8

5-1. Connecting the Power Cord

[Caution] Power supply voltage may be different when

using this product in other countries. Please only

use a power cord designed for your country.

(1) Insert the power cord into the power supply connector on

the rear side of the main unit.

(2) If the power supply is a three-prong plug 100V-120V outlet,

insertthepowercordintoVACoutlet.(Seetherightgand

in case of 100V-120V uses with blade plug condition)

Connect the included power plug conversion adapter into

the power cord first, then plug the cord into a 100V-120V

power outlet. Next, connect the ground wire on the power

cord to the ground.

[Caution] 200V-240V outlet is used, power cord B should be used.

[Caution] Ifthepowersupplyis200V-240Vwithatbladeplug,the

conversion adapter should be prepared by yourself.

[Caution] If the power supply is 100V-120V with round pin plug, the

conversion adapter should be prepared by yourself.

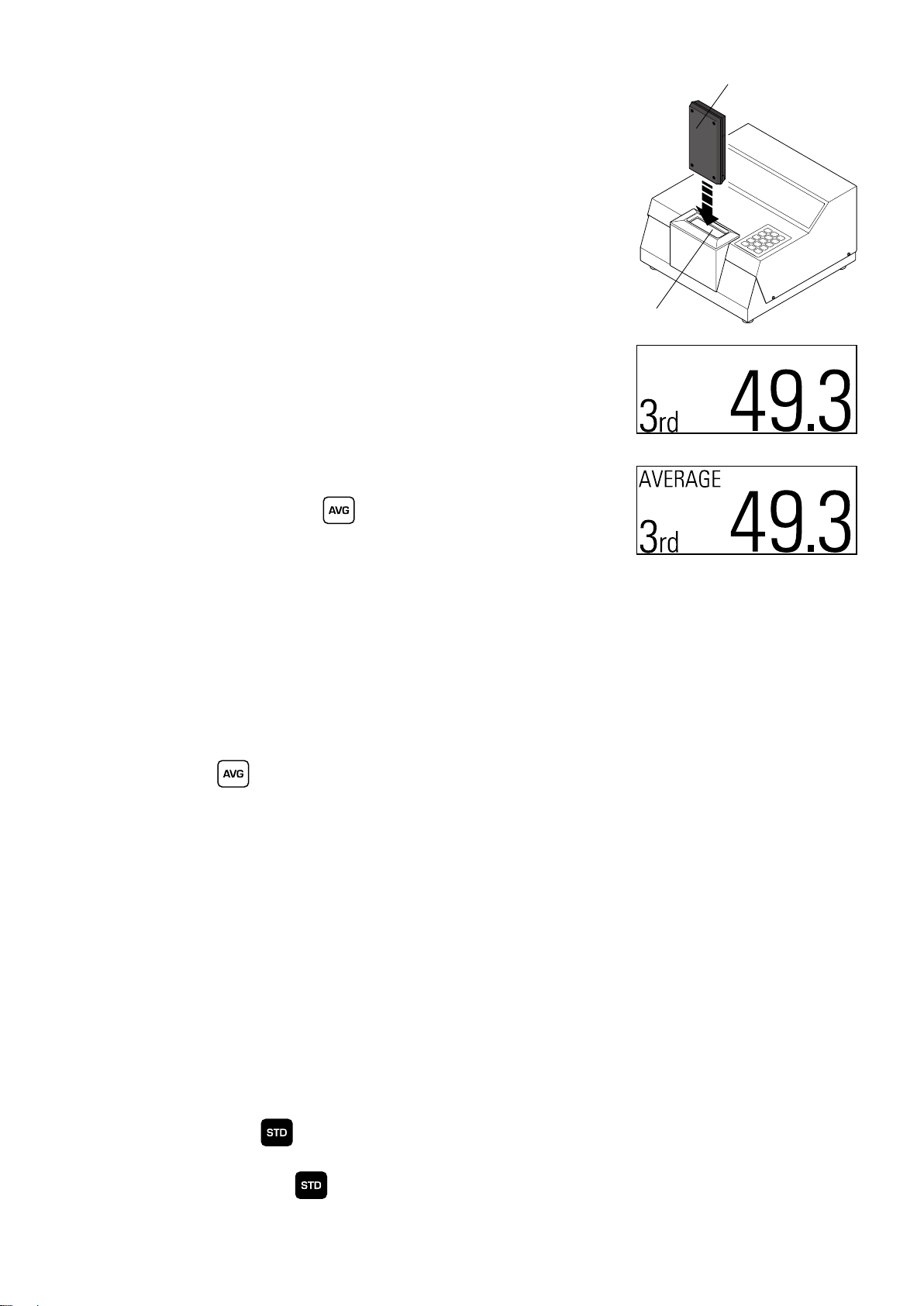

5-2. Inserting the Whiteness Standard Plate

Asshowninthegure,insertthewhitenessstandardplate

into the sample case slot on the main unit until it cannot be

inserted any further.

[Caution] The whiteness standard plate lid should never be

opened unless you need to clean the glass surface.

[Caution] Make sure the rice whiteness plate is facing in the

correct direction.

5-3. Starting Up the Main Unit

Turn the power switch located on the rear side of the main

unit to ON. "WARMING-UP" is displayed. You will see

numbersashingandafterapproximately20seconds,the

value of the whiteness standard plate is displayed. Once

the value of the whiteness standard plate is displayed,

remove the whiteness standard plate.

[Caution] If the whiteness standard plate is not inserted correctly

when the power switch is turned ON, the display will

repeatedly show "INSERT STD. "If this should occur,

insert the whiteness standard plate into the sample case

slot on the main unit until it cannot be inserted any further.

The C-600 is now ready for measurement.

5. Preparing for Measurement

Sample Case Slot

Whiteness Standard Plate

Rear Side