System Sensor®is a registered trademark of Honeywell International, Inc.

System Sensor warrants its enclosed product to be free from defects in materials and

workmanship under normal use and service for a period of three years from date of

manufacture. System Sensor makes no other express warranty for the enclosed product.

No agent, representative, dealer, or employee of the Company has the authority to in-

crease or alter the obligations or limitations of this Warranty. The Company’s obligation

of this Warranty shall be limited to the replacement of any part of the product which is

found to be defective in materials or workmanship under normal use and service during

the three year period commencing with the date of manufacture. After phoning System

Sensor’s toll free number 800-SENSOR2 (736-7672) for a Return Authorization number,

send defective units postage prepaid to: Honeywell, 12220 Rojas Drive, Suite 700, El Paso

THREE-YEAR LIMITED WARRANTY

TX 79936 USA. Please include a note describing the malfunction and suspected cause of

failure. The Company shall not be obligated to replace units which are found to be defec-

tive because of damage, unreasonable use, modifications, or alterations occurring after

the date of manufacture. In no case shall the Company be liable for any consequential

or incidental damages for breach of this or any other Warranty, expressed or implied

whatsoever, even if the loss or damage is caused by the Company’s negligence or fault.

Some states do not allow the exclusion or limitation of incidental or consequential dam-

ages, so the above limitation or exclusion may not apply to you. This Warranty gives you

specific legal rights, and you may also have other rights which vary from state to state.

FCC STATEMENT

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause harmful interference,

and (2) this device must accept any interference received, including interference that may cause undesired operation.

NOTE: This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio

frequency energy and, if not installed and used in accordance with the instructions, may cause harmful interference to radio communications. However, there

is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television reception,

which can be determined by turning the equipment off and on, the user is encouraged to try to correct the interference by one or more of the following

measures:

– Reorient or relocate the receiving antenna.

– Increase the separation between the equipment and receiver.

– Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

– Consult the dealer or an experienced radio/TV technician for help.

DEVICE AND SYSTEM SECURITY

Before installing this product ensure that the

tamper seal on the packaging is present and

unbroken and the product has not been tampered

with since leaving the factory. Do not install this

product if there are any indications of tampering.

If there are any signs of tampering the product

should be returned to the point of purchase.

It is the responsibility of the system owner to

ensure that all system components, i.e. devices,

panels, wiring etc., are adequately protected to

avoid tampering of the system that could result

in information disclosure, spoofing, and integrity

violation.

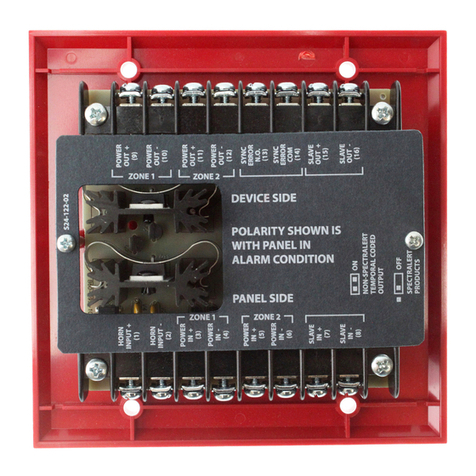

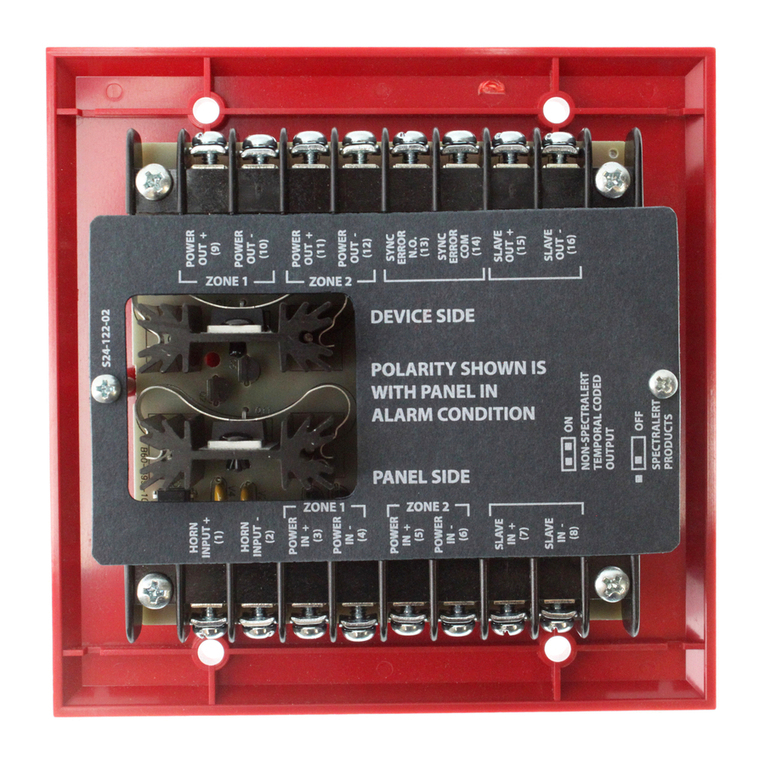

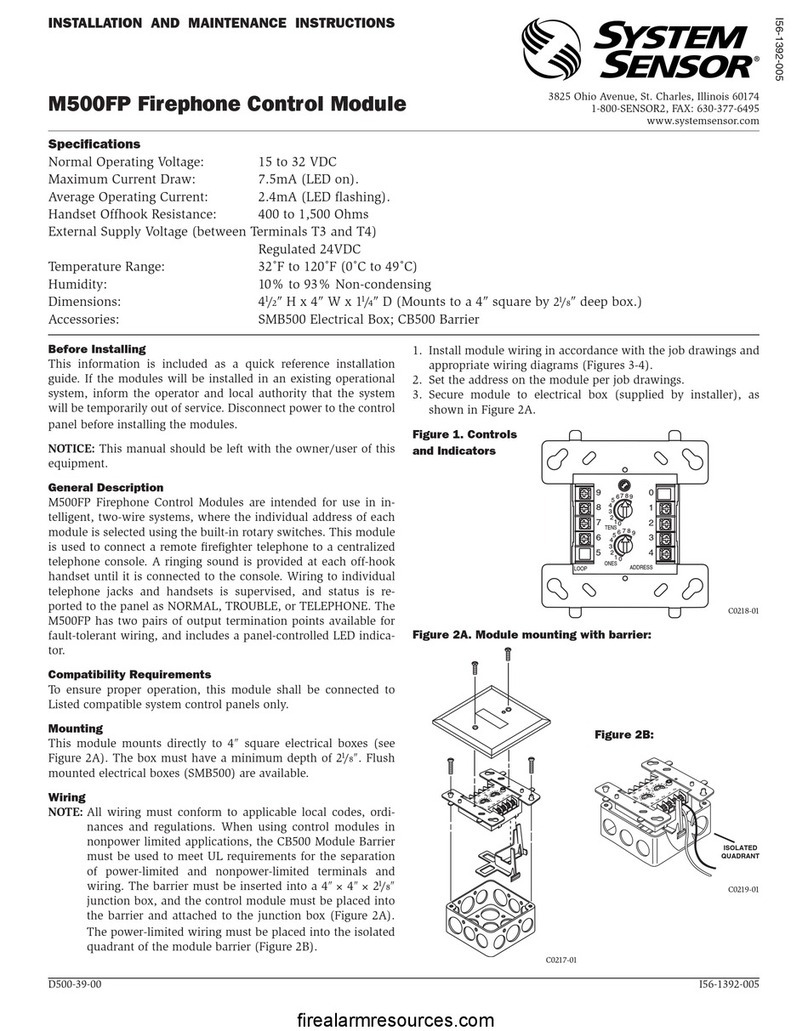

FIGURE 6. TYPICAL FAULT TOLERANT WIRING FOR SPEAKER SUPERVISION AND SWITCHING, NFPA CLASS A

(+)

(–)

(+)

(–)

(+)

(–) (+)

(–)

(–)

(+)

(–)

(+)

ALL WIRING SHOWN IS SUPERVISED

AND POWER LIMITED

TO NEXT

DEVICE

SIGNAL LINE CIRCUIT (SLC)

32 VDC MAX.

TWISTED PAIR

IS RECOMMENDED

WIRES MUST BE

SUPERVISED PER NFPA

CONNECT MODULES TO LISTED COMPATIBLE CONTROL PANELS ONLY

FROM

PANEL OR

PREVIOUS

DEVICE

CONTROL

MODULE

SPEAKERS MUST BE LISTED FOR

FIRE PROTECTION. REFER TO THE

RELAY CONTACT RATING TABLE

FOR MAXIMUM LOAD.

47K EOL RESISTOR

IS INTERNAL AT

TERMINALS 8 & 9

MODULE POLARITIES ARE

SHOWN IN ALARM

TO NEXT CONTROL MODULE

LAST MODULE MUST RETURN

WIRES FOR SUPERVISION

SUPERVISION

AUDIO CIRCUIT WIRING MUST BE TWISTED PAIR AS A MINIMUM. SEE PANEL INSTALLATION MANUAL FOR DETAILED INFORMATION.

AUDIO AMPLIFIER, 70.7 Vrms MAX.

AMPLIFIER MUST PROVIDE WIRING

SUPERVISION PER NFPA.

AUDIO CIRCUIT

DO NOT LOOP WIRE AROUND TERMINALS

10 & 11. BREAK WIRE TO ENSURE

SUPERVISION OF CONNECTIONS.

BYPASS CAPACITORS: 100µ

A2143-20 NONPOLARIZED

<10µA LEAKAGE

*NOTE: ANY FAULT IN THE POWER SUPPLY IS LIMITED TO THAT ZONE AND DOES NOT RESULT IN A FAULT IN A SEPARATE ZONE.

C0916-04

4 I56-6790-000

©2020 System Sensor. 8/19/2020