: 0.0003 mS/cm

Response time: 50 ms @1 m/s

Max pressure: 700 bar

Sensor body: black plastic and titanium

Compensation: automatic compensation of the

pressure and thermal effect on the

cell geometry are performed by the

acquisition software.

Life: unlimited.

Calibration frequency: yearly.

Maintenance: cleaning using the IDRONAUT

“Conductivity sensor cleaning

solution”.

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

6

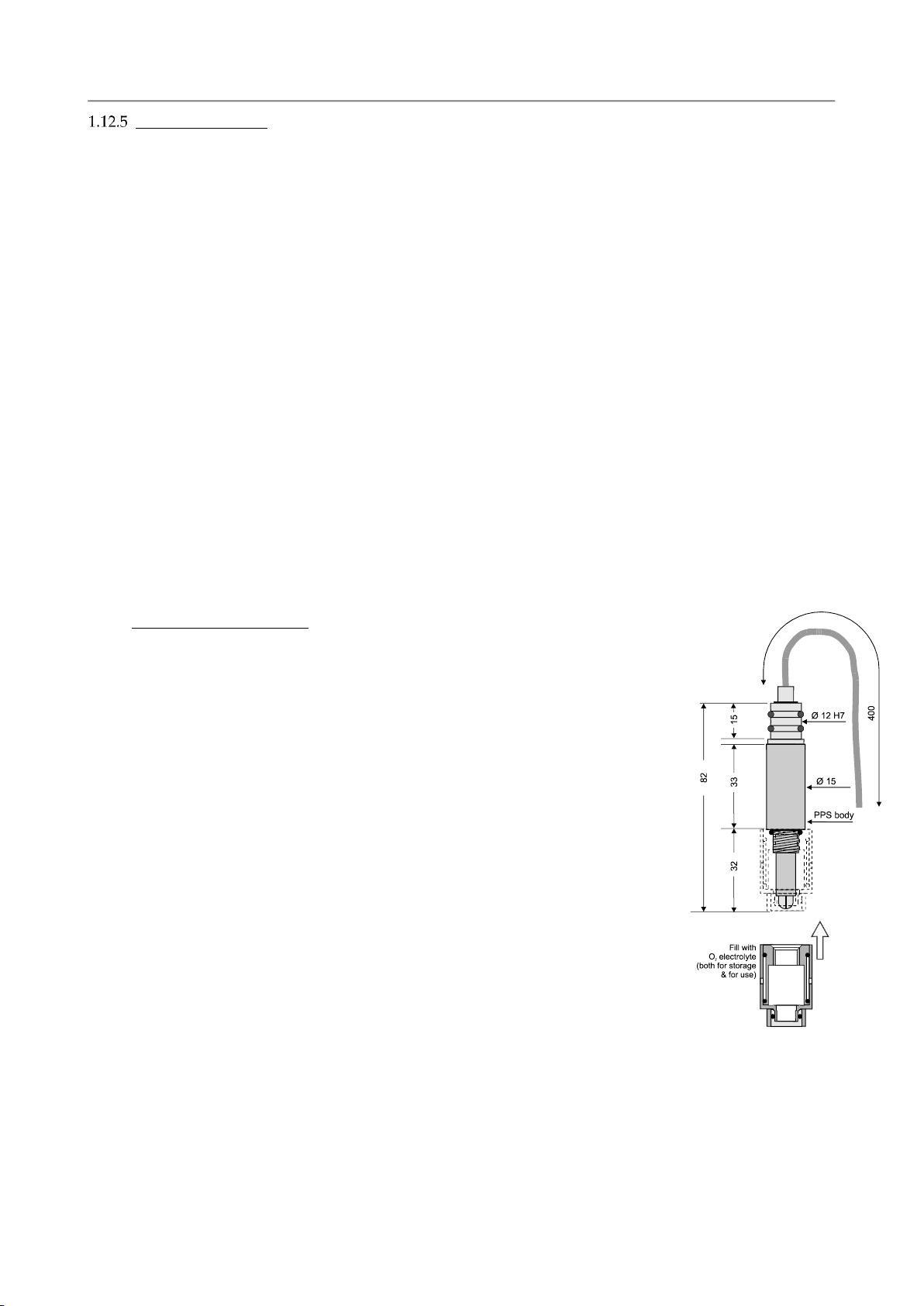

The oxygen sensor

The oxygen sensor is of the polarographic type and consists of two half-cells, the anode and the cathode.

The anode is a silver tube inside the sensor, which encircles a glass body where a platinum wire, forming

the cathode, is sealed. The platinum wire (cathode) ends at the tip of the sensor where the glass body is

rounded. A special membrane cap with a gas-permeable replaceable membrane screws onto the sensor.

The inside of the cap is filled with a special electrolyte which allows the current (measuring) to flow

between the anode and the cathode. The membrane is shielded from accidental bumps by a protective

ring. The anode acts as a reference cell, providing a constant potential with respect to the cathode. The

cathode, where oxygen is consumed or reduced, is separated from the sample to be analysed by a thin

layer of electrolyte and a special composite membrane. The electrolyte permits the chemical reaction to

occur whereas the membrane constitutes a barrier against ions and other substances. By applying a

polarizing voltage to the half-cells, the sensor develops a current proportional to the concentration of

oxygen in the sample in front of the cathode. Oxygen from the sample is drawn across the membrane,

at the sensor tip, in the area of the cathode. The applied polarization voltage is such that the sensor only

responds to oxygen. The sensor is insensitive to nitrogen, nitrous oxide, carbon dioxide and other gases.

To avoid stray ground current leaks, in case of membrane leaks, the anode is kept at ground potential

while the cathode is polarized at a fixed negative voltage. The oxygen sensor limits stirring effects on

the measurement and reads at least 97% of the true value, even with a stagnant aqueous sample. This is

because the very small cathode area and special cathode geometry, associated with a unique composite

membrane, minimize the consumption of the oxygen contained in the sample in contact with the

membrane. The function of this sensor depends on the reduction of oxygen at the cathode, as expressed

by the formula: O2+ 2 H2O + 4e->>> 4 OH-

The developed electrons represent the measuring current and are supplied by the silver/silver chloride anode.

Standard version, 150 bar

Type: polarographic with Pt/Ir cathode and

Ag(99.99%) anode.

Measurement range: 0... 50 ppm 0… 500% sat.

Accuracy: 0.1 ppm 1 % sat.

Resolution: 0.01 ppm 0.1% sat.

Polarization voltage: 650 mV DC.

Response time: 3s (green membrane @20°C)

0.9 s (blue membrane @20°C)

Max Pressure: 150 bar.

Sensor body: plastic and titanium.

Compensation: automatic compensation of pressure and

thermal variations.

Life: 2 years if intensively used to perform

continuous monitoring, up to 4 years if

used weekly to perform daily profiling or

monitoring.

Calibration frequency: weekly.

Maintenance: measuring membrane replacement,

electrolyte replacement

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

7

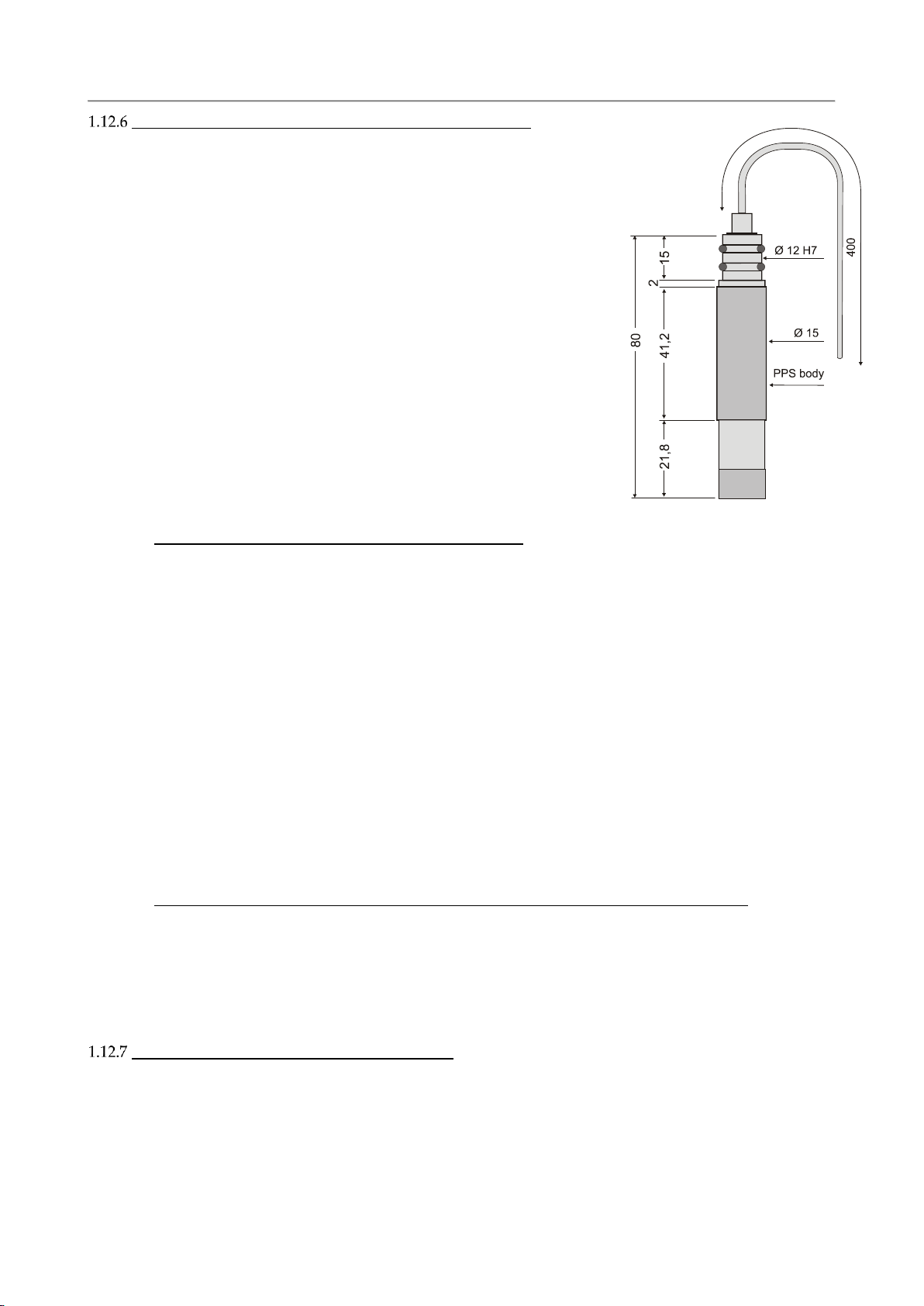

The oxygen sensor maintenance-free version - 5 bar only

Type: polarographic with Pt/Ir cathode

and Ag(99.99%) anode

Measurement range: 0... 50 ppm 0… 500% sat.

Accuracy: 0.1 ppm 1 % sat.

Resolution: 0.01 ppm 0.1% sat.

Polarization voltage: 650 mV DC

Response time: 30 s (membrane @ 20°C)

Max Pressure: 5 bar

Sensor body: black plastic (PPS)

Compensation: automatic compensation of

pressure and thermal variations.

Life: 2 years if intensively used to

perform continuous monitoring,

up to 4 years if used weekly to

perform daily profiling or

monitoring.

Calibration frequency: weekly.

Maintenance: maintenance free.

1.12.6.1 Polarographic Oxygen sensor measurement priming

The OCEAN SEVEN 314 allows the operator to obtain the oxygen data either expressed in ppm or %

Saturation. The formula which connects these two functions is given as by:

ppm = Saturation x Solubility / 100

The relevant formulae for the computation of saturation and solubility can be found in the below

“Calculation” section. The oxygen sensor for practical purposes is normally calibrated in air. The

reading obtained during the calibration is defined as the 100% saturation value for that particular air

temperature. This reading will vary with both temperature (3% per °C) and to a lesser extent with

barometric pressure (about 1% every 10 mBar or 7.6 mmHg). For the above reason during calibration,

the temperature is also automatically recorded and used by the OCEAN SEVEN 314 to immediately

compensate the calibration sensor slope for the temperature effect. This operation is performed during

real-time acquisition as well. Although the effect of barometric change is much smaller, the OCEAN

SEVEN 314 allows the operator to manually enter a correction coefficient during the calibration

procedure.

1.12.6.2 Oxygen depletion / Stirring effect and/or Barometric pressure correction coefficients

The oxygen sensor, like all the oxygen polarographic Clark sensors, sometimes needs that one or more

correction coefficients be applied to the final readings to account for extraneous factors. The OCEAN

SEVEN 314 has been designed such that, the application of such correction factors by the operator is a

relatively straightforward procedure. The oxygen sensor calibration and the correction coefficient

calculation are both described in the “Sensors Calibration” section of this manual.

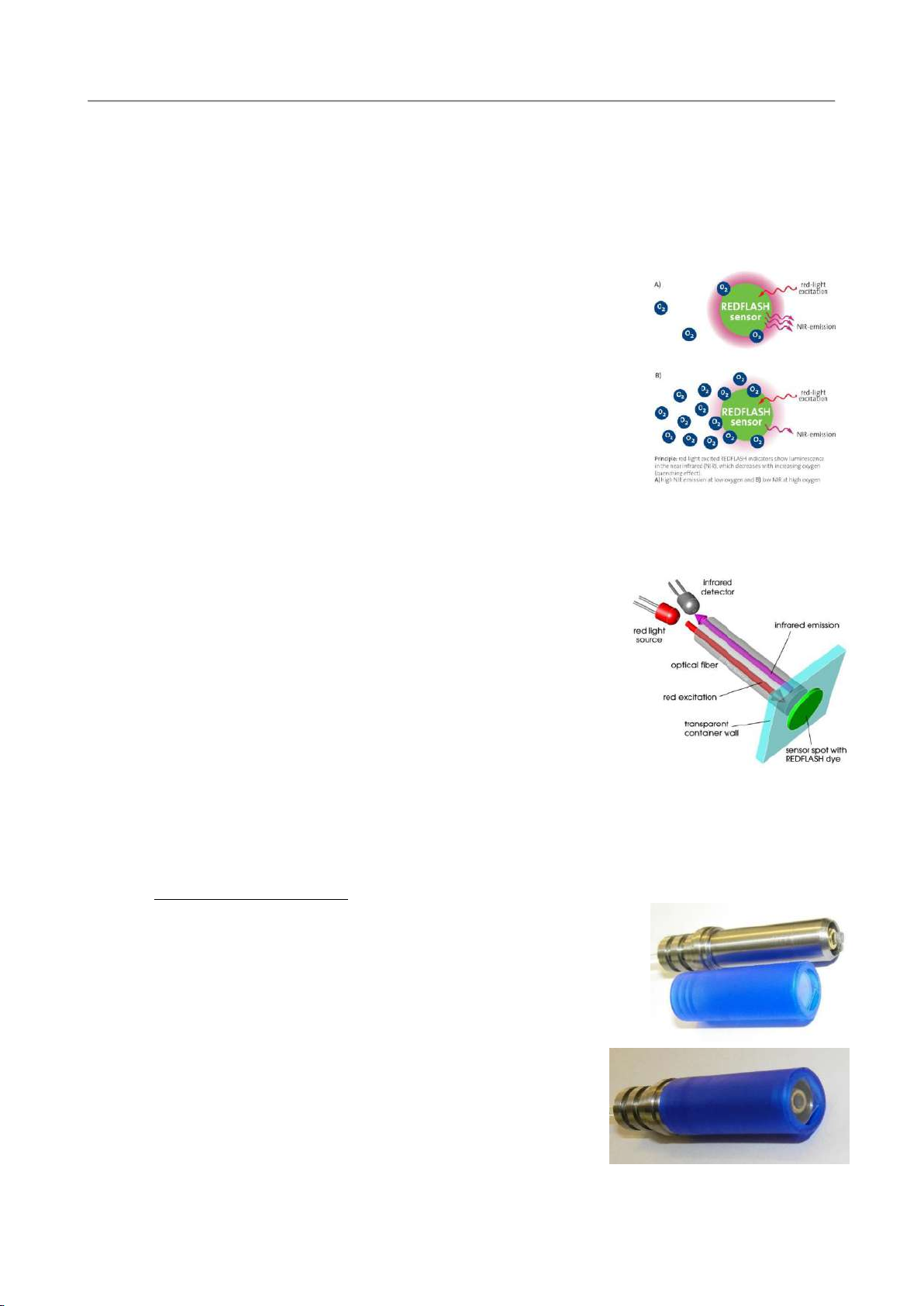

The Blue-cap optical dissolved oxygen sensor

Oxygen optical sensors work according to the principle of dynamic fluorescence quenching. The sensor

contains fluorescent dye that is excited by light of a certain wavelength. Depending on the amount of

oxygen molecules present, the luminescence response of the optical sensor varies. A polymer fiber

transmits the excitation light of the sensor and at the same time also transmits the fluorescence response

of the sensor to the measurement device. The oxygen sensitive dye is immobilized in a polymer matrix.

This polymer can be applied to carrier material and used as sensor spots or sensor foil. It can also be

coated directly onto the optical fiber. Oxygen quenching luminophores have been studied from at least

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

8

1939 when Kautsky described quenching of luminescence by oxygen. More recently, as optical sources,

detectors, and data processing have become more advanced, the application of luminophores to the

measurement of oxygen concentrations in liquids has resulted in bench-top instruments and optodes.,

with significant advances since 1990,s. Recent advances in blue light –emitting diodes and low-powers

high-speed electronics have enabled the miniaturization of oxygen sensitive optodes to the point of

field-deployable units. The sensors do not consume oxygen and are stable over long deployment period.

The new REDFLASH technology is based on the unique oxygen-sensitive REDFLASH dyes. In contrast

to common techniques using blue-light excitation, the REDFLASH dyes

are excitable with orange-red light and show and oxygen-dependent

luminescence in the near infrared (NIR). The REDFLASH technology

impresses by its high precision, high reliability, low power consumption,

low cross-sensitivity, and fast response time. The orange-red light

excitation significantly reduces interferences caused by auto-

fluorescence samples. Further, the NIR detection technology

significantly reduces interference with ambient light, known from the

old-blue-light techniques. The new REDFLASH technology is based on

the unique oxygen-sensitive REDFLASH indicator showing excellent

brightness. The measuring principle is based on the quenching of the

REDFLASH indicator luminescence caused by collision between oxygen

molecules and the REDFLASH indicator immobilized on the sensor tip or surface. The REDFLASH

indicators are excitable with the red light (More precisely orange-red at a wavelength of 610-630nm)

and show an oxygen-dependent luminescence in the near infrared (NIR 760-790 nm).

Principle: Red light exited the REDFLASH indicators show

luminescence in the near infrared, which decreases with the increasing

of oxygen (quenching effect). A) High NIR emission at low oxygen and

B) low NIR at high oxygen. The measuring principle is based on a

sinusoidal modulated red excitation light. This results in a phase-

shifted sinusoidal modulated emission in the NIR. The measurement

device measures this phase shift (termed dphi in the software) The

phase shift is then converted into oxygen units based on the Stem-

Vollmer-Theory. The red-light excitation significantly reduces

interferences caused by auto-fluorescence and reduces stress in the

biological systems. The REDFLASH indicators show much higher luminescence brightness than other

optical sensor working with blue light excitation. Further due to the excellent luminescence brightness

of the REDFLASH indicator, the actual sensor matrix can be now prepared much thinner, leading to

fast response times of the oxygen sensors.

1.12.7.1 BLUE CAP DESCRIPTION

The external par of the Blue Cap Oxygen Optical Sensor is a titanium

support with a 11,7mm diameter, where at its centre is placed a 3mm fiber

optics well sealed to guarantee 700 bar operations. The length of the

support is about 44mm (without the Blue replaceable membrane cap

installed); two 2-12 Parker O-rings seal the support onto the OS314

housing. The measuring membrane cap is simply fitted inside the titanium

support till it stops and is provided with a friction system (groovers)

to prevent unwanted removal or accidental loss. The membrane cap

is made of blue plastic to better shield the external light and is very

similar to the Idronaut pH watering cap. The only difference is that

a hole at its bottom allows the factory installation of the glass

window on its inside. The black sensor spot which allow the oxygen

measurement is centrally placed on the outside of the glass window.

The other side of the optical fiber remains indie the ON-LINE MODULE housing and is fitted in a

unique miniaturized transducer whose optics and electronics transform the optical signal into RS485

SECTION ONE –SYSTEM DESCRIPTION

IDRONAUT –Brugherio (MB) OCEAN SEVEN 314 On-line module 04-2019

9

output.

1.12.7.2 SPECIFICATIONS

Measuring range: 0-250% O2 (0-45 mg/l)

Detection limit: 0.02% O2 (0.01 mg/l)

Resolution: 0.01% O2 (0.005 mg/l) at 1% O2

0.05% O2 (0.025 mg/l) at 100% O2

Accuracy: +-0.02% O2 (0.01 mg/l) at 1% O2

+-0.2% O2 (0.1 mg/l) at 100% O2

Temperature range: 0 to 50°C

Response time (t90) gas/water: sensor spot down to 5 s

No cross-sensitivity: pH 1-14, CH4; CO2, H2S, any ionic species

Cleaning procedures: 3 % H2O2, ethanol, soap solution

Storage time: >3 years in darkness at room temperature. A black cap is provided to

dark the blue cap membrane installed on the ON-LINE MODULE.

Please remove it before deploying the ON-LINE MODULE in water

and before carrying out the calibration.

Calibration: single point

Optical Isolation: the sensor spots are covered with a final black layer in order to

minimize influence of strong external illumination

pH and reference sensors

The measurement of pH in seawater demands high accuracy since seawater has a high ionic strength

and is weakly buffered. The pH range in the oceans is particularly restricted and, only in very special

cases, the observed values are outside the range of 7.8 and 8.4 pH and, in some seas, the range extends

from 6.5 to 9.0 pH. Some problems have always arisen from the use of traditional reference sensors with

porous diaphragms, when measuring the pH in seawater, in particular at pressures in excess of a few

bars, due to the high and variable junction potentials that are generated. The IDRONAUT reference

sensor is in contact with the unknown solution by means of a small hole in the glass tip. This minimizes

and stabilizes the junction potential between the inner gel electrolyte and the liquid to be measured. The

reference sensor is a Silver/Silver Chloride cell in a saturated potassium chloride solid gel and the sensor

head is made of titanium. It is also available a reference sensor specifically developed for long-term

monitoring of seawater where the internal cell is 0.7 mol NaCl. The glass body of the sensor is fitted

with a plastic hydrating cap filled with the IDRONAUT REFERENCE SENSOR STORAGE SOLUTION

based on 3-mol KCl (or NaCl) or, if not available, even with KCl saturated solution to avoid drying of

the gel when not in use. This cap must be removed before measurements. The pH sensor has a titanium

head, a glass body and a pH sensitive glass tip, which can withstand pressures up to 150 bar or even

700 bar (special version). During all periods of inactivity, the glass tip must be fitted with a white plastic

hydrating cap filled with the pH 7 Buffer Solution, or simply with clean water. This is to prevent the

pH-sensitive glass from dehydration, which slows down the sensor response. This cap must be

removed before measurements.

Table of contents

Other idronaut Control Unit manuals

Popular Control Unit manuals by other brands

FUEL MASTER

FUEL MASTER AIM 2 installation manual

M-system

M-system EtherCAT R30GECT1 instruction manual

Ubisys

Ubisys C4 quick start guide

Blue Giant

Blue Giant BLUE GENIUS SERIES Installation & owner's manual

Tews Technologies

Tews Technologies TCP872 user manual

SEW-Eurodrive

SEW-Eurodrive MOVIAXIS MXR manual