IEC MASH BATH User manual

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1

THE ‘IEC’ MASH BATH

This manual covers all models for 2019

Designed and Manufactured by : Industrial Equipment & Control Pty. Ltd.

. Melbourne

Australia.

MASHB-2018-02-01.pdf

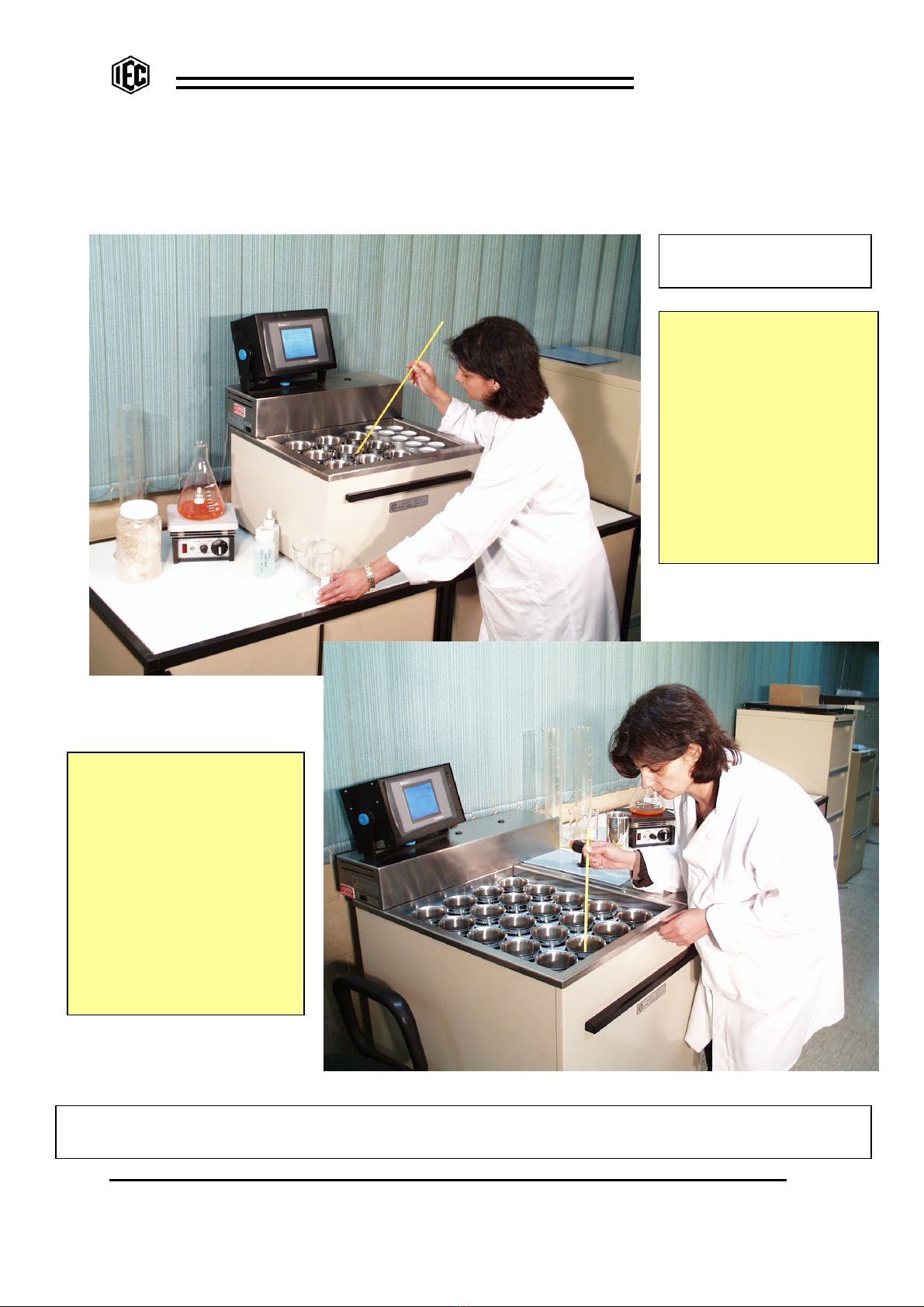

BENCH MODELS:

6, 9, 12 and 16 head.

Image shows 9 Head,

with ‘touch panel’

control system and

distilled water heating

tubes.

Belts are no longer

used for stirrer drives.

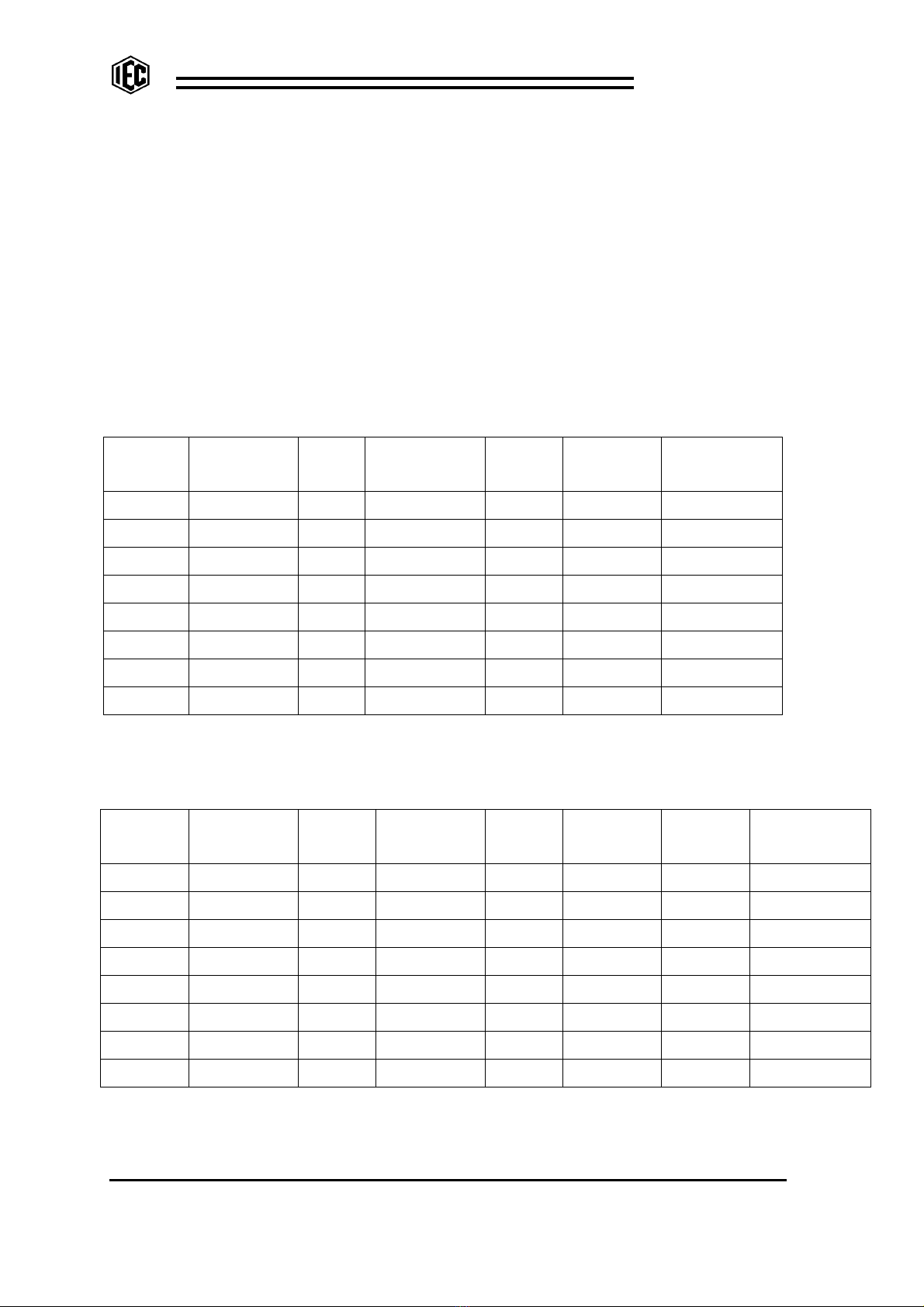

FLOOR MODELS:

16, 20, 25 and 30 head.

Image shows 20 Head,

with ‘touch panel’ control

system and distilled

water storage and

dispensing.

Belts are no longer used

for stirrer drives.

Models 290 & 290/530

: belt free stirrer drive

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

2

Bench models do not have distilled water storage or dispensing, but the

special bath lids carry tubes to carry distilled water that heat with the

bath and are used to add volume to the sample as required.

Floor standing models have temperature controlled distilled water

storage and a quick action dispensing system.

All models are controlled by a

‘touch panel’ system that

eliminates all buttons and

switches. The program is

visible to the user as a graph

with a ‘time line’ progressing to

indicate the status.

All the required information is

displayed and all programs can

be fully edited to suit the

requirements of the laboratory.

Floor models are

complete with a rugged

dispensing gun which is

used to initially fill the

pots and to add the

distilled water during the

mash, if required.

The gun is fitted with a

press switch which

initiates the discharge of

the correct volume of

distilled water at the

correct temperature as

set in the program.

The gun is neatly parked

in a receptacle in the

removable cover of the

storage tank.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

3

GENERAL DESCRIPTION:

A high quality, electronically controlled Mash Bath containing up to 8 selectable programs

that relate bath temperatures with times. The IEC Bath is carefully designed to

automatically perform the standard mash sequences as required by the various brewing,

barley, malt and cereal industries, however its versatility permits it to be easily programmed

for variations to these standard tests.

Some of the features of the ‘IEC’ Mash Bath are:

ALL MODELS:

•Fully adjustable touch screen controller is mounted above the rear cover to provide a

narrow machine with small footprint. Screen can be angled to suit any user. If

desired, the controller can be removed from the machine and mounted remotely.

•Fully sealed ‘wipe clean’ touch screen with no knobs or switches to clean.

•Outer panels are easy to remove and tools not required. All the front and side

panels are powder coated for excellent resistance to corrosion.

•Machine can be supplied for either single or three phase power.

•Stainless Steel construction and the whole design has been developed for easy

access and quick and simple maintenance.

•Very strong but quiet magnetic stirrers stir the mash samples from below the tank

and 30 to 40mm long laboratory ‘spinbars’ can be used in each sample pot.

•Stirrers are driven directly by independent motors. Belts and pulleys are no longer

used. If one drive should fail, it is automatically shut down without disturbing any

other drives. Drives are easily replaced in minutes.

•The temperature / time ramping of the bath is held to close accuracy.

•The bath automatically preheats the water to the programmed temperature and

provides an audible alert to advise when preheat is achieved.

•All audible alerts can be silenced or reinstated by the momentary press of a button

and can be altered in loudness to suit the environment.

•Different programs are easily created and any program can be selected by the touch

panel controller. Even the names of the programs can be edited to suit your lab.

•The special IEC designed bath lid accepts ‘Industry Standard’ 500ml stainless steel

beakers (pots). The lid seals grip gently to the pots to hold them firmly against

floating when empty and to prevent unwanted steam in the laboratory. The lid is

easily removable without tools for cleaning but cannot be dislodged when fitted for

operation.

•The sides of the bath are lagged to conserve energy.

•At the end of the selected program, a selectable cooling option is provided for either

a hot bath finish or to cool the samples slowly or to cool them quickly.

•The samples are stirred by magnetic stirrers below the tank. Automatic ON / OFF /

INTERMITTENT control over the magnetic stirrers is part of each program but

manual override is also provided.

•The ‘IEC’ Mash Baths have our specially designed quiet circulation pumps that run

fully immersed inside the main and the distilled water tanks for best temperature

control and for reduction in the complexity of pipes and hoses.

•Good bath circulation ensures accurate temperature through the whole bath.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

4

FLOOR MODELS:

•Floor models are mounted on small wheels for ease of moving for cleaning.

•The cabinet provided below the bath is for storage of Mash Beakers (pots), lab

equipment and spare parts.

•The distilled water is either gravity or pressure filled automatically from the

laboratory’s supply, which is sometimes mounted on the wall. Water level and

circulation in this tank is automatically controlled and the distilled water is

temperature held to within +/- 0.3 degrees. The tank is fitted with a cold water heat

exchanger coil for quick cooling of the distilled water between mashes. This cooling

can be instigated within the program to have the distilled water cold at the end of the

program. This avoids delays between mashing cycles..

•A special hand held gun with press switch dispenses the correct volumes of distilled

water into the pots as required both prior to mashing and at the ‘top-up’ time during

the cycle. An alert sounds at exactly the correct moment to remind the operator to

dispense the water. By using the touch screen in EDIT mode, the d/w volumes are

edited into each program to relate to the correct step.

•The dispensed distilled water volumes in millilitres are normally set inside each

program, however pressing a special button permits a manual setting to override the

programmed volumes without requiring a change to a program.

•All the larger sized floor mounted machines fit through standard width doorways.

IEC designs and manufactures a range of excellent Mash Baths:

Floor mounting Mash Baths for 16, 20, 25 or 30 Pots with magnetic stirring and distilled

water storage, temperature control and automatic dispensing.

Bench mounting Mash Baths for 6, 9, 12 or 16 Pots with magnetic stirring but without the

distilled water and dispensing facilities, but all other design features are retained.

FITTING THE CONTROLLER:

The machine is supplied with the control housing separate. It is complete with a ‘U’ shaped

support bracket that can be fixed to the top surface of the cover in up to 3 places

(depending on the machine model). The controller can be mounted remotely if desired and

an extra black ‘dress screw’ is provided in the spare parts to fill the unused hole in the cover.

To shift the position of the control unit, unclamp the blue locking knobs on the sides of the

controller and slide the controller from the ‘U’ bracket.

Take the bracket and position it in the preferred position on the cover. Remove the plastic

‘dress screw’ from the hole in the cover and use the blue clamp knob supplied to fix the

bracket to the cover tightly, but so it is able to twist a little if firmly forced.

Take the controller and re-position it into the slots in the bracket and tighten the clamp

knobs firmly. Adjust the controller’s twist and tilt to suit the operator’s viewing.

Take the cable at the back of the machine and engage the multi-pin plug to the larger

socket at the rear of the controller. Tighten the security screws.

NOTE:: Floor models use 2 cables but only one cable and socket is

used on the bench models.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

5

GENERAL INSTALLATION INFORMATION:

Bench mounting units are placed on the bench and are often used with sink to either the left

or right side of the machine. Floor machines are mounted on small wheels so that they can

easily be moved into and out of the laboratory location for cleaning or maintenance.

Electrical Services Required:

Standard voltages listed below. Machines frequency can be either 50 or 60 Hz. Please

contact IEC for other voltages if required.

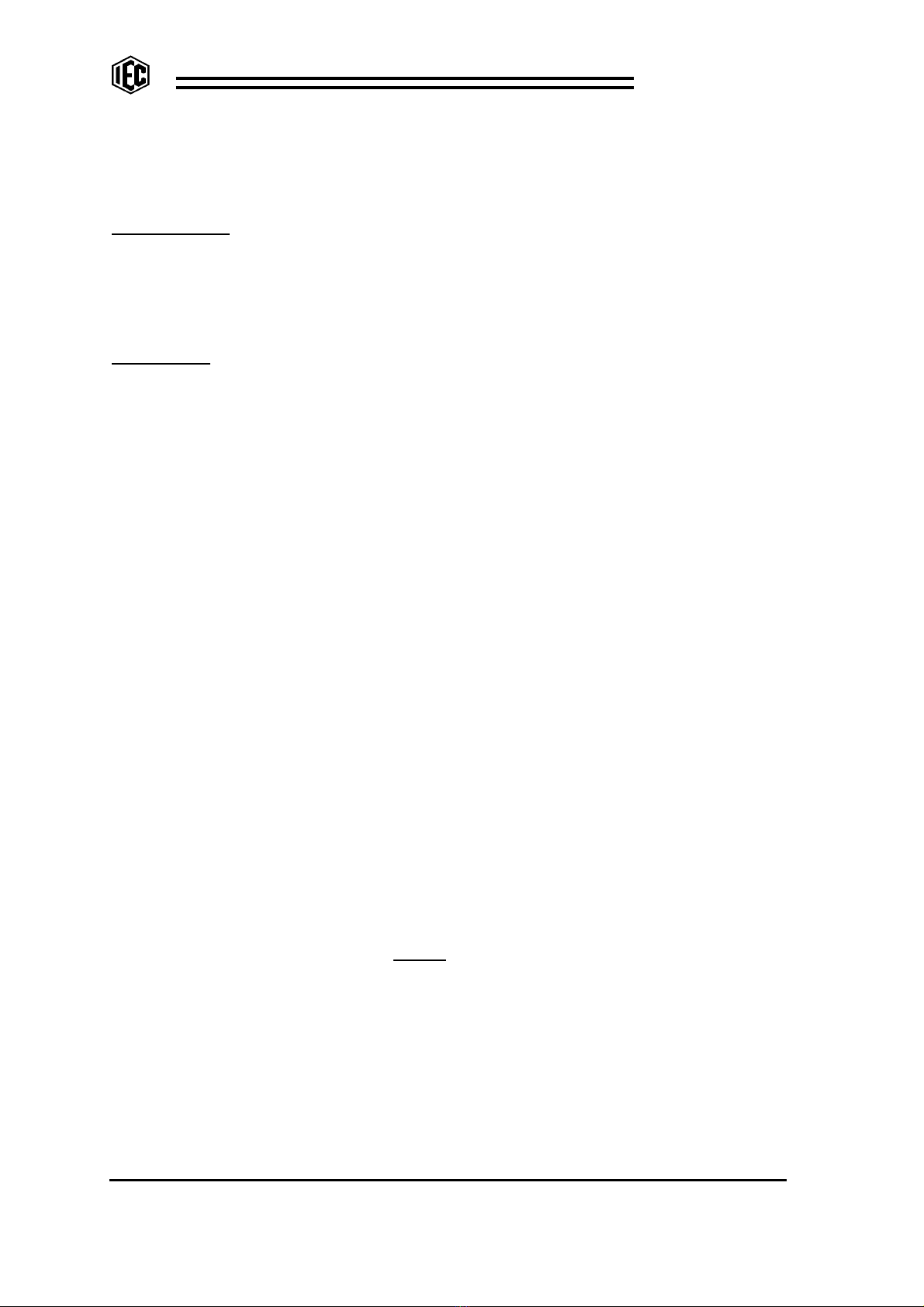

BENCH MOUNTING MODELS:

SIZE SINGLE

PHASE AMP THREE

PHASE

AMPS

/phase

HEATER

(bath)

SIZE WxDxH

cm

6 head 240V 1 ph 14 N/A - 1x 3.1 kW 45x61x46

208V 1 ph 16 N/A -

9 head 240V 1 ph 14 N/A - 1x 3.1 kW 56x61x46

208V 1 ph 16 N/A -

12 head 240V 1 ph 18 415V 3 ph 9 2x 2.0 kW 56x72x46

208V 1 ph 21 208V 3 ph 17

16 head 240V 1 ph 18 415V 3 ph 9 2x 2.0 kW 74x72x46

208V 1 ph 21 208V 3 ph 17

FLOOR MOUNTING MODELS:

SIZE SINGLE

PHASE AMP THREE

PHASE

AMPS

/phase

HEATER

(bath)

HEATER

(d/w)

SIZE WxDxH

cm

16 head 240V 1 ph 29 415V 3 ph 12 2x 2.0 kW 2.8 kW 75x72x102

208V 1 ph 34 208V 3 ph 24

20 head 240V 1 ph 33 415V 3 ph 12 2x 2.5 kW 2.8 kW 75x83x102

208V 1 ph 39 208V 3 ph 24

25 head 240V 1 ph 36 415V 3 ph 12 2x 2.8 kW 2.8 kW 86x83x102

208V 1 ph 42 208V 3 ph 24

30 head 240V 1 ph 39 415V 3 ph 13 2x 3.1 kW 2.8 kW 97x83x102

208V 1 ph 45 208V 3 ph 27

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

6

WIRE COLOURS:

Australian Standards: 415V 3 phase / 240V single phase & earth. 50 Hz,

Mains 3 Phase: RED, WHITE, BLUE ACTIVES with BLACK NEUTRAL

OR …………… RED, WHITE, BROWN ACTIVES WITH BLUE NEUTRAL.

Mains single phase: BROWN ACTIVE with BLUE NEUTRAL.

EARTH: GREEN / YELLOW STRIPE

Low Voltage: 24V.AC. GREY DC pos: GREY +red stripe. DC neg: GREY +black stripe

For USA and Canada: 208V 3 phase colours are: Red, Black, Blue. 60 Hz.

120V single phase neutral is: White

MAINS WATER:

Connection from mains water is normally by a 10 or 12mm diameter reinforced pressure

hose similar to that used on a domestic washing machine or dish washer. This hose is

supplied with the machine. A fine mesh water strainer should be installed to prevent foreign

matter lodging inside the various solenoid valves.

DISTILLED WATER: (Floor models only)

The source of distilled water is usually gravity fed from the laboratory water still on the wall,

so the supply pressure is very low. For gravity feed, the still should be mounted at least 1

metre higher than the Mash Bath so the head pressure is sufficient. Because of the low

source pressure, the hose and the connection from the distilled water source should be

large in diameter. The distilled water may be supplied by a 12mm bore rubber hose and

hose clip to the hose tail provided on the machine.

In some labs, the distilled water will be supplied pumped under pressure. A smaller hose or

pipe can be used and the solenoid valve used in the machine is suitable for both low and

high pressure sources.

DRAIN:

The machine has a bath drain hose and a bath overflow hose. They require a waste drain

facility, about 50mm diameter, close to floor level so the large diameter drain hoses can be

inserted directly into the floor drain. NOTE: For fast, efficient bath draining, the water

falling under gravity must completely FILL the hose. If possible, the two drain hoses should

be inserted into the drain say 300mm or more so that the ‘falling’ of the water down the long

straight hose will draw’ the water quickly from the bath. If the drain hose is too large or too

small or simply passes into a sink, the bath will drain much more slowly.

The bath overflow hose is not so important to drain fast, but on floor mount machines, this

hose also the water coming from the heat exchanger (cooling coil) in the distilled water tank.

IMPORTANT NOTE:: The drain hoses must not be kinked, flattened or restricted.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

7

FOR MAINTENANCE AND TRADES:

PREPARATION FOR CONNECTING:

•Remove all packing and ties that may be present for security of transport. Check the

machine generally for damage.

•Lift off the long rear cover (with controller disconnected) to expose the mains wiring

section of the machine. Observe the circuit breakers. They are for the following

circuits:

•Mains power. Heater #1 (and usually Heater #2) for the bath.

•(Floor Machines) Mains power. Heater for the distilled water tank

•Mains power: To transformer via ON/OFF switch.

•Low Voltage power. 24V.AC. for the Controller Unit and sensors etc.

The mains neutral block has several blue neutral connections. The earth connection is a

large brass screw mounted to the tray near the power entry point.

ELECTRICAL CONNECTIONS: The original test wiring is usually left connected to the

machine to assist only in the identification in electrical connections.

For 415V.AC. 3 phase connection, join the 3 phases to three contacts on one side of the

power contactor. Each heater connects between a phase and Neutral and all heaters are

240V rated. Incoming Neutral and Earth must be connected to terminal blocks.

For 240V or 110V.AC. single phase connection, join all 3 contacts on the contactor

together to the one power phase. For 110V machines, the heaters are 110V rated. Neutral

and earth must be connected to terminal blocks.

For connections for 208V.AC. 2 phase (USA & Canada), the connections are different

because they connect between phases. For all systems, the machines are the same and

only the connections of wiring are different. If assistance is required, please contact the

manufacturer for details. Drawings provided show the various electrical connections.

Mains power should be supplied from a mains isolation switch on the wall.

WATER and DRAIN CONNECTION:

Mains water should be from an isolation valve on the wall and, depending on water quality,.

through a fine gauze strainer or water filter. Connect mains water using the reinforced

pressure hose with the threaded fittings. The drain hoses must not be kinked or restricted

and, for fastest draining, the water must FILL the hose so that it draws out the water as if

passes down the drain. The drain hoses should be slipped into a drain pipe near the floor,

because keeping the drain hoses long and vertical helps to reduce the drain time.

ON FLOOR MODELS:

Distilled water supply, either gravity or pressurised, should be through a hand isolation

valve on the wall and then to the hose tail provided on the rear of the machine. To ensure

the distilled water tank fills quickly enough, the gravity HEAD for the distilled water source

should be about 1 metre. If the water is pressurised, the tank will always fill quickly.

The distilled water control solenoid valve is designed to control both low and high

pressure distilled water supplies.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

8

OUTER PANELS:

The outer panels of the machine have no screws. For removal, lift panel slightly and swing

the bottom edge outwards. The front panel is fitted with a lifting rail for easy removal.

While the first cycles are being run, always leave the front panel removed to observe any

signs of wetness or leaks in hoses and pipework.

IDENTIFICATION OF COMPONENTS:

Maintenance crew should spend a few minutes to identify the electrical components and it

will make things easier if you need to maintain or service the equipment at a later time

……………….

From the left end of the electrical section (under the cover), identify the following

components:

•Mains transformer 240/24V.AC. 50Hz/60Hz. Note that, depending on mains

power, it may be a 110/24V.AC. 60Hz transformer. Approx: 4 amps.

In some cases it may provide 24 or 26 or 28V.AC output.

•Mains contactor to isolate mains power from heaters.

•Set of several circuit breakers (mains power for transformer and heaters)

•One circuit breaker. Low voltage 24V.AC. for touch screen and control circuits.

•Terminal block. Low voltage 24V.AC. COMMON side.

•Temperature probe for bath. RTD probe. Can unplug from cable.

•Circulation pump motor for bath. Motor can disconnect from cable.

•High and low level switches for bath. Can unplug from cables.

•Mains connection for bath heating element (insulated).

•Neutral connection for bath heating elements..

ON FLOOR MODELS ONLY:

•Temperature probe for distilled water tank. RTD probe. Can unplug from cable.

•Circulation and dispensing pump motor for distilled water tank. Motor can

disconnect from cable.

•High and low level switches for distilled water tank. Can unplug from cables.

•Mains connection(s) for d/w tank heating element(s) (insulated).

•Neutral connection for d/w tank heating element.

NOTE: THE LARGE FLOOR MOUNTED MODELS NORMALLY HAVE 2x HEATING

ELEMENTS IN THE BATH AND ONE IN THE D/W TANK. EACH HAS A

SEPARATE CIRCUIT BREAKER.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

9

CONTINUE INSPECTION:

Inspect the machine further: Remove rear and front covers by lifting panels and allowing

bottom edges to come forward.

At the rear….. Observe the solenoid valves and hoses. These control mains water in and

drain water out. The third hose is for the important overflow inside the bath that must be

drained through a separate hose.

STIRRER BANKS:

At the front, see the racks of magnetic stirrers with electronic control. The small green

LED indicates that 24V.DC is applied to the stirrer PCB. The 4 connections to each socket

are: top: signal voltage controlling speed. Next: signal negative. Next: 24V.DC..positive.

bottom 24V.negative.

All stirrers on a bank run at the same speed. This speed is controlled by a DC voltage

provided to all the banks by the controller and it is adjustable on the touch panel. To be

sure that each bank is running at the same speed, the speed of each bank is adjusted by a

small control mounted above the connection blocks. Finally, the overall speed of all the

stirrers is then controlled by the touch screen controller.

REMOVE A STIRRER BANK OR A MOTOR:

To remove a stirrer bank, remove the green electrical plugs from the end of the circuit

board, remove the cap screw passing vertically through the aluminium rail at the front

(requires an allen key), Support the weight while extracting the rail from its support hole at

the far end. To change a motor and magnet assembly, undo the 2x wing nuts and remove

the spring washers that hold the motor bracket to the PCB. Unplug the 2x motor wires from

the small socket and unplug the 3x speed control wires from the socket. To fit a new motor,

simply reverse the procedure and tighten the wing nuts firmly with the spring washers fitted,

ON FLOOR MODELS:

In floor models, at the rear there are 2 additional solenoid valves for the filling of the d/w

tank and for the control of cooling water through the coiled heat exchanger in the d/w tank.

At the front, the stirrer arrangement is the same as the bench models but there could be

several more stirrer banks and there could be up to 5x stirrers on the one bank.

There is another solenoid valve and flow meter on the front of the distilled water tank and

This valve is for feeding the dispensing gun.

The flow meter measures the dispensed volume and can easily be disconnected for

removal. For water tight construction, ‘O’rings are used to seal all joints and threaded

connection fittings are not used. The signals from the flowmeter can be monitored on the

touch screen and the gun switch can be either monitored or simulated from the touch

screen.

An interface housing near the front of the d/w tank provides LEDs for visual indication of

24V.DC. power present, the dispensing gun’s trigger switch operation, the pulses from the

flow meter and the power supply to the flow meter. The solenoid valve has an illuminated

cap to monitor the power to the valve and it can be heard to ‘click’ loudly when opening.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 0

STARTUP:

•At this time, the machine should in position and connected to power and mains

water. Be sure the large drain hoses are down the drain facility pipe for a distance

of say 30 cm. Be sure there are no loops, kinks or obstructions in these large

hoses. The drain water should “fall” down the hoses directly into the drain.

NOTE: for the bench style machine, the drain hoses can be placed into a sink close

by, but if the hoses can be passed into a drain pipe that is lower than a sink, the

bath will drain much faster.

•To remove the bath lid, push the lid horizontally towards the rear and lift the front

edge past the retainer pips. Be sure there are no loose parts or packing materials in

the bath and be sure the mesh strainer is inserted into the drain hole in the bath and

is lying flat on the bath bottom. Earlier models have a mesh plate or a corrugated

plate that must lie flat in the bath to allow the bath water to circulate under the

beakers. Later models have small individual supports for the beakers.

•In the bath, observe the temperature sensor, the 2x level switches, the circulation

pump and the overflow upstand pipe.

•For floor mounting units, lift the cover from the d/w tank and remove it to permit

visual access. Observe the temperature sensor, upper and lower level switches,

the pump plus the heat exchanger cooling coil mounted towards the front.

•If the ‘U’ shaped bracket is not yet fitted to the cover, with fingers, remove the small

‘dress plug’ from the socket that is preferred for the mounting the control housing.

Place the bracket over the hole and insert the blue headed screw provided to fix the

bracket to the cover. Tighten firmly.

•Be sure mains power is off at the isolation switch on the wall. Lift and remove the

long cover and turn ON all circuit breakers that control the heater and control

circuit(s). Refer to the hardware layout drawing if necessary. Replace the cover,

turn ON mains power to the machine.

•Position the control unit into the ‘U’ shaped mounting bracket and gently tighten the

blue knobs to clamp it into position. Twist and tilt it until it suits your viewing angle.

At the rear, connect the multi pin plug and tighten the 2x security screws. The floor

models use two cables to connect to the control unit. Note the small rocker switch

on the front of the control unit. When switched towards the green indicator it is ON.

Note: The large diameter

overflow pipe is adjustable up

and down. If the bath must

be completely drained empty,

it can be removed completely

by twisting and pulling it

upwards from inside the bath,

but normally, the overflow

pipe is set to be about 3mm

higher than the upper level

switch level of water in the

bath. A lockable collar fitted

to the overflow pipe ensures

the pipe cannot be inserted

lower than the correct level.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 1

Be sure mains water supply to the bath is turned OFF. For floor models be sure the

distilled water isolation valve on the wall is turned OFF.

With the bath lid fitted, insert a stainless steel pot into each large hole in the lid. Drop a

30 to 40mm long spin bar into each empty pot but there is no need to load a mash

sample for this trial.

On the left SIDE of the rear S/S cover, see the red mains power rocker switch. Turn

ON mains power and turn ON the switch on the front of the electronic controller. The

cooling fan will softly sound and the screen should light up. Press the START button

on the screen.

The display will change to present the list of pre-installed programs. The water inlet

valve(s) should be heard to ‘click’. Now open the mains water valve on the wall and

water should begin to fill the bath. For floor mounting units, open the d/w isolation

valve and the d/w tank should also begin to fill. When both the bath and d/w tank (floor

model only) are full, the upper level switches will stop the filling automatically. Check

below the bath to be sure there are no leaks at the hose fittings.

When the bath is full, a message appears and ENTER can be pressed. Use the arrow

buttons to select the desired program. When ENTER is pressed, the temp/time graph

of the selected program will appear on the screen.

Press EXIT and return to the selection display. At this time we can say the machine is

operational.

NOW READ THE ‘OVERVIEW’ SECTION DESCRIBING THE DIFFERENT DISPLAYS AND

THE OPTIONS AVAILABLE.

OVERVIEW …………….

A TYPICAL MASH:

The Mash Bath is designed to accept a certain number of stainless steel pots through a

special lid so they rest into the water bath. On the bench models, the smaller pots are

manually filled with the correct volume of d/w that needs to be added to the mash part way

through the program. These small pots are located through the smaller holes in the lid so

that they heat to exactly the same temperature as the mash sample. The floor models do

not have these smaller pots because the d/w will be dispensed by the d/w gun directly into

the sample pots.

THE SAMPLE: After ENTERING the selected program, an exact amount of ground

sample of barley, hops, or similar, is placed into each pot together with a 30 to 40mm long

polypropylene or PTFE coated ‘spin bar’ for stirring the sample.

NOTE: sometimes the triangular style of spin bar is preferred where the bar runs slightly

raised on small pips and the mash cannot become ‘ground’ into finer particles between the

bar and the base of the pot.

PRE-HEAT: The GO button is pressed and the step zero begins. The display shows ‘pre-

heat’. The water is heated up to the starting temperature of the selected mashing program

and, to avoid loss of dry sample, the dry sample is not stirred at this time. When the

preset temperature is reached, the alert#1 sounds and the program automatically HALTS.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 2

ADD D / WATER: This first alert (#1) sounds to advise the operator to fill each pot with the

correct volume of distilled water at the same temperature as the bath so that the test can

begin. The required initial volume of distilled water is displayed on the screen and, with a

momentary press of the gun switch, this programmed volume at the correct temperature is

added to each pot. When all are filled this way, the mashing can begin.

NOTE:: In bench models, this d/w volume is held in the small pots that are placed in the

same bath as the sample. This ensures the d/w temperature is always correct. In the

larger floor mounted machines, d/w is stored, separately controlled for temperature, stirred,

metered and is quickly dispensed into each pot by pressing a switch on the top of the

special d/w dispensing gun. The dispensed volume depends on the volumes set in each

program on step #1.

START THE TEST: The program has HALTED awaiting the filling of all the pots. Press

the GO button to release the HALT and stirring begins and the program time progresses.

The temperature of the bath will follow the programmed course relative to time. The

stirring will operate as programmed step by step, but normally, stirring continues

throughout. When EDITING, the stir option can be changed on any step.

SOMETIMES ADD WATER: At a certain point, some programs require an additional

amount of distilled water to be added to the mash. On the bench models, the additional d/w

volume is placed in the smaller pots and they are inserted into the bath lid. The next alert

(#2) sounds at the correct point in the program but the program does not HALT. The

operator, one by one, lifts the small pots from the bath and adds the contents to the

corresponding sample pot (see note above relating to floor models).

THE MASHING CONTINUES: At the end of the program, the slower END alert (#3)

sounds and the pots may be allowed to remain in a warm bath or they may be cooled slowly

or quickly. This ‘end cycle’ action is selected by the operator as he/she edits the program.

Various programs require different end cycles. The program remains in cycle while the bath

draining and filling actions take place.

When the samples are removed from the bath, the RESET button cancels all program

function and the system resets back prior to step zero. The cooler in the distilled water tank

is fed with cold water and the d/w tank refills and cools quickly to prepare for the next

mashing cycle.

THE CONTROL OF THE BATH:

The control of the mashing process is performed by a touch screen PLC. This controller

permits programming of all 8 steps of all 8 programs. It controls the functions of all the

filling, draining, temperatures, alerts, circulation pumps, dispensing valves and tank levels

and so on as well as providing numerous on-screen operator assistance signals. In each

program, it performs GO, STEP, HOLD, RESET functions throughout the program pattern

selected.

The stirrers are adjustable for speed, the alerts are adjustable for volume and temperatures

of the bath and distilled water (floor models only) can be trimmed for best accuracy…. See

later in this manual.

In the floor mounted machines, the distilled water volumes are set inside each program and

the operator is not required to measure volumes. However, if a special volume needs to

be used or trialed, it can be set without altering a program and used during any program.

See later in this manual.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 3

In EDIT mode, a GRAPH of the program is created and is visible to the operator as the

information is entered into each step of the program. In running mode, the GRAPH of the

selected program appears on the screen and progress along the graph is indicated by a

visible cursor or ‘time-line’.

In the floor models, the distilled water temperature follows the bath so that the distilled

water is the same temperature as the mash at the time it is dispensed. At the end of a

program, the distilled water tank is cooled by a heat exchanger to prepare the tank for the

next mash. NOTE:: In the later models, the cooling of the d/w can be an extra step

programmed to begin d/w cooling prior to the end of the mash to create a longer d/w

cooling time.

THE AUDIBLE ALERTS:

The audible alert is controlled by the PLC and is automatically triggered at the start of

certain steps through the program. Each audible alert is programmed to run for only 5

minutes and then stop unless it has been stopped manually by the Shhh button. Alerts are

used for several purposes:

•To make sounds of different patterns to alert the operator that the preheat is

finished, or the top-up is required now or that the cycle is finished.

•To alert the operator that the machine is in distress because of low water level in

either tank or faulty temperature probe.

To STOP the audible alert at any time, a Shhh button is provided on the touch screen. The

alert will sound again only when another event occurs.

To MUTE the audible alert from sounding completely (silent machine), the alert volume can

be adjusted down to zero however, alarms due to faults always remain at full volume and

cannot be muted.

THE PROGRAMS:

To EDIT any program, it is first selected from the list and the EDIT P/W button is pressed.

A password is required to enter the editing mode. When the machine is first supplied, the

default password is ‘1111’ and, if desired, the password can be changed to improve

security …. see later in this manual..

When in the EDIT mode, the graph of the selected program appears and the program steps

can be selected back and forth by on-screen arrow buttons. A HELP button provides 2

displays of brief information on editing. When in the EDIT mode, the EDIT button takes

you to the ‘program name’ edit screen. If a name is pressed, a keyboard appears to allow

editing of the name or creating a completely new name. The EXIT takes you out of editing

and back to the SELECTION display. This is also for creating names of new programs.

MORE INFORMATION ON ALL DISPLAYS IS LATER IN THIS MANUAL.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 4

STIRRING OPTIONS: Normally the dry sample is not stirred during the preheat period

and, after the distilled water has been added to the sample and GO has been pressed to

cancel the HALT, the stirring begins and continues. The choices for stirring at any step

are: YES. NO, INT, IoB.

•YES means constantly stirring at the speed set in the “maintenance screen” …

usually 400 RPM.

•NO means no stirring at all.

•INT means intermittent stir and the timing of the ON / OFF can be set in the “stirring

screen”.

•IoB means the correct special stirring required to run the IoB program. 30 seconds

stir and 10 minutes no stir.

“COOL DISTILLED WATER” feature:

For floor models with distilled water tanks, during high production times, sometimes it

become useful to cool down the distilled water quickly, to be ready for the next mash. The

COOL D/W permits the starting of the cooling process before the mash program is

completely finished. An extra step is created with COOL D/W set to YES.

PROGRAMS ALREADY INSTALLED: When supplied, several selectable programs are

already installed in the machine. When in the SELECTION display, one program must be

selected by the arrow buttons and, if the bath and d/w are full of water, the selected

program can be ENTERED. If the bath and d/w are not full, a program cannot be entered

to run. A message appears to advise this condition. In floor mounting models, the d/w

tank also must be full before entering a program.

The selected program is always shown on any display together with the program’s step

number controlling the temperature and time relationships. When the program is running,

the GRAPH of the program and the moving cursor line can be seen as the program steps

proceed.

As supplied, the following programs are present in the controller but at any time program

names can be changed and any step in any program can be altered to suit requirements:

Program #1: EBC extraction

Program #2: Hartong index extraction

Program #3: EBC Diastase Power.

Program #4: AAL test, cold water added intermittently to keep bath cool.

Program #5: IoB extraction, intermittent stir on/off.

Program #6: Fermentability extraction

Program #7: Spare

Program #8: Spare

The following pages take you through each display and provide

information about each one.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 5

THE DISPLAY SCREENS:

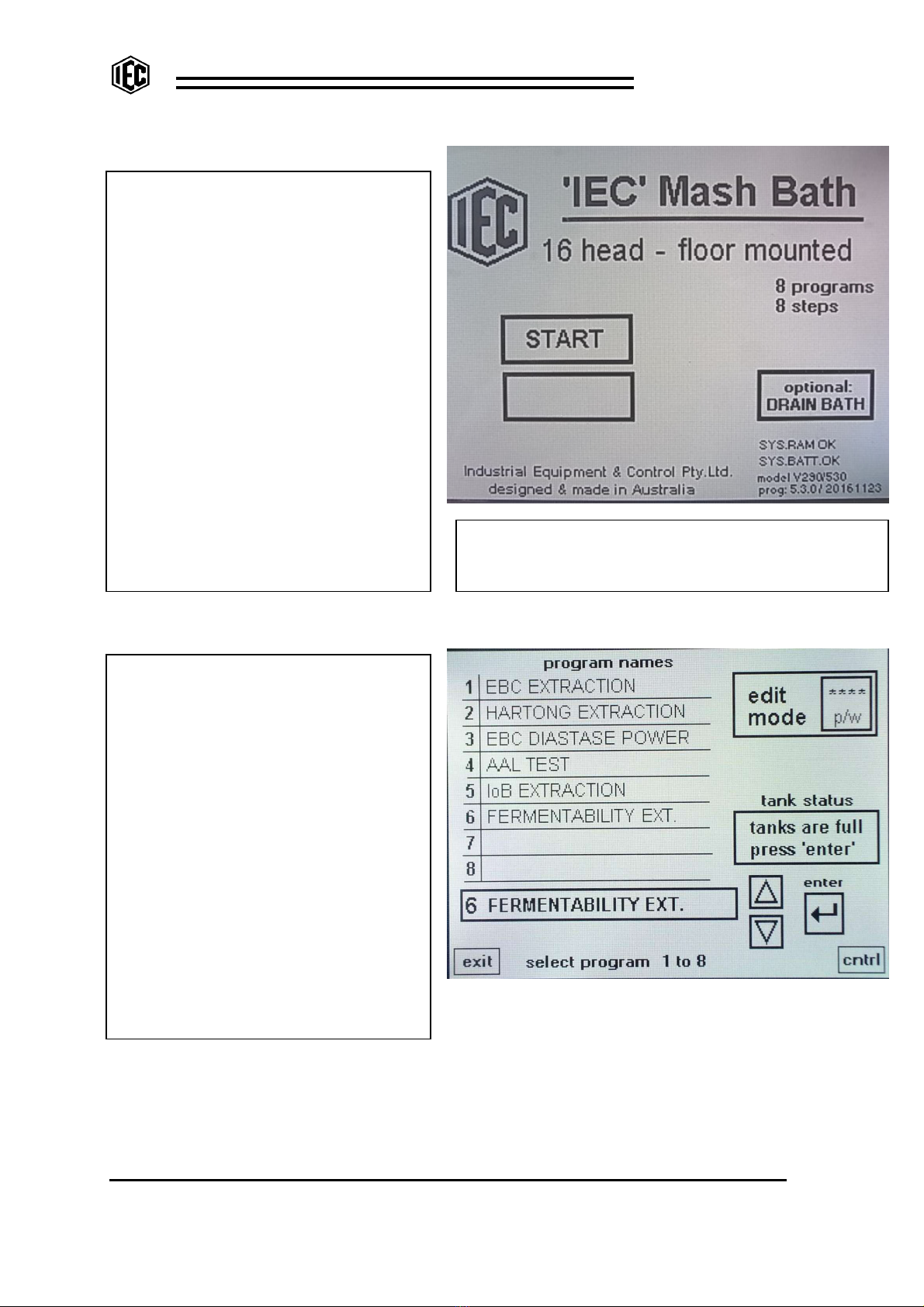

The first display shows the model type and

program version number. The condition of

the RAM and the long life memory battery is

also displayed on this screen

On later models a button permits the

optional complete draining of the mash bath

before shutting down. When pressed the

bath drains empty and the alert beeper

sounds to advise the draining is complete.

Normally the power would then be turned

OFF. If START is pressed, the bath will

refill to prepare for the next mash..

Press START to enter the system. The

system provides 8 different programs and 8

steps inside each program.

.When START is pressed, if either the bath

or the distilled water tank is low in level,

they will both fill. A cycle cannot be started

until bath and tank are full.

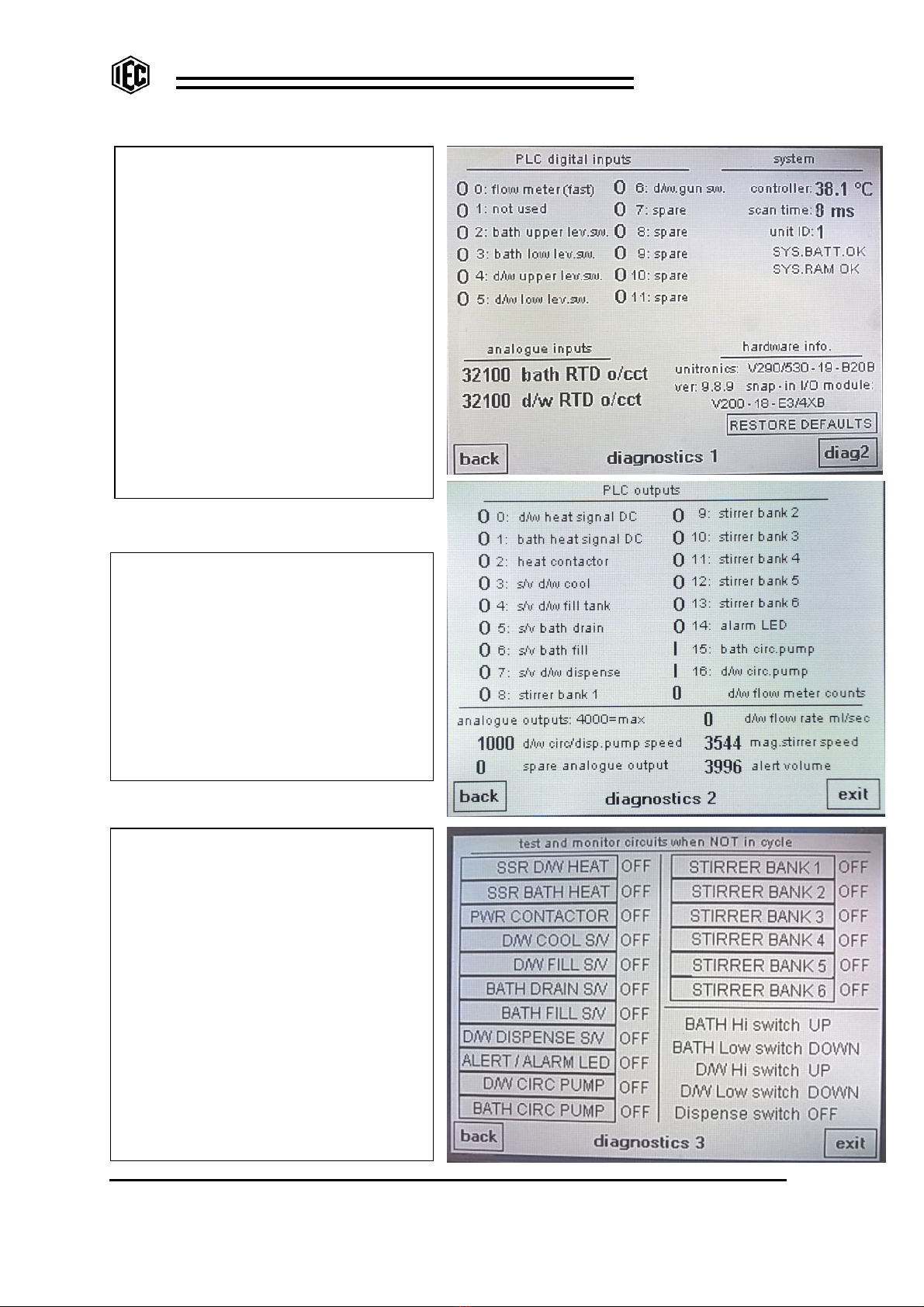

From START to SELECTION

The list of programs shows and arrow

buttons permit selection. All programs may

be edited.

‘Tank Status’ advises if the bath and d/w

tank (floor models) are full. If bath or tank

is filling, operator cannot execute ENTER

to begin a program.

The p/w (password) button permits entry

into the EDITING areas where program

steps and program names can be created

or edited. A four digit password is required.

Initially use ‘1111’.

EXIT returns to the opening display and

CNTRL allows access to manual control of

the bath functions. ENTER is pressed to

begin a mash program.

‘OPENING’ display

‘SELECTION’ display

Screen shows “16 head - floor mounted” as the

selected model type, but information is valid for all

model types..

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 6

SELECTION to CNTRL: Provides manual

control of some of the bath functions. In

the case of a malfunction or an unwanted

noise, magnetic stirrers banks can be

turned off or be permitted to run.

Bath filling and draining can be controlled.

Momentary press on FILL cancels DRAIN

and momentary press on DRAIN cancels

FILL. Second press executes command.

By press button, bath can be forced to fill

beyond ‘full’ and will overflow to waste.

Bath circulation pump can be turned

ON/OFF but is normally free to run. The

machine STATUS is shown and the audible

volume of the various ALERTS can be

altered to suit lab. noise conditions.

Fault Alarms are always fixed at full

volume.

For testing equipment, the mash cycle can

be run with the heaters OFF.

‘CNTRL’ display

CNTRL to D/W CNTRL: (Floor models

only). D/W tank cannot be filled beyond

‘full’. Cooler (heat exchanger) is

automatic, but can be turned ON or OFF.

If forced ON, will turn OFF after 30 min to

conserve water. Can be set as a step

inside a program to begin cooling the tank.

Circulation and dispensing pump can be

turned ON/OFF. Dispense switch on gun

can be simulated by pressing button.

Programs carry d/w volumes, but a fixed

volume can be entered and, if turned ON,

this volume will always be the dispensed

volume. Normally remains OFF.

Tank status and several important notes.

D/W CONTROL & COOLING

For bench models, there is no distilled

water storage or dispensing.

Choice is to EXIT back to the SELECTION

display or to move on to the DIAG display.

NO DISTILLED WATER display

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 7

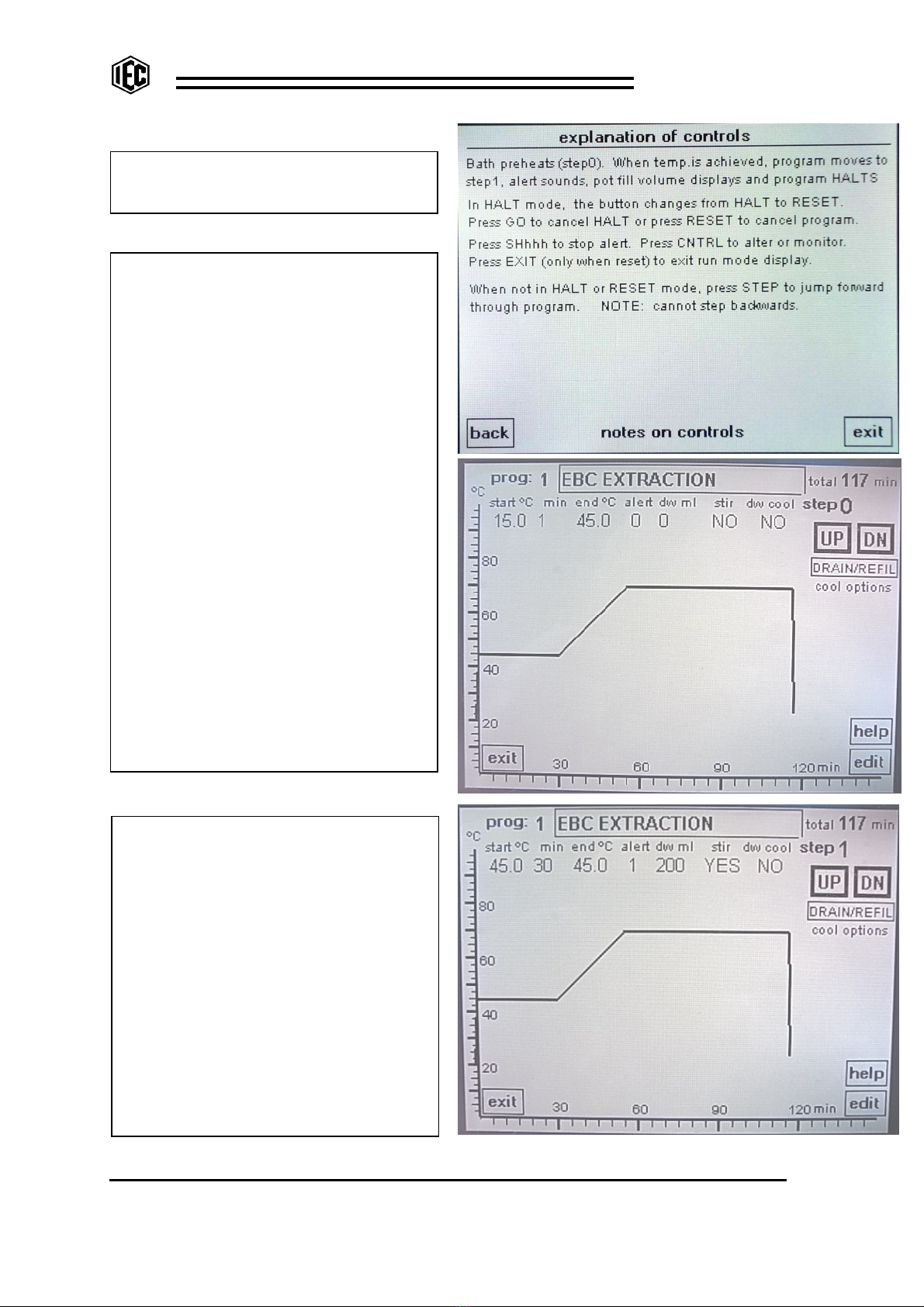

D/W CNTRL to DIAG: This display is

mainly for maintenance and fault finding.

PLC inputs status is displayed with values

of the controller’s internal temperature, the

temp.sensors, the scan time, RAM status

and battery status and ID info.is shown.

For bench models, the D/W RTD (temp.

sensor) value will show open circuit value

– but can be ignored.

If memory corruption should occur, if

‘RESTORE DEFAULTS’ is held depressed

(for 5 seconds) until the red LED comes

ON then OFF, the memory is re-loaded

with current data stored in a special area

of memory. This avoids keying in all the

program data again.

DIAGNOSTIC 1 display

DIAG to DIAG2: As above, this display is

for maintenance and fault finding. The

status of the PLC outputs is displayed

including the counts and flow rate from the

dispensing flow meter (floor models only).

The PLC drives the magnetic stirrers, the

alert beeper and d/w dispensing pump so

that each is adjustable. The value applied

to each device is monitored on this display.

4000 is the max value possible.

DIAGNOSTIC 2 display

DIAGNOSTIC 3 display

DIAG2 to DIAG3: As above, this display

is for maintenance and fault finding and it is

used when the bath is not in cycle.

Each rung of the display can be a press

button to force on each device. Other

rungs monitor most input devices. The UP

and DOWN status of the floats on the water

level switches is monitored.

If there is suspicion that a particular device

is not operating, it can easily be proven on

this screen. During manufacture it is used

as a check that each device is wired

correctly.

BACK will return you to the Diag 2 screen.

EXIT returns to the SELECTION display.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 8

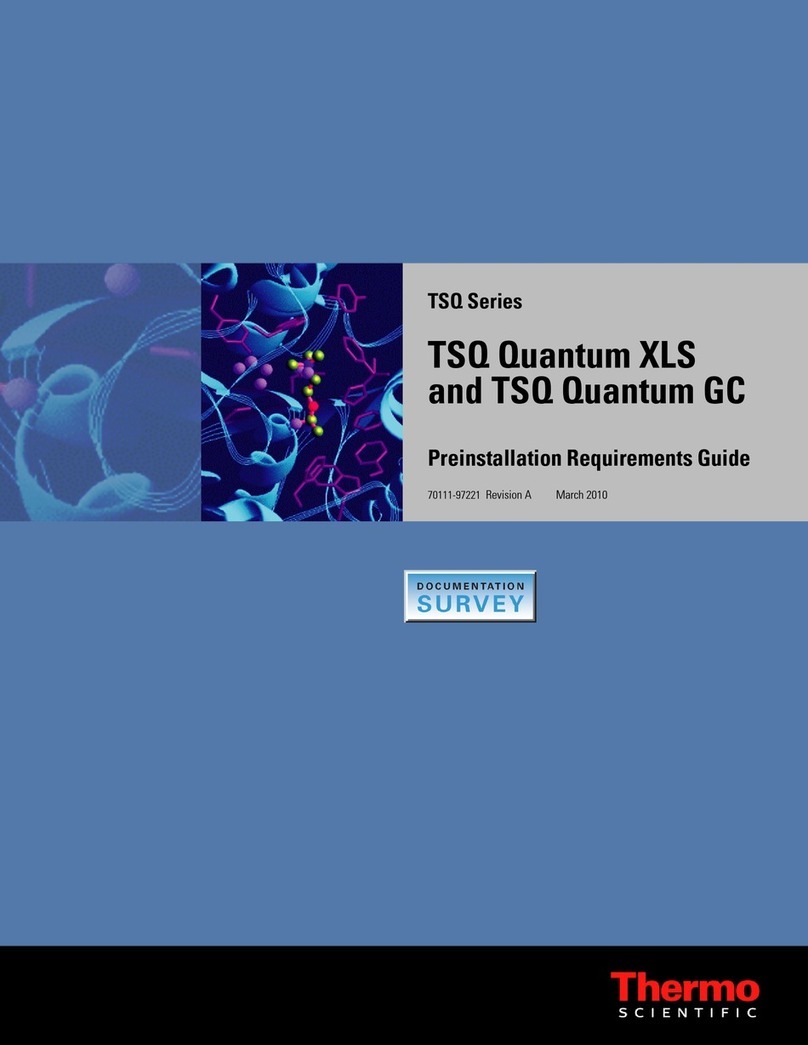

SELECT to ENTER: If the bath and d/w

tank are both full, the selected program

can be run. The graph displays to show the

temperature and time relationship for each

step.

Press GO to begin. Heaters come on and

‘H’ appears as heating monitor. If bath is

cooling, ‘C’ appears. Small square flashes

to monitor program running.

Step zero is the ‘pre-heat’ to 45

o

C. Stirrers

are normally off during pre-heat to avoid

fluffing the dry sample. When the short

time (1 minute) has expired AND bath initial

temperature is achieved, the program

jumps to Step#1 and HALTS. Stirrers

remain OFF and display shows the volume

of d/w to add to the sample. At this time,

alert#1 sounds for loading the pots with

distilled water. When pots are loaded, the

mash is about to start. Press GO to

release the HALT.

NOTE: When HALTED, the button

changes to RESET. If pressed, the

program resets and GO must be pressed

again. If a program needs to be RESET,

press HALT then press again to RESET –

otherwise press GO to cancel the HALT

and to continue.

For this particular program:

Step #1 starts at 45

o

C and remains 45

o

C

for 30 min.

Step #2 climbs a temperature ramp from

45

o

C to 70

o

C over 25 min. At the top of

the ramp, step #3 is triggered.

PROGRAM R

UN display

At the start of step #3, alert #2 sounds to call the operator to

add d/w to each mash pot. The volume to add (100 ml)

displays on the screen (see screen above at step #3). The

program does NOT automatically HALT at this point.

Step #3 runs for 60 minutes and holds 70

o

C.

…………………………………………………………

USEFUL OPTION: Pre-cool distilled water:

If it is required to cool the distilled water earlier than the END

of the mash cycle, an extra step (step #4) can be created at

say 50 minutes to maintain the 70

o

C and also COOL D/W

while the bath is holding the mash at 70

o

C (step#5) for the

extra 10 minutes. Then create step #6 to drop to 25

o

C for 1

minute so that heaters turn off immediately and the END of

cycle is reached and the slow “END alert” sounds during bath

draining.

……………………………………………………….

At the end of the 70

o

C period the next step (step#4) forces

the bath heaters off as the bath tries to cool from 70

o

to 25

o

in just one minute..

When step #5 is reached, the word END appears and the

beaker cooling cycle begins. This beaker cooling cycle can

be chosen during programming. In this case, the bath

automatically drains empty then re-fills again with cold water

to cool the samples quickly. The distilled water cooling coil

has water passing to cool down the D/W before the next

mash.

The samples are then removed and RESET is pressed.

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

1 9

PROGRAM RUN – NOTES…. continued………

As the program progresses, a vertical cursor or ‘time-line’ is seen to move from left to right

so that the current point on the graph can be seen. The program name, it’s number and

the step number are all displayed. The progressing time, the final temperature of that step

and the current bath temperature are all displayed on the screen. For floor models, the

distilled water temp. is displayed.

The program status is shown and this can be ‘RUNNING’ or ‘HALTED’ or ‘RESET’.

If an alarm occurs, this also is shown on the screen. An alarm can be bath ‘LEVEL LOW’ or

‘BATH TEMP o/c’ (temp.sensor open circuit). See later in manual for explanations.

The buttons have the following functions:

EXIT returns to SELECTION display when not in cycle. If in cycle, RESET must be pressed

before EXIT. . GO starts program and will always cancel HALT.

When program is RUNNING, the STEP button moves line forward to the start of the next

step of the program.

HALT will stop a program at any point. The stirrers stop and the timers stop but the bath

maintains current temperature. To cancel HALT, press GO. When HALTED, the HALT

button changes to RESET. If pressed, the program cancels. If cancelled accidentally, the

program can be continued by pressing GO, then STEP, then GO (to cancel the HALT),

then STEP to the closest place to resume cycle progress.

The Shhh button cancels the BEEPER at any time. If Shhh not pressed, the BEEPER self

cancels after 5 minutes running.

The INFO button provides 2 displays of brief information and CNTRL moves to the same

CNTRL and DIAG displays as described in previous pages.

First INFO display shows program status.

•Step number

•Time progress through whole

program

•Initial temperature

•Time progress through the step

•Final temperature

•Volume of d/w to add

•Stirring yes/no/intermittent/IoB

•Distilled water cooling

•Alert number (0 to 4)

•Selected cooling cycle at

program end

•Bath temperature

•Target temperature

•Distilled water temperature

INFO1 display

Mash Bath

I N D U S T R I A L E Q U I P M E N T & C O N T R O L P T Y . L T D .

6 1 - 6 5 M c C l u r e S t . T h o r n b u r y . 3 0 7 1 M e l b o u r n e . A u s t r a l i a

T e l : 6 1 ( 0 ) 3 9 4 9 7 2 5 5 5 F a x : 6 1 ( 0 ) 3 9 4 9 7 2 1 6 6

E m a i l : i e c @ i e c p l . c o m . a u

M A S H B - 2 0 1 9 0 3 1 4 . d o c 1 4 - M a r - 1 9

2 0

INFO2 display

This display contains notes to assist the

operator.

EXIT reverts to program run display.

EDIT PROGRAM display

Program is built from step0 up to final step

or END.

•On step0, start

o

C is 15

o.

. ‘min’ (time)

is 1 minute and “d/w ml” is zero. For

step0 these are fixed and cannot be

altered.

•Press “end

o

C” for keypad. Key in

desired end temperature for step0 (pre-

heat is usually to 45

o

).

•Press “alert” to cycle through the alert

options (0-4). Press HELP for

assistance.

•Press “stir” to cycle through the

options (NO/YES/INTERMITTENT). For

step0, stir is normally NO.

•Press below the arrows to cycle

through the cooling options. (WARM

BATH, SLOW COOL, DRAIN ONLY,

DRAIN / REFILL, DRAIN / REFILL

(twice), HOLD COOL). Press HELP

for assistance.

•Press HELP for useful information.

•Press EDIT for other program items

that can be edited. Press EXIT to

revert to the SELECTION display.

See next images showing steps 1, 2, 3, 4

and 5 of program #1.

STEP1:

•The “start

o

C” (45

o

C) is copied from the

“end

o

C” of the previous step. It cannot

be altered.

•Press “min” and set to 30. Press and

set “end

o

C” to be 45

o

C. This means

the temperature will remain steady at

45

o

C for 30 minutes.

•Set “alert” at the start of step1 at #1.

When pre-heat is finished, step1 is

entered and alert sounds. Programs

HALTS to load D/W into the pots.

•Press “d/w ml” to set the initial d/w fill

volume for the pots ( EBC is 200ml).

•Press ‘stir” to select YES so stirring

occurs when HALT is cancelled by GO.

STEP 1 display

Table of contents

Other IEC Laboratory Equipment manuals

Popular Laboratory Equipment manuals by other brands

RADWAG

RADWAG UYA 4Y PLUS Startup guide

Thermo Scientific

Thermo Scientific TSQ Quantum XLS Pre-installation requirements guide

Drucker Diagnostics

Drucker Diagnostics DASH Apex 24 Service manual

Beckman Coulter

Beckman Coulter CytoFLEX SRT Instructions for use

Qiagen

Qiagen EZ1 Advanced XL user manual

Metrohm

Metrohm 882 Compact IC plus manual

PI

PI Q-Motion Q-545 Series user manual

DIATECH PHARMACOGENETICS

DIATECH PHARMACOGENETICS EasyPGX qPCR instrument 96 user manual

Fluke

Fluke TIP900 operating instructions

AFi

AFi SS101 Assembly instructions

Hettich

Hettich MIKRO 185 operating manual

ATLAS BIOTECNOLOGIES

ATLAS BIOTECNOLOGIES AB2 instruction manual