Idutex xTuner PT101 User manual

Automotive Circuit Tester

PT101

Users Manual

www. idutex. com

CATALOG

1. Safety Precautions and Warnings..................................................................1

2. Using the Test Tool.......................................................................................... 2

2.1 Appearance and Controls................................................................... 2

2.2 Specifications........................................................................................4

2.3 Product Included.................................................................................. 5

2.4 General Description............................................................................. 5

2.5 Power..................................................................................................... 6

2.6 Quick Self-Test..................................................................................... 6

2.7 Circuit Breaker......................................................................................7

2.8 Work mode............................................................................................ 8

3. Test Applications............................................................................................ 13

3.1 Voltage & Polarity Testing.................................................................13

3.2 Continuity Testing.............................................................................. 14

3.3 Signal Circuit Testing.........................................................................16

3.4 Activating Components in Your Hand............................................. 17

3.5 Testing Trailer Lights and Connections.......................................... 18

3.6 Activating Components in The Vehicle........................................... 19

3.7 Activating Components w/Ground...................................................20

3.8 Checking for Bad Ground Contacts................................................ 22

3.9 Following & Locating Short Circuits................................................ 22

3.10 Red/Blue Polarity LED.................................................................... 23

4. Test Tool Know-how...................................................................................... 24

5. Equipment Repair........................................................................................... 26

5.1 Product acceptance...........................................................................26

5.2 Product warranty................................................................................26

5.3 Product warranty process.................................................................26

5.4 Over-warranty product maintenance regulations......................... 27

6 Contact Us........................................................................................................ 27

Shenzhen IDUTEX Tech Co., Ltd

1

1. Safety Precautions and Warnings

To prevent personal injury or damage to vehicles and/or the test tool,

read this instruction manual first and observe the following safety

precautions at a minimum whenever working on a vehicle:

●Always perform automotive testing in a safe environment.

●Wear safety eye protection that meets ANSI standards.

●Keep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

●Operate the vehicle in a well ventilated work area: Exhaust gases are

poisonous.

●Put blocks in front of the drive wheels and never leave the vehicle

unattended while running tests.

●Use extreme caution when working around the ignition coil, distributor

cap, ignition wires and spark plugs. These components create hazardous

voltages when the engine is running.

●Put the transmission in PARK (for automatic transmission) or

NEUTRAL (for manual transmission) and make sure the parking brake is

engaged.

●Keep a fire extinguisher suitable for gasoline/chemical/ electrical fires

nearby.

●Don’t connect or disconnect any test equipment while the ignition is

on or the engine is running.

●Keep the tool dry, clean, free from oil/water or grease. Use a mild

detergent on a clean cloth to clean the outside of the test tool, when

necessary.

Shenzhen IDUTEX Tech Co., Ltd

2

ƔWhen the power switch in the tool is depressed battery current/voltage

is conducted directly to the tip which may cause sparks when contacting

ground or certain circuits. Therefore the tool should NOT be used around

flammables such as gasoline or its vapors. The spark of an energized tool

could ignite these vapors. Use the same caution as you would when using

an arc welde

2. Using the Test Tool

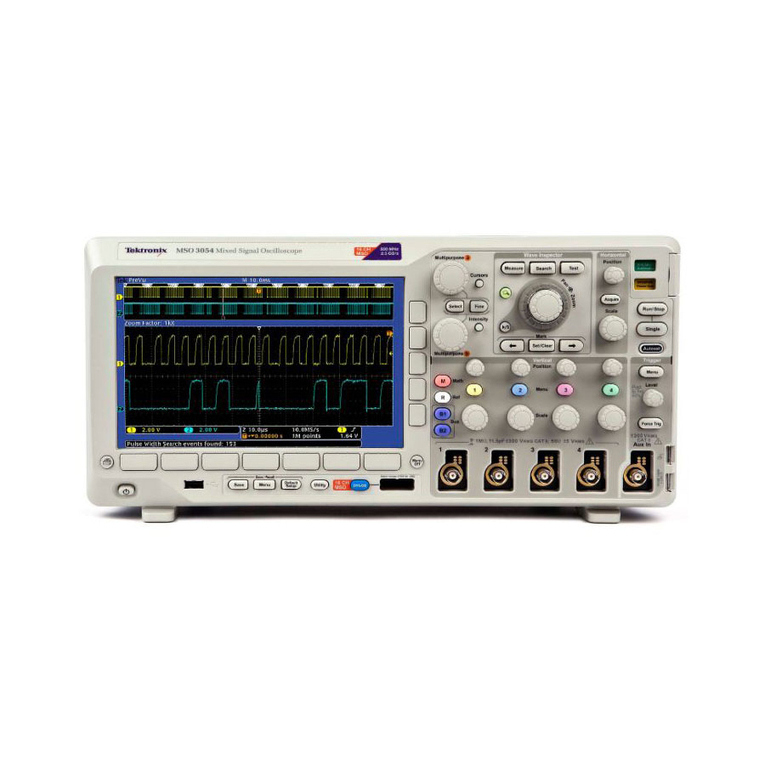

2.1 Appearance and Controls

Figure 1

r

Shenzhen IDUTEX Tech Co., Ltd

1

1. Safety Precautions and Warnings

To prevent personal injury or damage to vehicles and/or the test tool,

read this instruction manual first and observe the following safety

precautions at a minimum whenever working on a vehicle:

ƔAlways perform automotive testing in a safe environment.

ƔWear safety eye protection that meets ANSI standards.

ƔKeep clothing, hair, hands, tools, test equipment, etc. away from all

moving or hot engine parts.

ƔOperate the vehicle in a well ventilated work area: Exhaust gases are

poisonous.

ƔPut blocks in front of the drive wheels and never leave the vehicle

unattended while running tests.

ƔUse extreme caution when working around the ignition coil, distributor

cap, ignition wires and spark plugs. These components create hazardous

voltages when the engine is running.

ƔPut the transmission in PARK (for automatic transmission) or

NEUTRAL (for manual transmission) and make sure the parking brake is

engaged.

ƔKeep a fire extinguisher suitable for gasoline/chemical/ electrical fires

nearby.

ƔDon’t connect or disconnect any test equipment while the ignition is

on or the engine is running.

ƔKeep the tool dry, clean, free from oil/water or grease. Use a mild

detergent on a clean cloth to clean the outside of the test tool, when

necessary.

Shenzhen IDUTEX Tech Co., Ltd

4

2.2 Specifications

Display

TFT color display (160 x 128 PPI)

Dimensions

195 mm (7.68”) *50.5 mm (1.99”)*33mm

External Power 12.0 - 30.0V power provided via vehicle

battery. Recommended 12v power supply

Min Operating Voltage

8 VDC

Max Operating Voltage 12 VDC

Max Tip Voltage

40 Volts

Probe Tip Resistance

to Ground

1000 K Ohms

Computer Safe

0.1mA floating tip

Voltage Measurement

0 to 40 VDC / VAC

Voltage Resolution 0V -to 40V – 0.01V (10mV)

Glitch Capture

> 50 µS Min Pulse Width

Power Feed Test

< 3 mA

Resistance

Measurement

0 Ohms to 1M Ohms

Frequency

Measurement

40 Hz to 20KHz

Circuit Breaker 8 Amp Thermal – Auto Reset

Shenzhen IDUTEX Tech Co., Ltd

5

Breaker Trip Response

8 Amps = No Trip

8 Amps = 1 sec.

Short Circuit = 0.3 sec.

Operating Temperature -20°C (-4°F) to 50°C (122°F)

Storage Temperature

-40°C (-40°F) to 65°C (149°F)

2.3 Product Included

(1) User manual.

(2) Cigarette lighter adapter.

(3) Battery hookup clips.

(4) Probe tip.

(5) Extension cable.

(6) Rugged blow molded case.

2.4 General Description

Thank you for purchasing the Diagnostic Electronic Circuit

tester. The tool is the best electrical tester for reducing diagnostic time in all

6 to 30 volt vehicle electrical systems. After a simple hook-up of the tool to

the vehicle's battery, you can:

XTUNER PT101

Shenzhen IDUTEX Tech Co., Ltd

6

●determine at a glance if a circuit is positive, negative, or open without

having to reconnect clips from one battery pole to another.

●test for continuity with its built-in auxiliary ground lead.

●by depressing the power switch, conduct a positive or negative

battery current to the probe tip for testing the function of an electrical

component without the use of jumper wires.

●test for poor ground contacts instantly without performing voltage

drop tests. The tool is also short-circuit protected; its internal circuit

breaker will trip if it becomes overloaded.

●follow and locate short circuits without wasting fuses. The tool's long

cable allows you to test along the entire length of the vehicle without

constantly searching for suitable vehicle grounds.

2.5 Power

The tool is powered via the vehicle battery. Connect the RED battery

clamp to the POSITIVE terminal of the vehicle‟s battery, and the

BLACK clamp to the NEGATIVE terminal.

2.6 Quick Self-Test

Before you test a circuit or component, be sure your tool is in good order

by doing a quick self-test.

With the tool connected, perform a quick self-test. The power switch is a

momentary rocker switch located on the tool's body. Flanking the switch

are positive and negative markings.

Press the Power Switch forward to activate the tip with a positive

voltage. The Red LED should light and the LCD display will read the

battery voltage.

Shenzhen IDUTEX Tech Co., Ltd

7

Press the Power Switch rearward to activate the tip with a negative

voltage. The Blue LED should light and the LCD display will read the

“0.0V” (ground).

Your tool is working correctly and is now ready for use. (Figure 2)

Figure

IMPORTANT:

When powering-up components, you can

increase the life of power switch in the tool if you first press the

switch, then contact the tip to the component. The arcing will take

place at the tip instead of the contacts of the switch.

2.7 Circuit Breaker

The tool is short-circuit protected. Its internal circuit breaker will trip if

it becomes overloaded. The circuit breaker is a valuable test tool as well

as a safety measure to protect the tool from overload.

When circuit breaker tripped, All other functions of the tool are still active,

which means you can still probe a circuit and observe the voltage reading.

When the circuit breaker is tripped, the tool will NOT be able to conduct

2

Shenzhen IDUTEX Tech Co., Ltd

8

battery current to the tip even when the power switch is pressed.

Intentionally tripping the breaker and using the tool to probe can be

considered an added precaution against accidental pressing of the power

switch.

2.8 Work mode

There are four modes to diagnose the electrical systems, which can

be accessed by depressing the Mode Button and cycling through each

one.

DC voltage

While the tool in this mode, contact the probe tip to a circuit, then the LCD

display will read the DC voltage with a resolution of 0.01 volt.(Figure 3)

Figure

3

Shenzhen IDUTEX Tech Co., Ltd

9

AC voltage

While the tool in this mode, contact the probe tip to a circuit, then the LCD

display will read the Max. voltage, the Min. voltage, frequency. ( Figure 4)

Figure

4

Shenzhen IDUTEX Tech Co., Ltd

10

Resistance

While the tool in this mode, contact the probe tip to a circuit, then the

LCD display will read the resistance between the tip and auxiliary

ground lead. (Figure 5)

Figure 5

Shenzhen IDUTEX Tech Co., Ltd

11

Diode

While the tool in this mode, contact the probe tip to a circuit, then the

LCD display will read the diode voltage between the tip and auxiliary

ground lead. (Figure 6)

Figure 6

Shenzhen IDUTEX Tech Co., Ltd

12

Current

While the tool in this mode, contact the probe tip to a circuit and press the

power switch up, then the LCD display will read the current with a

resolution of 0.1 A.( Figure 7)

Figure 7

Please do not test when power up more than 20V.

Shenzhen IDUTEX Tech Co., Ltd

13

3. Test Applications

3.1 Voltage & Polarity Testing

While the tool is in DC Voltage mode, contact the probe tip to a POSITIVE

circuit. The red LED will light and the LCD displays the voltage with a

resolution of 0.01V, a high pitched tone will sound.

If contact the probe tip to a NEGATIVE circuit, the blue LED will light and

the LCD displays the voltage with a resolution of 0.01V, a low pitched

tone will sound.

If contact the probe tip to an OPEN circuit, neither of the LED will

light.(Figure 8)

Figure 8

Shenzhen IDUTEX Tech Co., Ltd

14

3.2 Continuity Testing

While the tool is in Resistance mode, using the probe tip with chassis

ground or the auxiliary ground lead, continuity can be tested on wires

and components attached or disconnected from the vehicleெs electrical

system.

When the probe tip is contacting a good ground, the LCD will indicate “0

ȍ” and blue LED will be on, a low pitched tone will sound.喉Figure 9喊

Figure 9

Shenzhen IDUTEX Tech Co., Ltd

15

ƔIn other cases, the LCD only indicates the resistance value. (Figure 10)

Figure 10

ƔIf the resistance value is greater than 1Mȍ, the LCD will show “1.”.

NOTE: You can use the probe tip to pierce the plastic insulation on a

wire. This means that you can test the circuit without

disconnecting anything.

Shenzhen IDUTEX Tech Co., Ltd

16

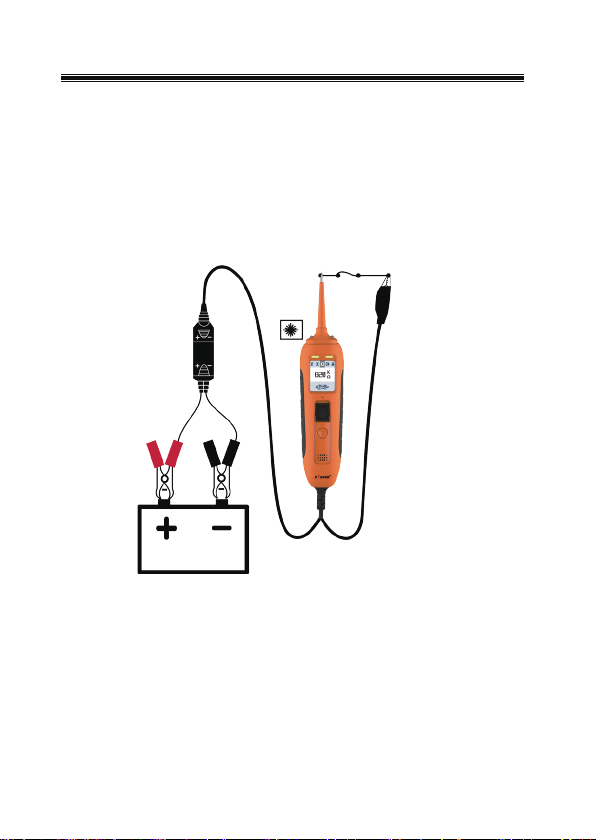

3.3 Signal Circuit Testing

Once you extract a DTC from the vehicle and realize that troubleshooting

begins with some kind of sensor circuit, there is a quick test you can

perform to verify the code. Testing your sensor is easy while using the tool.

For example, you suspect there is a problem with your M.A.P. sensor

circuit, then follow the procedure involved with testing this sensor:

ƔSet the tool in AC Voltage mode, using the probe tip with chassis

ground or the auxiliary ground lead.

ƔConnect vacuum pump to MAP sensor.

ƔContact the probe tip to the MAP sensor positive terminal and

observe the LCD readings which should be a sine wave in

normal condition.

ƔApply vacuum.

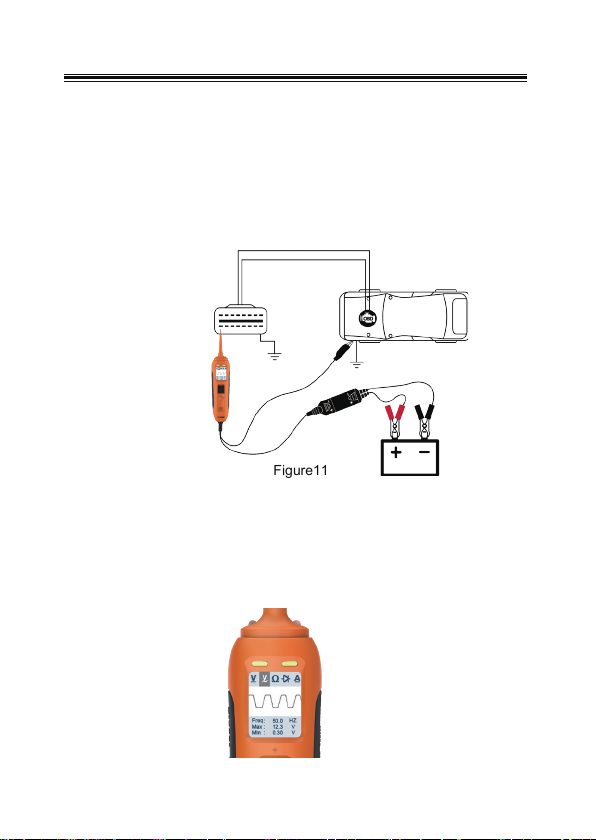

ƔRelease vacuum and observe the LCD readings.喉Figure 12喊

Figure11

If the LCD readings are abnormal, there is a problem with this sensor.

喉Figure 11喊

Figure 12

Shenzhen IDUTEX Tech Co., Ltd

17

3.4 Activating Components in Your Hand

While the tool is in DC Voltage mode, by using the probe tip in connection

with the auxiliary ground lead, components can be activated right in your

hand, thereby testing their functions.

Connect the auxiliary ground lead to the negative terminal or ground side

of the component being tested. Then contact the probe tip to the positive

terminal of the component, the blue LED should light, indicating continuity

through the component.

While keeping an eye on the blue LED, quickly press and release the

power switch forward. If the blue LED went out and the red LED came on,

you may proceed with further activation. Rock the power switch forward

and hold it down to provide power to your component. With the power

switch rocked forward, power will flow from the positive lead on the battery

into the probe tip, through the tip into the componentெs positive terminal,

into the component and out of the component, through the auxiliary

ground lead and back into the tool, and back to the vehicleெs batteryெs

ground. (Figure 13)

Figure 13

Contact the tip to the

p

ositive terminal of the

b

ulb

C

onnect the negative

auxiliary clip

Press the power switch

forward to active the

bulb

Shenzhen IDUTEX Tech Co., Ltd

18

If the circuit breaker tripped, the tool has been overloaded. This

could happen for the following reasons:

ƔThe contact you are probing is a direct ground or negative voltage.

ƔThe component you are testing is short-circuited.

ƔThe component is a very high current component (i.e., starter motor).

If the circuit breaker is tripped, reset it by waiting for it to cool down

(15 sec.) and then Reboot the device.

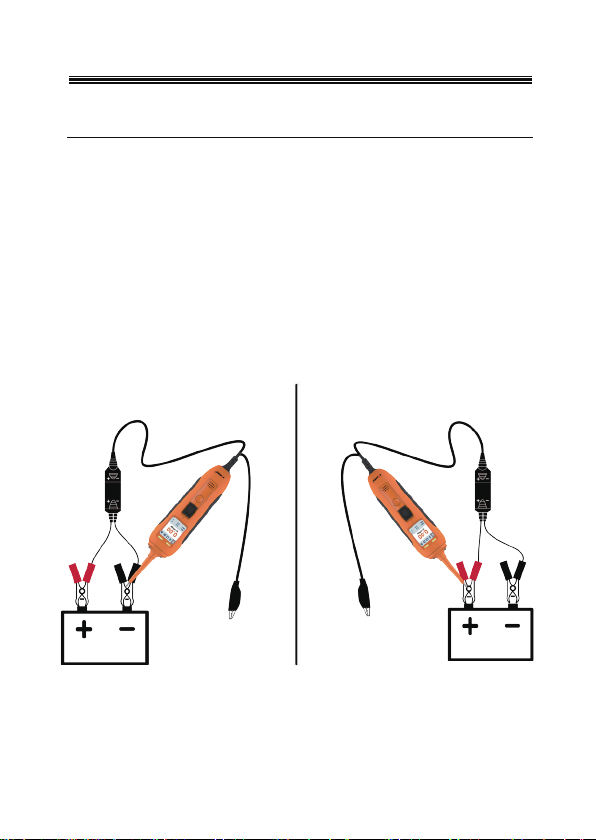

3.5 Testing Trailer Lights and Connections

While the tool in DC Voltage mode, clip the auxiliary ground lead to the

trailer ground, probe the contacts at the jack and then apply voltage to the

probe tip. This lets you check the function and orientation of the connector

and trailer lights. (Figure 14)

Figure 14

Table of contents