IEC Centra-CL3 Series User manual

I

j .

..

:'.>i

IE<:

.,

·'

.

'·

OPERATION·.··

MANUAL

OM3750

I

Revision 0

~~-i~~l~l~::~ge

Cit~

NC)//

~1e1.·

+;

2io~·ii•~

240

VAC,

60/60 Hz

~k-~I.~~~~

Cenbifuge

9~t.

No.~

..

·.·

•....

·.·

3765

.....

~

2~V~C.

·

60

Hz

C~tJ

ff:C)~

{

37.6

....

a29,

j$f)~

240 VAC,

50

Hz

(;•t•

~o.

37,7

....

aa~tVA(;,

60

Hz

..df.11~~

r

-·~UALITY

IEC

CENTRIFUGES

V"Jl.

IEC

INTERNATIONAL

EQUIPMENT

COMPANY

300 SECOND

AVENUE,

NEEDHAM HEIGHTS, MA 02194

U.SA

TEL.

(781) 449-8060

•TOLL

FREE (800) 843-1113

•FAX

(781) 444-6743

f

l

1 Introduction

1.1

General Product Description

Centra-CL3 series units are high-speed, multipurpose

centrifuges, used

in

medical, industrial, and scientific

applications.

The CL3 Series

is

available in two versions: ventilated

(Centra-CL3) and refrigerated (Centra-CL3R). Sections

of

this manual that apply

to

the refrigerated version will be

designated Centra-CL3R

or

refrigerated only.

Both units accommodate a wide variety

of

rotors, including

fixed angle, swinging bucket, and fixed horizontal designs.

They can process tubes, bottles, microplates, microcapillary

tubes, cytological slide carriers, and microsample tubes.

The units can centrifuge up to one liter

of

fluid in a single

operation.

Each centrifuge has an easy to use front panel that provides

two modes

of

operation: Manual and Programmed.

Manual mode

is

used for entering temperature (CL3R only),

speed/force, and time values for individual runs.

Program mode allows you to define and save a maximum

of

ninety-nine specific sets

of

run parameters, to recall and

reuse.

Centra-CL3 Series Operation Manual

1

I

t TABLE

OF

CONTENTS

.Centra-CL3 Series Operation Manual

.Chapter 1: Introduction

1.

1 General Product Description ............................................................................... 1

1.2 About this Manual .............................................................................................. 2

1.3

Warnings, Cautions,

and

Notes ........................................................................... 3

Chapter 2: Installation

2.1

Receiving the Unit .............................................................................................. 5

2.2 Site Preparation .................................................................................................. 5

2.3 Power Configuration........................................................................................... 7

2.4 Moving the Unit.................................................................................................. 8

2.5 The Front Panel .................................................................................................. 8

.Chapter 3: Operation

3.

1 Rotor and Accessories ......................................................................................

13

3

.2

Starting and Stopping a Run .............................................................................

17

3.3 Stored Programs............................................................................................... 20

3

.4

Centra-CL3 Series Refrigeration .......................................................................

21

3.

5 Diagnostic Messages and Error Codes ..............................................................

23

Chapter 4: Applications

4.1

Introduction......................................................................................................

25

4.2 Speed and Force Tables .................................................................................... 27

4.3

Derating for Dense Samples Table ....................................................................

36

4.4 Chemical Resistance Table ................................................................................ 39

4.5 Decontamination Table ..................................................................................... 40

4.6 RCF Nomograph ..............................................................................................

41

Chapter

5:

Maintenance

5.1

Introduction......................................................................................................

43

5.2 Care and Cleaning.............................................................................................

43

5.3

Cover Interlock Bypass Switch ......................................................................... 46

5.4 Condition

of

Returned Equipment..................................................................... 47

5.5

Warranty........................................................................................................... 47

Chapter 6: Specifications

Unit Specifications................................................................................................... 49

Centra-CL3 Series

Operation

Manual

I

The CL3 Series features a maintenance-free, brushless

motor, and an easy-to-use front panel, which provides three

versatile timing modes: automatic timed run, momentary

spin, and continuous operation (hold mode). Acceleration

and brake rates may be controlled,

to

optimize runs: rapid

for fast separations or slow for delicate samples. Repeat

runs, with the same speed and time settings, may be

achieved at the touch

of

a

key.

A fail-safe cover interlock insures that

the

cover is closed,

before a run can begin, and keeps the cover closed, until the

rotor has reached a safe low speed (below 100 rpm), even in

the event

of

a power failure.

The rugged steel cabinet and rigid construction provide

quiet operation and long term reliability.

1.2 About This Manual

The Operations Manual contains all

of

the

information

needed to install, operate, and maintain a CL3 Series

centrifuge. Refrigerated and ventilated models operate

similarly, and any differences are highlighted and noted,

throughout this manual. This manual, also, contains speed

and force, derating, chemical resistance, and

decontamination tables. The last chapter lists the units'

specifications.

This manual

is

written for centrifuge operators. In addition

to operation information, it contains a few basic

troubleshooting techniques, and a chapter on maintenance.

This Operation Manual

is

not a guide for servicing

centrifuge units.

Centra-CL3 Series Operation Manual

2

..

.t

,!

~·,

."

! ;

I

1.3 Warnings, Cautions, and Notes

The tenns warning, caution, and

note

have specific

meanings

in

this manual.

• A

Warning

advises against certain actions

or

situations

that could result

in

personal injury.

• A

Caution

advises against actions

or

situations that

could damage equipment, produce inaccurate data, or

invalidate a procedure.

• A Note provides useful infonnation regarding an

operation, function,

or

procedure.

Centra-CL3 Series OperationManual

3

2 Installation

t

- !

-

2.1

Receiving the Unit

·

2.2

Site Preparation

International Equipment Company (IEC) ships the

centrifuge

in

a carton that protects it from shipping hazards.

Follow the unpacking instructions on the carton.

Be

sure

to

complete and return the postage-paid warranty card.

The unit normally resides on a bench top. The Centra-CL3

(ventilated model) can be placed

in

a cold room (no colder

than 0°C), for processing temperature-sensitive samples.

When you remove the centrifuge from a cold environment,

do not operate for a minimum

of

two hours, so that any

condensation will evaporate.

Note: When used

in

a cold room environment, some bearing

noise may become evident. The bearing lubricant thickens

at low temperatures.

As

the centrifuge speeds up, it

is

thinned and distributed more evenly. Once this occurs, any

noise should subside.

Centra-CL3 Series Operation Manual

s

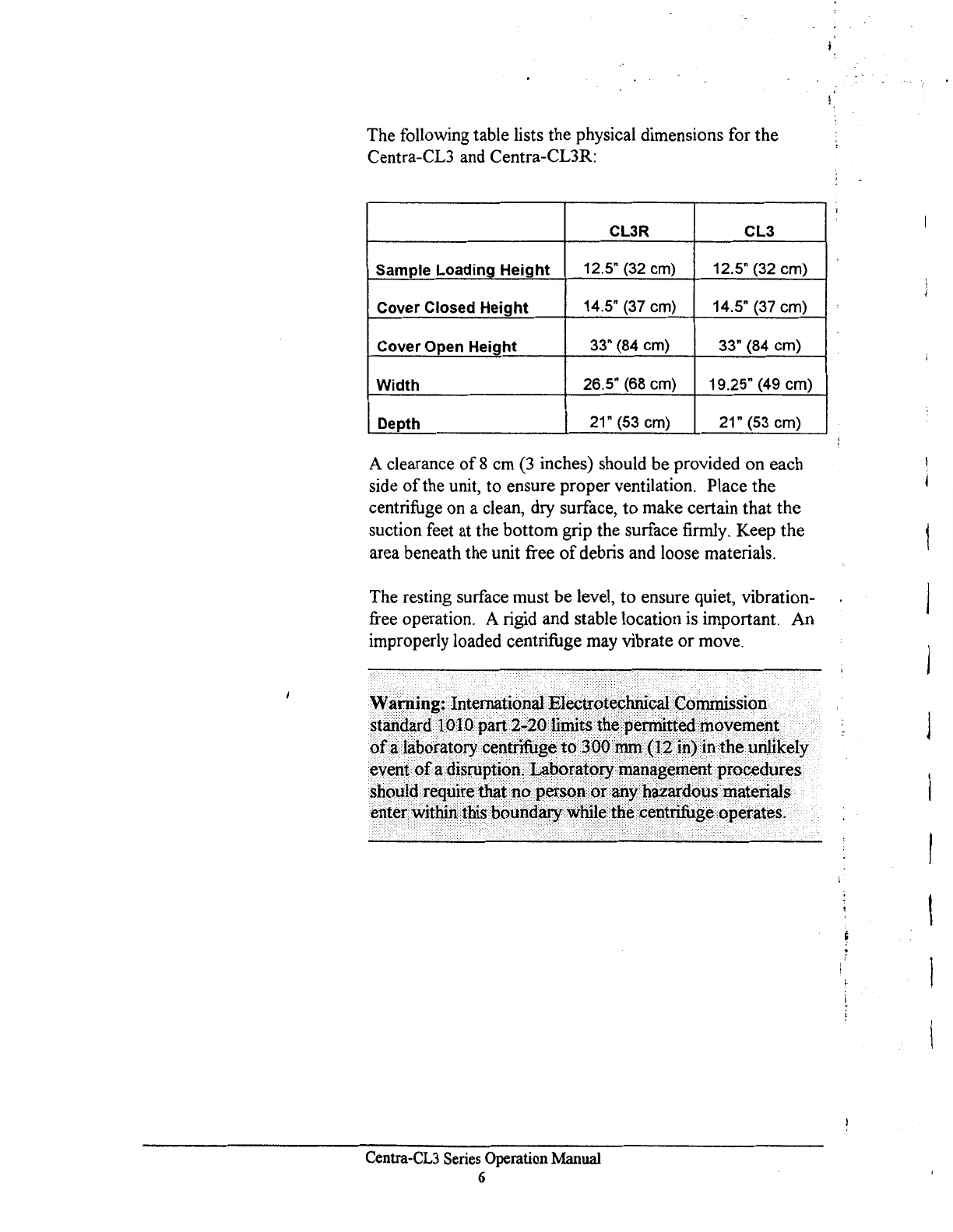

The following table lists the physical dimensions for

the

Centra-CL3 and Centra-CL3R:

CL3R

CL3

Sample

Loading

Height

12.5" (32 cm) 12.5" (32 cm)

Cover

Closed

Height

14.5" (37 cm) 14.5" (37 cm)

Cover

Open

Height

33" (84 cm) 33" (84 cm)

Width

26.5" (68 cm) 19.25" (49 cm)

Depth

21" (53 cm) 21" (53 cm)

A clearance

of

8 cm (3 inches) should

be

provided on each

side

of

the unit,

to

ensure proper ventilation. Place

the

centrifuge on a clean, dry surface,

to

make certain that

the

suction feet at the

bottom

grip the surface firmly. Keep

the

area beneath the unit free

of

debris and loose materials.

The resting surface must

be

level,

to

ensure quiet, vibration-

free operation. A rigid and stable location is important. An

improperly loaded centrifuge may vibrate

or

move.

~al"Jling;·.•1nternationa1••~lectrot~(;hnlcal

••

G<)nunission•.

~t3#4?rcf•i<no••part;·g¢20•A#rlt8••th~

pe~tie<l••rti()velJleJ1~•

•

<>fa.•fabol"atc>&·•ce11trifUge••t()•$QQ~H@IP)iri·the••uillikely

•:JZQ~ai;e~~~~~t~~1;~~;~~rl~~i~~sP~1i:!~zs•.

eriier•\ViiliiJit~•·bqun(iaw.W-lii~~

tp~

petit#fuge

qperat~s.

Centra-CL3

Series

Operation

Manual

6

2.3

Power Configuration

Power Cord

Circuit Breaker

The CL3 Series uses

AC

power in different configurations,

appropriate for use throughout the world. Please check

the

catalog number

of

the model that you have purchased,

to

ensure that the machine you have is the proper power

configuration. Forbest results, the refrigerated centrifuge,

Centra-CL3R, should be used

on

a dedicated line.

Variations in line voltage

or

frequency affect the

unit's

speed and other characteristics. Less than nominal line

voltage may prevent the centrifuge from reaching maximum

published specifications

of

speed and/or temperature.

Power line voltage, at some locations, may sag, when

the

refrigeration system turns on.

The unit requires a grounded power supply

(3

prong

outlet).

If

your facility does not have grounded

power

outlets, arrange for a proper grounding. The power

cord

plugs in on the left rear side

of

the unit.

~=~o~=:i:ili~~~t~~~e

powerplug tbatdoes not

have

~

gr~Undilig

pin.

··

·.···

··

The

power

cord

provided withthetiJlltiscorrectly rated

forthe

highest

current

demand.

This

poweirord.shouldJ1ot

be

interchanged

with

cords

from

equipinentwitb.Jower current

demand.

Exchange

of

power

cords

befiVeell

equipment•may

createa

fire

hazard.

The system provides

an

automatic circuit breaker, for

emergency situations, such as power surges, that could

damage the unit.

If

the circuit breaker trips:

1.

Unplug the unit.

2.

Press the white button, on the left side

of

the unit.

3.

Plug the unit back

in.

Centra-CL3 Series Operation Manual

7

2.4 Moving the Unit

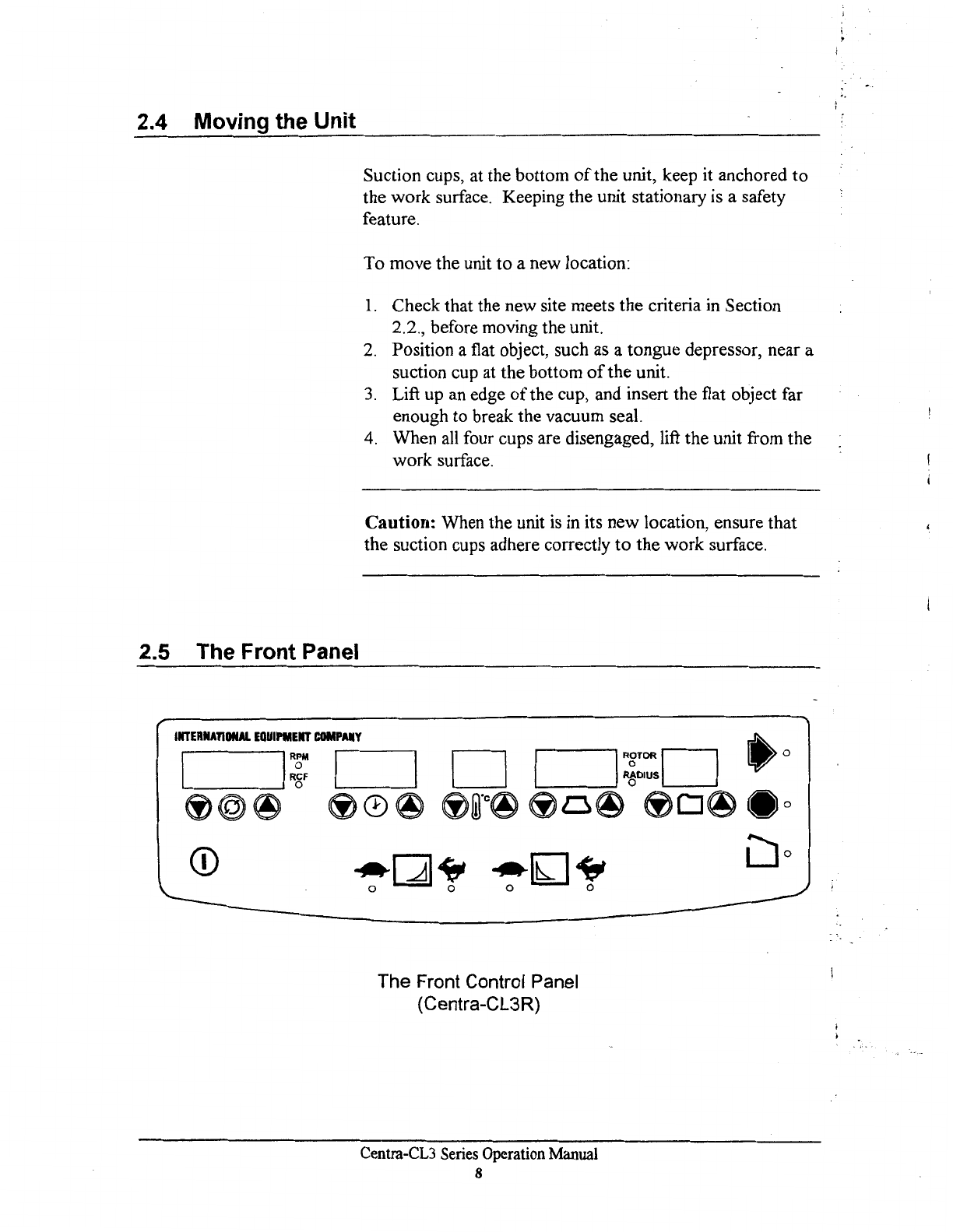

2.5 The Front Panel

©

Suction cups, at the bottom

of

the unit, keep it anchored

to

the work surface. Keeping the unit stationary is a safety

feature.

To move the unit to a new location:

1.

Check that the new site meets the criteria

in

Section

2.2., before moving the unit.

2.

Position a flat object, such as a tongue depressor, near a

suction cup at the bottom

of

the unit.

3.

Lift up

an

edge

of

the cup, and insert the flat object far

enough to break the vacuum seal.

4.

When

all

four cups are disengaged, lift the unit from the

work surface.

Caution: When the unit

is

in

its new location, ensure that

the suction cups adhere correctly to the work surface.

The Front Control Panel

(Centra-CL3R)

Centra-CL3

Series

Operation

Manual

8

© On/Off

key:

The On/Offkey must be activated,

to

enable

use

of

the front panel. This key applies power

to

the

control panel and refiigeration system (Refrigerated model

only). The On/Offkey is inoperative during actual runs.

Stop a run with the STOP key. Refrigerated models

display chamber temperature whenever they are plugged in,

but will not cool down

if

the unit

is

off

The red STOP

light indicates that the centrifuge is plugged

in.

The control panel contains numeric displays for

RPM/RCF

(Speed/Force), Time, and Temperature (Refrigerated only).

These displays have

two

states

or

modes: Actual (bright

display) and Set (dim display).

In Actual mode (bright display), they indicate current run

conditions, such as:

• rotor speed

or

force

• elapsed time of,

or

time remaining

in,

the run

• actual temperature (Refrigerated only).

In Set mode (dim display), the display indicates the desired

settings for the run. Set mode

is

operative:

• whenever you use the up and down arrows

• briefly, at the start

of

a run

• briefly, after the unit

is

switched ON

The display

is

bright, when it shows Actual run conditions.

The display

is

dim, when it shows Set parameters.

The

numeric displays can, also, display warning

or

error

messages (see Section 3.5). Descriptions

of

the displays

appear on the following pages.

Centra-CL3 Series Operation Manual

9

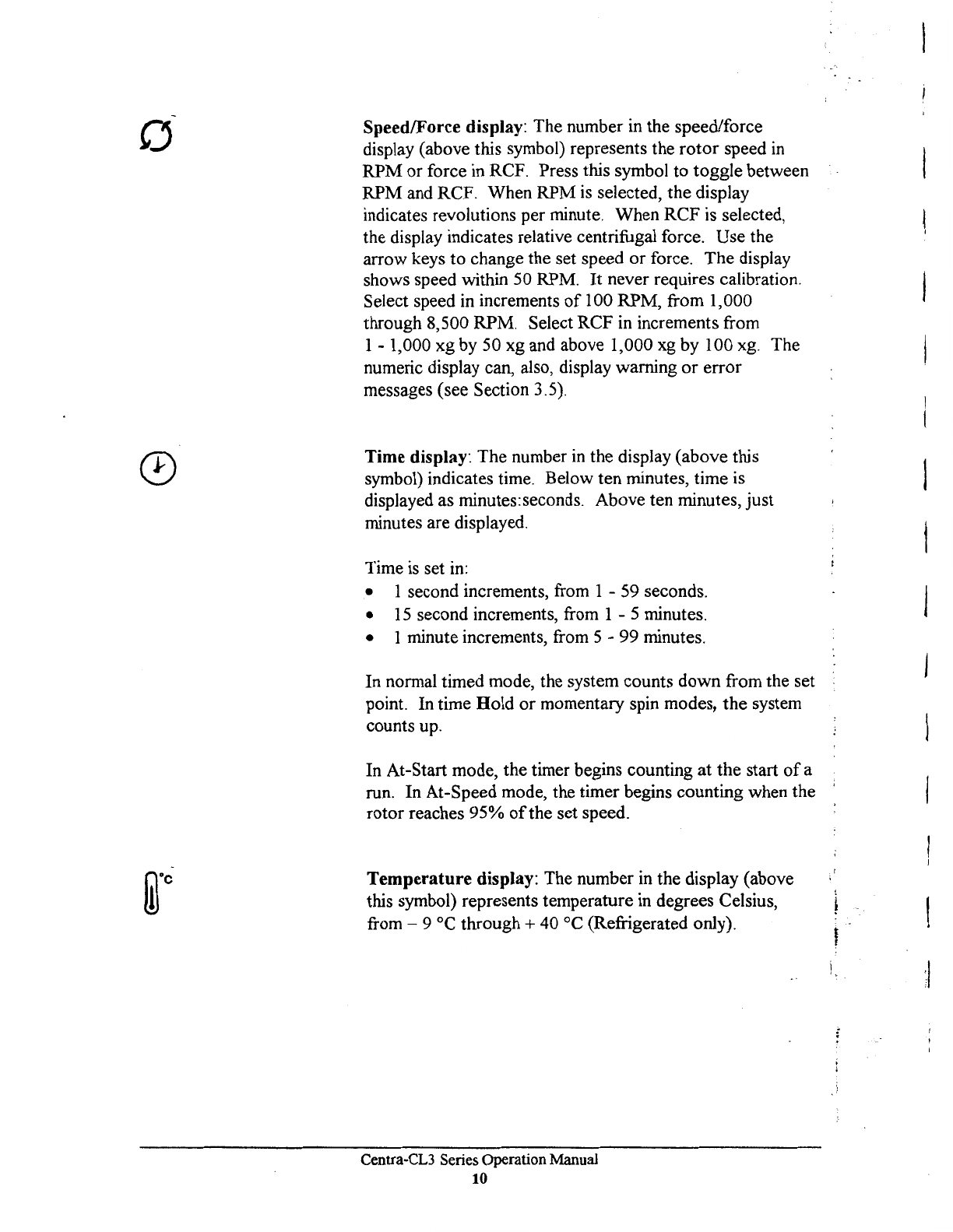

0 Speed/Force display: The number in the speed/force

display (above this symbol) represents the

rotor

speed

in

RPM

or

force in RCF. Press this symbol

to

toggle between

RPM

and RCF. When

RPM

is selected, the display

indicates revolutions per minute. When

RCF

is selected,

the display indicates relative centrifugal force.

Use

the

arrow keys

to

change the set speed

or

force.

The

display

shows speed within 50 RPM. It never requires calibration.

Select speed in increments

of

100 RPM, from 1,000

through 8,500 RPM. Select RCF in increments from

1 - 1,000 xg by 50 xg and above 1,000 xg by 100 xg. The

numeric display can, also, display warning

or

error

messages (see Section 3.5).

Time display: The number

in

the display (above this

symbol) indicates time. Below ten minutes, time is

displayed as minutes:seconds. Above ten minutes,

just

minutes are displayed.

Time is set

in:

• 1 second increments, from 1 -

59

seconds.

•

15

second increments, from 1 - 5 minutes.

• 1 minute increments, from 5 - 99 minutes.

In normal timed mode, the system counts

down

from the set

point. In time

Hold

or

momentary spin modes,

the

system

counts up.

In At-Start mode, the timer begins counting

at

the

start

of

a

run. In At-Speed mode, the timer begins counting when the

rotor

reaches

95%

of

the set speed.

Temperature display: The number

in

the display (above

this symbol) represents temperature

in

degrees Celsius,

from - 9 °C

through+

40 °C (Refrigerated only).

Centra-CL3 Series Operation Manual

10

:I

Program

key: This key saves the currently displayed

desired settings as stored programs I through 99 (see

Section 3.3). The numeric display (above this symbol)

shows the stored program number and mode

of

operation

(see Section 3.2).

Rotor/Radius

Key: The display (above this symbol)

indicates the selected rotor number

or

the

rotor radius,

in

centimeters. The rotor/radius key toggles between the two

displays. The applicable IEC rotor numbers are supplied

in

the memory, along with their maximum radii, in

centimeters. To select a rotor number, toggle

to

ROTOR,

and press an arrow key under the rotor/radius display. To

change the radius, toggle to RADIUS, and press an arrow

key under the rotor/radius display.

Note

that the radius

cannot be changed to a radius larger than the maximum

radius,

or

less than the minimum radius, for the selected

rotor.

Use the arrow keys to view or change the Set parameters

for Speed/Force, Time, Temperature (Refrigerated only)

Rotor/Radius,

or

Program. The first time the key is

pressed, the numeric display switches from Actual readings

to Set parameters, without changing them.

If

you press the

key a second time, the selected parameter increases

or

decreases once for each depression.

If

you hold the key

down, the setting

will

keep changing, until you release the

key.

The longer you hold the key, the more rapidly the setting

changes. Hold a key down, to approach a desired setting.

Then, press the up or down key, repeatedly, to select the

exact setting. When you release the arrow keys for

3 seconds, the display returns to the Actual readings.

Centra-CL3 Series Operation Manual

11

Acceleration and Braking

•

Gentle acceleration and braking can be selected, when

centrifuging delicate samples. The gentle settings avoid

mixing

of

density gradients

or

breakup

of

pellets.

This key controls rotor acceleration up to 400 RPM.

If

the

yellow light over the rabbit is lit,

full

acceleration

is

selected.

If

the yellow light over the turtle

is

lit, slow

acceleration

is

selected. Slow acceleration takes from

15

to

35 seconds to achieve 400 RPM, depending on the rotor

and its contents. After 400 RPM,

full

acceleration

is

applied, until the set speed is reached.

This key controls rotor braking.

If

the yellow light over the

rabbit

is

lit,

full

braking

is

selected.

If

the yellow light over

the turtle

is

lit,

slow braking is selected. (This means the

rotor

will

coast down from 600 RPM.)

If

both lights are

out,

all

braking is disabled; and the rotor

will

coast from

operating speed to a stop.

This key starts a run. A run is governed by the Set

parameters (manual

or

programmed). The associated green

light blinks, until the rotor reaches 95%

of

the set run

speed. The light stays on until the end

of

the run.

This key stops a run. (A run will, also, stop automatically

when the set time has elapsed

or

the start key

is

released, in

momentary mode.) The red light will flash, to indicate the

rotor

is

still slowing down (braking

or

coasting). When the

run ends, the red light stays on, indicating that the rotor has

stopped.

This key unlocks the cover. This key

is

inoperative

if

a run

is

in

progress. Pressing it will not stop the run. The cover

will not unlock, until the rotor has slowed to below 100

rpm. The cover will open automatically, on ventilated units

only, at the end

of

a run.

Centra-CL3

Series

Operation Manual

12

l

l

}

I

l

1

3 OPERATION

3.1

Rotor and Accessories

A balanced

lo.ad

is

essential for all centrifuges.

An

unbalanced load produces vibration, and can damage the

unit. A 2 gram load imbalance, at a speed

of

4600 RPM,

imparts force equivalent to

9.

I kg (20 pounds) at rest.

Always ensure that the rotor is loaded symrn.etrically, with a

full

complement

of

accessories, and a

full

(or paired) set

of

tubes. Tube adapters should also be installed symmetrically.

IEC rotors are dynamically balanced at the factory. IEC

matches removable parts (trunnion rings, shields, buckets,

and carriers) to within I gram, and stamps the weight on

each piece. Check these markings, whenever you

interchange parts, to ensure that opposite parts are matched.

Ensure that the total weight

of

samples and removable

parts, loaded

in

opposing positions, are equal

in

weight, to

within 1 gram. The position numbers, present on many

rotors and adapters, identify opposing tube positions.

To

obtain good dynamic balance, opposite loads must not

only be equal

in

mass, but must, also, have the same centers

of

gravity. Opposing containers must be alike

in

shape,

thickness, and distribution

of

glass

or

plastic. This

is

especially important for large containers.

Centra-CL3 Series Operation Manual

13

Rotor Balance

Tubes loaded into swinging bucket

rotors

must be

symmetric, around the

ax.is

of

rotation. Verify this by

rotating the entire rotor 180°,

by

hand.

The

loads should be

in

the same apparent positions (not mirror images). In

addition, the loads within each bucket must, also, be

symmetric around the bucket's pivot axis. Verify this

by

ensuring that each bucket

is

loaded so that it does not tilt

from the vertical, when the rotor is

at

rest. Maintaining

balance within each bucket ensures that

the

bucket and the

tubes swing out to horizontal, when

the

rotor reaches

operating speed, applying centrifugal force toward the

bottom

of

the tubes. Failure to achieve full swing-out

causes vibration and premature wear

of

the rotor and the

motor.

Samples oflike (similar) specific gravities may be processed

in

the same run, provided that the samples

of

the same type

are balanced around the rotor, as though they were the only

pairs

in

the rotor.

Caution:

Do

not exceed maximum rated speed for each

rotor/accessory combination. Maximum rated speeds can

be found

in

Section 4.2 -Speed

And

Force

Tables.

Load tubes

in

the following manner:

1.

Load two tubes at positions:

9

and

18.

2. Load four tubes at positions:

1,

5 and 10,

14

or

7, 3 and 16,

12

3.

Load six tubes at positions:

1,

9, 5 and 14, 18,

10

or

7, 9, 3 and 12, 18,

16

4.

Loading

an

odd number

of

tubes is not

recommended.

Centra-CL3 Series Operation Manual

14

I

I

Ir -

V~ration

(

Rotor Installation

I.

PRESS

UP

HERE

AND

HOLD

Rotor Removal

All

centrifuges have critical speeds, at which vibration

occurs.

As

the

speed increases, beyond

the

critical speed,

vibration will cease. This inherent condition, also,

occurs

during deceleration. An imbalanced load intensifies

these

critical vibrations. Do not continuously operate this

centrifuge at observed critical speeds.

To

install the #243 rotor:

1.

Press the disk (located

on

the

underside

of

the

rotor)

to

the rotor.

2. Slide the

rotor

over

the shaft, until it snaps into place.

Release

the

disk.

3. Pull the rotor straight up, to insure a positive lock.

3.

PULL

STRAIGHT

UP

ON

ROTOR

TO

CONf

IRM

SECURE

ATTACHMENT

0 0

2.

SLIDE

ONTO

SHAFI

AND

RELEASE

To remove the 243 rotor:

1.

Press the disk (located on the underside

of

the

rotor)

to

the rotor.

2.

Lift the

rotor

straight up.

3.

Release the disk.

Centra-CL3 Series Operation Manual

15

Rotor Adapter To install the shaft adapter for an existing rotor:

1.

Press the adapter disk, and slide the adapter over the

rotor shaft. Release the disk.

2.

Pull the adapter straight up, to insure a positive lock.

3.

Align the rotor keyway with the key on the shaft

adapter, and place the rotor onto the adapter.

4.

Tighten the rotor locking nut (with the provided

wrench), until it tightly engages the rotor.

To remove existing rotors from the shaft adapter:

1.

Remove any sample tubes, shields, buckets, and other

accessories, from the rotor.

2.

Unscrew and remove the locking screw.

3.

Grasp the rotor, and rock

it

front-to-back, and side-to-

side.

4.

Remove the rotor from the shaft.

Centra-CL3

Series

Operation

Manual

16

3.2 Starting

and

Stopping a

Run

Read Section 2.5, for a general description

of

the front

panel. The settings displayed on the front panel always

govern the operation

of

the unit. 'fhe number

or

symbol,

above the Program icon, shows the unit's operating mode.

It is important that the unit be in the correct mode for the

desired operation.

These digits and symbols are displayed above the program

icon. They can be any

of

the following:

blank The unit

is

in

manual operation.

1-99 The unit

is

under control

of

the displayed stored

program number.

C The unit

is

set to Rapid Condition, a special

program discussed

in

Section 3.4.

The display indicates the last parameters selected for each

Program mode operation.

Centra-CL3

Series

Operation

Manual

17

Manual Operation

For

manual operation, set the mode so that the display

above the Program icon

is

blank. Select the desired

temperature (CL3R only), speed/g-force, run time,

acceleration mode, and braking mode. Press START, to

start the spin.

The minutes display counts down, and displays the time

remaining

in

the current spin, during manual operation.

The specified run time begins when the

START

key

is

pressed,

or

when the rotor reaches 95%

of

set speed (see

Timing Mode). Braking begins when the elapsed time

reaches this desired setting. Run time does not include

braking time.

The spin

will

stop automatically, at the end

of

the desired

interval. A run can, also, be stopped, at any time,

by

pressing the

STOP

key.

The settings can be changed during a manual run. These

changes affect the run

in

progress.

If

the time setting is

changed, during a run, the unit adjusts the count-down

timer, to display the revised setting as the total time

of

the

run.

If

the new time selected

is

less than the elapsed time,

the run

will

end.

The unit's mode (settings) cannot be changed during a

program mode spin.

Centra-CL3

Series

Operation Manual

18

- j

.Timing Mode Fourtiming modes are available on these units:

To

select a

timing mode, press the down arrow, under the time display,

until the time goes below zero, and the appropriate symbol

is

displayed.

Momentary

Mode

(--)

-Momentary spin is useful for

easily separated samples, for simultaneous mixing

of

samples, and

to

deposit condensate droplets at the bottom

·of

the tube.

For

momentary spin, set the mode so that three dashes (---)

appear above the Clock icon. Select temperature

(CL3R

only), speed/g-force, acceleration mode, and braking mode,

as for manual operation.

Press and hold the

START

key.

The run starts when you

press the key, and ends when you release the key. In this

mode, you can perform very quick separations

or

protocols.

During a momentary spin, the unit displays actual values,

not desired settings. The time display counts upward, and

displays the elapsed time since the

START

key was

pressed.

Hold

Mode

(HLd)

-

For

hold mode (operation without

preset time limit), set the mode so that

HLd

appears in the

Time display.

Select temperature (CL3R only), speed/g-force, acceleration

mode, and braking mode, as with manual operation. Press

and release the

START

key. The run starts when you press

the

key,

and stops only when you press the

STOP

key.

Hold mode

is

like manual operation, except that the time

setting

is

not used. During a run

in

hold mode, the time

display counts upward, and displays the elapsed time

of

the

spm.

At-Start

Mode

(ACC) -The set time

will

start counting

down

at

the beginning

of

acceleration (when the start key

is

pressed). The unit

is

originally set to this mode.

At-Speed

Mode

(SPd) -The set time

will

start counting

down, when the rotor has reached 95%

of

set speed. The

display

will

alternately show the set time and SPd, during

acceleration to 95%

of

the set speed.

Centra-CL3 Series Operation Manual

19

This manual suits for next models

1

Table of contents

Other IEC Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

Hanna Instruments

Hanna Instruments Groline HI981413 instruction manual

Bego

Bego Gelovit 200 Translation of the original instructions

Hanna Instruments

Hanna Instruments HI922 instruction manual

biochrom

biochrom EZ Read 400 quick start guide

Julabo

Julabo EH operating manual

Sutter Instrument

Sutter Instrument TRIO MP-245A Operation manual

NuAire

NuAire LabGard NU-543-300J Operation and maintenance manual

Kendro

Kendro Heraeus Biofuge haemo Instructions for use

Graco

Graco GCI Series instructions

Tecno-gaz

Tecno-gaz Multisteril Fast Technical manual

Parker

Parker Domnick Hunter 060 Series user guide

Zimmer Biomet

Zimmer Biomet GPS III Processing instructions