IEF Werner easyLINE User manual

October 2019 Mounting instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 1 of 34

IEF-Werner GmbH

Wendelhofstraße 6

78120 Furtwangen - Germany

Phone: +49 7723-925-0

Fax: +49 7723-925-100

www.ief.de

info@ief-werner.de

Mounting instructions (Translation)

Module easyLINE

Issue: October 2019

Article no.: 1040582

Mounting instructions October 2019

Page 2 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

Change History:

Trademarks and trade names are used without any warranty of their free usability. Texts and examples

were created with great care. Nevertheless, errors cannot be excluded. IEF-Werner GmbH does not

assume legal responsibility nor any liability for missing or incorrect statements and their consequences.

IEF-Werner GmbH reserves the right to modify or improve the software or hardware or parts of it, as

well as the supplied documentation or parts of it, without previous notice.

IEF-Werner GmbH expressly reserves all rights for replication and photomechanical reproduction,

including in extracts.

We are always grateful for suggestions for improvements and information about errors.

© October 2019, IEF-Werner GmbH

Document Code Date Revision

MAN_EN_1040582_easyLINE_R2b.doc 26.02.2007 Release of the English Document (“MAN_EN_

1040582_easyLINE_R2b.doc”).

MAN_EN_1040582_easyLINE_R3a.doc 13.06.2013

Document updated regarding the new machinery directive

(MRL 2006/42/EC).

Made from German document

“MAN_DE_1040581_easyLINE_R3a.doc”.

MAN_EN_1040582_easyLINE_R3b.doc 21.10.2019 Standards updated in the Declaration of incorporation.

October 2019 Mounting instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 3 of 34

Table of Contents

1Safety 5

1.1 Definition or warning notes 5

1.2 General warning notes 5

1.3 Special hazard warnings 6

2Intended use 7

2.1 Reasonably foreseeable misuse 7

3Assembly instructions 8

3.1 Installation position 8

3.2 Overview of motor installation variants 8

3.2.1 Installation variant 1 9

3.2.2 Installation variant 5 9

3.3 Attachment 10

3.3.1 Mounting with clamping elements 10

3.3.2 Attachment at the carriage of the linear module 12

3.3.3 Installation of actuators 13

3.4 Wiring 14

3.4.1 Motors 14

3.4.2 Initiators 14

3.4.2.1 Plug end position switch 16

3.4.3 Cable routing 16

3.5 Technical data 17

3.5.1 Tightening torques for screw connections 17

3.5.2 Technical Data of easyLINE module 17

3.5.4 Technical data when using a planetary gear 18

3.5.5 Load cases 19

3.5.5.1 Torques and load carrying capacity 19

4Maintenance 20

5Trouble shooting 21

6Repair instructions 23

6.1 Toothed belt tension 23

6.2 Belt tension gear toothed belt 23

7Parts lists and drawings 24

Mounting instructions October 2019

Page 4 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

7.1 easyLINE installation variant 1 24

7.2 Reversing unit easyLINE (Article.No. 526261) 26

7.3 Carriage easyLINE completed (Article no. 526311) 27

7.4 Long carriage easyLINE complete (Article no. 526609) 28

7.5 Gearbox (Subassembly no. 1000002) 29

7.6 Flange i = 1:1 (Subassamly no. 1000003) 30

7.7 easyLINE clamping block complete – exploded view (Article no. 526262) 31

7.8 easyLINE long carriage clamping block complete - exploded view (Article no.

526610) 32

7.9 easyLINE, parallel drive – exploded view 33

8Declaration of incorporation 34

October 2019 Mounting instructions Safety

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 5 of 34

1 Safety

1.1 Definition or warning notes

WARNING

Indicates potential danger. Non-observance of the safety provisions

may cause death or severe injury.

CAUTION

Indicates potential danger. Non-observance of the safety provisions may

cause property damage or injury.

NOTE Offers additional information.

1.2 General warning notes

The module must only be commissioned by specialists who received safety-technical

instruction and are able to assess potential dangers. Furthermore, all chapters of these

operating instructions must have been read and understood completely.

WARNING

The system must be powered down for all assembly, disassembly or

repair work. There is a high danger of injury.

WARNING OF HOT SURFACE

During operation, heating of the motor, in particular of stepper motors, can

cause burns of the skin when touching the motor. Install a protective device, if

possible! Do not touch the marked areas or wait for an adequate cooling time.

CAUTION

Motor connectors must not be inserted or disconnected when live. Risk of

burning of the contacts and risk of flying sparks.

Safety Mounting instructions October 2019

Page 6 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

CAUTION

Linear modules always have to be operated in connection with suitable safety

devices (e.g., safety cell, protective room, protective housing, light curtain).

NOTE Observe the Manufacturer's Declaration (see section Declaration of

incorporation, page 34).

1.3 Special hazard warnings

In addition, this operating instructions also contains the following special hazard warning:

DANGER FROM CRUSHING

These places of the components pose the danger of crushing limbs in

operation.

October 2019 Mounting instructions Intended use

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 7 of 34

2 Intended use

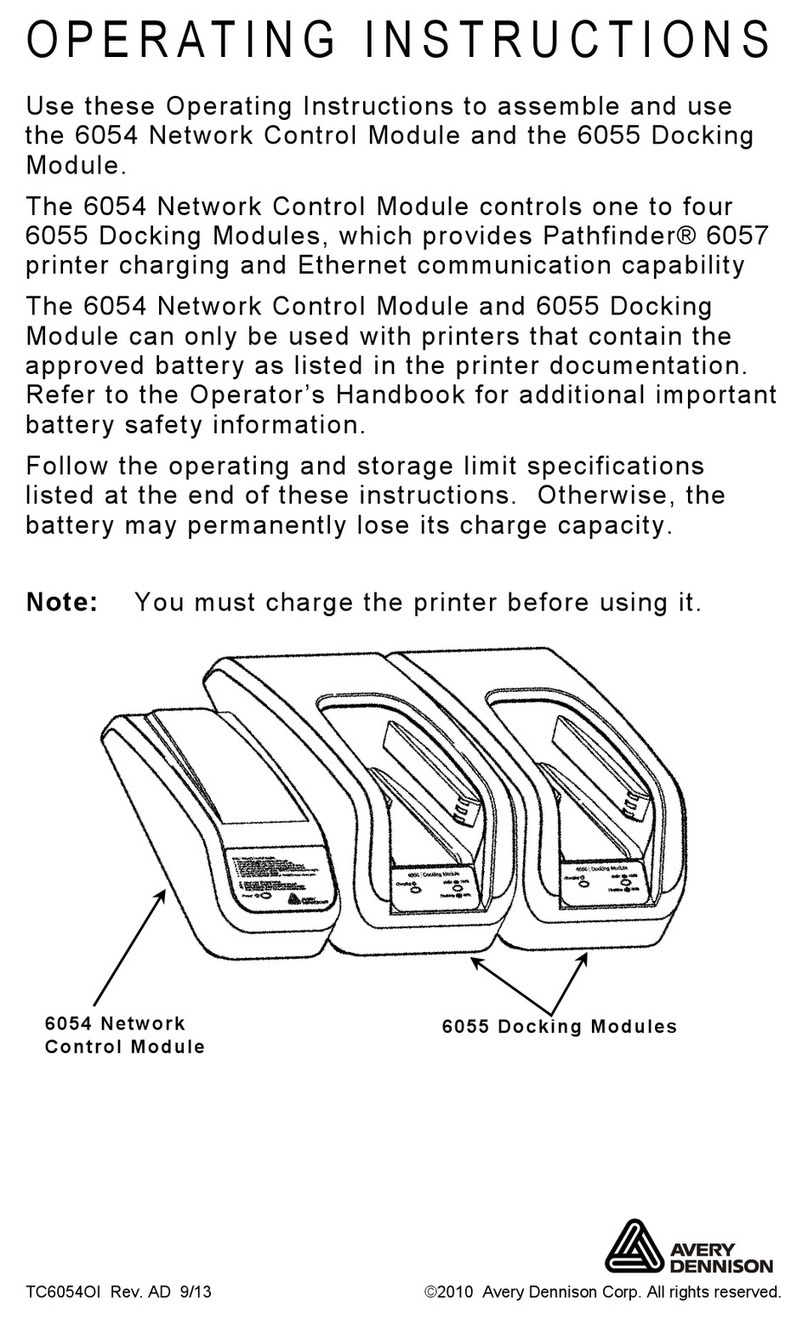

The easyLINE module (see Figure 1) is a precise, linear adjustment unit with toothed belt drive

that is used in the commercial area as an attachment part in connection with other

components. In combination with many standardised installation elements and the other linear

modules of IEF-Werner GmbH (e.g. module 68 and 68D, module 105, module 105 S, module

142 and module 142 S), complex multi-axis handling systems can be developed as well.

Figure 1: easyLINE module

The areas of application of an easyLINE module are accordingly diverse.

They encompass:

■Stop adjustment in the wood industry

■Equipment systems for SMD components

■Joining and press-in processes in precision mechanics

■Loading and unloading station of tool machines up to

■Manipulators for the packaging industry

2.1 Reasonably foreseeable misuse

The easyLINE module is not to be used for certain applications, and in particular not for such

as the transport of persons and animals or as a pressing/bending device for cold working of

metal.

Use of the linear module without additional measures is also notpossible in special fields of

application, such as the chemical or food industry or in explosive atmospheres.

In case of doubt, consult the manufacturer.

Assembly instructions Mounting instructions October 2019

Page 8 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

3 Assembly instructions

3.1 Installation position

The installation position is optional, i.e. the easyLINE module can be used horizontally as well

as vertically.

CAUTION

In the vertical installation position, use only motors with spring-operated brake

to prevent the lowering of the drive in de-energized condition!

3.2 Overview of motor installation variants

The generally variants of installation are (see Figure 2):

Figure 2: Installation variants easyLINE module

Installation variant 5

Installation variant 1

October 2019 Mounting instructions Assembly instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 9 of 34

3.2.1 Installation variant 1

A, B: stroke limited switch

A: standard reference point

AB

M6; 12 deep (4x)

DIN74; Km5 (2x)

DIN 74; Km5 (4x)

M6x12 (10x)

option: easyLINE long carriage

89 (mounting proportion)

65

68 112

stroke-eff. + 105

92

177,2

stroke-eff. + 285

105

89

92

112

92

194

82

105

8

52,5

97

141,5

186

89

Figure 3: easyLINE installation variant 1

3.2.2 Installation variant 5

A, B: stroke limited switch

A: standard reference point

AB

M6; 12 deep (4x)

DIN74; Km5 (2x)

DIN 74; Km5 (4x)

M6;12 deep (10x)

option: easyLINE long carriage

89 (mounting proportion)

65

68

112

stroke-eff. + 105

stroke-eff. + 285

103,5

105

89

92

112

92

194

82

105

8

52,5

97

141,5

186

89

Figure 4: easyLINE installation variant 5

Assembly instructions Mounting instructions October 2019

Page 10 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

3.3 Attachment

3.3.1 Mounting with clamping elements

The use of clamping elements (see Figure 6) allows the linear unit easyLINE to be easily

secured to a level mounting surface. Standard length clamping elements are available for the

cross-mounting of linear units. For safety reasons, continuous clamping sections are advised.

This ensures hazardous shear points are avoided.

Please avoid additional drilling holes in the basic body. This might damage the internal parts of

the linear unit and could distort the guide base.

CAUTION

The clamping area should have a planeness of 0.1 mm/m²

89

Figure 5: Attachment with clamping elements

Figure 6: Dimensions clamping element

Clamping element Clamping element

Bore distance

October 2019 Mounting instructions Assembly instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 11 of 34

CAUTION

Observe the hazard points shown in Figure 7and Figure 8 !

crushing position

shearing points

Figure 7: Attachment with standard-clamping elements

crushing position

Figure 8: Attachment with continiously clamping elements (no shearing points)

Assembly instructions Mounting instructions October 2019

Page 12 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

3.3.2 Attachment at the carriage of the linear module

As a second possibility the linear module can be attached at its carriage

(use easyLINE with a long carriage and a stroke longer than 300 mm).

The basic body moves free. However, in this case the motor, motor cable, limit switch cable

and also encoder or resolver cable have to be moved as well.

Figure 9: Mounting example

Via two borings M5 (see in Figure 10) the linear unit can be tighten up on a mounting table.

A further mounting possibility is using the 4 threaded borings M6 (see ) possibly through a

distance plate.

89

92

105

=M6x12 (4x)

=DIN74; Km5 (2x)

1

1

12

2

2

2

2

Figure 10: Mounting detail standard slide

Both attachment variants are possible. The respective application determines the needed

variant (long side, see Figure 11, page 13).

October 2019 Mounting instructions Assembly instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 13 of 34

112

92

194

82

105

8

52,5

97

141,5

186

89

=M6x12 (10x)

=DIN74; Km5 (4x)

1

2

1

1

1

1

2

2

2

2 2

2 2

2 2

2

Figure 11: Mounting detail long slide

3.3.3 Installation of actuators

Actuators (pick-up modules, cylinders etc.) to be installed on the module easyLINE are usually

attached to the linear unit using the drill template of the end plates, see Figure 10 , page 12 or

Figure 11, above.

If you assemble according to Figure 9, page 12, you can mount the actuators according to the

mounting example of Figure 12, below.

Only very light elements (less than 1 kg) can be attached directly on the end plate. In this case,

you should equip the end plate with a suitable mounting plate.

clamping element Typ 105

mounting plates

end plate

Figure 12: Mounting example

Assembly instructions Mounting instructions October 2019

Page 14 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

3.4 Wiring

3.4.1 Motors

CAUTION

The electrical connection of the motors is performed according to the motor

data sheet. For customer-specific motors, the data sheet must be requested

from the respective manufacturer and the motor connected accordingly.

3.4.2 Initiators

Inductive proximity switches (PNP normally closed contacts, article no.: 025165 see Figure 14)

are used as standard limit switches for the running path. These switches are no safety limit

switches pursuant to EN60204-1. Optionally, (also subsequently) an additional reference point

switch (PNP normally open contact article no.: 726744, see Figure 13), can be installed in the

easyLINE module. The active button is marked with a coloured circle. Normally closed contacts

are marked with a green, normally open contacts with a red dot. The initiators and their supply

lines are protected in a cable channel integrated in the basic body and are wired to a joint plug.

A plastic strip serves to cover the cable channel. An initiator can be replaced or relocated

easily after removal of this plastic strip from the cable channel.

brown + 24VDC

black signal

blue 0V

Figure 13: Connection allocation PNP normally open contact

brown + 24VDC

black signal

blue 0V

Figure 14: Connection allocation PNP normally closed contact

October 2019 Mounting instructions Assembly instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 15 of 34

M4

1

4

9,9

5

active area

20

40

Figure 15: Dimensions initiator

Technical data of initiators

Parameter Value

Operating voltage, incl. residual ripple 10...30 VDC ≤15 %

Current load capacity I

a

≤200 mA

Switching frequency ≤1000 Hz

Consume current ≤15 mA

Nominal switch distance at steel 1.5 mm ±10 %

Switching hysteresis (3...20) %

Reproducibility (U = konst.) ±0.1 mm

Operating temperature - 25 °... + 70 °C

Protection class IP 65

Short-circuit proof yes

Reverse battery protection yes

Figure 16: Technical data of initiators

Assembly instructions Mounting instructions October 2019

Page 16 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

3.4.2.1 Plug end position switch

The end position switch is assigned as follows (see Figure 17)

Pin-No. Assignment IEF-Werner cables

1 + 24 V brown

2 Limit switch negative direction green

3 0 V white

4 Limit switch positive direction yellow

5 Reference switch grey

Figure 17: Connection assignment plug end position switch

3.4.3 Cable routing

For all moving cables, suitable cable routing has to be used to effectively prevent cable breaks.

The minimum radius rmin for cable carriers results from the following formula:

rmin ≥10 x cable diameter

When different cables are used, EN 60204 must be observed. In addition, it must be ensured

that a space reserve of 30% is kept free within the routing chains. A strain relief for the cables

has to be attached at the outlet of the cable routing chain.

We recommend procuring original cables and cable routing chains from IEF-Werner. Please

contact us, we will be pleased to provide advice.

October 2019 Mounting instructions Assembly instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 17 of 34

3.5 Technical data

3.5.1 Tightening torques for screw connections

Screw 8.8 Tightening torque [Nm]

M3 1.1

M4 2.5

M5 5.0

M6 8.5

M8 21.0

M10 41.0

M12 71.0

Screw 12.9 Tightening torque [Nm]

M4 (fixation of

guiding rail) 4.9

3.5.2 Technical Data of easyLINE module

Parameter Value

Repeating accuracy +/- 0.04 mm

Weight (without motor, without

planetary gearbox) at stroke 0 mm

4.4 kg

Weight increase per 100 mm stroke 0.7 kg

Maximum speed 2.5 m/s

Torque Mx 35 Nm

Torque My 50 Nm

Torque Mz 20 Nm

Static load carrying capacity C1 1000 N

Static load carrying capacity C2 550 N

Assembly instructions Mounting instructions October 2019

Page 18 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

3.5.3 Type label

Figure 18: Type label (example)

3.5.4 Technical data when using a planetary gear

Before commissioning, observe the possible input speeds of the gear manufacturers.

Too-high input speeds can lead to increased wear at the gear and/or thermal problems.

The accuracy of the linear unit is influenced by the reverse play of the gears.

Example:

The gear reverse play (S) is 9 angle minutes.

How high is the reverse play at the carriage of the linear unit?

Infeed constant of the linear unit (Vk): 140 mm

Reverse play at the carriage = (Vk • S) / (360 x 60)

= (140 mm • 9) / (360 x 60)

= 0.058 mm

Consider the information of the respective gear manufacturer in any case.

e.g. http://www.neugart.de/index.php/gb/Produkte/Standardgetriebe

http://www.wittenstein-alpha.de/en/drive-systems.html

easyLINE

October 2019 Mounting instructions Assembly instructions

MAN_EN_1040582_easyLINE_R3b.doc easyLINE Page 19 of 34

3.5.5 Load cases

3.5.5.1 Torques and load carrying capacity

Figure 19: easyLINE load capacitiy

Extract of technical data (see chapter of Technical Data of easyLINE, page 17)

Parameter Value

Maximum torque Mx 35 Nm

Maximum torque My 50 Nm

Maximum torque Mz 20 Nm

Static load carrying capacity C1 1000 N

Static load carrying capacity C2 550 N

Maintenance Mounting instructions October 2019

Page 20 of 34 easyLINE MAN_EN_1040582_easyLINE_R3b.doc

4 Maintenance

During the design of the linear unit easyLINE, great importance was placed on the use of low-

maintenance components. All roller elements were provided with lifetime lubrication in the

factory.

To avoid danger of over-lubrication of the linear bearings, no external lubrication nipples were

attached to the carriage part. However, to achieve a high service life of the wipers, we

recommend moistening the guide shafts with special grease at regular intervals. The lubricant

may be procured from IEF in tubes of 50 gr (Art. no.732934) each:

The recommended maintenance intervals add up to approx. 200 operating hours under regular

ambience conditions. The maintenance intervals should be reduced for unfavourable ambient

conditions.

Table of contents

Other IEF Werner Control Unit manuals