Translation of the original instructions

© 2020 all rights reserved to Festo SE & Co. KG

1 About this document

1.1 Applicable Documents

All available documents for the product èwww.festo.com/sp.

2 Safety

2.1 Safety Instructions

– Take into consideration the ambient conditions at the location of use.

– Only use the product in original status without unauthorised modifications.

– Observe labelling on the product.

– Store the product in a cool, dry, UV-protected and corrosion-protected envir-

onment. Ensure that storage times are kept to a minimum.

– Prior to mounting, installation and maintenance work: Switch off compressed

air supply and secure it from being switched back on.

– Observe tightening torques. Unless otherwise specified, the tolerance is

±20%.

2.2 Intended Use

The intended use of the gripper kit for robots is for integration into the UR soft-

ware and hardware connection for handling tasks of payloads.

Use the product only as follows:

– In perfect technical condition

– Within the limits of the product defined by the technical data

– In the industrial sector, in research laboratories, in assembly areas, in series

and special machines

– Permanently mounted

2.3 Training of Qualified Personnel

Installation, commissioning, maintenance and disassembly should only be con-

ducted by qualified personnel.

The specialized personnel must be familiar with the installation and operation of

electrical and pneumatic control systems.

3 Service

Contact your regional Festo contact person if you have technical questions

èwww.festo.com.

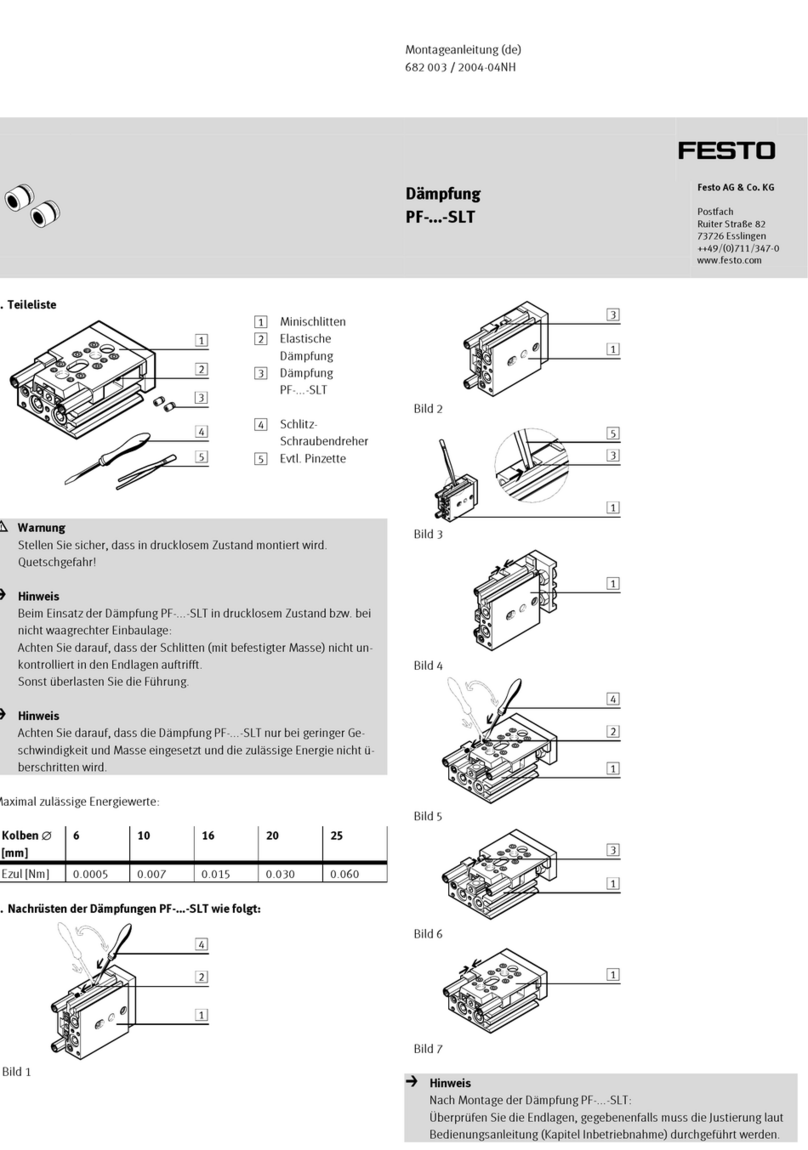

4 Design

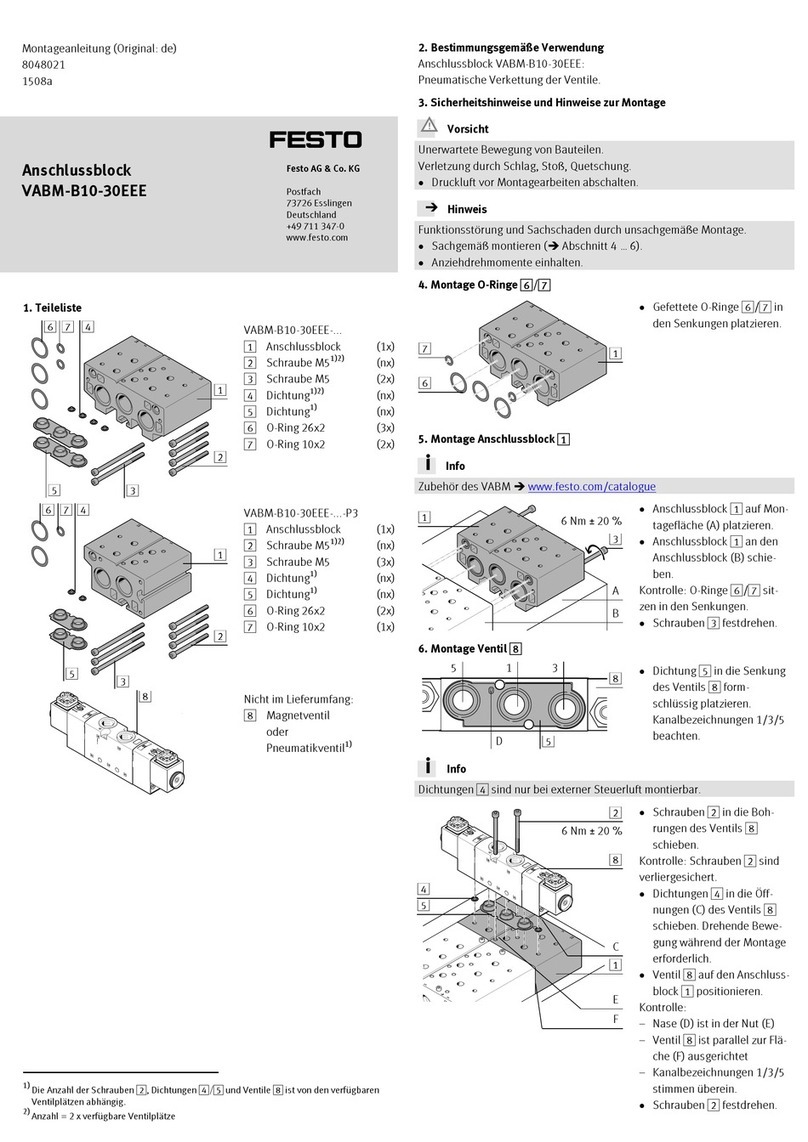

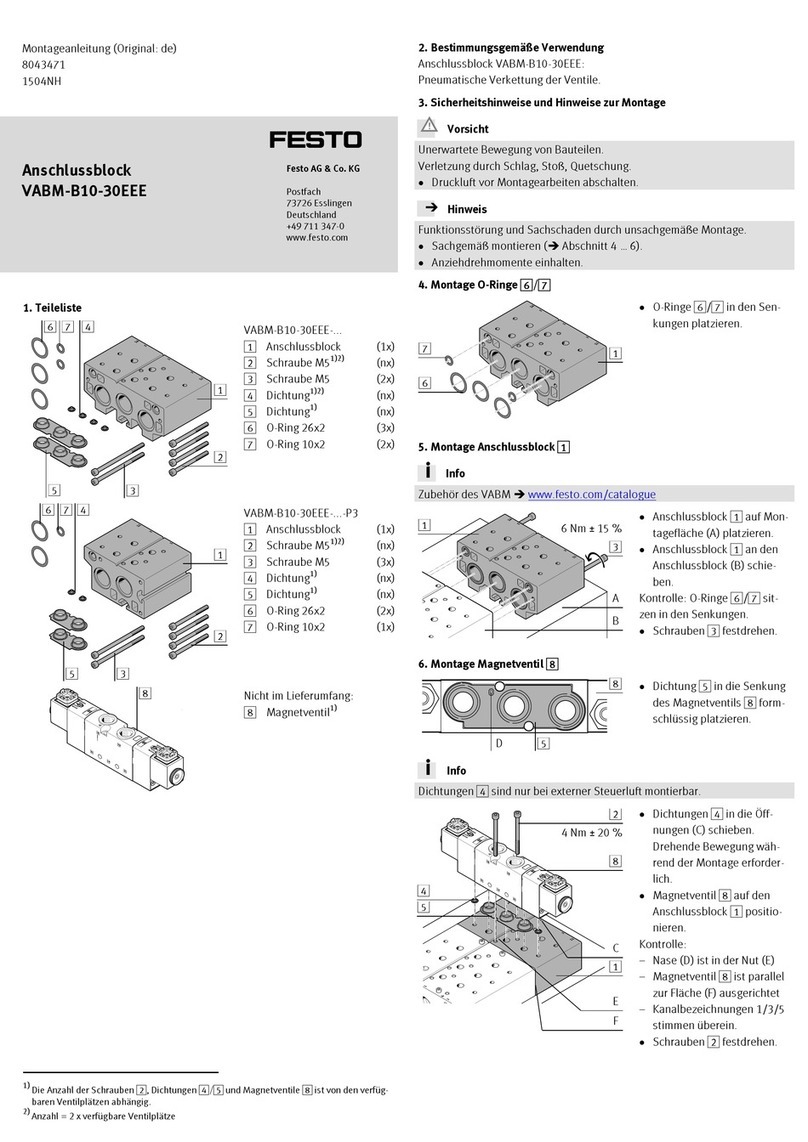

1Robot flange

2Proximity sensor (2x)

3Socket head screw (4x)

4Adaptive shape gripper

5Velcro strap (2 m)

6Solenoid valve

7Silencer UC-M5

8Silencer UC-QS-4H

9USB memory stick

10 Proportional-pressure regulator

11 Connecting cable NEBU-

M8G4-R-5-LE4

12 Connecting cable NEBU-

M8G3-R-5-LE3 (2x)

13 Tubing PUN-6 (4m)

14 Tubing PUN-4 (2m)

15 Push-in fitting QSM-M5-6-I (5x)

16 Push-in fitting QSM-M5-4-I

Fig. 1 Parts overview

4.1 Functional Principle

"Grip" /"Release"- only adaptive shape gripper active

The "Grip" /"Release" functions are intended for operation of the adaptive shape

gripper - without movement of the robot arm.

– "Grip": the lower cylinder chamber is pressurised. The piston rod retracts.

– "Release": the upper cylinder chamber is pressurised while the lower one is

exhausted. The piston rod advances. Then both chambers are exhausted

(neutral position).

"SmartGrip" - Adaptive shape gripper and robot arm active

The process "SmartGrip" consists of four phases:

1. The robot arm moves in the Z-direction by the "Workpiece distance" value.

2. The workpiece is detected and the proximity sensor switches.

3. After detection of the workpiece, the robot arm moves the adaptive shape

gripper further in the Z-direction towards the workpiece. The piston rod

moves into the adaptive shape gripper and the cap slides around the work-

piece. The distance travelled by the piston rod is determined by the "Work-

piece grip height" parameter.

4. If it returned over the defined path "Workpiece grip height", the lower piston

chamber is pressurised and the piston rod is fully retracted. The adaptive

shape gripper does not move further down during the active retracting pro-

cess.

"SmartRelease" - Adaptive suction gripper and robot arm active

When the workpiece is released, the gripper moves upwards in the Z-direction

over the full stroke (66mm). At the same time, a pressure pulse is applied to the

upper piston chamber to advance the piston rod and release the object.

Precise placement

For precise placement, the gripped object should be positioned approx. 1 mm

above the support surface. If the object is completely enclosed by the cap, the

lower edge of the cap should be positioned accordingly.

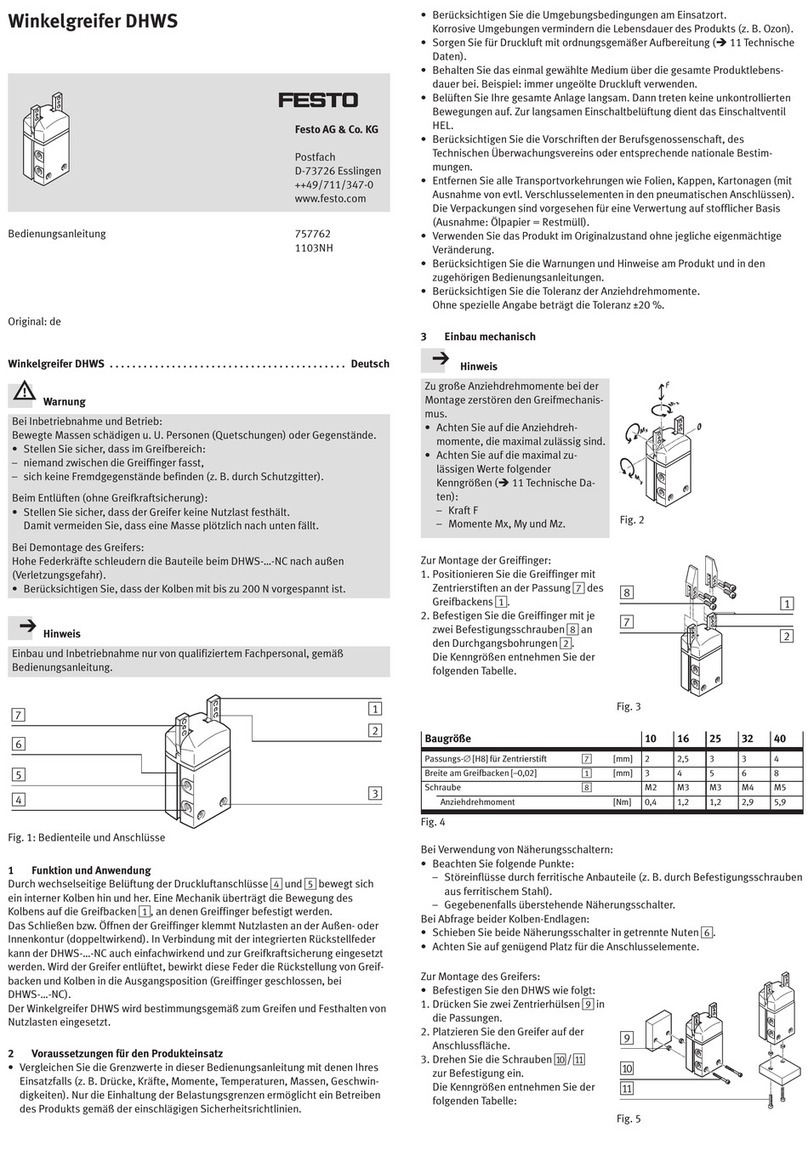

5 Mechanical assembly

1. Screw push-in fittings aE (2x) into ports A and B on the adaptive shape grip-

per.

2. Screw push-in fitting aF into port C on the adaptive shape gripper.

3. Position adaptive shape gripper 4 on the robot flange 1 and tighten with

socket head screws 3 (4x). Tightening torque: 8 Nm

4. Screw push-in fittings aE (3x) into ports 1, 2 and 4 on the solenoid valve 6.

Tightening torque: 1.3 Nm

5. Screw silencer 7 (2x) into ports 3 and 5 on the solenoid valve 6.

6. Plug silencer 8 into port 3 on the proportional-pressure regulator aJ.

8123229

DHEF-...-A-RA1

Adaptive shape gripper

8123229

2020-01

[8123231]

Instructions| Assembly, Installation, Parameterisation

Festo SE & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com