Neurtek PHT User manual

PHT Pencil Hardness Tester

INSTRUCTION MANUAL

NEURTEK S.L.

your supplier of instruments for quality control

Maintenance and Calibration Services

www.neurtek.com

Tel. 943 82 00 82

info@neurtek.com

Rev. 02/ Page. 1 of 5

NEURTEK S.A. RESERVES THE RIGHT TO CHANGE WITHOUT PRIOR NOTICE.

.

Ref. 0300200

Read this manual carefully before using the equipment.

PHT Pencil Hardness Tester

INSTRUCTION MANUAL

NEURTEK S.L.

your supplier of instruments for quality control

Maintenance and Calibration Services

www.neurtek.com

Tel. 943 82 00 82

info@neurtek.com

Rev. 02/ Page. 2 of 5

NEURTEK S.A. RESERVES THE RIGHT TO CHANGE WITHOUT PRIOR NOTICE.

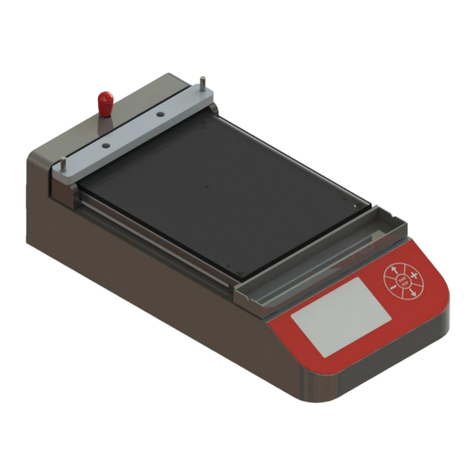

1 Description of the product

Equipment developed to test the scratch hardness of paints, inks, coatings and varnishes, also known as

the Wolff-Wilborn test. The equipment complies with ISO 15184 and ASTM D3363 regulations, among

others.

The device consists of a pencil holder supported by two rollers, the weight of which is adjusted to

ensure the force of the pencil acting on the tested surface is 7.5 Newtons.

It can also be supplied with a fitting that allows testing to 10 Newtons.

2 General information

Scratch test following the Wolff-Wilborn method, the pencils pass over the surface under pressure and

at a fixed angle to ensure minimum user error. The test is conducted using a fixed pressure of 7.5 N

and at an angle of 45 degrees.

The test is well regarded and used in sectors such as furniture and automotive paint and is also useful

for developing synthetic resins or other coatings.

The pencil holder ensures the test is consistent. The pencils can be changed easily to minimise

interruptions during the test.

3 Equipment components

The equipment is supplied with:

Carrying case including:

•Test pencil holder

•Set of 14 pencils: from 6B to 6H

•Pencil sharpener

Optional accessories:

•Set of 14 pencils (replacement)

•Set of three pencils with special hardness: 7H, 8H, and 9H

•Attachment for 10 N test

PHT Pencil Hardness Tester

INSTRUCTION MANUAL

NEURTEK S.L.

your supplier of instruments for quality control

Maintenance and Calibration Services

www.neurtek.com

Tel. 943 82 00 82

info@neurtek.com

Rev. 02/ Page. 3 of 5

NEURTEK S.A. RESERVES THE RIGHT TO CHANGE WITHOUT PRIOR NOTICE.

4 Carrying out the test

The surface to be tested should be prepared and correctly cleaned before beginning.

•Select the pencil

•Sharpen the pencil

oIt is essential that the point of the pencil is flawless, neither too thick nor over

sharpened (degree of sharpness). The pencil should be sharpened with a pencil

sharpener and rounded to ensure it can move backwards and forwards across a rough

piece of paper (not sandpaper or glass). Obviously, sharp edges must be avoided.

Levelling

It is important that the device is level for the test to be conducted correctly.

To ensure the device is level, place it vertically on a flat surface.

Place the pencil in its housing, until the point of the pencil touches the surface. Once the pencil is

correctly positioned, fix it in place with the side control.

This will ensure that when the device is horizontal, it will remain parallel to the surface to be tested.

•Carefully place the device in a horizontal position on the sample to be tested.

•Move the device forward by 6 to 12 mm, holding the device by the centre of the wheels with

your thumb and index finger, maintaining a steady speed.

PHT Pencil Hardness Tester

INSTRUCTION MANUAL

NEURTEK S.L.

your supplier of instruments for quality control

Maintenance and Calibration Services

www.neurtek.com

Tel. 943 82 00 82

info@neurtek.com

Rev. 02/ Page. 4 of 5

NEURTEK S.A. RESERVES THE RIGHT TO CHANGE WITHOUT PRIOR NOTICE.

The hardness of the surface is determined by the hardness of the pencil and the marks the pencil

makes.

We recommend conducting several tests, beginning with a softer pencil and gradually increasing the

firmness. Clean the surface with a damp sponge or soft cloth, to make it easier to see the results.

Two pencil hardnesses will register as marks on the surface. For example, a 6H-7H hardness means that

the 6H pencil marks the surface while the 7H pencil leaves a slight mark on the coating.

5 Accessory to test with 10 N

With this accessory we can carry out test of 10 N.

PHT Pencil Hardness Tester

INSTRUCTION MANUAL

NEURTEK S.L.

your supplier of instruments for quality control

Maintenance and Calibration Services

www.neurtek.com

Tel. 943 82 00 82

info@neurtek.com

Rev. 02/ Page. 5 of 5

NEURTEK S.A. RESERVES THE RIGHT TO CHANGE WITHOUT PRIOR NOTICE.

This accessory is very easily attachable to the main equipment:

•First level the equipment and hold the right pencil

•Next, you can install the PHT 10 N accessory by sliding the pins through the holes intended for

this purpose

•Lower it until it stops, and it will lock in its correct position

•Afterwards, you can perform the test as described in point 3, but now the equipment will

perform with a force of 10 N.

•To remove the accessory, you must proceed in the opposite way.

6 Maintenance and precautions

•The equipment is designed to be robust and hard wearing but should not be dropped or

knocked.

•Clean the equipment after each use, with a soft, dry cloth.

•Never use mechanical methods, brushes or abrasive paper to clean the equipment.

•Always use the carrying case to store the equipment when not in use

This manual suits for next models

1

Table of contents

Other Neurtek Test Equipment manuals