Introduction 4................................................................................................................

Safety 5...........................................................................................................................

Specifications - Turbo 5.................................................................................................

Specifications - Turbo MINI 6.......................................................................................

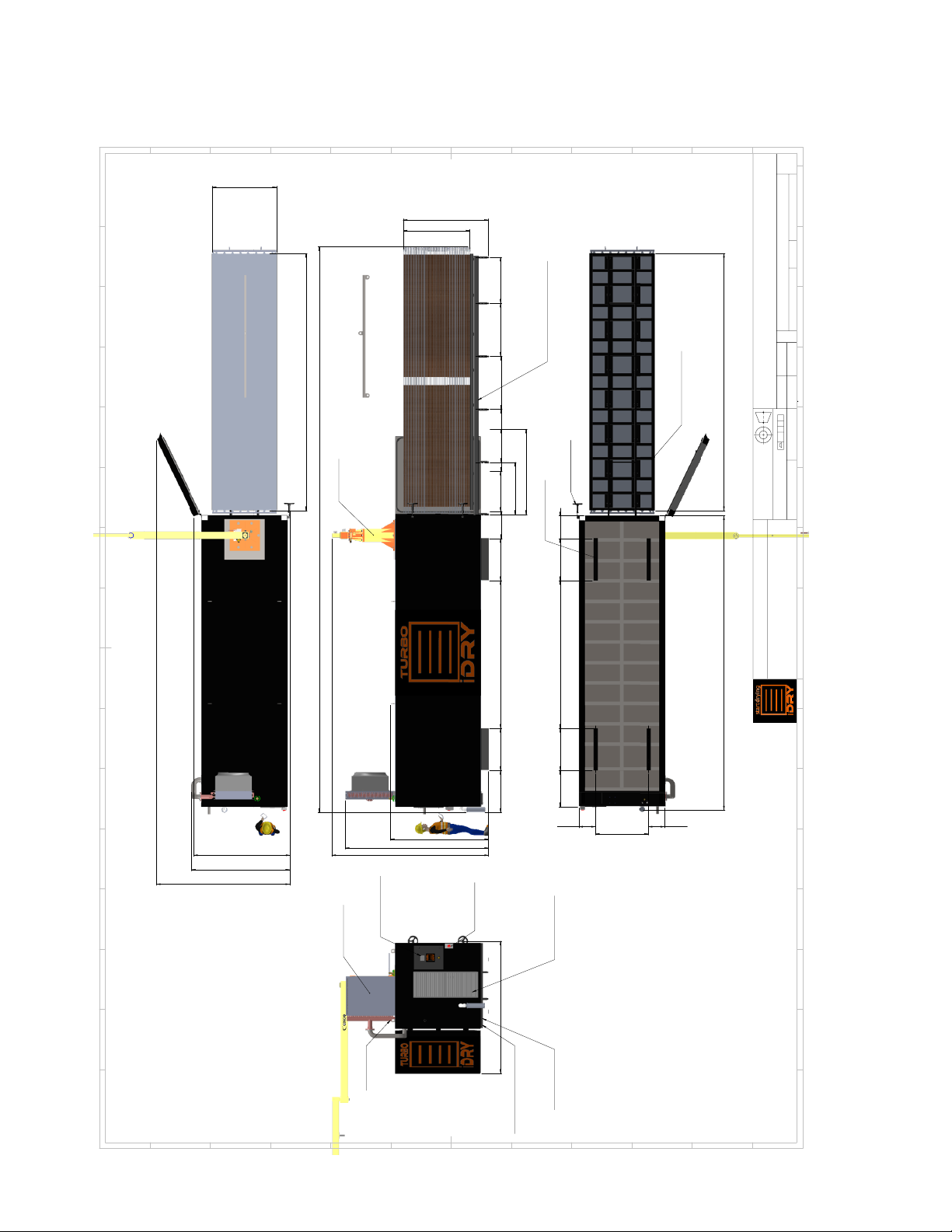

Technical Drawings - Turbo 7........................................................................................

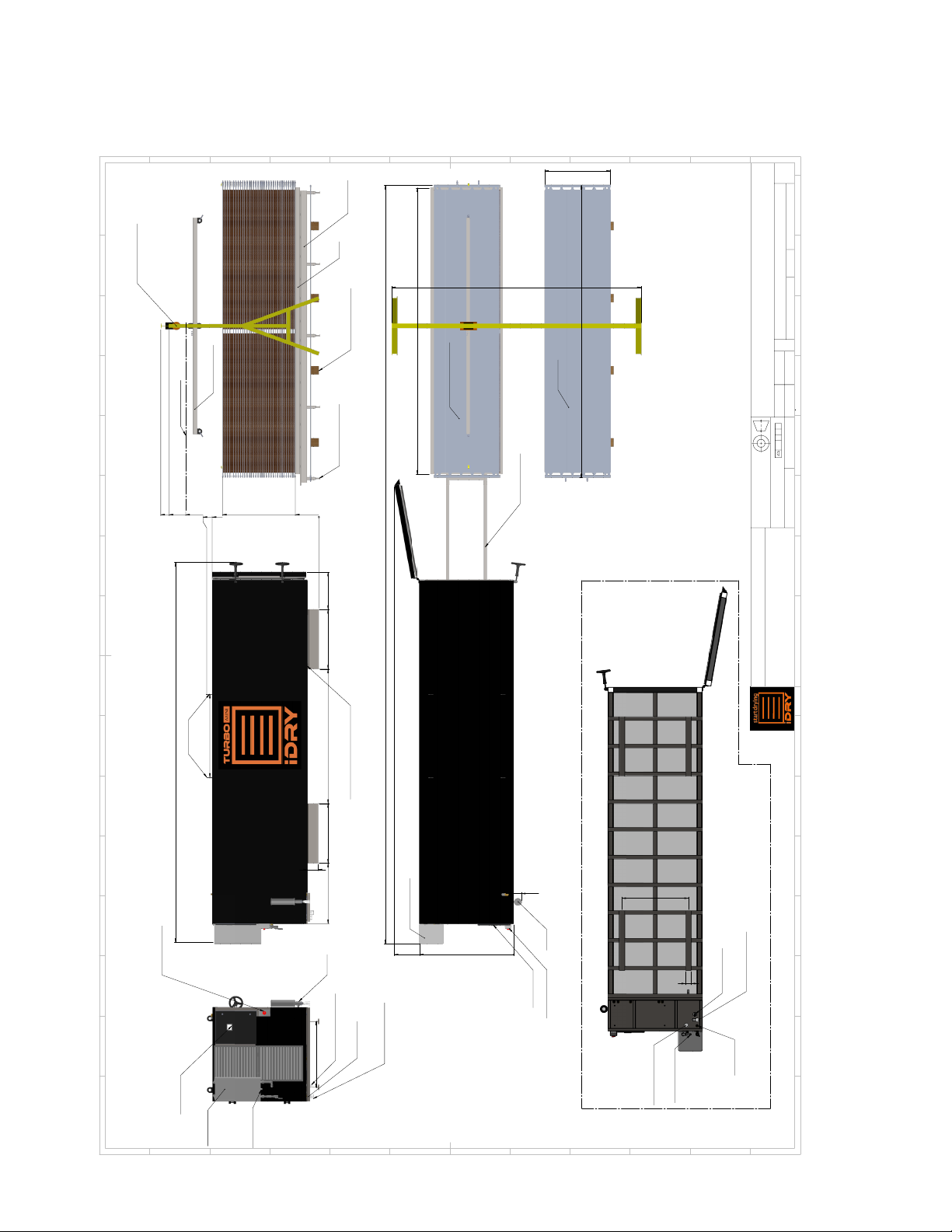

Technical Drawings - Turbo MINI 8.............................................................................

Technical Drawings - Turbo 9.......................................................................................

Technical Drawings - Turbo MINI 10...........................................................................

Installation & Startup: 11...............................................................................................

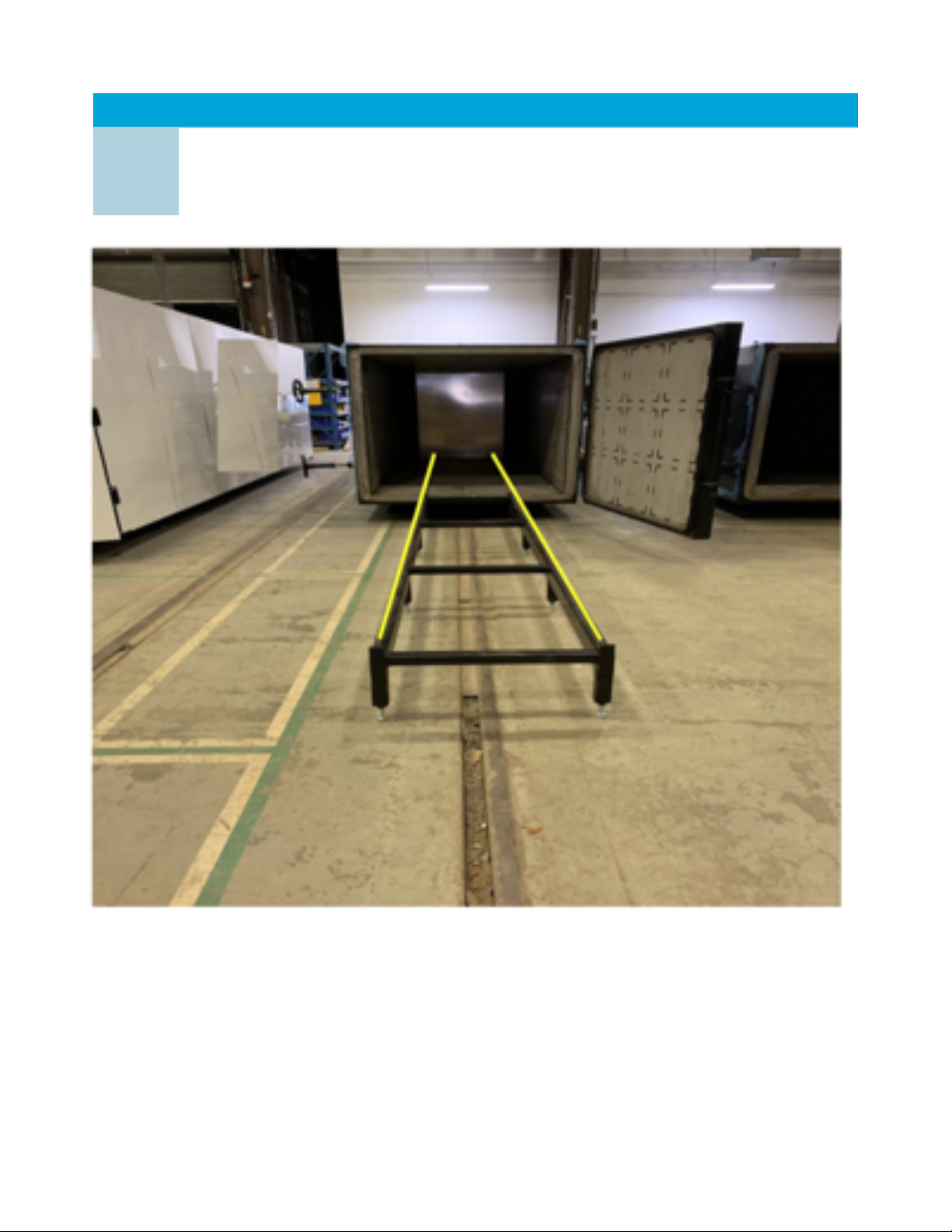

Placement 11........................................................................................................................

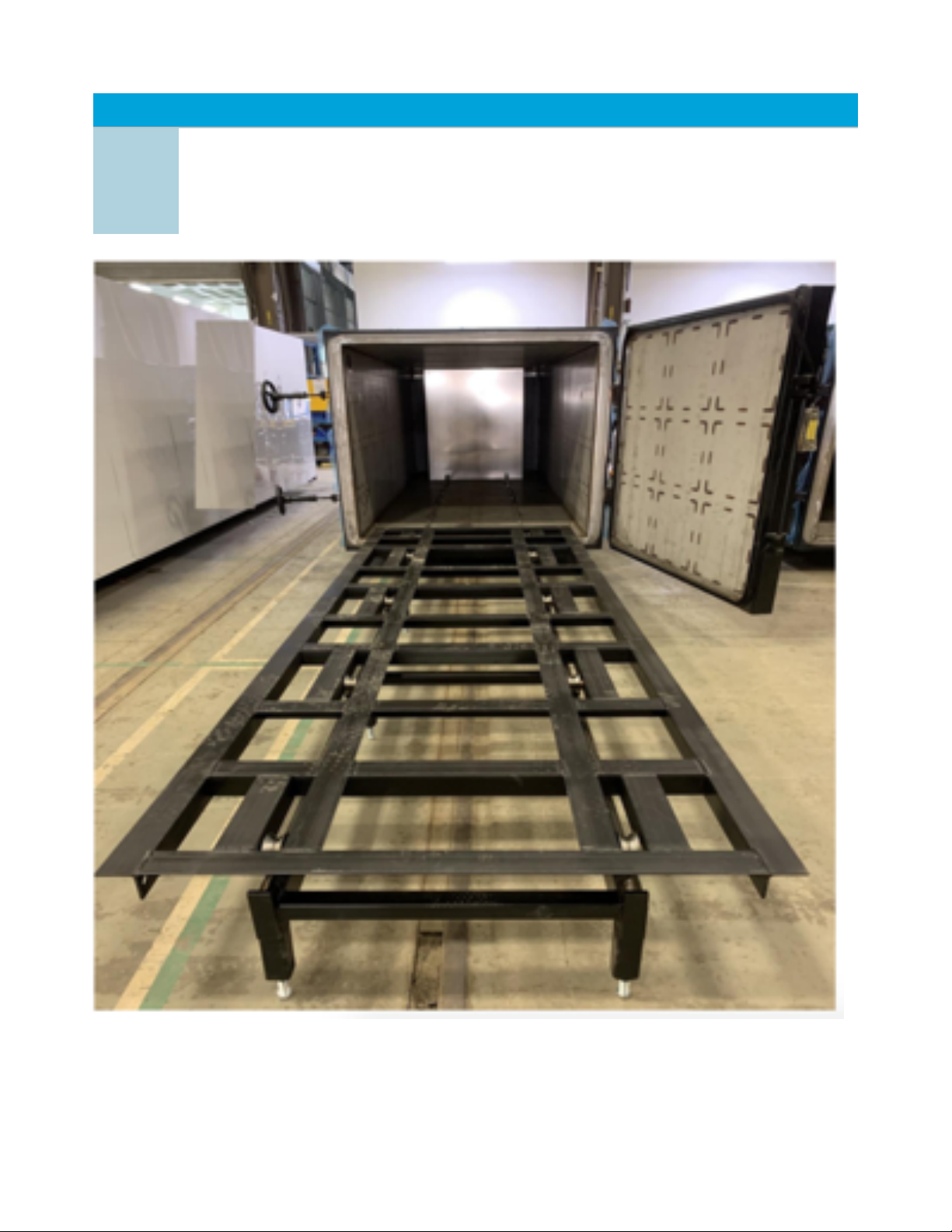

Track & Trolley Installation 11............................................................................................

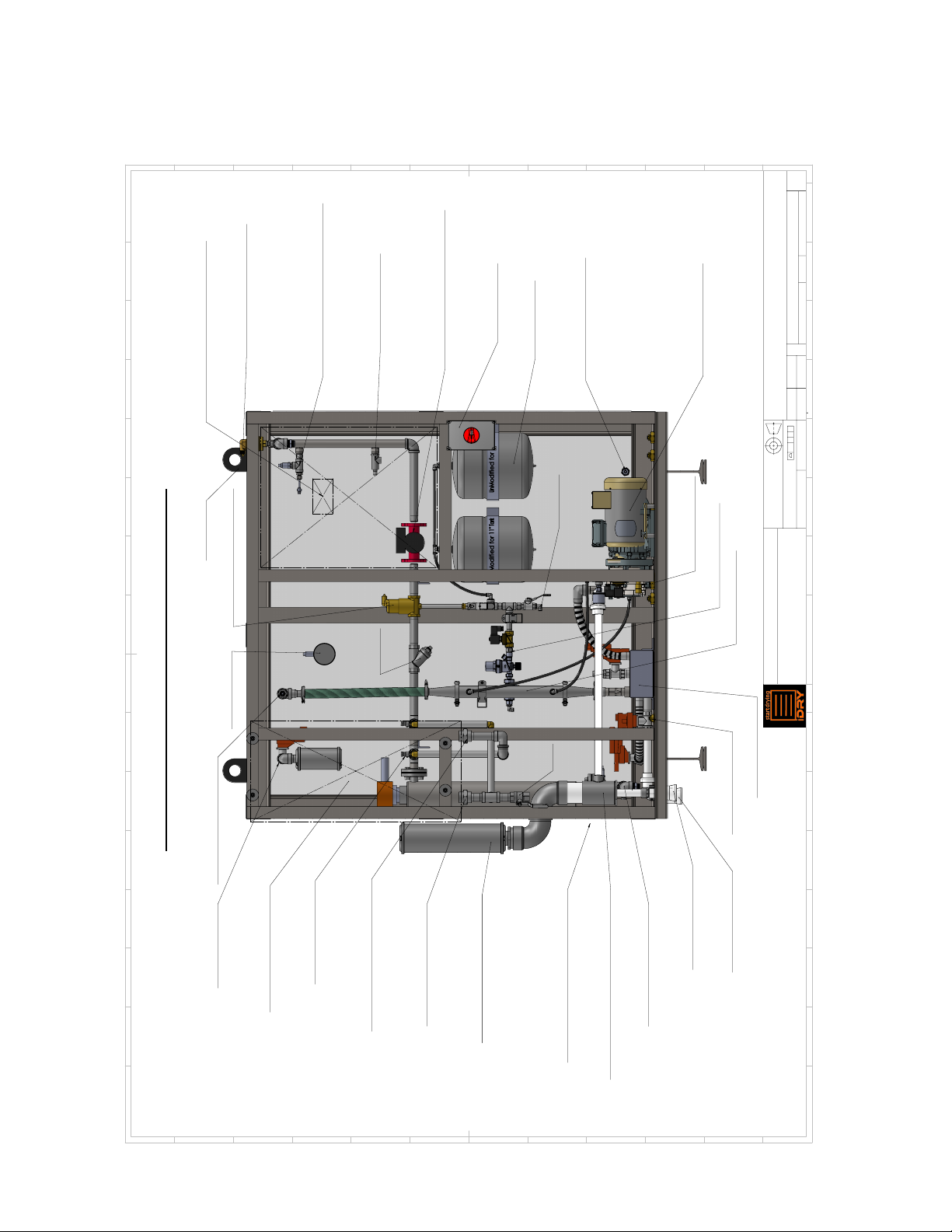

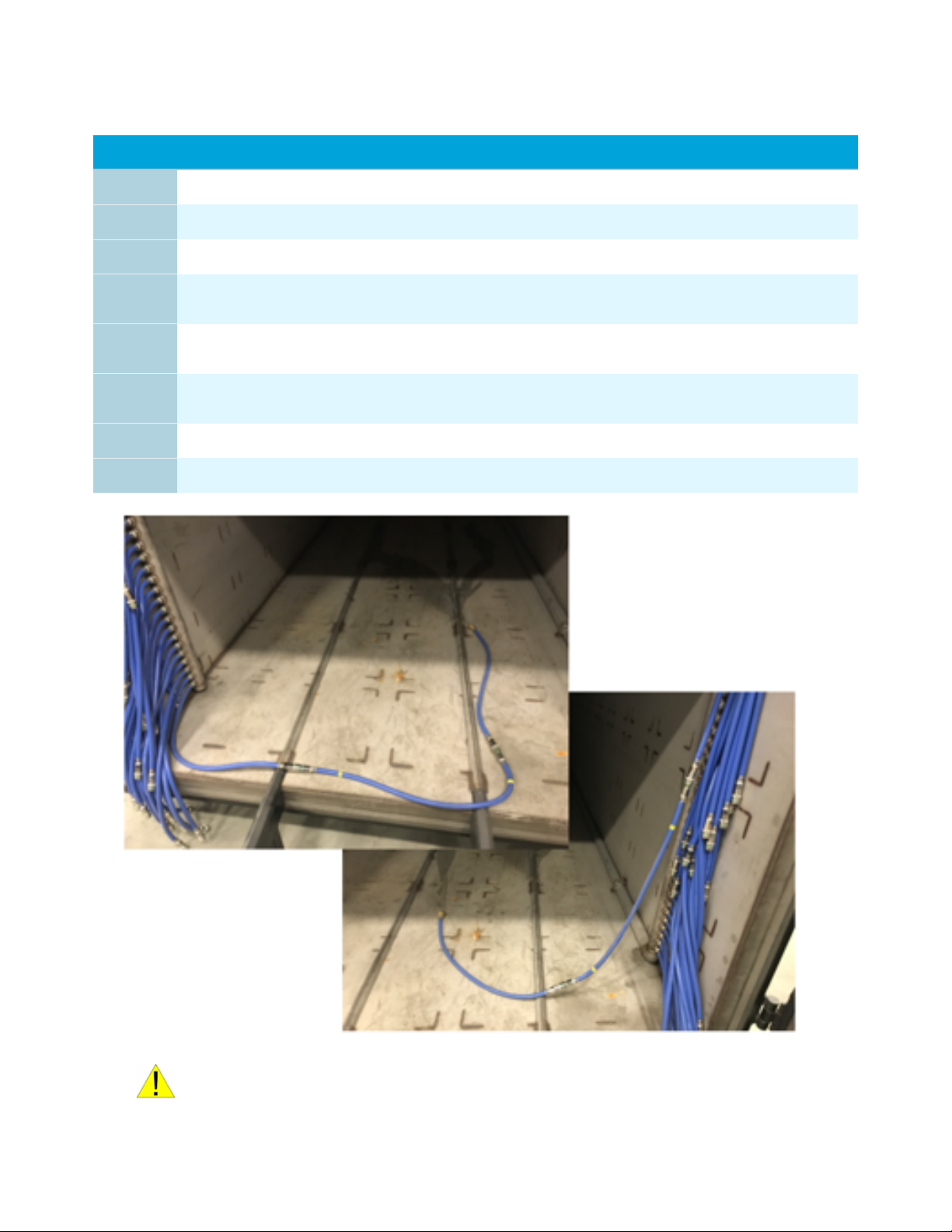

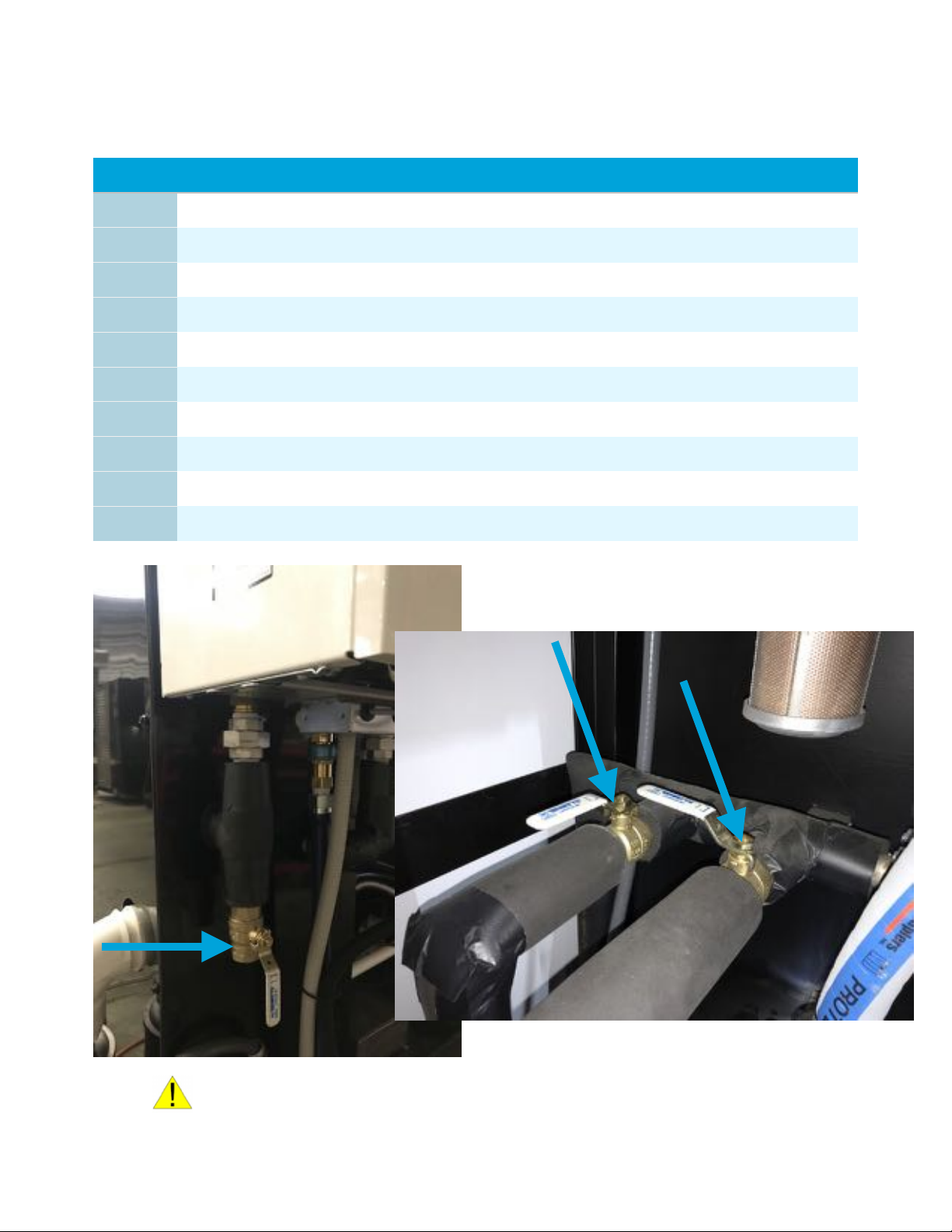

Plumbing 14.........................................................................................................................

Condenser - Turbo Only 15..................................................................................................

Jib Crane - Turbo Only 16...................................................................................................

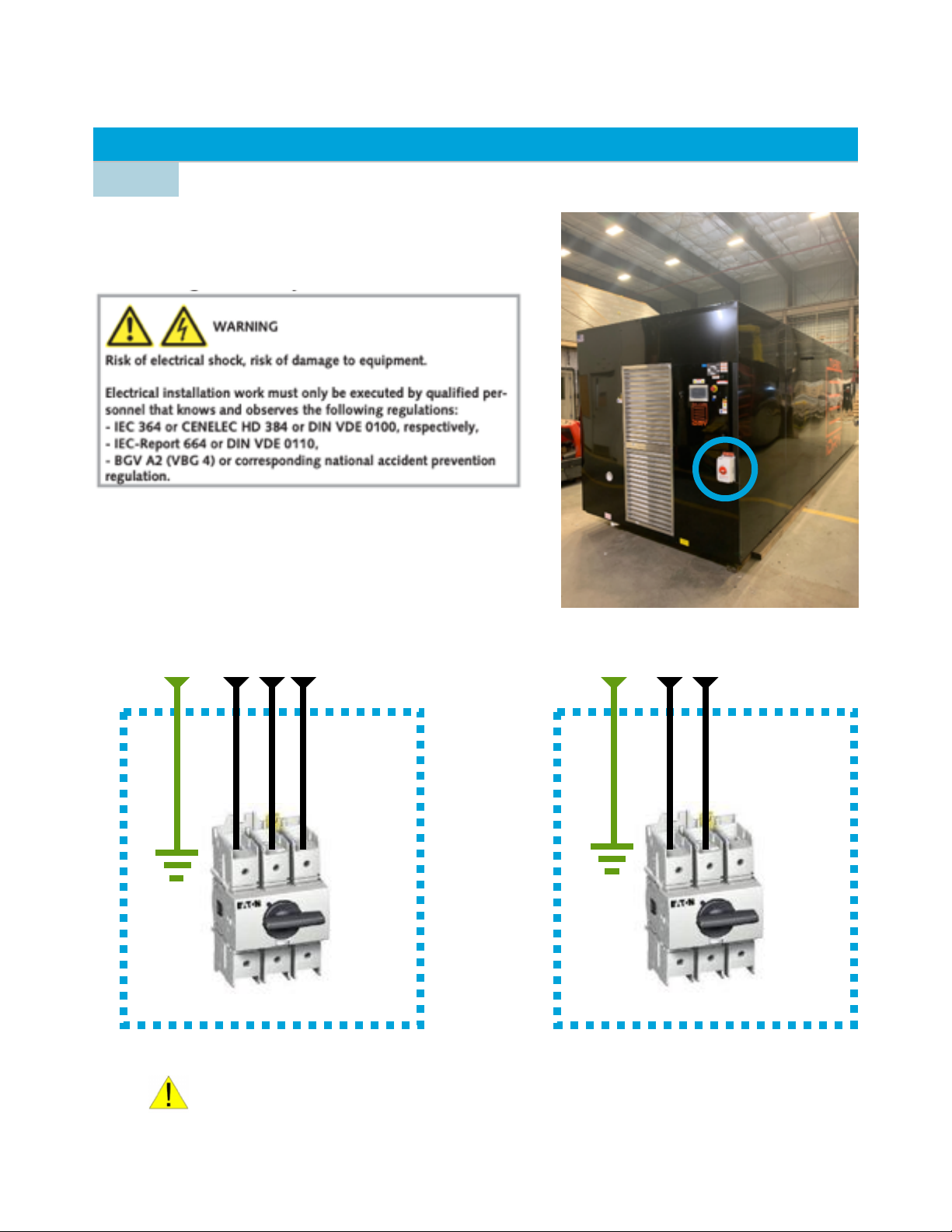

Power 17...............................................................................................................................

Powering Up 18....................................................................................................................

Heating System Water Filling Procedure 19.......................................................................

Boiler Setup and water fill procedure - Gas Boiler Only 20...............................................

Heating Plates Water Filling Procedure 21.........................................................................

Water System Test 22..........................................................................................................

Using the Press Bladder 23.................................................................................................

Closing the Door 24.............................................................................................................

Starting the Kiln 25..............................................................................................................

Kiln Monitoring 25..............................................................................................................

Unloading the Kiln 26.........................................................................................................

Unloading the Kiln - Check Moisture Content 26..............................................................

SYSTEM SETUP 27........................................................................................................

TOOLS 27.............................................................................................................................

SCREEN #1 SETUP PARAMETERS 28..............................................................................

SCREEN #2 SETUP PARAMETERS 29..............................................................................

SCREEN #3 SETUP PARAMETERS 30..............................................................................

CORRECT USE 31..........................................................................................................

Lumber preparation 31........................................................................................................